Fiber metal laminated plate forming device and method

A fiber metal laminate, progressive forming technology, applied in the field of fiber metal laminate forming, fiber metal laminate forming device, can solve the problems of unstable forming performance, difficult to maintain temperature, uneven deformation of laminates, etc., to achieve continuous stability and reliability Support, save mold manufacturing costs, and reduce error factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

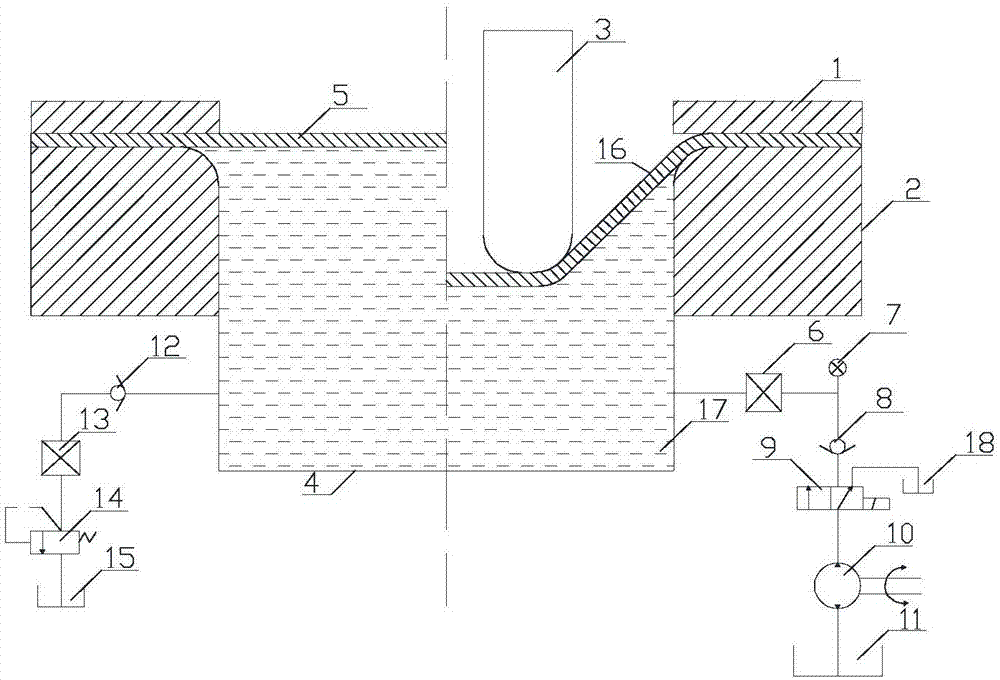

[0040] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

[0041] 1. Preparations

[0042] (1) Select the component materials of the fiber metal laminates, metal materials, fiber prepregs, and adhesives; the laminate 5 in this embodiment is an aramid fiber aluminum alloy laminate for aircraft wing materials and an aluminum alloy laminate for fuselage materials. Glass fiber aluminum alloy laminate;

[0043] ⑵Surface treatment, metal surface decontamination, chemical heat treatment, surface pretreatment of fiber prepreg;

[0044] (3) Unload the laminate 5 so that the geometric center of the laminate coincides with the geometric centers of the upper forming jig 1 and the lower forming jig 2, press the laminate 5 and clamp around;

[0045] ⑷Establish the three-dimensional CAD model of the laminate, use the CAM function to discretize the CAD model along the direction of the processing path, and generate the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com