Aluminum alloy powder material for aviation additive manufacturing, preparation method and 3D printing method

A technology of additive manufacturing and aluminum alloy, which is applied in the field of preparation of aluminum alloy powder materials for aviation additive manufacturing, and can solve the problems of material cracking, uneven structure, strength, tensile strength in deposited state and low tensile strength in annealed state, etc. , to achieve the effect of solving easy oxidation and optimizing welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

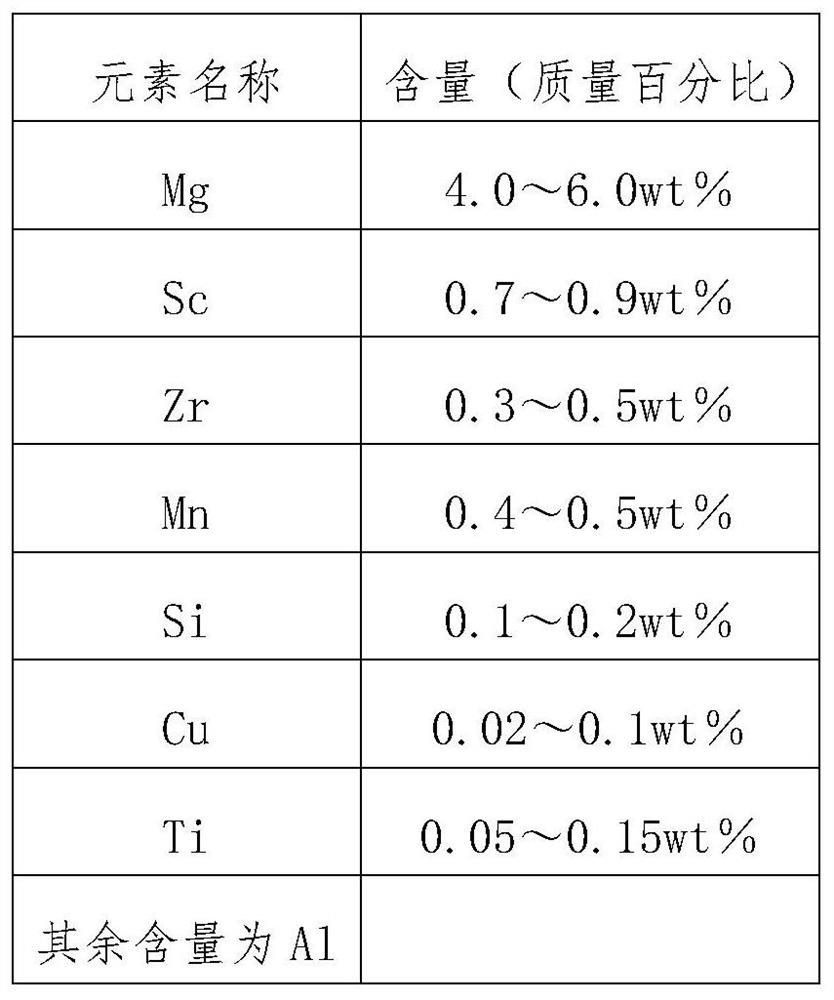

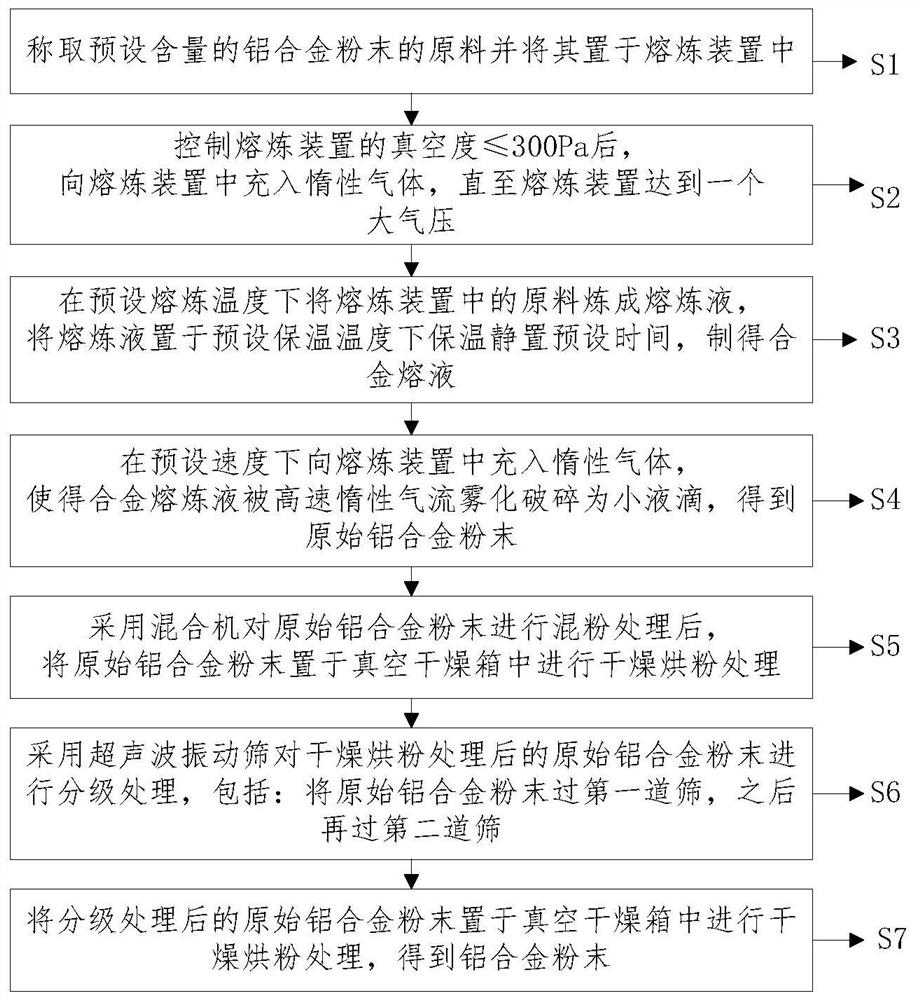

[0047] Specifically this preparation method comprises the following steps:

[0048] Step S1: weighing a raw material of aluminum alloy powder with a preset content and placing it in a smelting device.

