Welding process of superconductive cable and box type copper connector in large high temperature superconductive current lead

A high-temperature superconducting and current lead technology, which is applied to welding equipment, conductors, circuits, etc., can solve the problems of high welding rate of the first layer cable, reduce the blocking rate of superconducting cables, and high welding strength, and achieve high welding rate and high welding strength. High, uniform welding thickness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

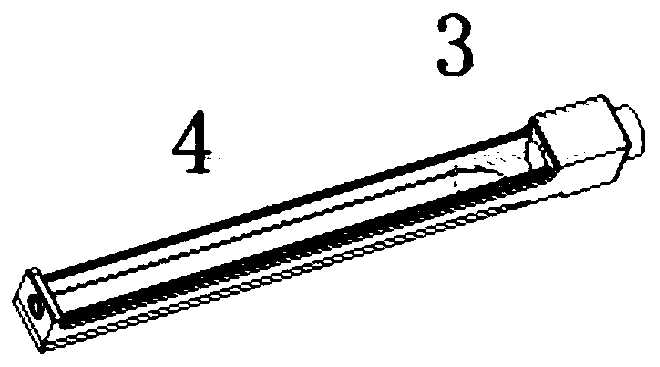

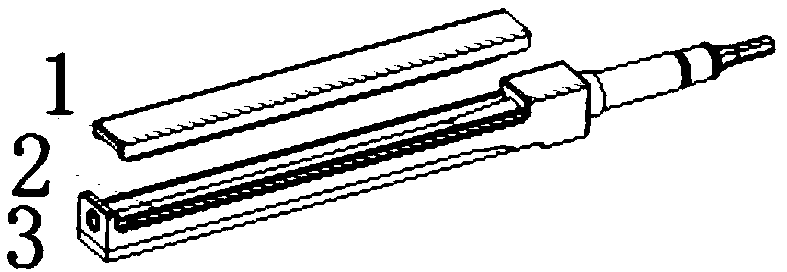

[0036] See attached figure 1 , the welding process of superconducting cables and box-type copper joints in large-scale high-temperature superconducting current leads, including the following steps:

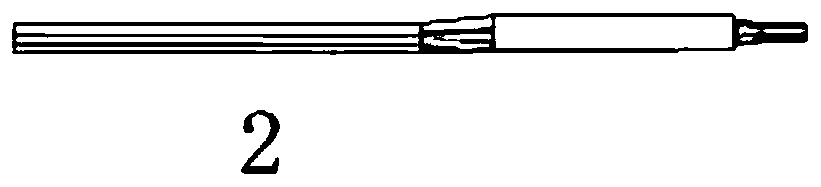

[0037] (1) Take the superconducting cable 2, remove the armor on the surface of the superconducting cable, then remove the nickel on the surface of the superconducting cable, and finally perform silver plating on the surface of the superconducting cable. The method of removing nickel on the surface of the superconducting cable is as follows: firstly, dry nitrogen gas is introduced on the unarmored side, and acetone is used to degrease the surface of the superconducting cable, and then cleaned with deionized water, and then the superconducting cable is slowly immersed in the diluted In the reverse electroplating solution composed of phosphoric acid and glycerol, the weight ratio of the phosphoric acid and glycerol is 10% and 5% respectively, the temperature of the reverse plating s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com