Al-Si-Cu-Mg aluminum-base alloy foil solder and preparation method thereof

An al-si-cu-mg, aluminum-based alloy technology, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the problems of severe softening of welded joints, easy overburning of the base metal, excessive dissolution of the base metal, etc. Achieve the effects of mass production, good brazing processability, and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

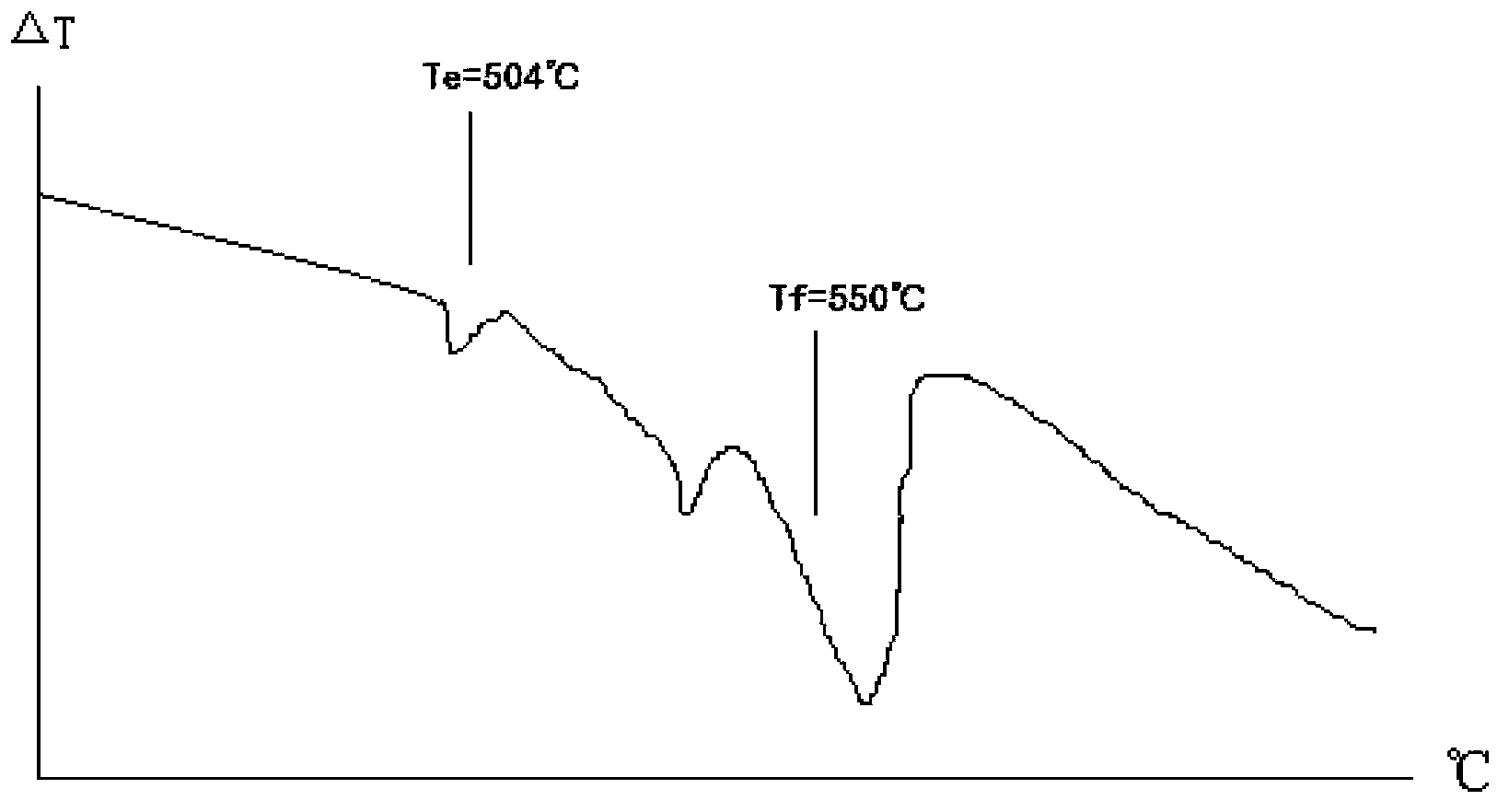

Image

Examples

Embodiment 1

[0062] The furnace capacity of the intermediate frequency induction furnace during alloy casting is 80kg

[0063] First prepare Al-Cu50 and Al-Si30 master alloys with raw materials, prepare 7.2kg of Al-Cu50 and 33.3kg of Al-Si30 from the prepared master alloy raw materials, mix the two master alloys, and then add 38.3kg of aluminum, 1.2 kg of magnesium is smelted, and the obtained alloy ingot contains 4.5wt% Cu, 12.5wt% Si, and 1.5wt% Mg, then undergoes homogenization heat treatment, and finally performs hot extrusion, hot billet rolling and cold rolling.

Embodiment 2

[0065] The furnace capacity of the intermediate frequency induction furnace during alloy casting is 100kg

[0066] First prepare Al-Cu50 and Al-Si30 master alloys with raw materials, prepare 8kg of Al-Cu50 and 41.7kg of Al-Si30 from the prepared master alloy raw materials, mix the two master alloys, and then add 48.8kg of aluminum, 1.5kg of Magnesium is smelted to obtain an alloy ingot containing Cu4.0wt%, Si12.5wt%, Mg1.5wt%, then homogenized heat treatment, and finally hot extrusion, hot billet rolling and cold rolling.

Embodiment 3

[0068] The furnace capacity of the intermediate frequency induction furnace during alloy casting is 120kg

[0069] First prepare Al-Cu50 and Al-Si30 master alloys with raw materials, prepare 9.6kg of Al-Cu50 and 48.0kg of Al-Si30 from the prepared master alloy raw materials, mix the two master alloys, and then add 60.6kg of aluminum, 1.8 kg of magnesium is smelted, and the obtained alloy ingot containing Cu4.0wt%, Si12.0wt%, and Mg1.5wt%, is subjected to homogenization heat treatment, and finally hot extrusion, hot billet rolling and cold rolling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com