Pre-treatment improving target material binding method

A technology of pretreatment and target material, which is applied in the direction of metal material coating process, ion implantation plating, welding equipment, etc., can solve the problems of poor pretreatment effect, roughness and dimensional tolerance range, uneven heat dissipation and other problems of rotating targets, and achieve The conductive effect is uniform, the operation difficulty is reduced, and the binding effect is enhanced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

[0038] A target binding method with improved pretreatment, comprising the following steps:

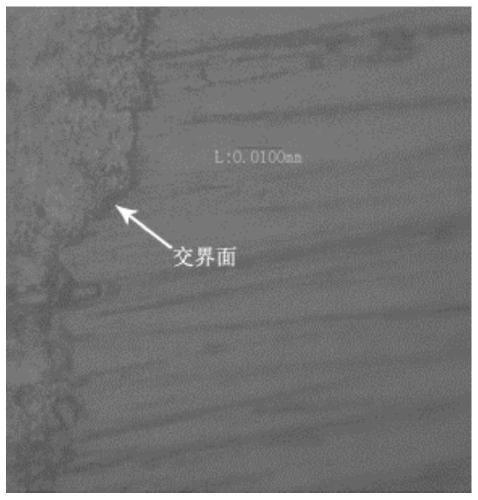

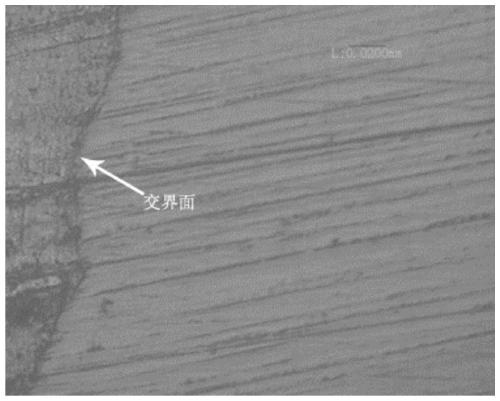

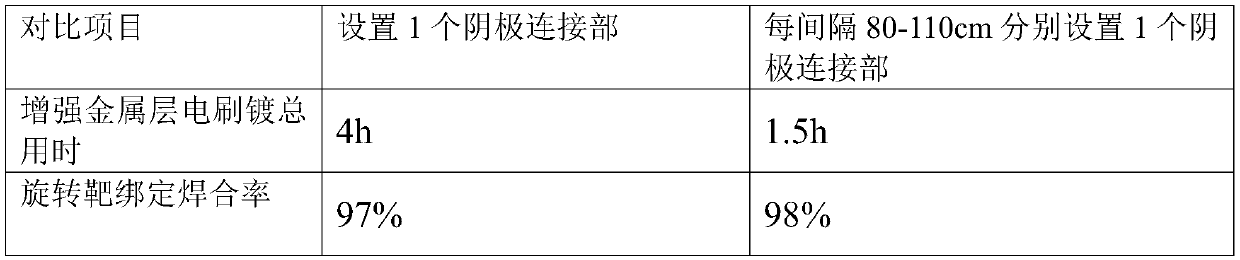

[0039] a. Steps before pretreatment, sandblasting, cleaning and drying the binding surface of the metal target tube and the binding surface of the back tube respectively;

[0040] Before the pretreatment of the metal target tube and the back tube, the metal target tube and the back tube must be pretreated, and the preliminary treatment includes sandblasting and cleaning the binding surface of the metal target tube and the back tube. Sandblasting makes the surface rough, increases the surface area, that is, the contact surface, and increases the adhesion of the coating on the sandblasting surface; the machining of the outer circle of the back tube can achieve a lower roughness, and the surface is smoother. The inner circle of the targe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com