[0049] The raw materials for preparing aluminum alloy powder include: any one of pure magnesium, pure aluminum, aluminum-magnesium alloy, aluminum-scandium alloy, aluminum-zirconium alloy, aluminum-manganese alloy, aluminum-silicon alloy, aluminum-copper alloy or aluminum-titanium alloy or a combination thereof.

[0050] Step S2: After controlling the vacuum degree of the smelting device to be ≤300 Pa, fill the smelting device with inert gas until the smelting device reaches atmospheric pressure.

[0051] Specifically, the purpose of keeping the vacuum degree of the smelting device within 300 Pa is to draw away the air in the smelting chamber to ensure that the smelting device is in a vacuum state. When the inert gas is filled into the smelting device later, the atmosphere in ...

Embodiment 1

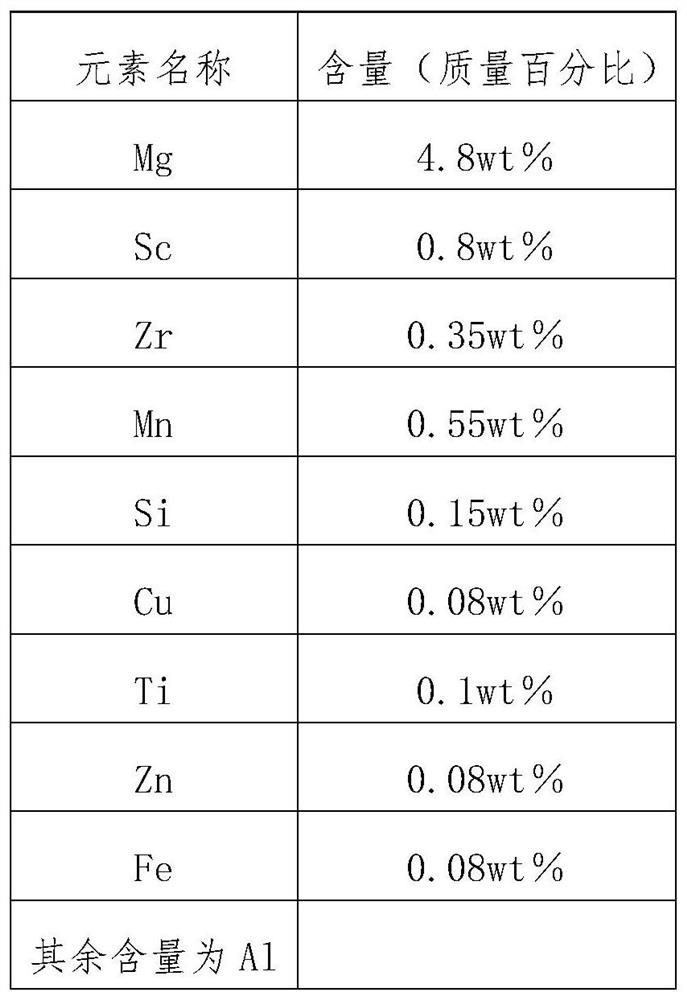

[0073] image 3 It is a schematic diagram of the raw material ratio of the aluminum alloy powder used for aviation additive manufacturing in Example 1 provided by the present invention, please refer to image 3 , the aluminum alloy powder material for aerospace additive manufacturing provided by the present invention contains the following components in mass percentage:

[0074] Mg: 4.8wt%, Sc: 0.8wt%, Zr: 0.35wt%, Mn: 0.55wt%, Si: 0.15wt%, Cu: 0.08wt%, Ti: 0.1wt%, Zn: 0.08wt%, Fe: <0.08wt%; the remaining content is Al.

[0075] According to the content of raw materials in the above aluminum alloy powder, weigh pure magnesium alloy, pure aluminum alloy, aluminum-scandium alloy, aluminum-zirconium alloy, aluminum-manganese alloy, aluminum-silicon alloy, aluminum-copper alloy and aluminum-titanium alloy, and place them in the melting device middle.

[0076] The smelting device is evacuated to a vacuum degree of 280 Pa, and then filled with nitrogen, so that the inside of the ...

Embodiment 2

[0087] Figure 4 It is a schematic diagram of the raw material ratio of the aluminum alloy powder used in the aviation additive manufacturing of the second embodiment provided by the present invention, please refer to Figure 4 , the aluminum alloy powder material for aerospace additive manufacturing provided by the present invention contains the following components in mass percentage:

[0088] Mg: 4.5wt%, Sc: 0.83wt%, Zr: 0.38wt%, Mn: 0.5wt%, Si: 0.2wt%, Cu: 0.05wt%, Ti: 0.15wt%; the remaining content is Al.

[0089] According to the content of raw materials in the above aluminum alloy powder, weigh pure magnesium alloy, pure aluminum alloy, aluminum-scandium alloy, aluminum-zirconium alloy, aluminum-manganese alloy, aluminum-silicon alloy, aluminum-copper alloy and aluminum-titanium alloy, and place them in the melting device middle.

[0090] The smelting device is evacuated to a vacuum degree of 300 Pa, and then filled with argon to make the inside of the smelting device...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com