Diffusion welding method for W-Ti alloy target assembly

A diffusion welding and alloy target technology, which is applied in the field of microelectronics, can solve the problems of increasing process steps, bag leakage, and inability to weld, etc., and achieve the effect of small machining amount, high welding rate and large contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

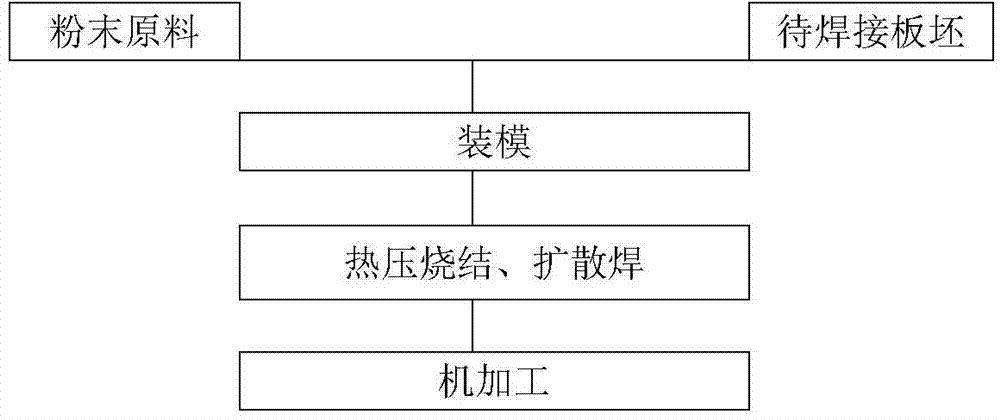

[0026] according to figure 1 Shown process flow chart, its steps are as follows:

[0027] 1. Preparation of powder and slab to be welded

[0028] According to the design in this embodiment, the target powder raw material to be hot-pressed and the corresponding slab material to be welded are prepared.

[0029] The W-Ti alloy powder is: the mass content of Ti is 5-20%, especially the mass content of Ti is 10%, and the balance is W. The average particle size of W powder is 2-10 μm, and the average particle size of Ti powder is 20-200 μm. The diameter of the forming target is Φ50~500mm, and the thickness is 3~15mm. The thickness of the backplane depends on the requirements of the model specification, and the thickness of the transition layer is 0.5-5mm. Sand blasting or machining can be performed on the welding surface of the slab in advance to improve the roughness of the welding surface and increase the welding strength.

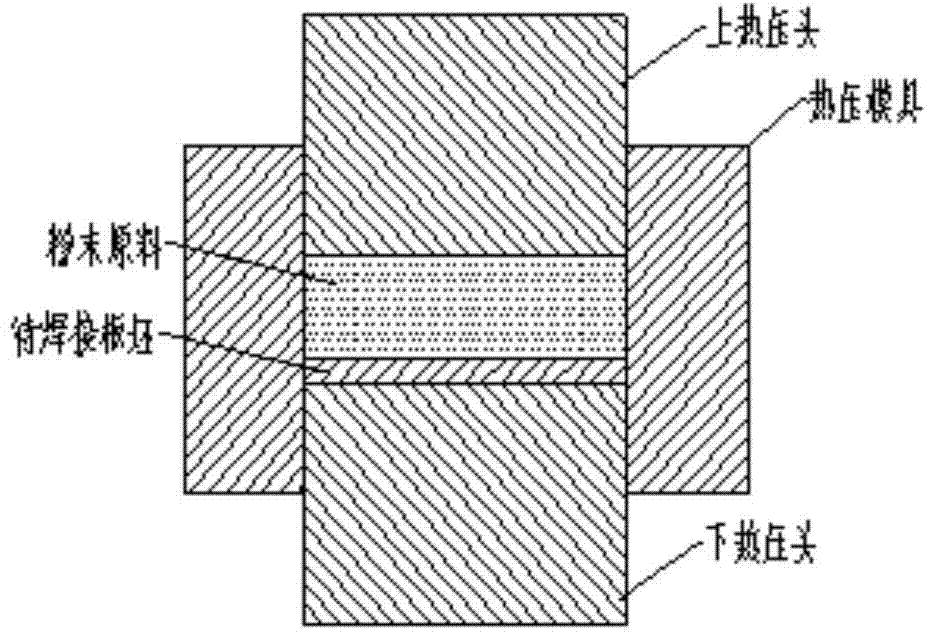

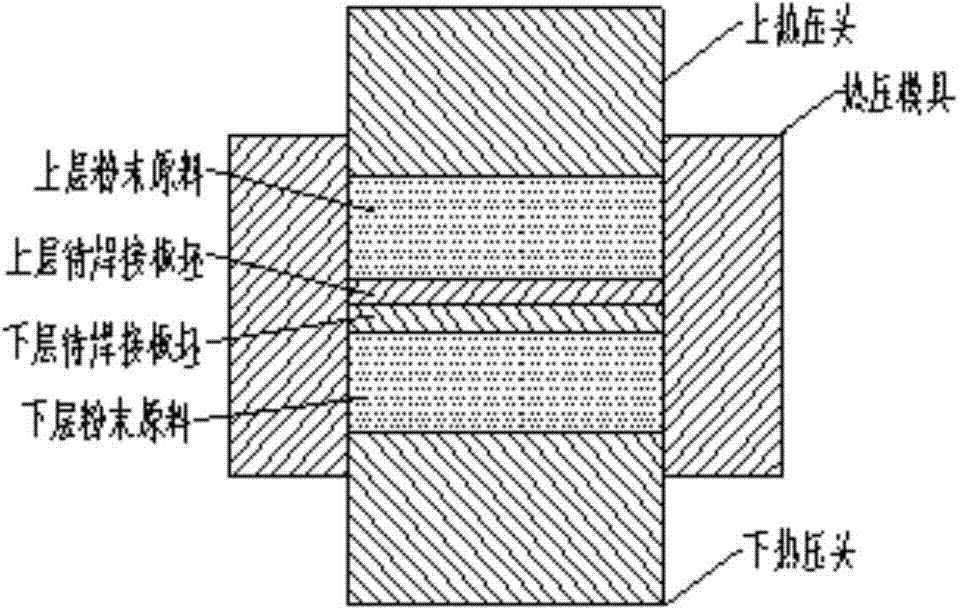

[0030] 2. Molding

[0031] Put the target powder r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com