Preparation method of high-temperature alloy four-layer lattice lightweight structure

A high-temperature alloy and lightweight technology, which is applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems that it is difficult to fully utilize the high-strength and light-weight characteristics of the lattice structure, and achieve good mechanical properties and high welding rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0035] The present invention will be described in detail below with reference to the accompanying drawings and examples.

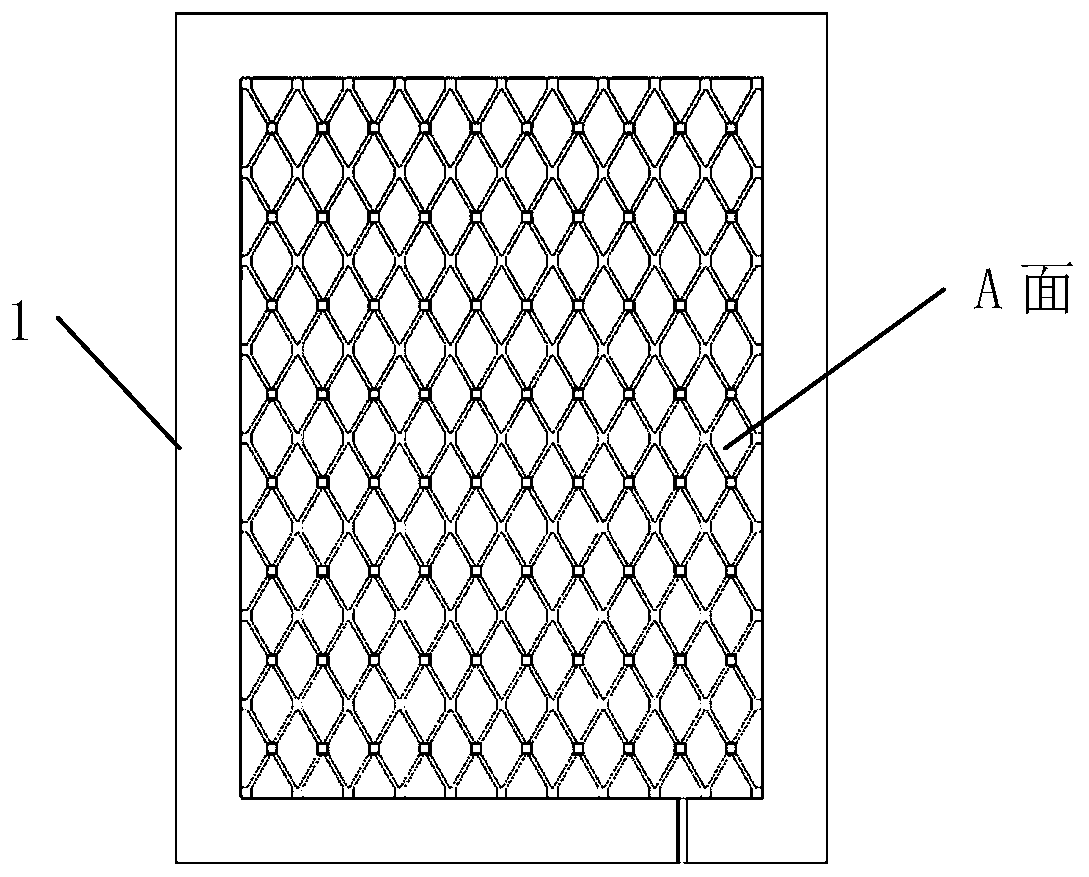

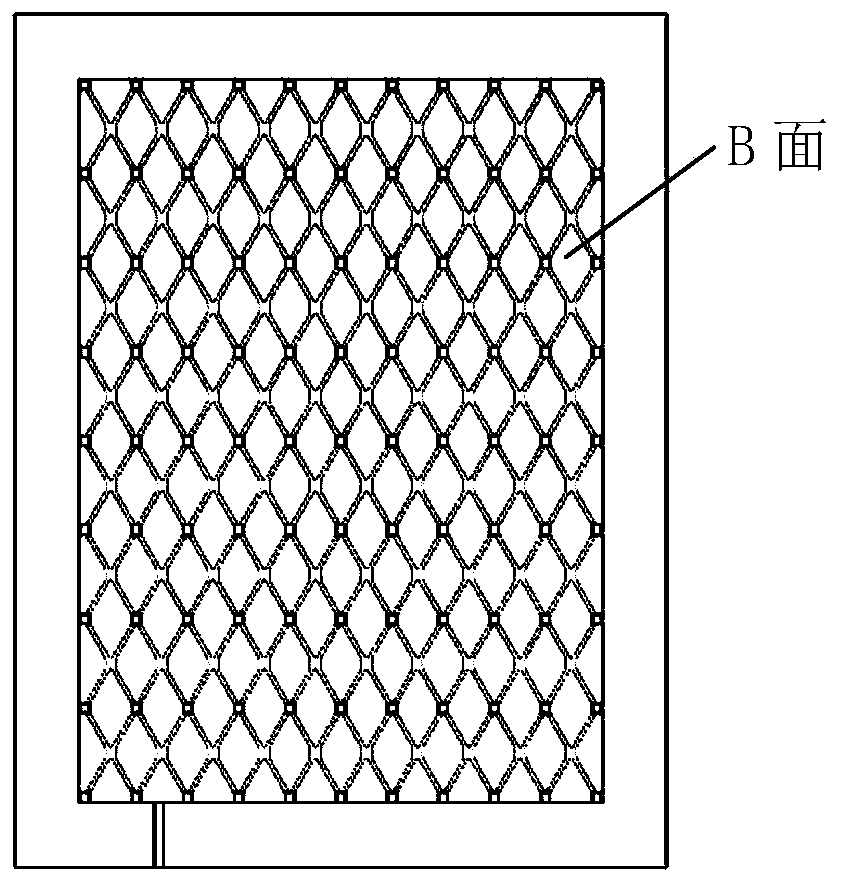

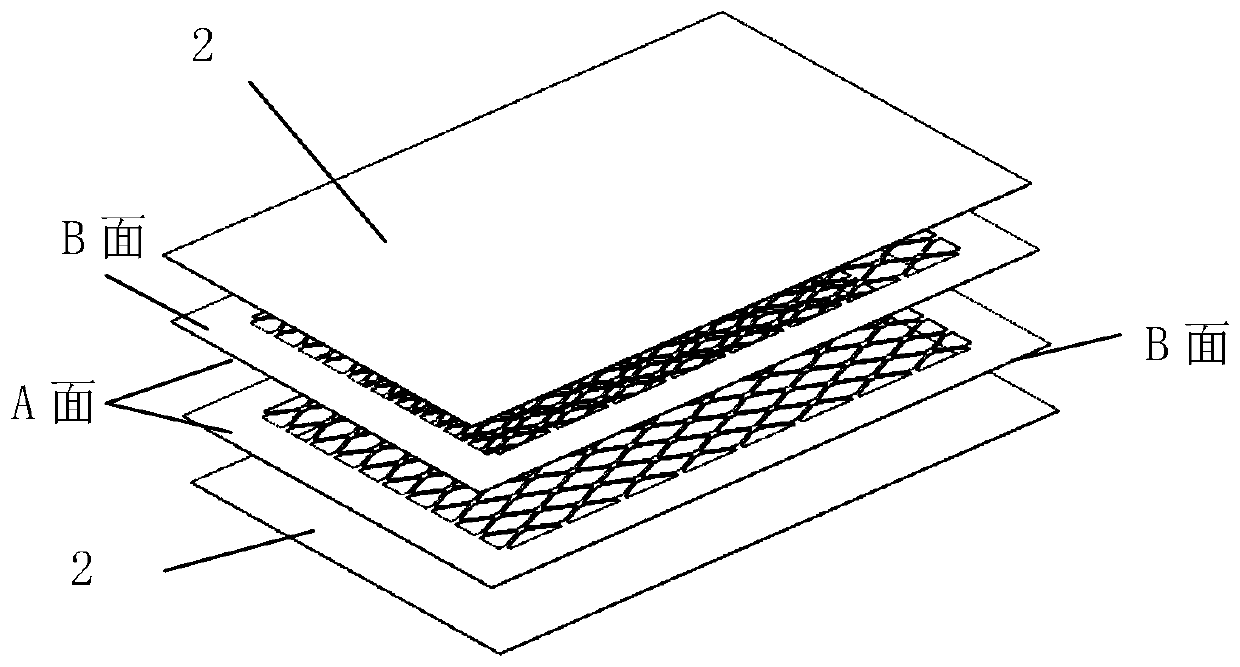

[0036] Such as Figure 1-Figure 4 As shown, a method for preparing a superalloy four-layer lattice lightweight structure comprises the following steps:

[0037] Step 1. Process the hollowed diamond grid structure of the middle laminate: use laser cutting or machining to process the GH4169 superalloy plate into a hollow diamond grid structure according to the design pattern; complete the hollow diamond grid structure of the middle laminate After the structure, use a belt machine or a white steel knife to remove the cutting burrs; the thickness of the middle laminate is 1mm;

[0038] Step 2. Process the skin panel: use laser cutting or machining to process the GH4169 superalloy plate int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com