Al-Ag-Cu-Mg aluminium base alloy-state brazing filler metal and preparation method thereof

An al-ag-cu-mg, aluminum-based alloy technology, used in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of over-burning of base metal, poor corrosion resistance and brazing process, and achieve enhanced The effect of welding rate and welding strength, good brazing processability and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

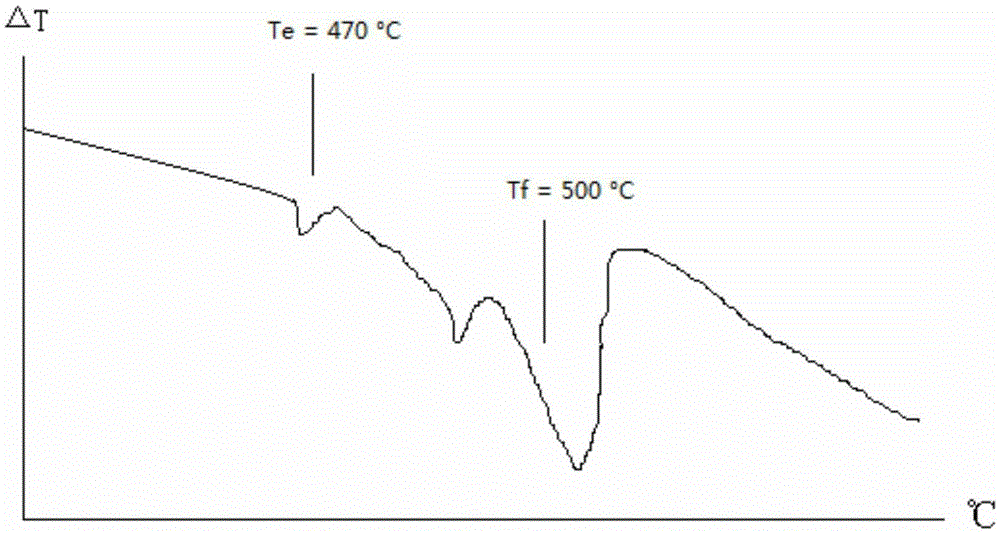

Image

Examples

Embodiment 1

[0041]Embodiment 1 prepares Al-Ag-Cu-Mg aluminum-based alloy solder (1)

[0042] Step I: Raw material selection

[0043] Aluminum: use high-purity aluminum with a purity of not less than 99.9%; use high-purity silver with a purity of not less than 99.9%; use oxygen-free copper for copper; magnesium: have a purity of not less than 99.99%.

[0044] Step II: Master Alloy Preparation

[0045] 1. Melting of Al-Cu50 master alloy

[0046] 1) Equipment: medium frequency induction furnace;

[0047] 2) Mold: water-cooled mold: 30×210×440mm;

[0048] 3) Ingredients: 10kg ingredients for each furnace;

[0049] 4) Operation: Weigh the aluminum ingot and the copper ingot respectively according to the weight ratio of 1:0.5. After adding aluminum ingots into the crucible, raise the temperature. After the aluminum ingots are melted, add copper ingots, raise the furnace temperature to 700°C, stir thoroughly, and cast the alloy after all the copper ingots are melted. The alloy casting tempe...

Embodiment 2

[0073] Embodiment 2 prepares Al-Ag-Cu-Mg aluminum-based alloy solder (two)

[0074] Step I: Raw material selection

[0075] Aluminum: use high-purity aluminum with a purity of not less than 99.9%; use high-purity silver with a purity of not less than 99.9%; use oxygen-free copper for copper; magnesium: have a purity of not less than 99.99%.

[0076] Step II: Master Alloy Preparation

[0077] 1. Melting of Al-Cu50 master alloy

[0078] 1) Equipment: medium frequency induction furnace;

[0079] 2) Mold: water-cooled mold: 30×210×440mm;

[0080] 3) Ingredients: 10kg ingredients for each furnace;

[0081] 4) Operation: Weigh the aluminum ingot and the copper ingot respectively according to the weight ratio of 1:0.5. After adding aluminum ingots into the crucible, heat up. After the aluminum ingots are melted, add copper ingots, raise the furnace temperature to 750°C, stir thoroughly, and cast the alloy after all the copper ingots are melted. The alloy casting temperature is 7...

Embodiment 3

[0105] Example 3 Preparation of Al-Ag-Cu-Mg Aluminum-Based Alloy Solder (3)

[0106] Step I: Raw material selection

[0107] Aluminum: use high-purity aluminum with a purity of not less than 99.9%; use high-purity silver with a purity of not less than 99.9%; use oxygen-free copper for copper; magnesium: have a purity of not less than 99.99%.

[0108] Step II: Master Alloy Preparation

[0109] 1. Melting of Al-Cu50 master alloy

[0110] 1) Equipment: medium frequency induction furnace;

[0111] 2) Mold: water-cooled mold: 30×210×440mm;

[0112] 3) Ingredients: 10kg ingredients for each furnace;

[0113] 4) Operation: Weigh the aluminum ingot and the copper ingot respectively according to the weight ratio of 1:0.5. After adding aluminum ingots into the crucible, heat up. After the aluminum ingots are melted, add copper ingots, raise the furnace temperature to 740°C, stir well, and cast the alloy after all the copper ingots are melted. The alloy casting temperature is 700°C....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com