Sheet material micro-forming device by use of high-pressure water jet

A high-pressure water jet, micro-forming technology, applied in feeding devices, positioning devices, storage devices, etc., can solve the problems of limited compression, high price, and difficulty in miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

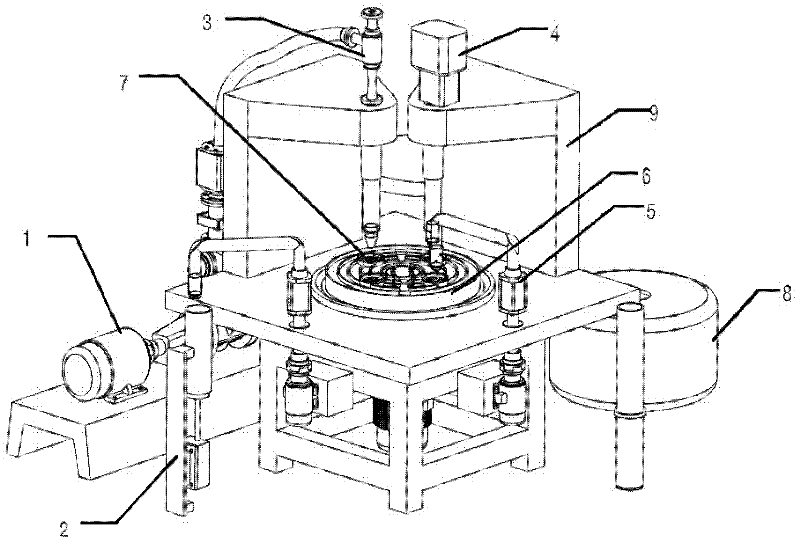

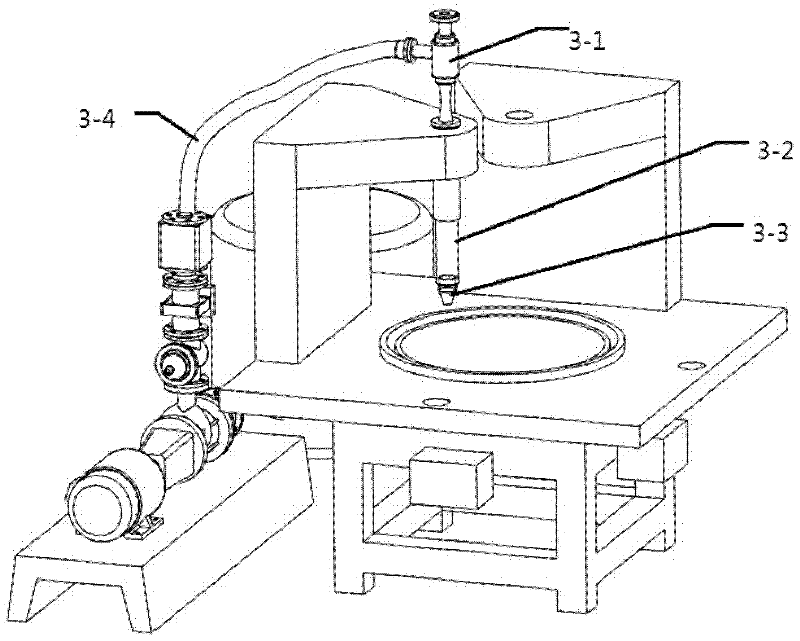

[0029] refer to figure 1 , a high-pressure water jet plate micro-forming device, including a high-pressure system 1, a feeding system 2, a jet forming system 3, a drying system 4, a pick-up system 5, a workbench 6, a plate blanking system 7, a water recovery system 8 and Support 9, high-pressure system 1 is a high-pressure water supply device, high-pressure system 1 is connected with jet forming system 3, high-pressure system 1 provides high-pressure water for jet forming system 3, discharge system 2, jet forming system 3, drying system 4, Component system 5 and workbench 6 are installed on the support 9.

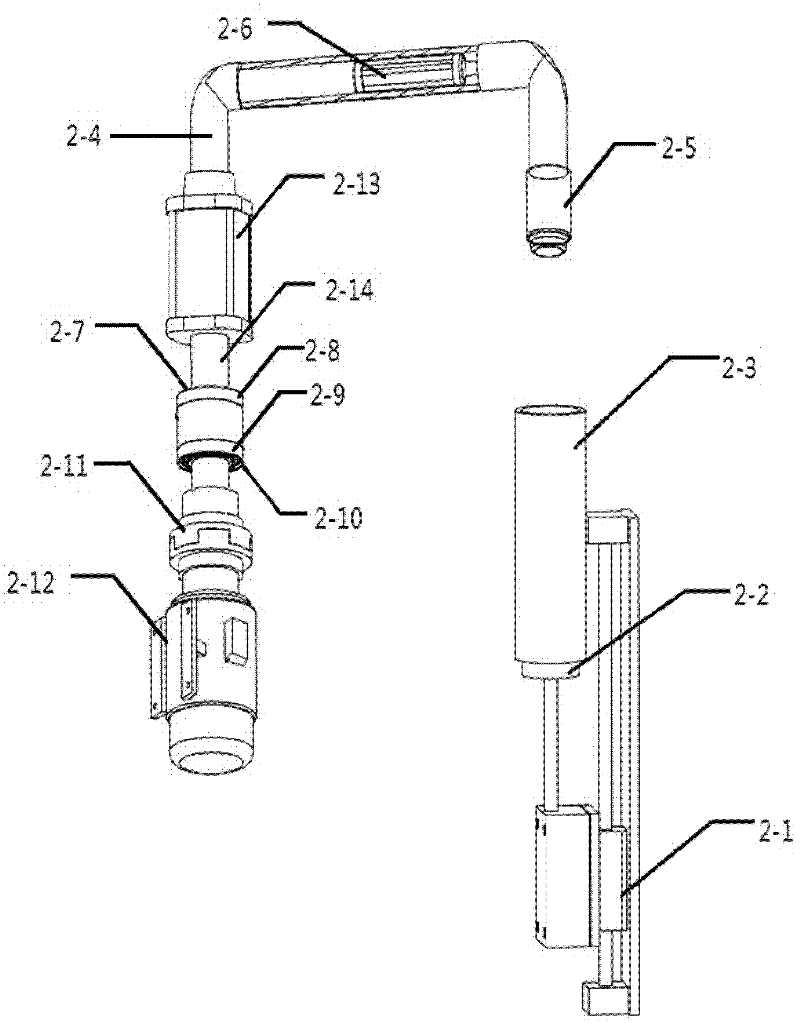

[0030] refer to figure 2, the discharge system 2 includes a movable material cylinder 2-3, and the plate blanks for processing are stacked in the movable material cylinder 2-3, and connected with the top material end cover 2-2 matched with the movable material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com