Welding method and device for large-area ferromagnetic target material

A welding device and ferromagnetic technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of target blank edge deformation, difficult welding quality control, uneven thickness, etc., and achieve high thickness uniformity of finished products, Good magnetron sputtering performance, good uniformity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

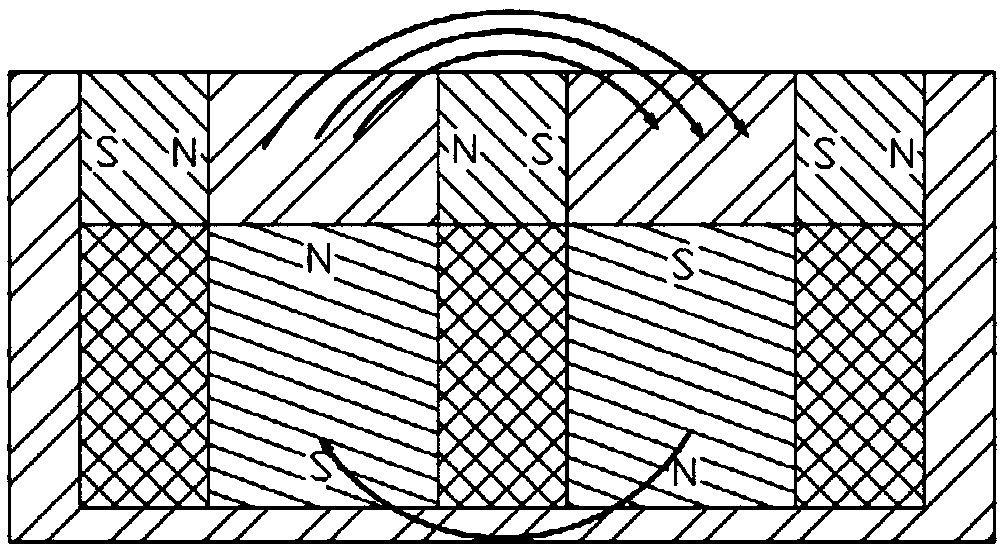

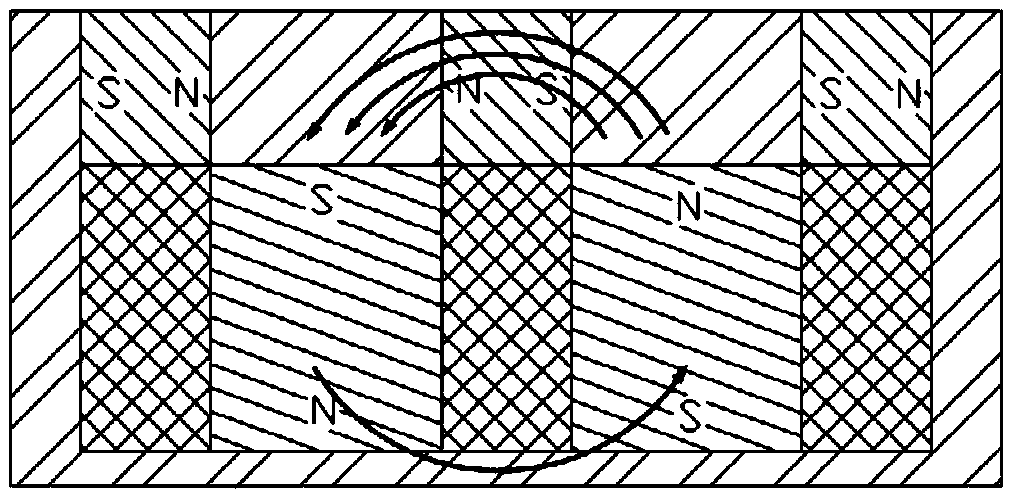

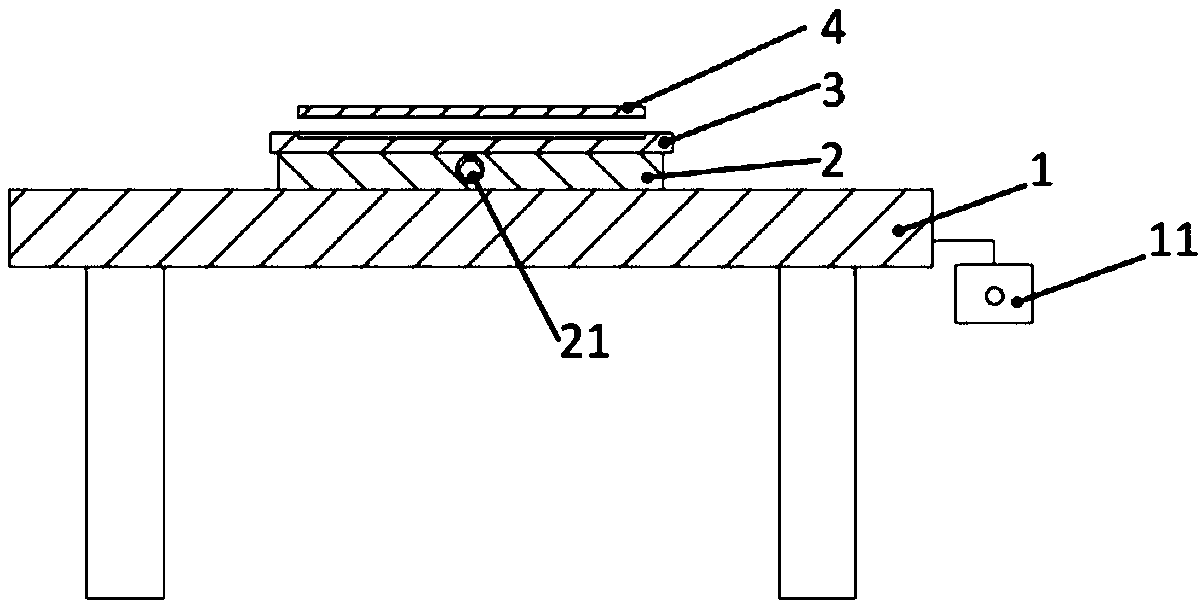

[0023] 1. The permanent magnetic chuck made of heat-resistant magnetic steel is used for target welding.

[0024] 2. Place the permanent magnetic chuck, back plate and target blank on the heating table, turn on the heating controller to heat, and the temperature rises to 180°C.

[0025] 3. Cu alloy back plate, after the back plate is heated on the suction cup, solder is formed in the groove, and the depth of the groove is 0.5mm.

[0026] 4. The ferromagnetic cobalt target blank with a purity of 99.999% has a size of Φ450×3.5. The target blank is heated on the welding table, and the welding surface is coated with solder.

[0027] 5. Fasten the target blank and the back plate slowly, and slowly discharge the air between the joint surfaces during the process.

[0028] 6. Rotate the knob of the permanent magnetic suction cup to make the surface of the suction cup magnetic, so that the cobalt target blank and the back plate are fixed in the groove.

[0029] 7. Turn off the heati...

Embodiment 2

[0032] 1. The permanent magnetic chuck made of heat-resistant magnetic steel is used for target welding.

[0033] 2. Place the permanent magnetic chuck, back plate and target blank on the heating table, turn on the heating controller to heat, and the temperature rises to 200°C.

