High temperature vacuum brazing clamp for internally finned tube

A high-temperature vacuum, inner fin technology, applied in manufacturing tools, welding equipment, auxiliary devices, etc., can solve the problem that stainless steel tube flatness, inner fin roundness, fin peak flatness cannot be accurately guaranteed, and welding effect cannot be obtained, etc. problems, to achieve the effect of reducing manufacturing costs, improving strength and plasticity, and reducing contact thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

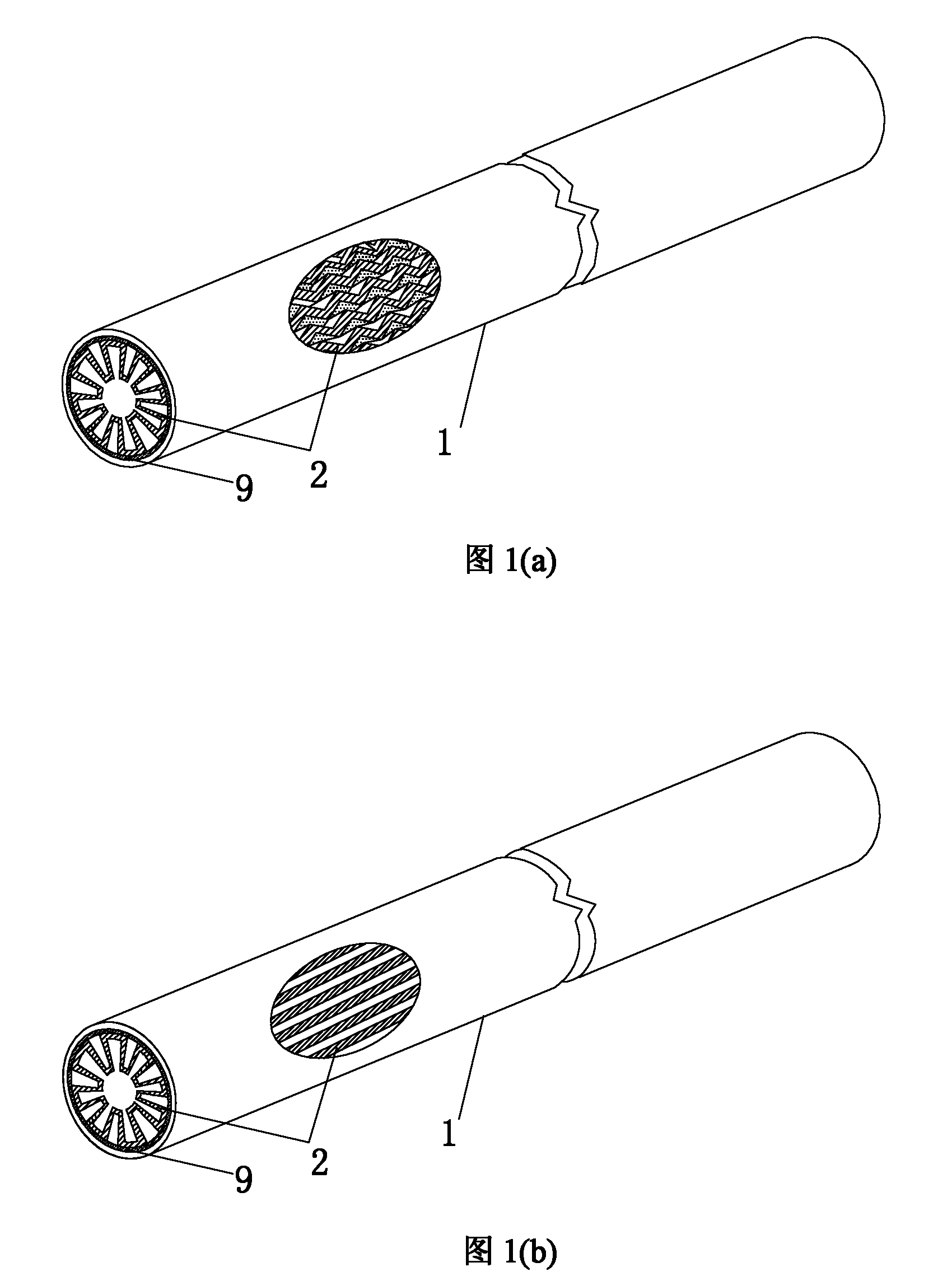

[0029] figure 1 (a) and figure 1 (b) has described two kinds of inner fin tube structure schematic diagrams that the present invention needs brazing, wherein, figure 1 (a) The inner fin 2 described is a longitudinal corrugated fin, figure 1 The