Braze welding clamp of plate-fin type heat exchanger

A plate-fin heat exchanger, brazing technology, applied in the direction of manufacturing tools, welding equipment, auxiliary devices, etc., can solve the problems of high temperature resistance, high pressure resistance, strength and service life, etc., to reduce welding defects, brazing The effect of short welding time and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

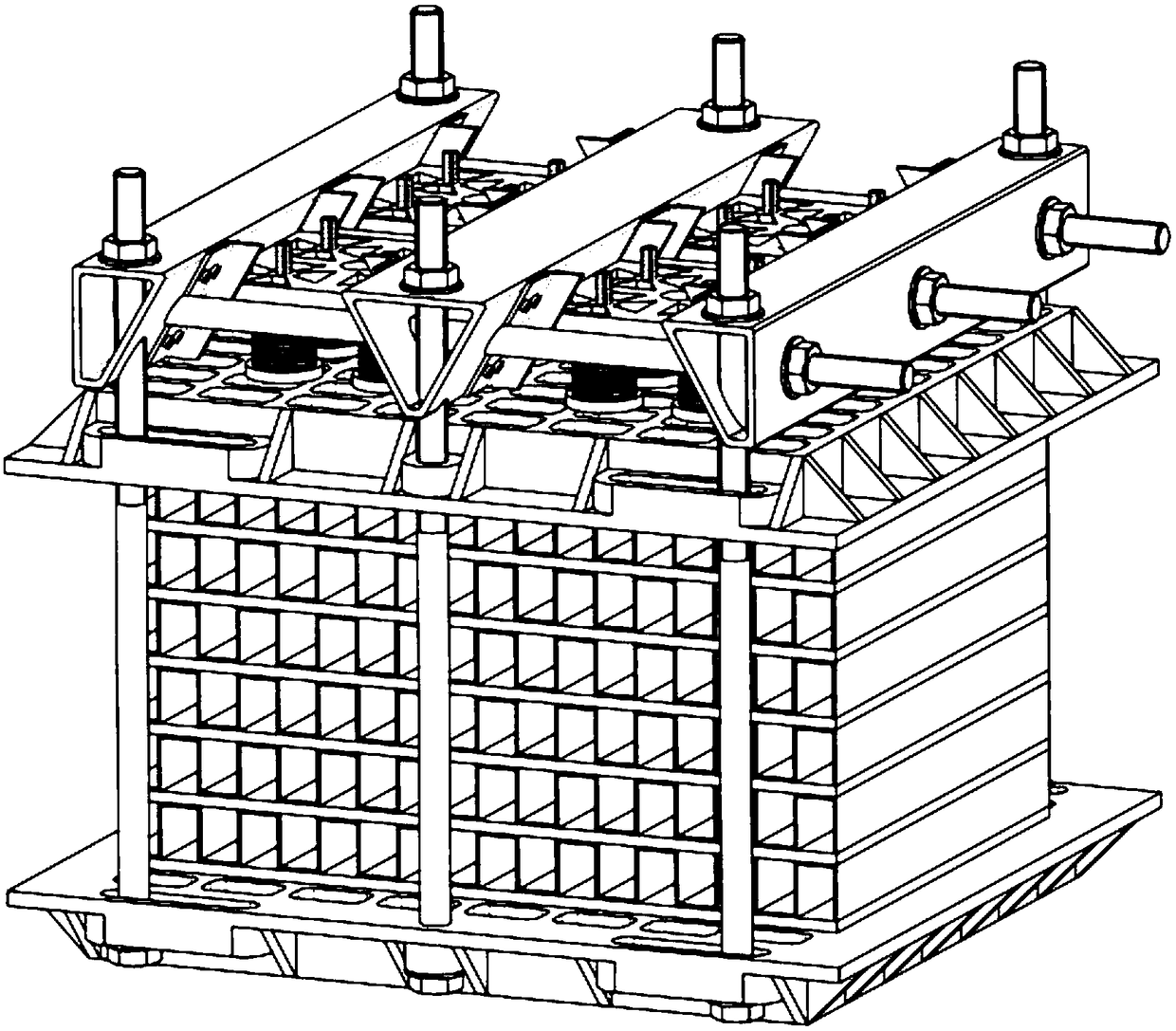

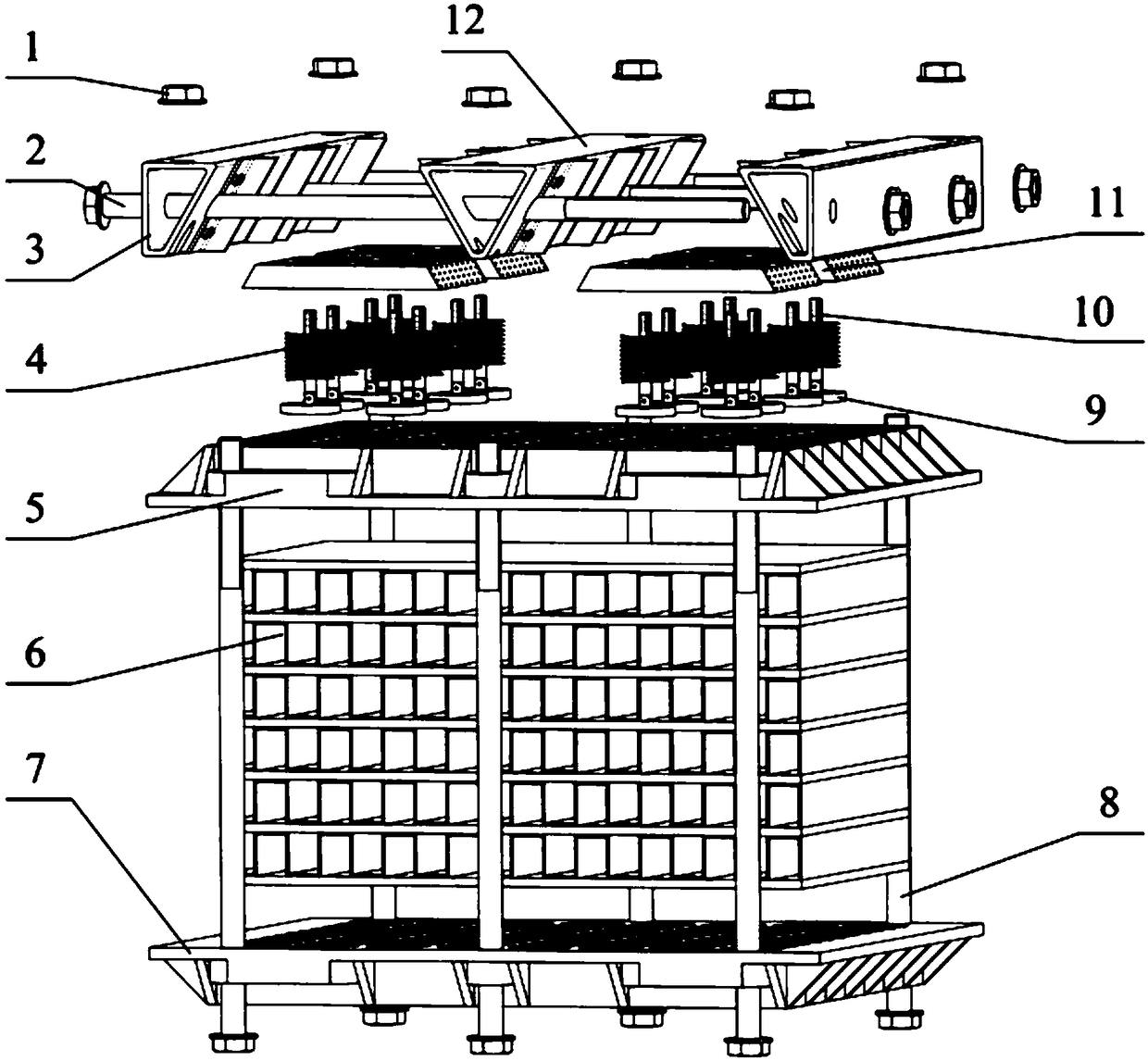

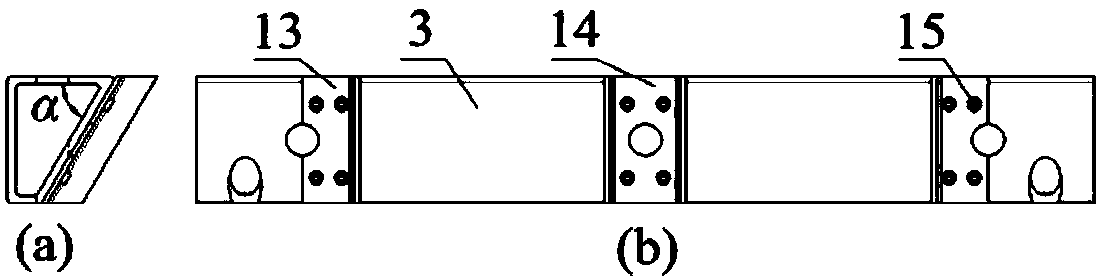

[0035] The present invention proposes a brazing fixture for a plate-fin heat exchanger, which consists of a nut 1, a top bolt 2, a side top bar 3, a spring 4, an upper cover plate 5, a lower bottom plate 7, a vertical bolt 8, a support plate 9, Measuring rod 10, pressing plate 11, middle top bar 12, side guide 13, middle guide 14, screw 15, ball 16, pin 17 form. A pressure plate 11 is placed between the side roof bar 3 and the middle roof bar 12, and a measuring rod 10 is interspersed on the pressure plate 11. The spring 4 is placed between the support plate 9 and the pressure plate 11, and the support plate 9 is placed on the upper cover plate 5. The plate-fin structure 6 is located between the upper cover plate 5 and the lower bottom plate 7 . The middle of the pressing plate 11, the upper cover plate 5 and the lower base plate 7 is a hollow structure, and between the side top bar 3 and the middle top bar 12, between each top bar and the lower base plate are assembled by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com