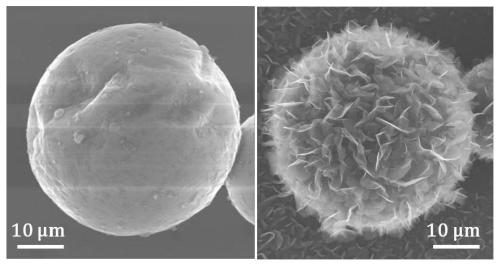

A kind of low laser reflectance powder particle and preparation method

A technology of powder particles and laser reflection, applied in metal processing equipment, transportation and packaging, coating, etc., can solve the problems of reducing block properties, destroying the sphericity of matrix powder, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing powder particles with low laser reflectivity, preparing the powder particles with low reflectivity as described above, characterized in that the steps of preparation are as follows:

[0023] 1. Powder washing: Weigh the raw materials according to the proportion of adding at least 10ml of absolute alcohol to 1g of spherical core, put the spherical core and absolute alcohol into a beaker and mix, ultrasonically mix for at least 20min, let stand for at least 30min, pour off the alcohol solution, put Dry in a vacuum oven with a vacuum degree of at least 10Pa and a temperature of 60°C to 120°C for at least 1 hour;

[0024] 2. Preparation of nano catalyst particles:

[0025] 2.1. After the oven temperature drops to room temperature, take out the beaker, add distilled water at the ratio of 50ml to 100ml of distilled water to 1g of spherical core, and add catalyst precursor at the ratio of 0.03g to 0.09g of catalyst precursor to 1g of spherical core. Cata...

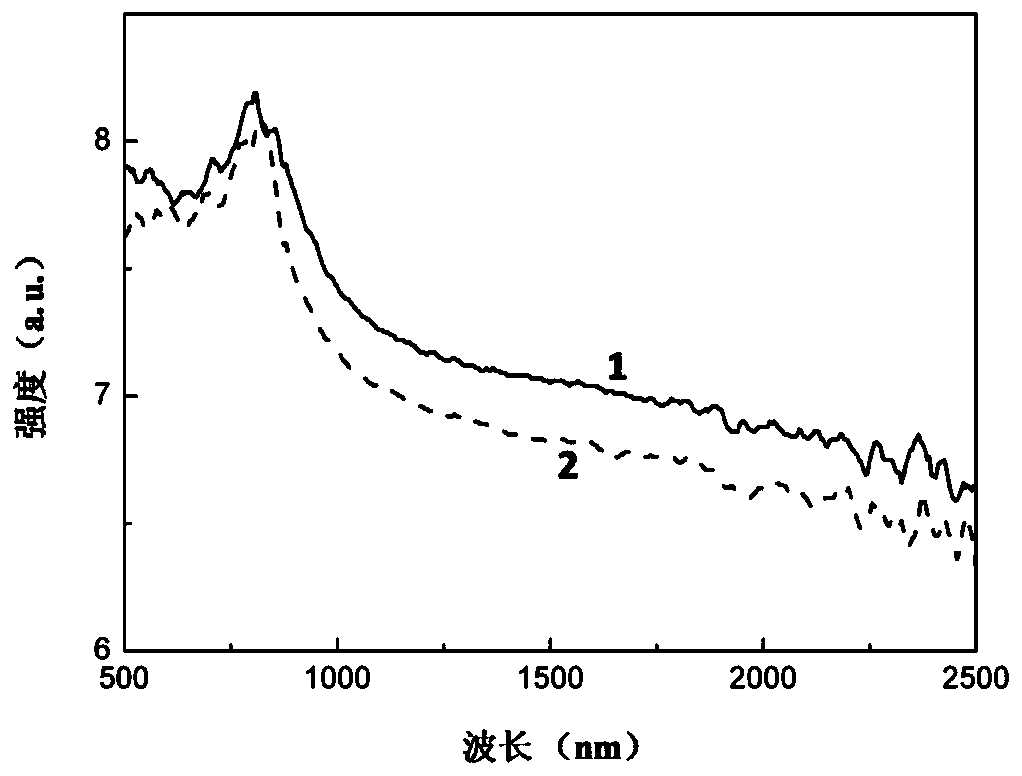

Embodiment 1

[0033] 1. Powder washing: Add 10g of 300-mesh aluminum powder into a beaker filled with 100ml of absolute alcohol, mix it ultrasonically for 20 minutes, let it stand for 30 minutes, pour off the alcohol solution, and dry it in a vacuum oven with a vacuum degree of 10Pa and a temperature of 60°C, dry for 2 hours;

