Laser welding method for copper-aluminum dissimilar metals

A laser welding, dissimilar metal technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of brittle phase intermetallic compounds, easy to appear pores, difficult to weld, etc., to reduce brittle phase intermetallic compounds The production of aluminum, avoid the excessive melting of aluminum, improve the effect of welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

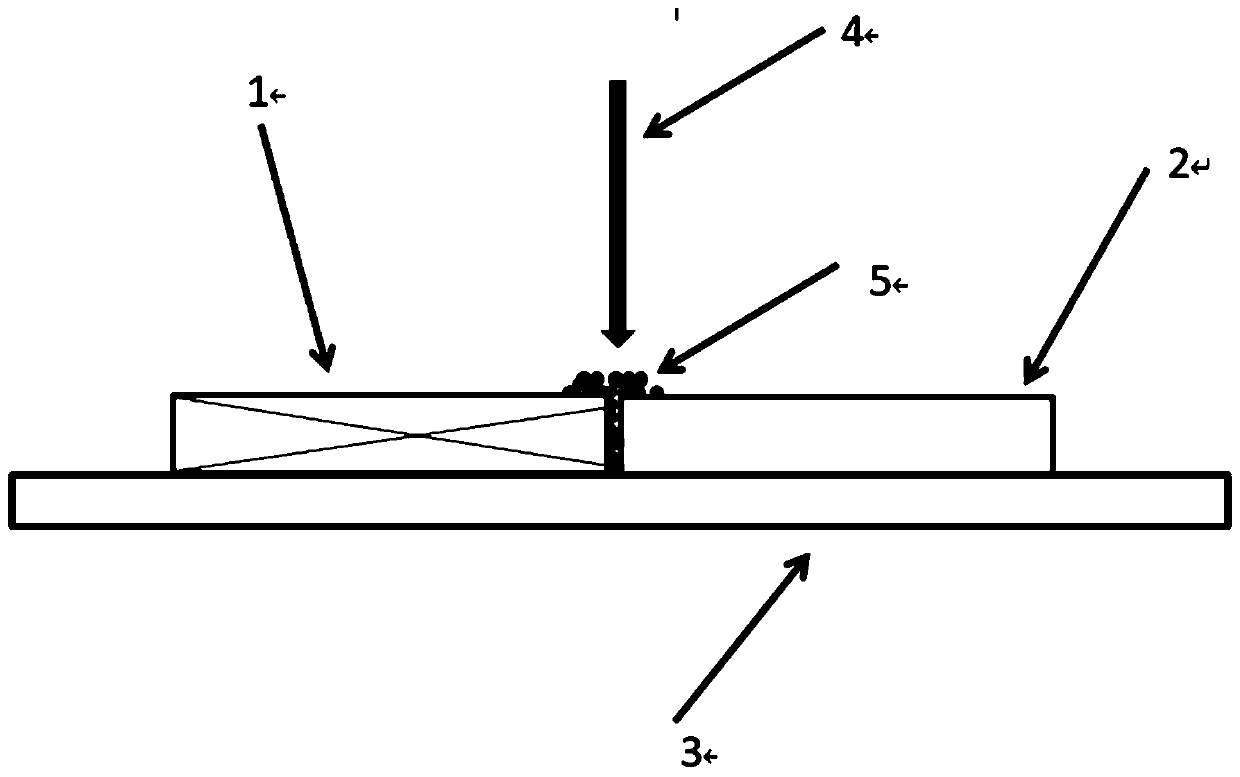

Image

Examples

Embodiment 1

[0046] T2 copper plate is selected as the welding workpiece, the machining specification is 1*1*1mm, and the machining specification of 1060 aluminum plate is 1*1*1mm;

[0047] Pre-treat the welding area of the workpiece to be welded, clean up dust, oil or rust, and dry to obtain a clean and dry welding surface;

[0048] Place the copper plate and the aluminum plate on the welding platform, and fix them with clamps so that the areas to be welded of the copper plate and the aluminum plate are in contact as much as possible;

[0049] The mass ratio of 1g of cerium oxide to yttrium oxide is 1:1 mixed powder evenly paved on the area to be welded of the copper plate and the aluminum plate;

[0050] Adjust the 90° between the laser and the surface of the workpiece, and perform laser welding. Welding process parameters: current is 260A, pulse width is 3.5ms, frequency is 60Hz, maximum power is 800W, laser wavelength is 1064nm, and welding speed is 5mm / s.

[0051] Welding under thi...

Embodiment 2

[0053] T2 copper plate is selected as the welding workpiece, the machining specification is 1*1*1mm, and the machining specification of 1060 aluminum plate is 1*1*1mm;

[0054] Pre-treat the welding area of the workpiece to be welded, clean up dust, oil or rust, and dry to obtain a clean and dry welding surface;

[0055] Place the copper plate and the aluminum plate on the welding platform, and fix them with clamps so that the areas to be welded of the copper plate and the aluminum plate are in contact as much as possible;

[0056] Evenly spread 0.5g of cerium oxide and yttrium oxide mixed powder in the area to be welded on the copper plate and the aluminum plate with a mass ratio of 1:3;

[0057] Adjust the 90° between the laser and the surface of the workpiece, and perform laser welding. Welding process parameters: current is 260A, pulse width is 3.5ms, frequency is 60Hz, maximum power is 800W, laser wavelength is 1064nm, and welding speed is 5mm / s.

[0058] Welding under...

Embodiment 3

[0060] T2 copper plate is selected as the welding workpiece, the machining specification is 10*1*1mm, and the machining specification of 1060 aluminum plate is 10*1*1mm;

[0061] Pre-treat the welding area of the workpiece to be welded, clean up dust, oil or rust, and dry to obtain a clean and dry welding surface;

[0062] Place the copper plate and the aluminum plate on the welding platform, and fix them with clamps so that the areas to be welded of the copper plate and the aluminum plate are in contact as much as possible;

[0063] The mixed powder that the mass ratio of 15g cerium oxide and yttrium oxide is 1:2 is evenly paved on the region to be welded of copper plate and aluminum plate;

[0064] Adjust the 90° between the laser and the surface of the workpiece, and perform laser welding. Welding process parameters: current is 260A, pulse width is 3.5ms, frequency is 60Hz, maximum power is 800W, laser wavelength is 1064nm, and welding speed is 5mm / s.

[0065] Welding un...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com