Preparation method of shear thickening gel, and application of gel in anti-break fabric

A technology for thickening gels and fabrics, applied in textiles, papermaking, fiber processing, etc., can solve the problems of complex process, high fluidity, insufficient breaking resistance, etc., and achieve the effect of solving too fast reaction and enhancing breaking resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] This embodiment provides a method for preparing a shear-thickening gel, which includes the following raw material components in parts by weight:

[0035]

[0036] As a preferred embodiment, the borate is a nitrogen-containing borate.

[0037] As a preferred embodiment, the borate is triethanolamine borate.

[0038] As a preferred embodiment, the hemp stalk core short fibers have a diameter of 50-500 nm and a length of less than 100 μm.

Embodiment approach

[0039] As a preferred embodiment, the preparation method of the shear thickening gel comprises the following steps:

[0040] Step 1: Disperse the silica balls in the mixed solution of water and ethanol, add resorcinol and formaldehyde in sequence, stir the mixed solution at 30-50°C for 4-24 hours, suction filter and recover the mixed liquid, and dry After that, the modified silica is obtained; as figure 1 and 2 Shown are SEM images of two sets of modified silica.

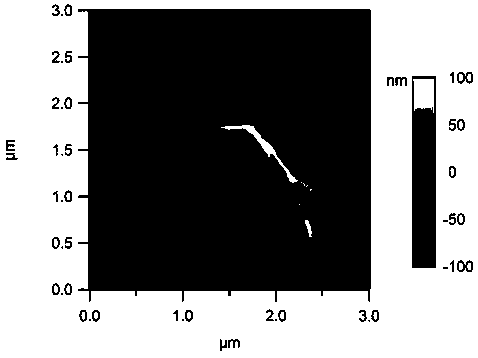

[0041] Step 2: Mix the hemp stalk core fiber with the alkaline compound solution and place it in a ball mill tank, mill it for 2 to 8 hours, wash it with water to neutrality, and dry it to obtain the hemp stalk core short fiber; Figure 3-4 Shown are AFM images of hemp stalk core staple fibers and their corresponding height maps.

[0042] Step 3: put hydroxyl silicone oil, boric acid ester, hemp stalk core short fiber, and modified silica into the polymer mixing equipment in proportion, mix them into a base mater...

Embodiment 1

[0055] The preparation method of fabric in the present embodiment, comprises the steps:

[0056] Step 1: Disperse the silica balls in the mixed solution of water and ethanol, add resorcinol and formaldehyde in sequence, stir the mixed solution at 30°C for 24 hours, suction filter and recover the mixed liquid, and obtain the improved product after drying. Silica; wherein the weight ratio of water and ethanol is 1:8, and the weight ratio of resorcinol, formaldehyde and silicon dioxide is 1:2:20;

[0057] Step 2: Mix the hemp stalk core fiber with the alkaline compound solution and put it in a ball mill tank. After ball milling for 4 hours, wash with water until neutral, and dry to obtain the hemp stalk core short fiber. The ball-to-material ratio is 40:1, and the rotation speed is 350rpm ;

[0058] Step 3: put 100 parts by weight of hydroxyl silicone oil, 5 parts by weight of boric acid ester, 5 parts by weight of hemp stalk core short fiber, and 30 parts by weight of modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com