[0034] 3. After the Cu alloy backplane is heated, an indium pool is formed in the groove, and the depth of the groove is 1mm.

[0035] 4. The ferromagnetic nickel-platinum target blank with a purity of 99.995% has a size of Φ450×3. The target blank is heated on the welding table, and the welding surface is coated with indium material.

[0036] 5. Fasten the target blank and the back plate slowly, and slowly discharge the air between the joint surfaces during the process.

[0037] 6. Turn the knob of the permanent magnetic chuck to make the surface of the chuck magnetic, so that the nickel-platinum target blank and the back plate are fixed in the groove.

[0038] 7. Turn off the heating controller o...

Embodiment 3

[0041] 1. The permanent magnetic chuck made of heat-resistant magnetic steel is used for target welding.

[0042] 2. Place the permanent magnetic chuck, back plate and target blank on the heating table, turn on the heating controller to heat, and the temperature rises to 200°C.

[0043] 3. After the Cu alloy backplane is heated, an indium pool is formed in the groove, and the depth of the groove is 2mm.

[0044] 4. The ferromagnetic nickel-iron target blank with a purity of 99.999% has a size of Φ450×2.5. The target blank is heated on the welding table, and the welding surface is coated with indium material.

[0045] 5. Fasten the target blank and the back plate slowly, and slowly discharge the air between the joint surfaces during the process.

[0046] 6. Rotate the knob of the permanent magnetic suction cup to make the surface of the suction cup magnetic, so that the nickel-iron target blank and the back plate are fixed in the groove.

[0047] 7. Turn off the heating cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com