Method for cooperative treatment of kitchen waste, household waste and sewage plant sludge

A technology for kitchen waste and domestic waste, which is applied in combustion methods, chemical instruments and methods, and solid waste removal, etc. The effect of saving water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

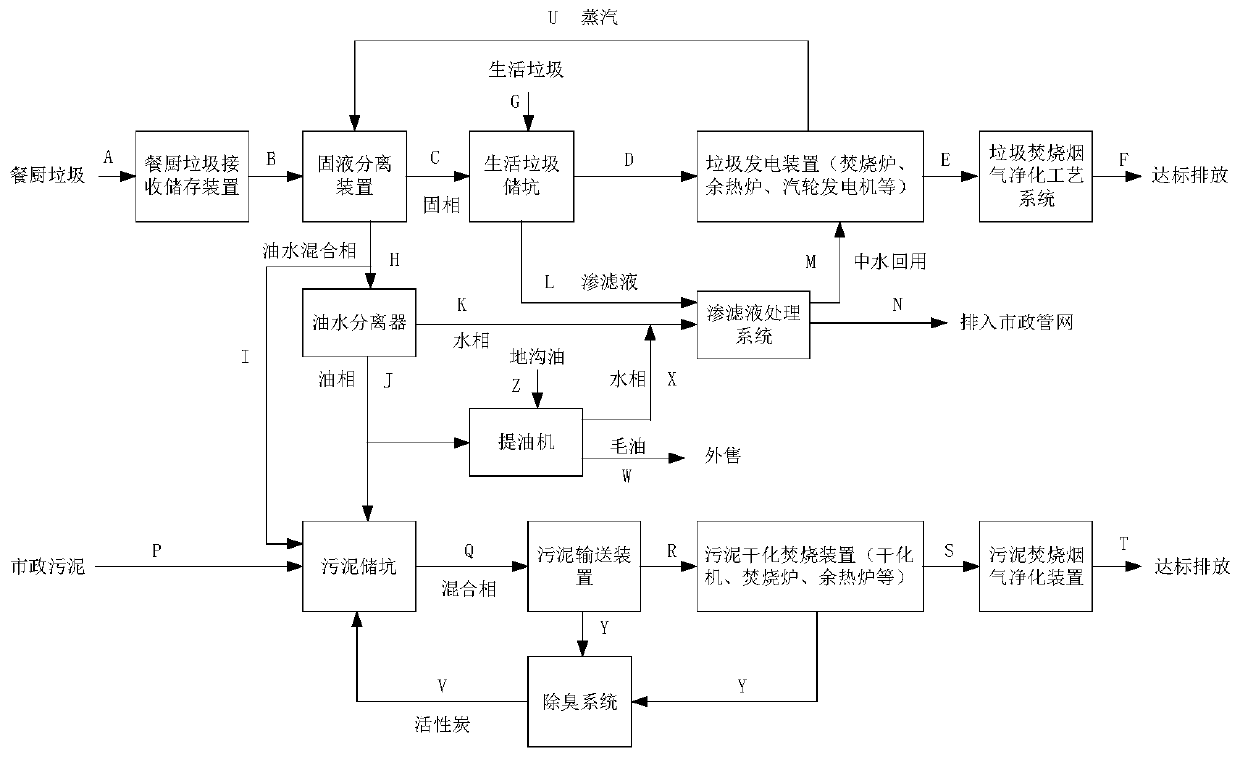

[0033] figure 1 It is a process flow diagram of an embodiment of the present invention. As shown in the figure, in this example, a method for the co-processing of kitchen waste, domestic waste and sewage plant sludge includes a domestic waste treatment step, a kitchen waste treatment step and a sludge treatment step, and the domestic waste treatment step includes incineration step and leachate treatment step,

[0034] The steps of incinerating domestic waste include:

[0035] 1. Domestic waste enters the domestic waste storage pit (step G),

[0036] 2. After the domestic waste is fermented in the storage pit for 3-5 days, it is sent to the waste incinerator for incineration to generate electricity (step D),

[0037] 3. The flue gas produced by incineration is carried out through the waste incineration flue gas purification process system to remove secondary pollutants (step E),

[0038] 4. The flue gas discharges up to the standard (step F).

[0039] The kitchen waste tre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com