Patents

Literature

77results about How to "Improve brazing performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

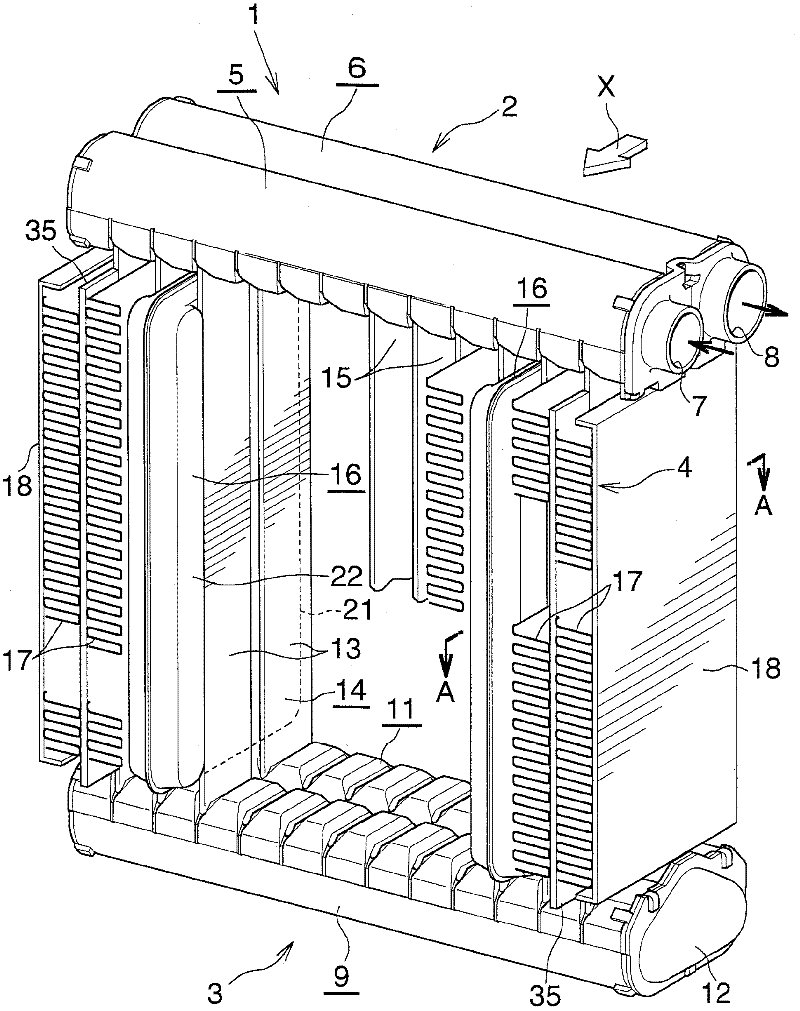

