Composite board and preparation method thereof

A technology for composite plates and alloy plates, which is applied in chemical instruments and methods, layered products, and improvement of process efficiency. Oil spots, low surface oxygen content, and fast grinding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

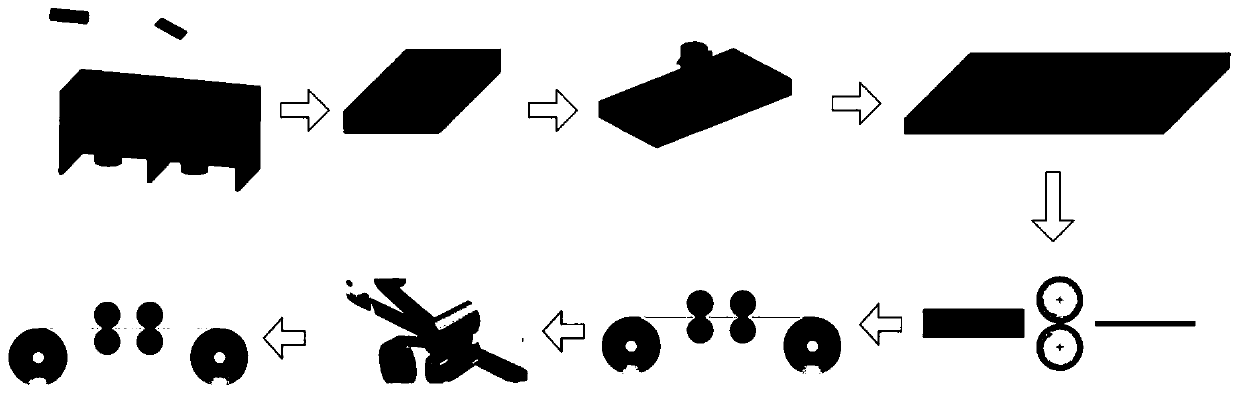

[0043] figure 1 It is a schematic flow chart of the preparation method of the composite plate of the present invention, as figure 1 Shown, the preparation method of three-layer composite material or five-layer composite material can comprise the following steps:

[0044] 1) The filling layer alloy slab and the covering layer alloy slab are prepared by 3D metal printing process.

[0045] 2) Welding the small-size filling layer slabs and covering layer alloy slabs obtained in step 1) into large-size filling layer sheets and covering layer sheets respectively by means of friction stir welding, so as to improve production efficiency and adapt to industrial production.

[0046] 3) Core material preparation. According to the design composition ratio alloy, the ingot is cast by semi-continuous casting line ( figure 1 not shown).

[0047] 4) Overlay rolling. Annealing the covering sheet prepared in step 2) in an annealing furnace at 300-400° C. for 2 hours, and then rolling to a ...

Embodiment 1

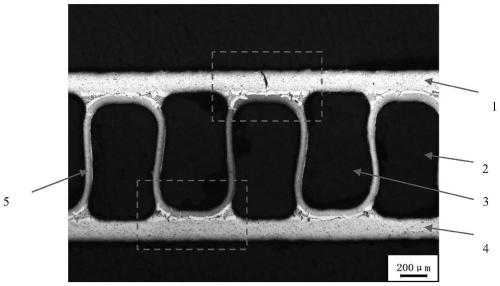

[0059] An aluminum alloy composite material for flux-free brazing and a preparation method thereof, the composite material includes a core material, a filling layer and a covering layer; wherein, the filling layer is compounded on the core material, and the covering layer is compounded on the On the filling layer; both the filling layer and the covering layer are Al-Si alloy, wherein the alloy composition of the covering layer is Si 7.5%, Bi 0.15%, Sr 0.03%, Eu 0.05%, Yb 0.05%; the rest is Al and the total amount of unavoidable impurities less than 0.15%; the alloy composition of the filling layer is Si 12.5%, Mg 0.15%, Bi 0.12%, Sr 0.03%, Gd 0.05%, the rest is Al and the total amount of unavoidable impurities less than 0.15% . Both the filling layer and the covering layer are prepared from atomized particles with a particle size of 15-53 μm through an EOS280 type 3D metal printer. The core material is AA3003 aluminum alloy.

[0060] The preparation method of this composite ...

Embodiment 2

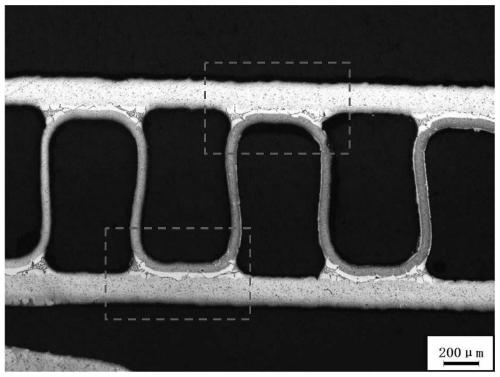

[0073] An aluminum alloy composite material for flux-free brazing and a preparation method thereof, the composite material includes a core material, a filling layer and a covering layer; wherein, the filling layer is compounded on the core material, and the covering layer is compounded on the On the filling layer; both the filling layer and the covering layer are Al-Si alloy, wherein the alloy composition of the covering layer is Si 12.6%, Bi 0.15%, Sr0.03%; the rest is Al and the total amount is less than 0.15%. Inevitable impurities; the alloy composition of the filling layer is 15% Si, 0.15% Mg, 0.12% Bi, 0.03% Sr, 0.05% Gd, and the rest are Al and unavoidable impurities less than 0.15% in total. Both the filling layer and the covering layer are prepared from atomized particles with a particle size of 15-53 μm through an EOS280 type 3D metal printer. The core material is AA3003 aluminum alloy.

[0074] The preparation method of this composite material:

[0075] 1) Filling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com