inner fins 2 described in (b) are longitudinal straight fins. In order to obtain a good heat transfer effect, the fin peaks on the outer surface of the inner fin 2 must be welded to the inner surface of the outer tube 1 to reduce the contact thermal resistance, but it can be seen from Figure (1) that there are many and irregular welding points, The nickel-based solder 9 used in high-temperature vacuum brazing is a foil strip with a thickness of 0.03-0.05mm, which puts forward very high requirements on the assembly process of the inner finned tube before brazing. This patent is aimed at this The problem proposes a new mold for high temperature vacuum brazing of inner finned tubes.

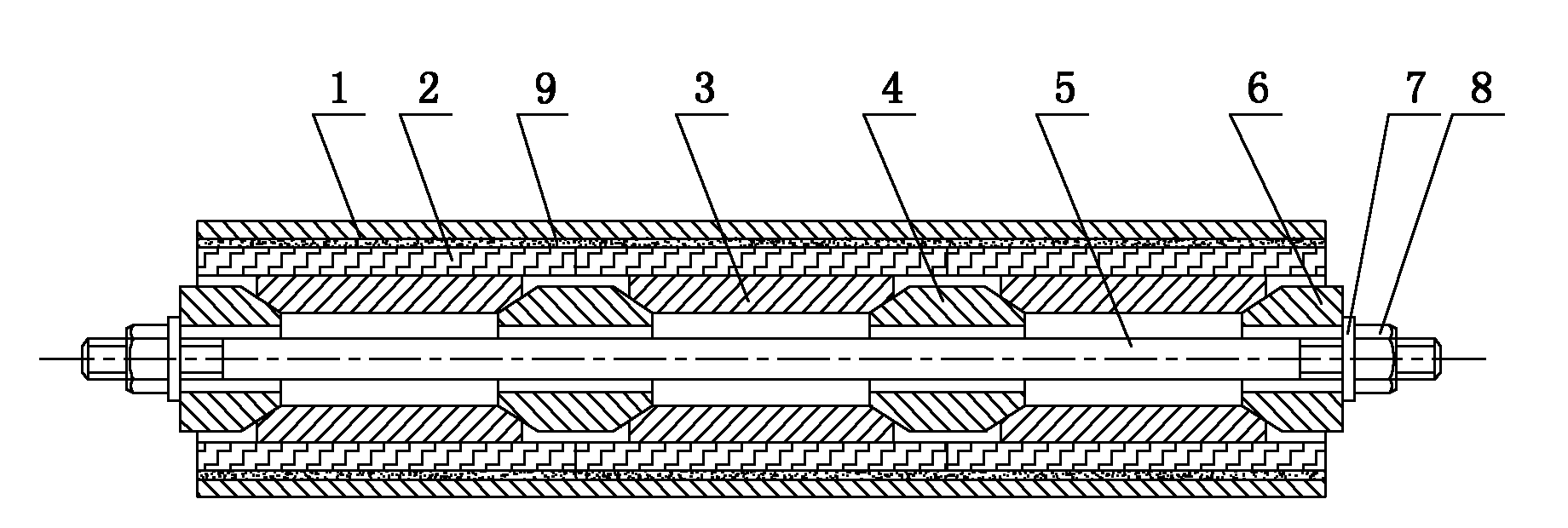

[0030] figure 2 It is a specific embodiment of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com