Aluminum alloy cable, manufacturing device and manufacturing method thereof

An aluminum alloy wire and aluminum alloy technology is applied in the direction of cable/conductor manufacturing, cables, insulated cables, etc. It can solve the problems of single twisting method of cable manufacturing equipment and poor cable tensile performance, so as to enhance the anti-breakage performance and enhance Fire resistance performance, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Refer to the attached Figure 1-10 , an aluminum alloy cable in this embodiment, including a cable body 800, characterized in that: the cable body 800 includes an outer cladding 802, and the outer cladding 802 is provided with an aluminum alloy wire 103, and the aluminum alloy wire 103 There are six groups, and the six groups of aluminum alloy wires 103 constitute the cable 801 , and the outer cladding layer 802 is provided with a waterproof layer 803 .

[0045] Further, the six groups of aluminum alloy wires 103 are twisted into a twisted shape and then twisted into a twisted shape. The outer cladding layer 802 is made of polyethylene material or polyvinyl chloride material, and the outer cladding layer 802 is provided with a filling material. .

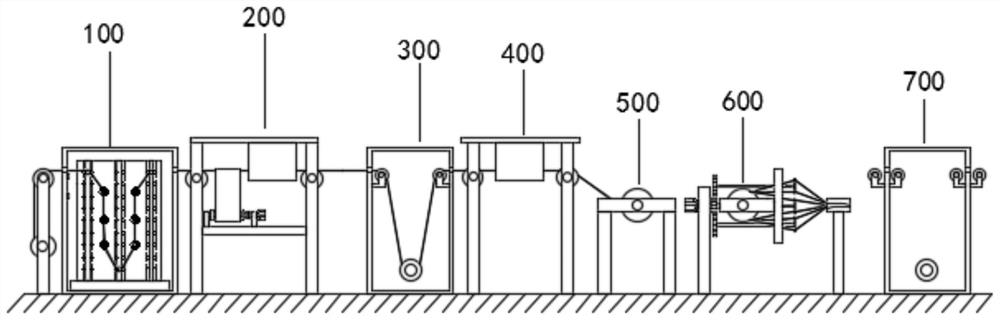

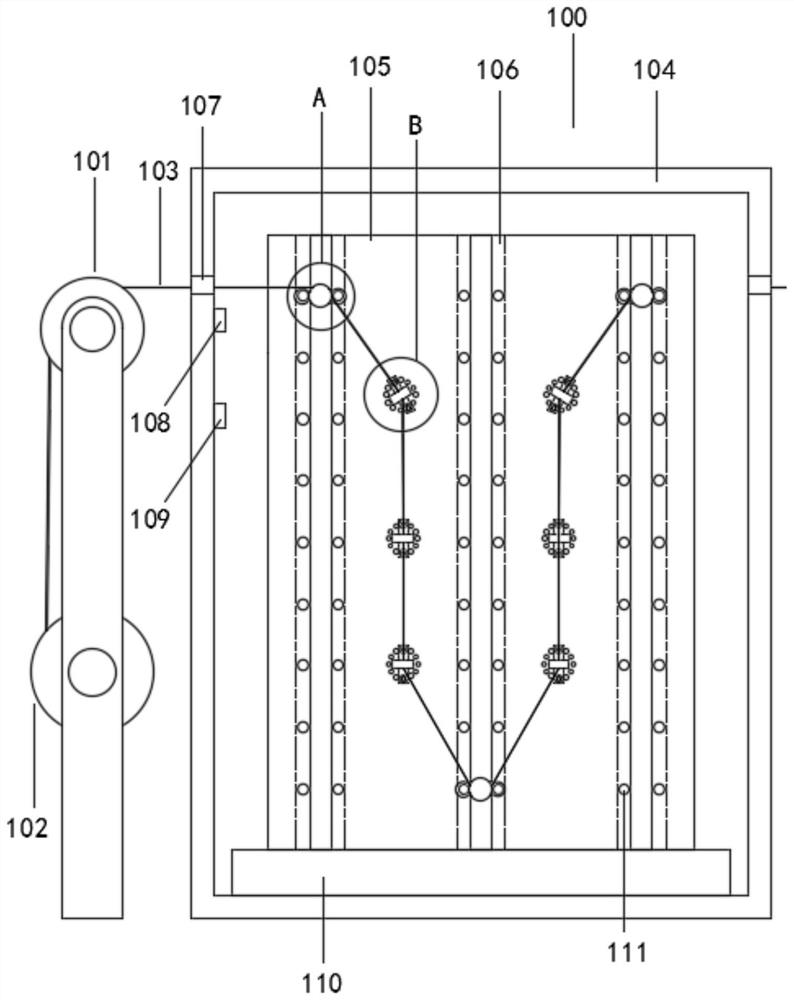

[0046] Refer to the attached Figure 1-10 , a kind of aluminum alloy cable production equipment of this embodiment, comprises wire drawing device 100, dewatering device 200, fireproof layer preparation device-300, drying de...

Embodiment 2

[0062] Refer to the attached Figure 11 , the difference from Embodiment 1 is: the cable body 800 also includes a fireproof layer 804, and the fireproof layer 804 is provided outside the waterproof layer 803;

[0063] The specific implementation scenarios are:

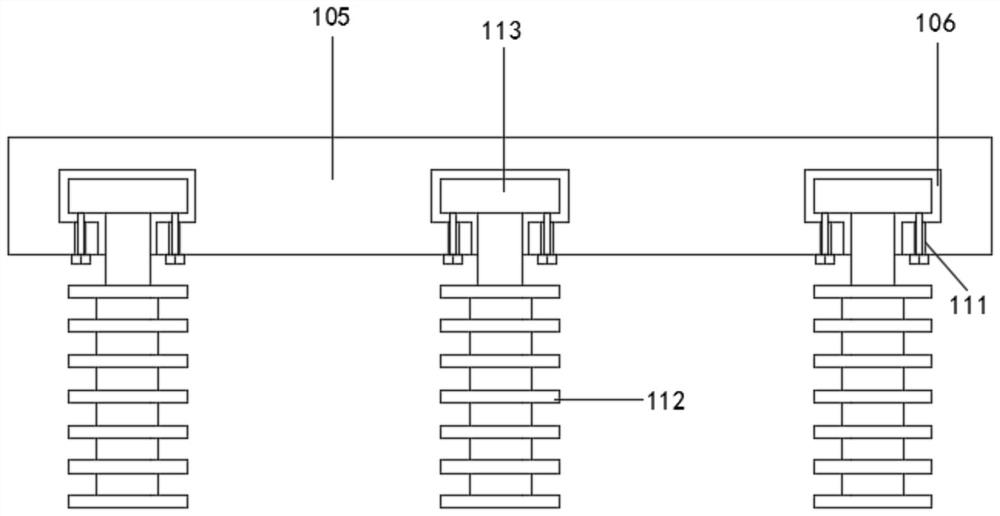

[0064]When using the present invention, the six aluminum alloy wires 103 wound on the reel one 102 pass through the six groups of wire drawing discs 114 on the square plate 105. Since the apertures of the six groups of wire drawing discs 114 decrease successively, thick wires will be made into suitable Thick and thin aluminum alloy wires 103, and the aluminum alloy wires 103 pass through the water in the first box 104 to prevent the friction between the aluminum alloy wires 103 and the wire drawing hole wall of the wire drawing disc 114 to cause heat breakage, and the six aluminum alloy wires 103 pass through the non-woven fabric 208, The output end of the servo motor one 206 drives the cloth rolling wheel one 207 to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com