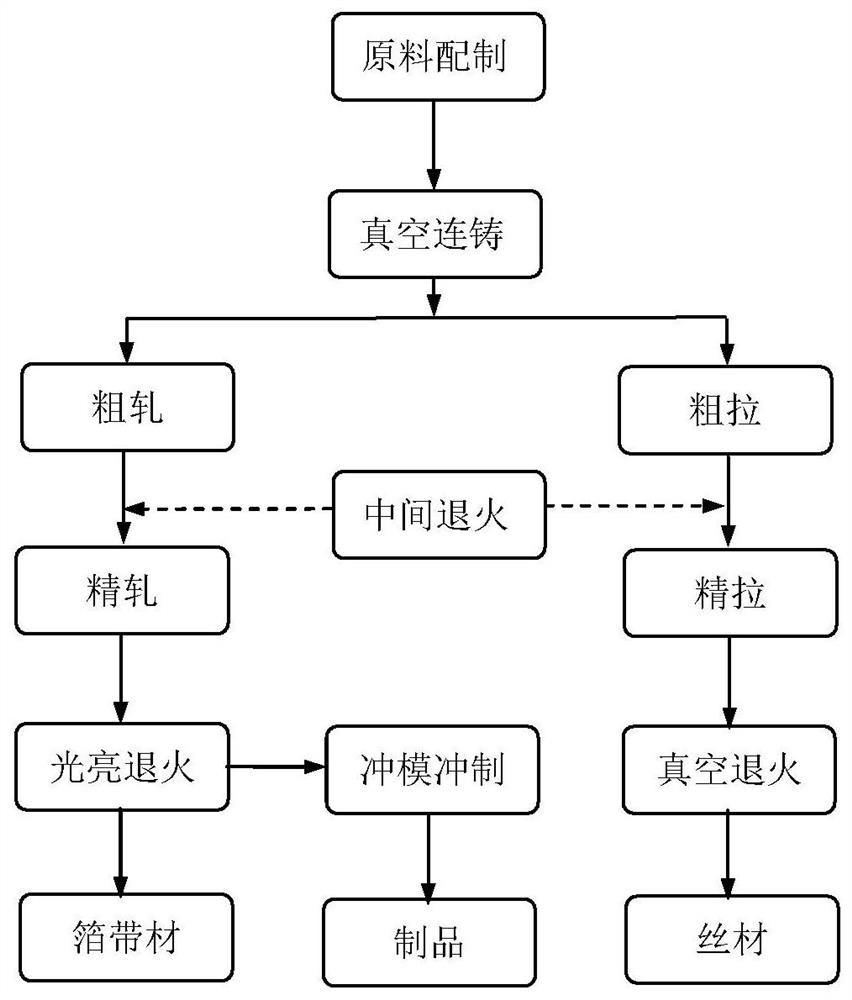

A kind of silver-based solder alloy and its preparation method, the preparation method of foil strip material and wire material

A silver-based solder and alloy technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve the problems of inconsistent melting point and high welding temperature of alloy solder, so as to ensure spattering and improve burnout rate , The effect of the process equipment is simple and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

