Collecting chamber, production method of collecting chamber, automobile radiator, and production method of automobile radiator

A technology of automobile radiator and production method, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of many radiator parts, high manufacturing cost, low production efficiency, etc. Simplified work steps, reduced assembly and welding processes, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

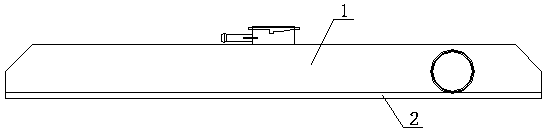

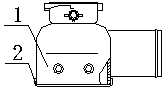

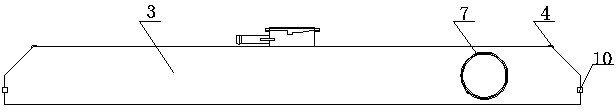

[0065] Such as Figure 3-Figure 9 As shown, a collection chamber of the present invention is a collection chamber of an automobile radiator. The water chamber 1 and the main sheet 2 of the automobile radiator form a collection chamber as a whole, and the collection chamber includes a collection chamber main body 3 and a plugging chamber. Plate 4, the main body of the collecting chamber 3 is a square tube, the bottom surface of the main body of the collecting chamber 3 is provided with a plurality of collecting holes 5, the top surface of the main body of the collecting chamber 3 is provided with a transverse through weld 6, and the blocking plate 4 is sealed and fixed on the The two ends of the collecting chamber main body 3 and the side surface of the collecting chamber main body 3 are provided with inlet and outlet holes 7 .

Embodiment 2

[0067] Such as Figure 3-Figure 9 As shown, a collection chamber of the present invention is a collection chamber of an automobile radiator. The water chamber 1 and the main sheet 2 of the automobile radiator form a collection chamber as a whole, and the collection chamber includes a collection chamber main body 3 and a plugging chamber. Plate 4, the main body of the collecting chamber 3 is a square tube, the bottom surface of the main body of the collecting chamber 3 is provided with a plurality of collecting holes 5, the top surface of the main body of the collecting chamber 3 is provided with a transverse through weld 6, and the blocking plate 4 is sealed and fixed on the The two ends of the collecting chamber main body 3 and the side surface of the collecting chamber main body 3 are provided with inlet and outlet holes 7 .

[0068] Such as Figure 10 As shown, the main body 3 of the collecting chamber and the blocking plate 4 are both made of 4343 / 3003 / 7072 composite alum...

Embodiment 3

[0070] Such as Figure 3-Figure 9 As shown, a collection chamber of the present invention is a collection chamber of an automobile radiator. The water chamber 1 and the main sheet 2 of the automobile radiator form a collection chamber as a whole, and the collection chamber includes a collection chamber main body 3 and a plugging chamber. Plate 4, the main body of the collecting chamber 3 is a square tube, the bottom surface of the main body of the collecting chamber 3 is provided with a plurality of collecting holes 5, the top surface of the main body of the collecting chamber 3 is provided with a transverse through weld 6, and the blocking plate 4 is sealed and fixed on the The two ends of the collecting chamber main body 3 and the side surface of the collecting chamber main body 3 are provided with inlet and outlet holes 7 .

[0071] The main body 3 of the collecting chamber and the blocking plate 4 are all made of composite aluminum plates of the type 4343 / 3003 / 7072 of Grän...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com