Device for rapidly and continuously preparing gas hydrate

A gas hydrate and hydrate technology, which is applied in the methods of chemically changing substances by atmospheric pressure, chemical/physical processes, and pressure vessels used in chemical processes, etc. Unable to complete the mixing task and other problems, to achieve the effect of convenient transportation operation, improve efficiency, and enhance heat and mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

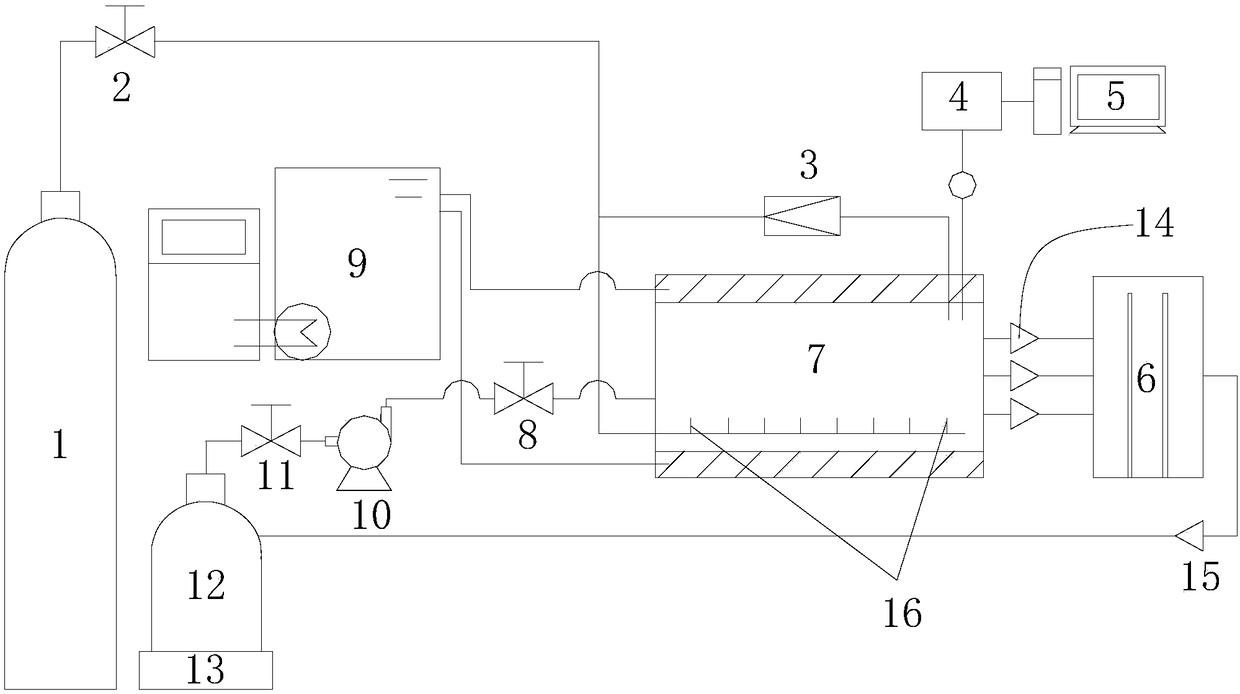

[0021] refer to figure 1 , is a kind of equipment for rapid and continuous preparation of gas hydrates, including a reaction kettle 7 with a water jacket on the outside, a gas supply unit for providing a gas source for the reaction kettle 7, an ice supply unit for providing ice liquid for the reaction kettle 7, The temperature control unit used to control the temperature of the external jacket, the hydrate filtration collection unit connected to the reactor 7 and used to filter and collect the hydrate crystals formed therein, and the data used to collect and record the temperature and pressure of the reactor 7 Collection and processing unit; the rear end of the hydrate filtration and collection unit is connected to the ice supply unit through a quick-connect valve 15 .

[0022] Reactor 7 is a container for the gas-water system to react to form hydrates. The water jacket is set to enable the temperature control unit to control the temperature of the system; the hydrate filtrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com