Large-flow state light foamed mixed soil

A technology of lightweight foam and mixed soil, which is applied in the field of building materials to achieve the effects of high foaming ratio, reduced settlement deformation, and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

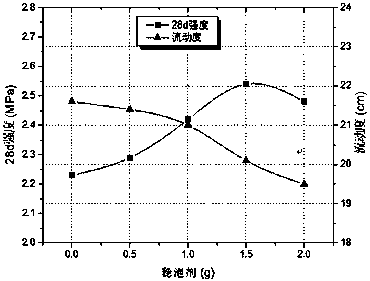

Embodiment 1

[0025] Select components of the following qualities:

[0026]

[0027] Preparation process and test results:

[0028] 1) Take 35 parts of water, add 5 parts of animal protein and 10 parts of sodium lauryl sulfate successively, stir at a constant speed at room temperature until the mixed solution is clear and transparent, and obtain the stock solution of foaming agent, take 35g of the stock solution.

[0029] 2) Add 2 parts of dodecyl alcohol into 8 parts of n-butanol solution and stir at a constant speed at room temperature until the mixture is clear and transparent. Take 55 parts of water, add 1.5 parts of gelatin, 1.5 parts of triethanolamine, and 0.5 parts of tea saponin in sequence, soak for 2-3 hours, and stir evenly at room temperature until the transparent colloid mixture is obtained to obtain a foam stabilizer with excellent performance.

[0030] 3) Mix and stir the solutions prepared in 1) and 2) evenly to obtain a foaming agent with excellent performance, and use...

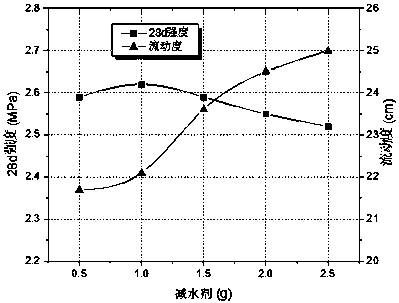

Embodiment 2

[0036] Change the foam stabilizer component into 1.5g in Example 1, and all the other components and contents remain unchanged.

[0037] Preparation process and test results:

[0038] 1) Take 35 parts of water, add 5 parts of animal protein and 10 parts of sodium lauryl sulfate successively, stir at a constant speed at room temperature until the mixed solution is clear and transparent, and obtain the stock solution of foaming agent. The component takes 35g.

[0039] 2) Add 2 parts of dodecyl alcohol into 8 parts of n-butanol solution and stir at a constant speed at room temperature until the mixture is clear and transparent. Take 55 parts of water, add 1.5 parts of gelatin, 1.5 parts of triethanolamine, and 0.5 parts of tea saponin in sequence, soak for 2-3 hours, and stir evenly at room temperature until the transparent colloid mixture is obtained to obtain a foam stabilizer with excellent performance.

[0040] 3) Mix and stir the solutions prepared in 1) and 2) evenly to ob...

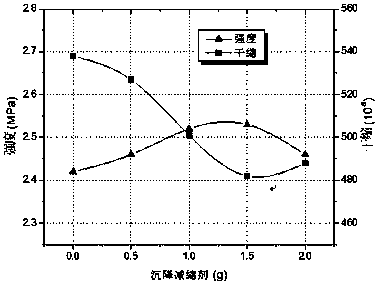

Embodiment 3

[0046] Change the foam stabilizer component into 2.0g in Example 1, and all the other components and contents remain unchanged.

[0047] Preparation process and test results:

[0048] 1) Take 35 parts of water, add 5 parts of animal protein and 10 parts of sodium lauryl sulfate successively, stir at a constant speed at room temperature until the mixed solution is clear and transparent, and obtain the stock solution of foaming agent. The component takes 35g.

[0049] 2) Add 2 parts of dodecyl alcohol into 8 parts of n-butanol solution and stir at a constant speed at room temperature until the mixture is clear and transparent. Take 55 parts of water, add 1.5 parts of gelatin, 1.5 parts of triethanolamine, and 0.5 parts of tea saponin in sequence, soak for 2-3 hours, and stir evenly at room temperature until the transparent colloid mixture is obtained to obtain a foam stabilizer with excellent performance.

[0050] 3) Mix and stir the solutions prepared in 1) and 2) evenly to ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com