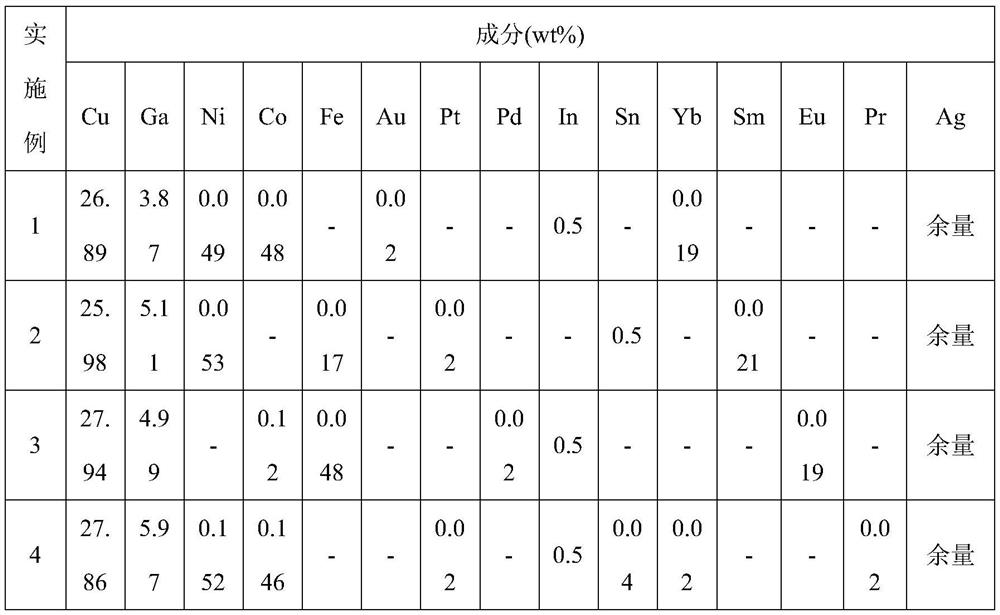

Embodiment 1

[0049] 1) Using silver, oxygen-free copper, gallium, nickel, cobalt, gold, indium and ytterbium with a purity of 99.99% as raw materials, the components and mass percentages of the selected raw materials are: Cu, 27%; Ga, 4%; Ni , 0.05%; Co, 0.05%; Au, 0.02%; In, 0.5%; Yb, 0.02%; Wherein, the shape of the copper material should be a sheet, and the copper sheet is used to wrap all the indium. In addition, rare earth elements are added in the form of a master alloy by refining silver and ytterbium, which account for 30% of the total silver content. The preparation steps of the silver-ytterbium master alloy are as follows: successively put the silver accounting for 30% of the total silver and all the ytterbium raw materials into the medium-frequency induction melting furnace. Under the argon protective atmosphere with a pressure of 0.05MPa in the furnace, adjust the melting voltage to 30V, the current to 300A, and raise the temperature to the target heating temperature of 1200°C...

Embodiment 2

[0055] 1) Using silver, oxygen-free copper, gallium, nickel, iron, platinum, tin and samarium with a purity of 99.99% as raw materials, the components and mass percentages of the selected raw materials are: Cu, 26%; Ga, 5%; Ni , 0.05%; Fe, 0.02%; Pt, 0.02%; Sn, 0.5%; Sm, 0.02%; Among them, the shape of the copper material should be sheet, and the copper sheet is used to wrap all the tin. In addition, rare earth elements are added in the form of a master alloy by refining silver and samarium, which account for 35% of the total silver content. The preparation steps of the silver-samarium master alloy are as follows: successively put the silver accounting for 30% of the total silver and all the samarium raw materials into the medium-frequency induction melting furnace. Under an argon protective atmosphere with a pressure of 0.06MPa in the furnace, adjust the melting voltage to 35V, the current to 350A, and raise the temperature to the target heating temperature of 1300°C. After ...

Embodiment 3

[0061] 1) Using silver, oxygen-free copper, gallium, cobalt, iron, palladium, indium and europium with a purity of 99.99% as raw materials, the components and mass percentages of the selected raw materials are: Cu, 28%; Ga, 5%; Co , 0.1%; Fe, 0.05%; Pd, 0.02%; In, 0.5%; Eu, 0.02%; Wherein, the shape of the copper material should be a sheet, and the copper sheet is used to wrap all the indium. In addition, rare earth elements are added in the form of a master alloy by refining silver and europium, which account for 30% of the total silver content. The preparation steps of the silver-europium master alloy are as follows: successively put the silver accounting for 30% of the total silver and all the europium raw materials into the medium-frequency induction melting furnace. Under the protective atmosphere of argon gas with a pressure of 0.07MPa in the furnace, adjust the melting voltage to 25V, the current to 250A, and raise the temperature to the target heating temperature of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com