Sea sand treatment process

A treatment process, sea sand technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. The problem of low ion removal efficiency, etc., achieves the effect of reducing water consumption, good economic and environmental benefits, and realizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

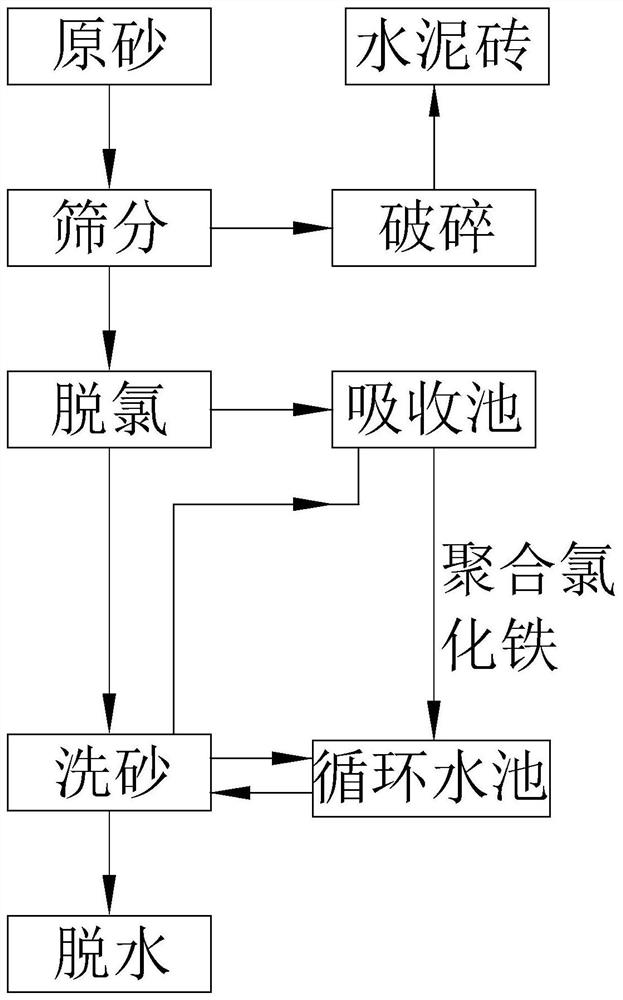

[0039] A sea sand treatment process, comprising the following steps:

[0040] (1) Screening: vibrating screen the raw sand to remove impurities such as shells and gravels in the sea sand; crush the shells, gravels and other impurities obtained from the screening, and recycle them as raw materials for cement bricks to achieve solid Recycling and recycling of waste;

[0041] (2) Dechlorination: Transport the sieved sea sand to the dechlorination tank, immerse in the dechlorination agent and stir the sea sand for dechlorination. The dechlorination agent uses ozone water solution with a mass concentration of 30mg / L, and the dechlorination time is 30min . The dechlorination pool is equipped with a gas collection hood and an absorption pool. The absorption pool is filled with scrap iron scraps and 3% hydrogen chloride solution. The scrap iron scraps react with the hydrogen chloride solution to form a ferrous chloride solution. The chlorine gas produced is collected by the gas colle...

Embodiment 2

[0048] A sea sand treatment process, comprising the following steps:

[0049] (1) Screening: vibrating screen the raw sand to remove impurities such as shells and gravels in the sea sand; crush the shells, gravels and other impurities obtained from the screening, and recycle them as raw materials for cement bricks to achieve solid Recycling and recycling of waste.

[0050] (2) Dechlorination: Transport the sieved sea sand to the dechlorination tank, immerse in the dechlorination agent and stir the sea sand for dechlorination. The dechlorination agent uses ozone water solution with a mass concentration of 65mg / L, and the dechlorination time is 75min . The dechlorination pool is equipped with a gas collection hood and an absorption pool. The absorption pool is filled with scrap iron scraps and 7% hydrogen chloride solution. The scrap iron scraps react with the hydrogen chloride solution to form a ferrous chloride solution. The chlorine gas produced is collected by the gas colle...

Embodiment 3

[0057] A sea sand treatment process, comprising the following steps:

[0058] (1) Screening: vibrating screen the raw sand to remove impurities such as shells and gravels in the sea sand; crush the shells, gravels and other impurities obtained from the screening, and recycle them as raw materials for cement bricks to achieve solid Recycling and recycling of waste.

[0059] (2) Dechlorination: Transport the sieved sea sand to the dechlorination pool, immerse in the dechlorination agent and stir the sea sand for dechlorination. The dechlorination agent uses ozone water solution with a mass concentration of 100mg / L, and the dechlorination time is 120min . The dechlorination pool is equipped with a gas collection hood and an absorption pool. The absorption pool is filled with scrap iron scraps and 10% hydrogen chloride solution. The scrap iron scraps react with the hydrogen chloride solution to form a ferrous chloride solution. The chlorine gas produced is collected by the gas co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com