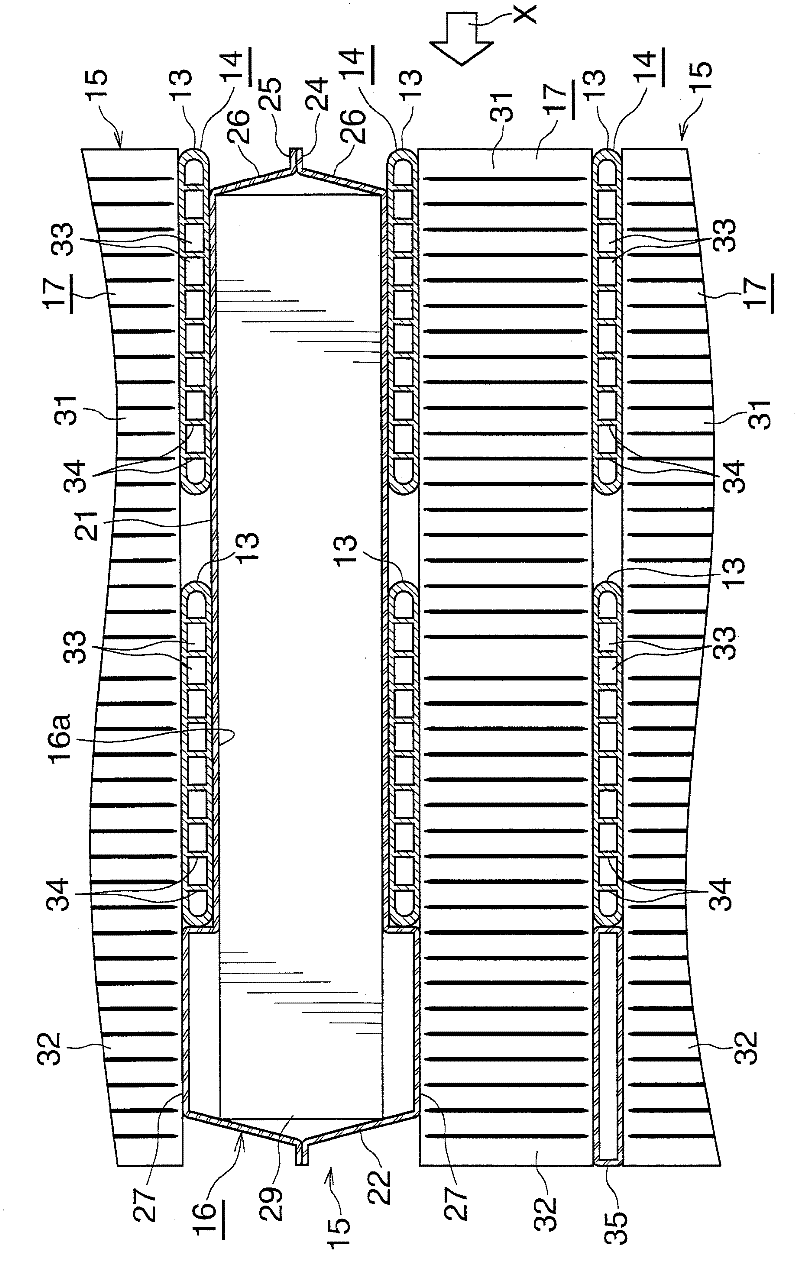

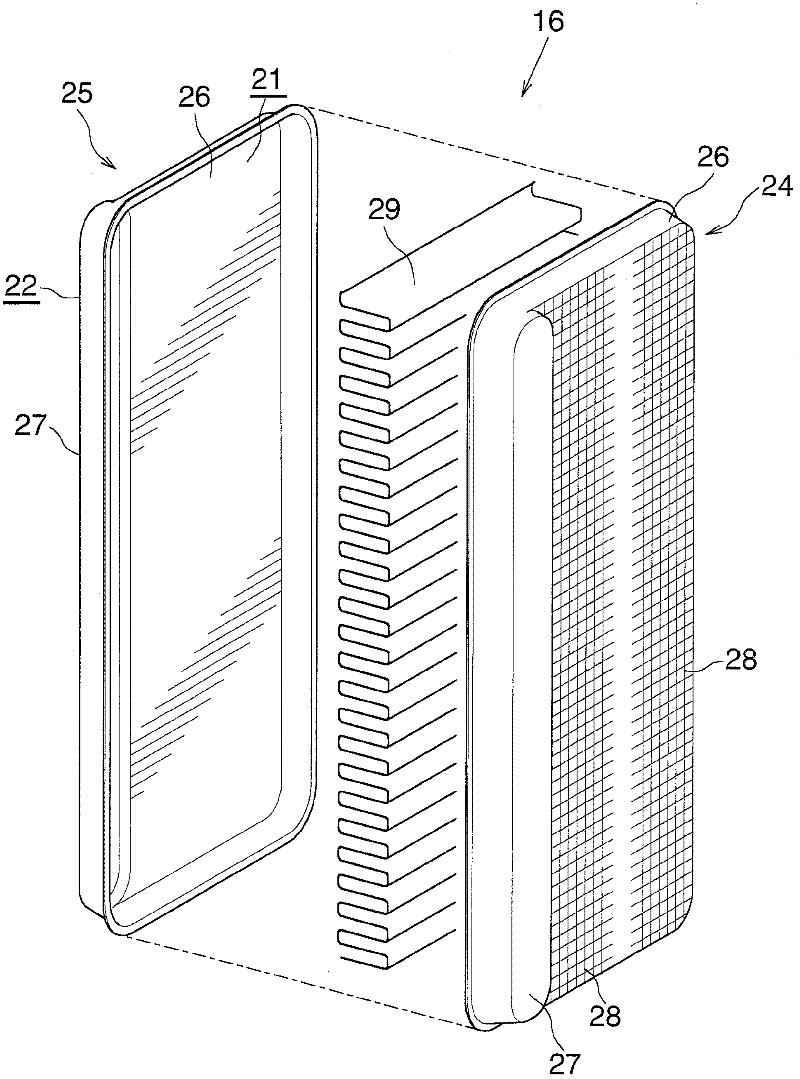

