Induction brazing temperature field control method with selective wetting effect

A control method and induction brazing technology, which are applied to the brazing connection of dissimilar material joints and the field of induction brazing temperature field control, can solve the problems of inability to obtain intact welding parts and different wettability of brazing materials, and achieve easy automation. Simple production, method, and effect of improving uneven wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

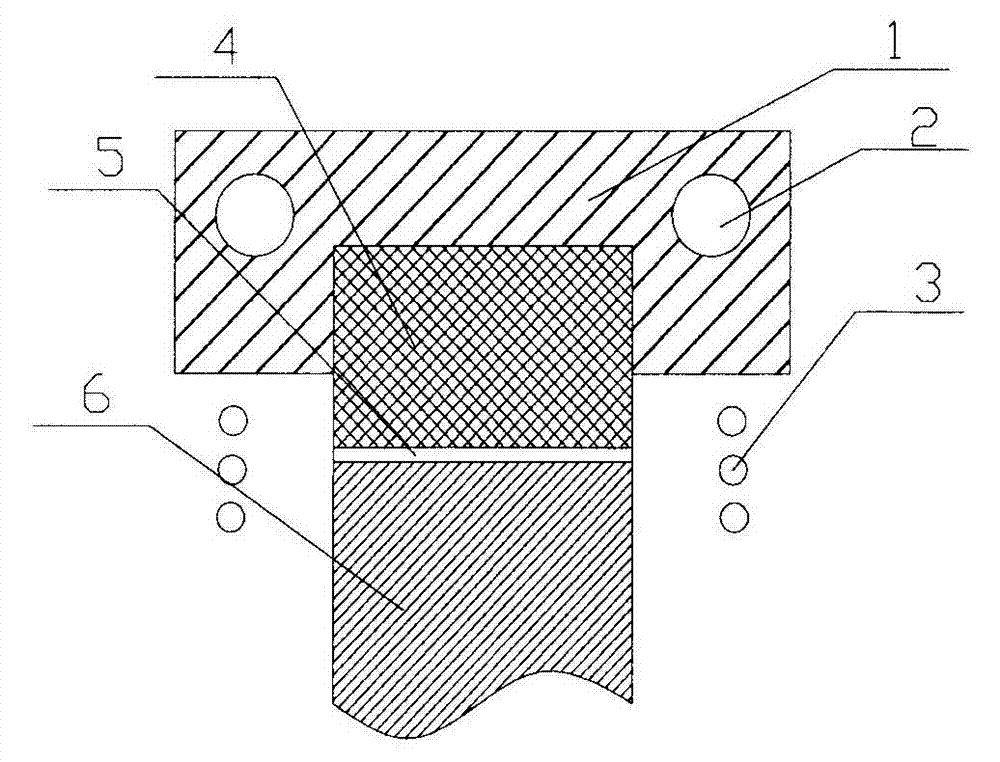

[0034] Induction Brazing Manufacturing of Carbide Saw Blades:

[0035] 1. The cleaned workpieces 4 are hard alloy YG8, and 6 is steel substrate (65Mn steel). Butt joints are used, and flux is applied to the welding surfaces of hard alloy and 65Mn steel respectively, and brazing sheets (silver-based Solder tab) 5;

[0036] 2. Press cemented carbide 4, brazing sheet 5 and 65Mn steel 6 into figure 1 After the sequence shown is assembled and installed in the center position of the induction heating coil 3 of the high-frequency induction brazing equipment;

[0037] 3. Clamp the hard alloy in the copper alloy cooling fixture 1 and fasten it mechanically; the copper alloy fixture is processed from pure copper or high thermal conductivity copper alloy; the diameter of the water hole 2 arranged on the copper alloy fixture is 10mm, the ports at both ends are connected to the circulation pipeline, and a flow valve is set in the circulation pipeline to control and adjust the flow rat...

Embodiment 2

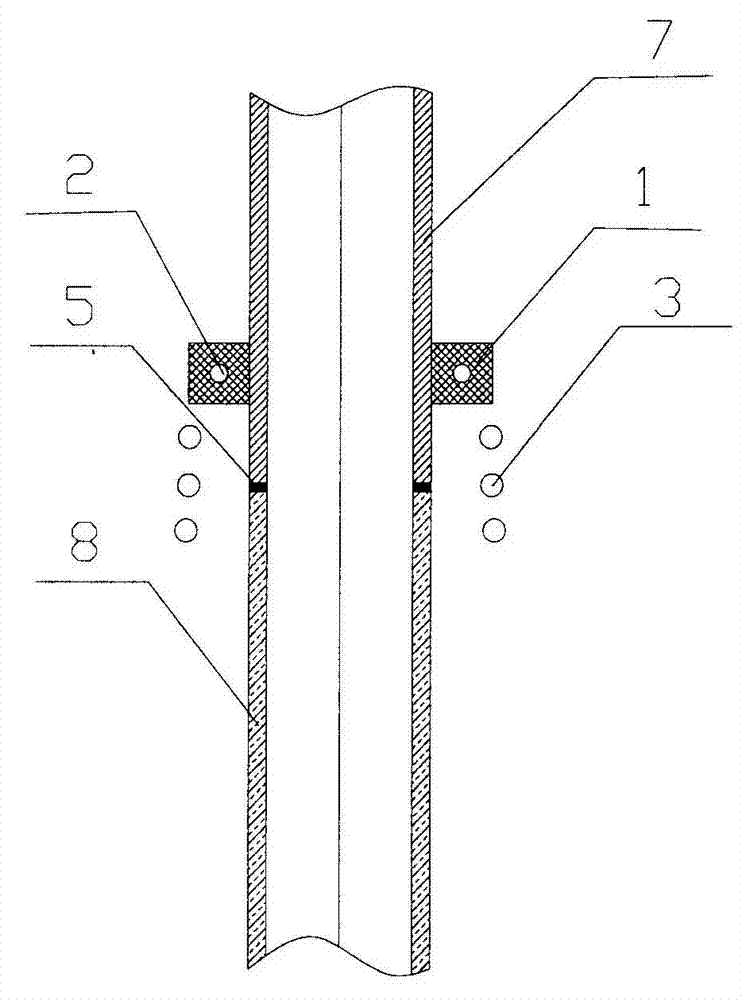

[0042] Induction brazing of copper to stainless steel:

[0043] 1. The workpieces 7 to be cleaned to be welded are 1Cr18Ni9Ti stainless steel pipes, and 8 are pure copper pipes. Butt joints are used, and flux is applied to the welding surfaces of copper and stainless steel pipes respectively, and brazing welding pieces (silver-based welding pieces) 5 are preset;

[0044] 2. Press the copper tube, solder lug and stainless steel tube into the figure 2 After the sequence shown is assembled and installed in the center position of the induction heating coil 3 of the high-frequency induction brazing equipment;

[0045] 3. Fasten the stainless steel tube in the copper alloy cooling fixture 1; the copper alloy fixture is processed from pure copper or high thermal conductivity copper alloy; the diameter of the water hole 2 arranged on the copper alloy fixture is 20 mm, and the two ends The port is connected to the circulation pipeline, and a flow valve is set in the circulation pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com