A Continuous Mining Method Applicable to High and Middle Sections

A mining method and high-tech technology, applied in ground mining, mining equipment, underground mining, etc., can solve the problems of high ore loss rate and dilution rate, reduce mine economic benefits, and low-grade ore selection, so as to reduce stope prospecting , Improve the mining intensity and recovery efficiency, and the effect of improving the ore extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

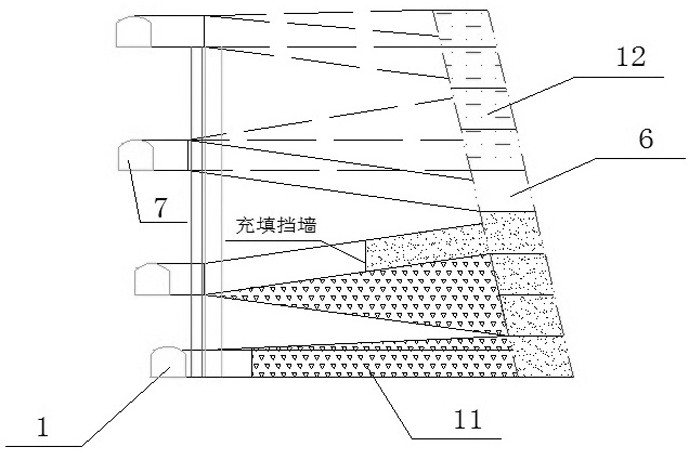

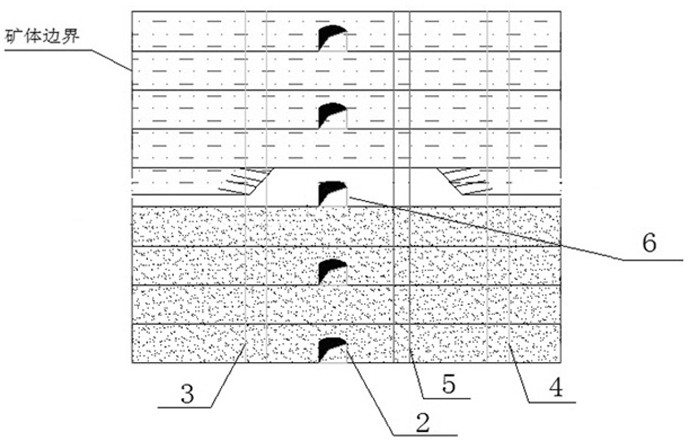

[0025] The specific embodiments of the present invention will be further described below with reference to the accompanying drawings.

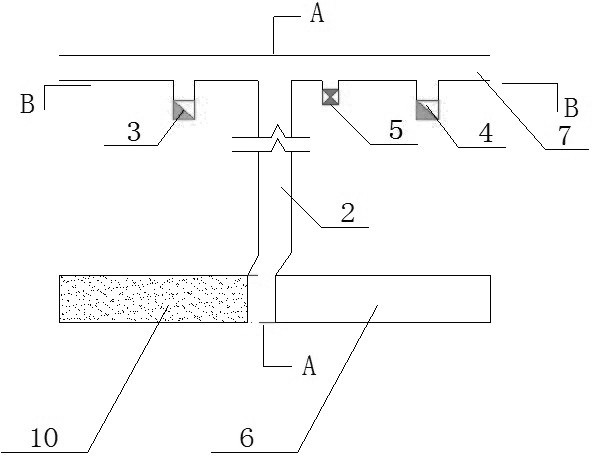

[0026] like Figure 1-4 As shown, the continuous mining method applicable to the middle and middle section involved in the present invention includes the following steps:

[0027] Step 1, adopting the quasi-project, which includes the following steps:

[0028] Step 101: Divide the stope in the middle and middle sections into several stratified stopes 6, wherein the stope in the middle section refers to the stope with a height of 80 meters to 150 meters in the middle section, and the mining sequence is mined according to the order of the stratified stopes 6 from bottom to top. , the bottom layer stope 6 is recorded as the first layer stope. In this embodiment, it is assumed that the height of the middle section of the high and middle section stopes is 150m. First, the middle section stope is divided into several subsection stopes, and the sub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com