Brazing filler metal suitable for tc4 titanium alloy thin-walled honeycomb structure and its preparation method and brazing method

A technology of honeycomb structure and brazing method, applied in welding equipment, metal processing equipment, welding/cutting medium/material, etc., can solve the problems of reduced shear performance of brazing interface, corrosion of honeycomb panel, long brazing time, etc. , to achieve good interdiffusion, improve brazing quality and reduce welding holding time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

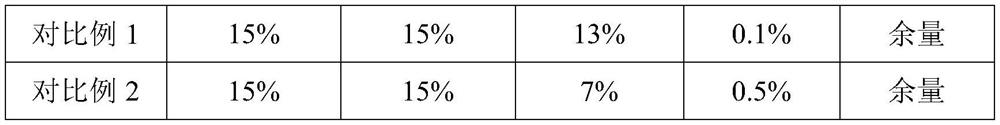

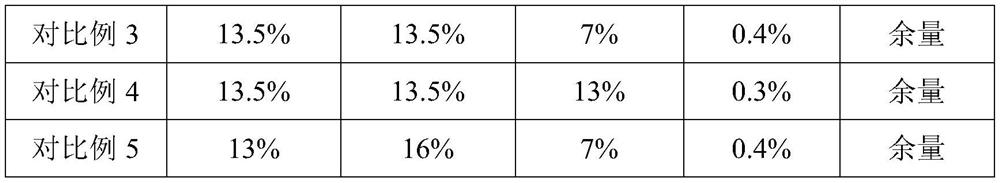

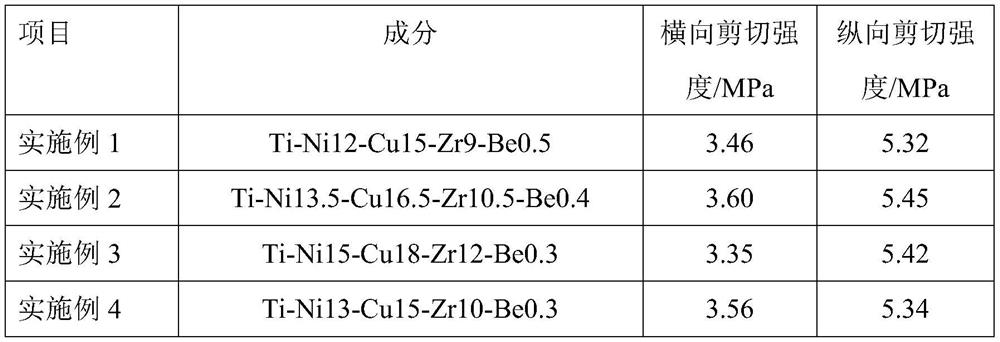

[0035] A preparation method for brazing filler metal suitable for TC4 titanium alloy thin-walled honeycomb structure, comprising the following steps: material preparation: see Table 1, the weight percent of the chemical composition of the filler metal is: Ni: 12%; Cu: 15%; Zr: 9%, Be: 0.5%, and the balance is Ti. According to the chemical composition ratio of the above-mentioned solder, weigh the required sponge titanium, sponge zirconium, industrial pure nickel, industrial pure copper, and beryllium powder. Purity not less than 99.5%;

[0036] Vacuum smelting: use a vacuum induction furnace to smelt the raw materials, the melting temperature is 1900°C, the holding time is 0.5h, and the vacuum degree is not lower than 10 -2Pa, cast into ingot, air-cooled to room temperature, repeated smelting 3 times;

[0037] Preparation of brazing filler metal: use amorphous foil stripping equipment, put the melted alloy ingot into the melting crucible of the equipment for melting, the melt...

Embodiment 2

[0045] A preparation method for brazing filler metal suitable for TC4 titanium alloy thin-walled honeycomb structure, comprising the following steps: material preparation: see Table 1, the weight percent of the chemical composition of the filler metal is: Ni: 13.5%; Cu: 16.5%; Zr: 10.5%, Be: 0.4%, and the balance is Ti. According to the chemical composition ratio of the above-mentioned solder, weigh the required sponge titanium, sponge zirconium, industrial pure nickel, industrial pure copper, and beryllium powder. The purity is not less than 99.5%; vacuum smelting: the raw materials are smelted in a vacuum induction furnace, the melting temperature is 1950°C, the holding time is 0.75h, and the vacuum degree is not less than 10 -2 Pa, cast into ingot, air-cooled to room temperature, repeated smelting 3 times;

[0046] Preparation of brazing filler metal: use amorphous foil stripping equipment, put the melted alloy ingot into the melting crucible of the equipment to melt, the m...

Embodiment 3

[0054] A preparation method for brazing filler metal suitable for TC4 titanium alloy thin-walled honeycomb structure, comprising the following steps: material preparation: see Table 1, the weight percent of the chemical composition of the filler metal is: Ni: 15%; Cu: 18%; Zr: 12%, Be: 0.3%, and the balance is Ti. According to the chemical composition ratio of the above-mentioned solder, weigh the required sponge titanium, sponge zirconium, industrial pure nickel, industrial pure copper, and beryllium powder. Purity not less than 99.5%;

[0055] Vacuum smelting: use a vacuum induction furnace to smelt the raw materials, the melting temperature is 2000°C, the holding time is 1h, and the vacuum degree is not lower than 10 -2 Pa, cast into ingot, air-cooled to room temperature, repeated smelting 5 times;

[0056] Preparation of brazing filler metal: use amorphous foil stripping equipment, put the melted alloy ingot into the melting crucible of the equipment for melting, the melt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com