Strip-shaped brazing filler metal for lap joint brazing of copper plate and aluminum plate and preparation method thereof

A technology of strip brazing filler metal and aluminum plate, applied in the direction of welding equipment, welding/cutting medium/material, welding medium, etc., can solve the problems of poor brazing process, high temperature, poor wettability, etc., and achieve brazing process Excellent performance, wide application range and high mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

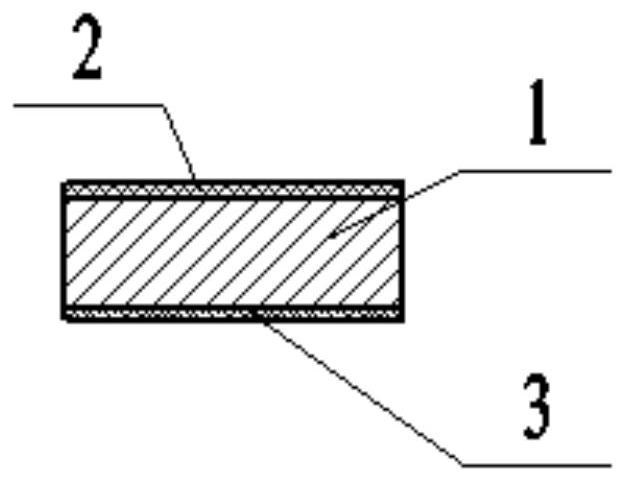

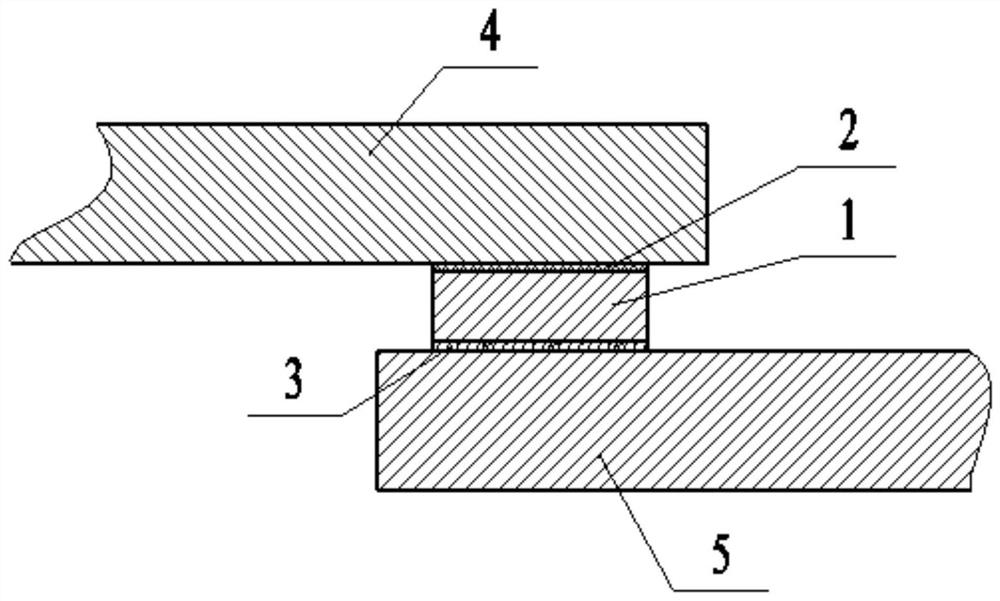

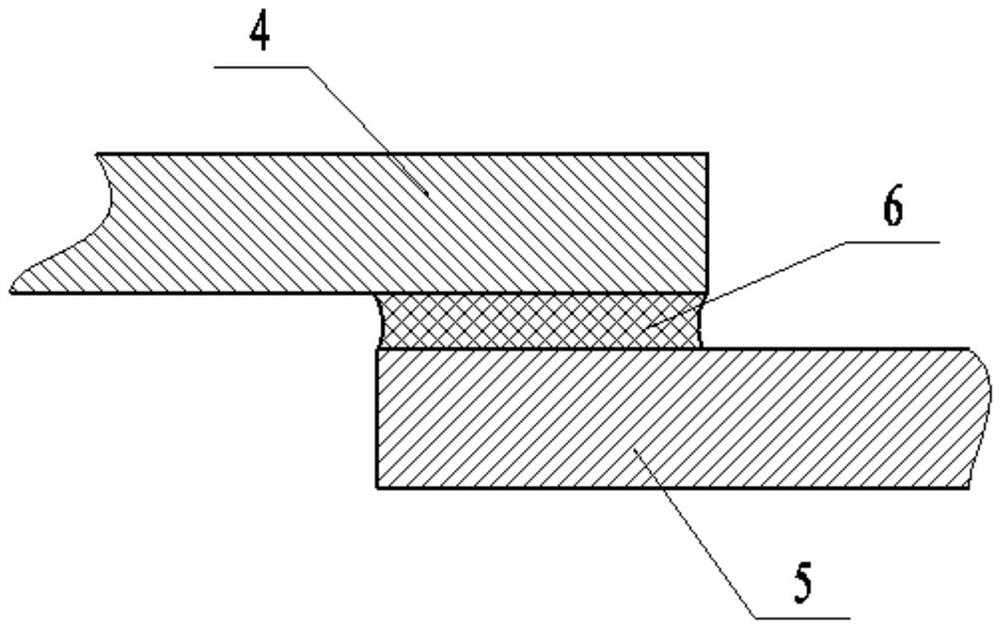

[0039] like figure 1 As shown, a strip-shaped brazing filler metal for overlapping brazing of a copper plate and an aluminum plate includes a brazing filler metal body 1, a coating I2 and a coating II 3, the brazing filler metal body 1 is a strip with a rectangular cross section, and the upper surface There is a coating I2 in contact with the copper plate, and a coating II3 in contact with the aluminum plate is provided on the lower surface of the solder body 1 .

[0040] The chemical composition of the solder body 1 is calculated by mass percentage: 3.2% of nano-zinc oxide, 6.8% of selenium, 2.6% of aluminum, and the balance is zinc; coating I2 is composed of surface-modified nano-copper and polyvinyl alcohol; coating II3 is composed of surface-modified nano-aluminum and polyvinyl alcohol.

[0041] The molecular weight of polyvinyl alcohol is 8000-12000.

[0042] The mass percentage of surface-modified nano-copper in coating I2 is 90%, and the balance is polyvinyl alcohol; ...

Embodiment 2

[0053] Basically the same as Example 1, the difference is: 1. the chemical composition of the solder body 1 is calculated by mass percentage: 3.9% of nano-zinc oxide, 7.5% of selenium, 3.4% of aluminum, and the balance is zinc; 2. surface modification in coating I2 The mass percentage of permanent nano-copper is 91%, and the balance is polyvinyl alcohol; the mass percentage of surface-modified nano-aluminum in coating II3 is 91%, and the balance is polyvinyl alcohol.

Embodiment 3

[0055] Basically the same as Example 1, the difference is that: 1. the chemical composition of the solder body 1 is calculated by mass percentage: 4.5% of nano-zinc oxide, 8.2% of selenium, 4.2% of aluminum, and the balance is zinc; The mass percentage of permanent nano-copper is 92%, and the balance is polyvinyl alcohol; the mass percentage of surface-modified nano-aluminum in coating II3 is 92%, and the balance is polyvinyl alcohol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com