[0034] 2. Preparation of nano catalyst particles:

[0035] 2.1. After the oven temperature drops to room temperature, take out the beaker, add 500ml of distilled water and 0.09g of aluminum nitrate nonahydrate, and stir for 30 minutes;

[0036] 2.2. Then slowly drop in ammonia solution with a concentration of 20% until the pH value of the solution reaches neutrality, and let it stand for 2 hours to form a suspension;

[0037] 2.3. Put the suspension into a centrifuge for centrifugation for 2 minutes, then wash with distilled water; centrifuge and wash twice again;

[0038] 2.4. Take out the precipitate and put it in a vacuum oven with a vacuum degree of 10Pa, a tem...

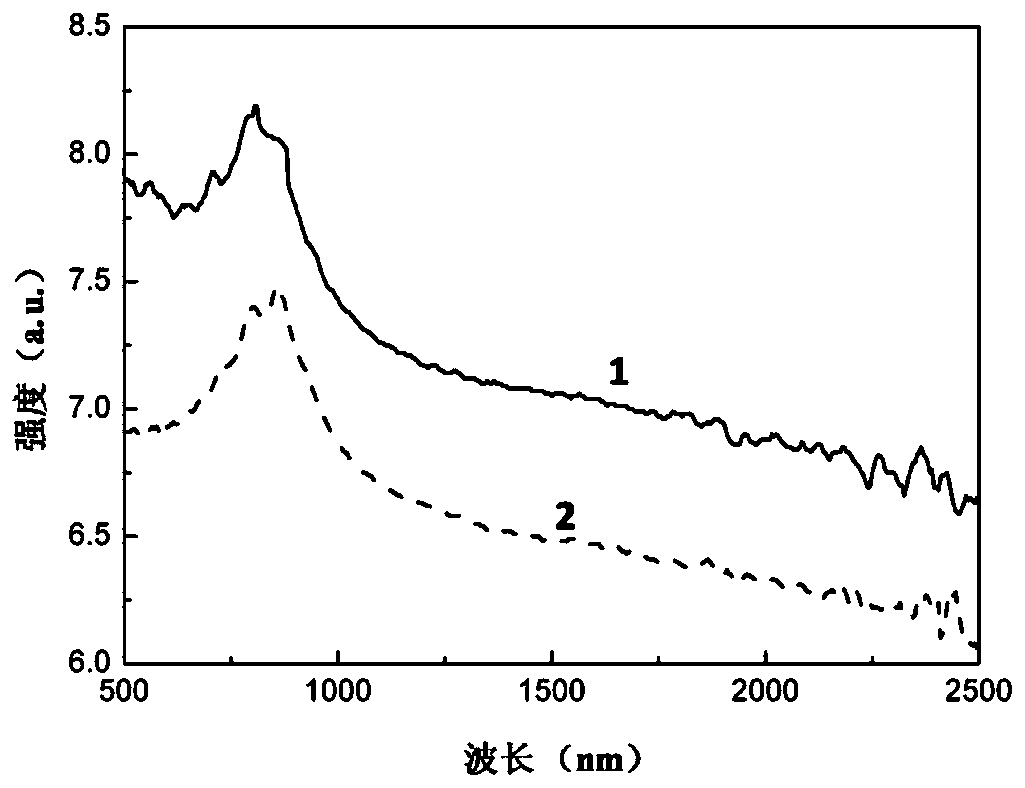

Embodiment 2

[0042] 1. Powder washing: Add 20g of 100 mesh nickel-based superalloy powder into a beaker filled with 200ml of absolute alcohol, mix it ultrasonically for 20 minutes, let it stand for 30 minutes, pour off the alcohol solution, put it in a vacuum oven for drying, and the vacuum degree of the oven is 10Pa , the temperature is 120 ℃, drying 1h;

[0043] 2. Preparation of nano catalyst particles:

[0044] 2.1. After the oven temperature drops to room temperature, take out the beaker, add 1000ml of distilled water and 0.06g of nickel nitrate hexahydrate, and stir for 30 minutes;

[0045] 2.2. Then slowly drop in ammonia solution with a concentration of 30% until the pH value of the solution reaches neutrality, and let it stand for 2 hours to form a suspension;

[0046] 2.3. Put the suspension into a centrifuge for centrifugation for 2 minutes, then wash with distilled water; centrifuge and wash again for 3 times;

[0047] 2.4. Take out the precipitate and put it in a vacuum oven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com