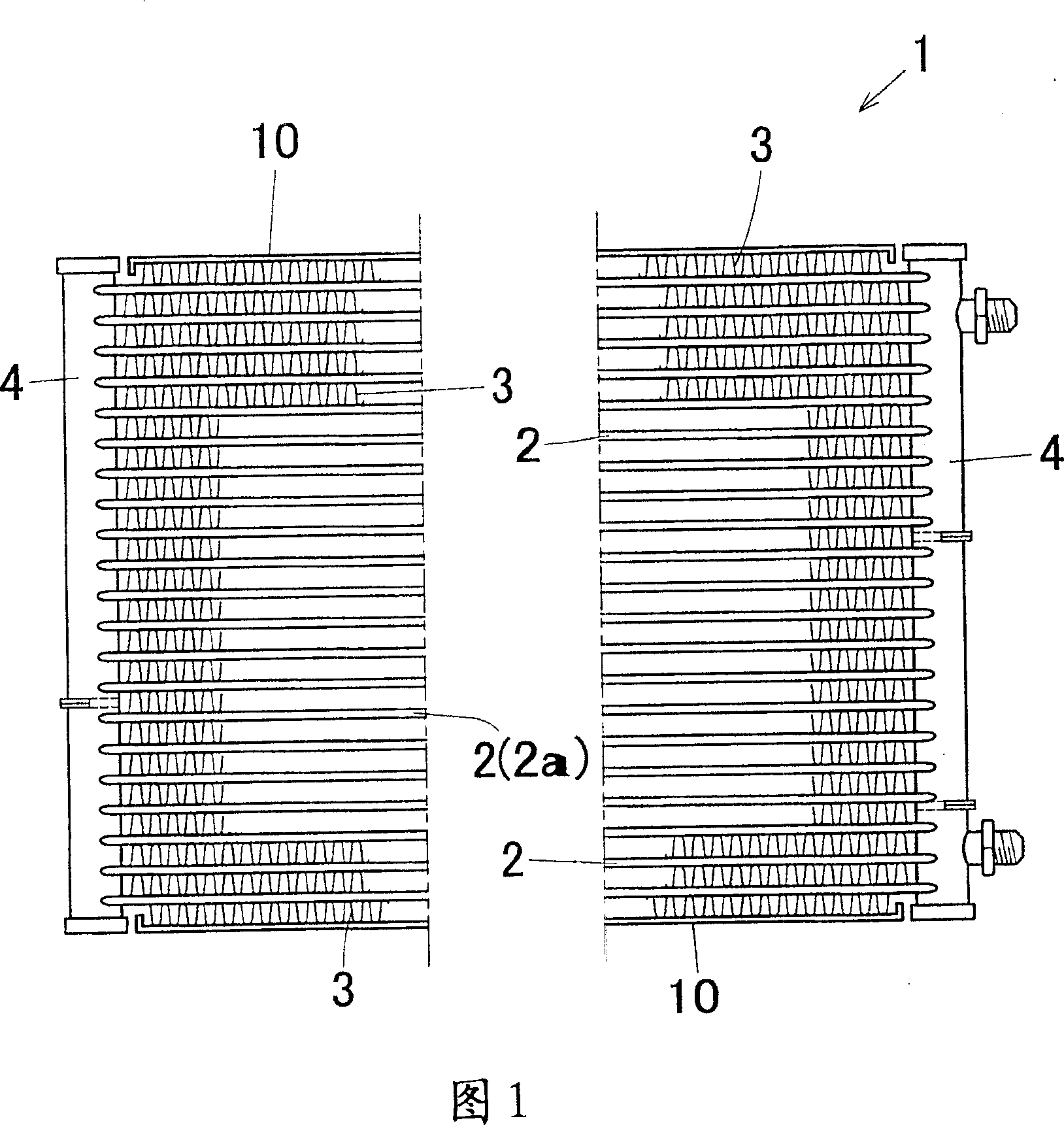

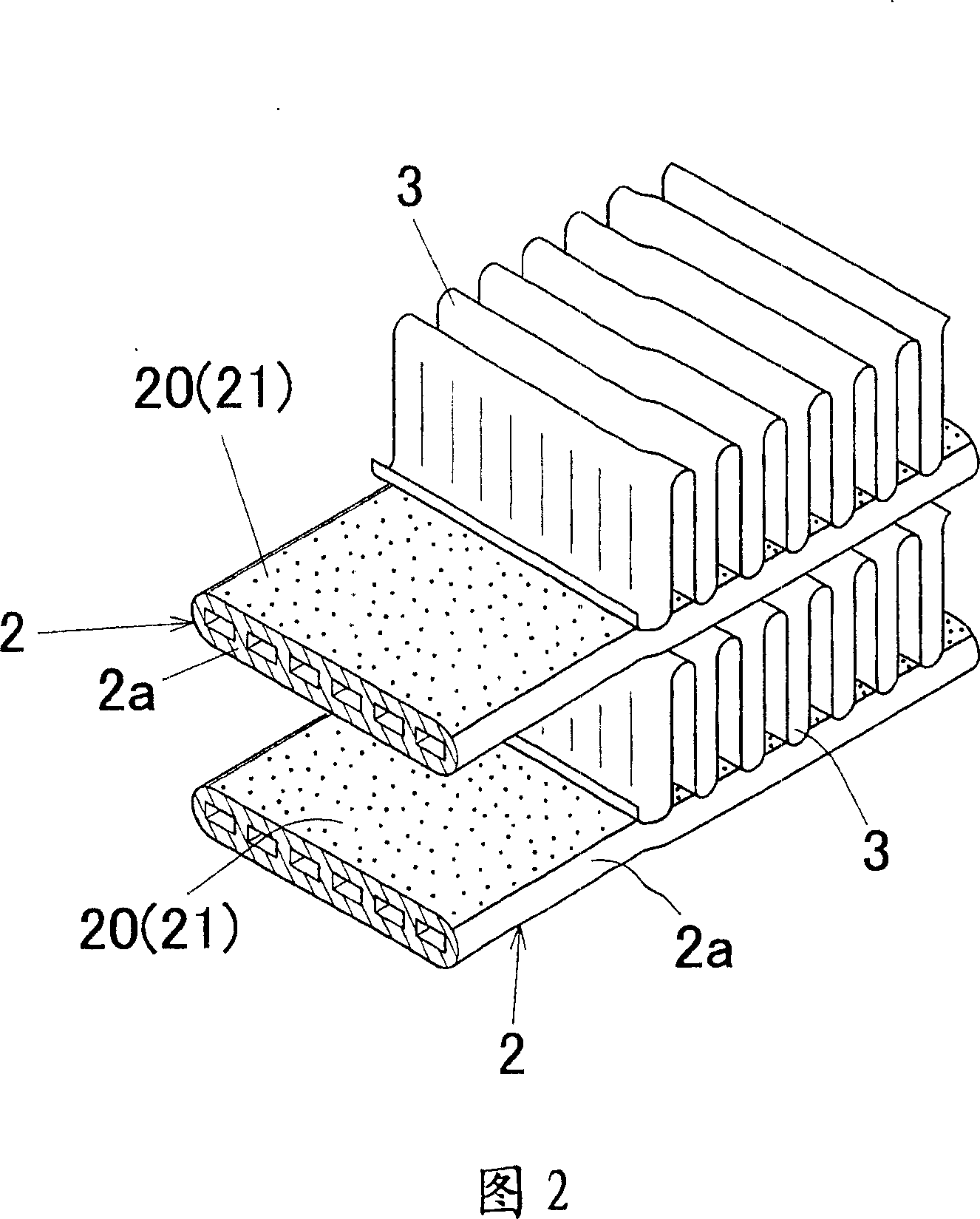

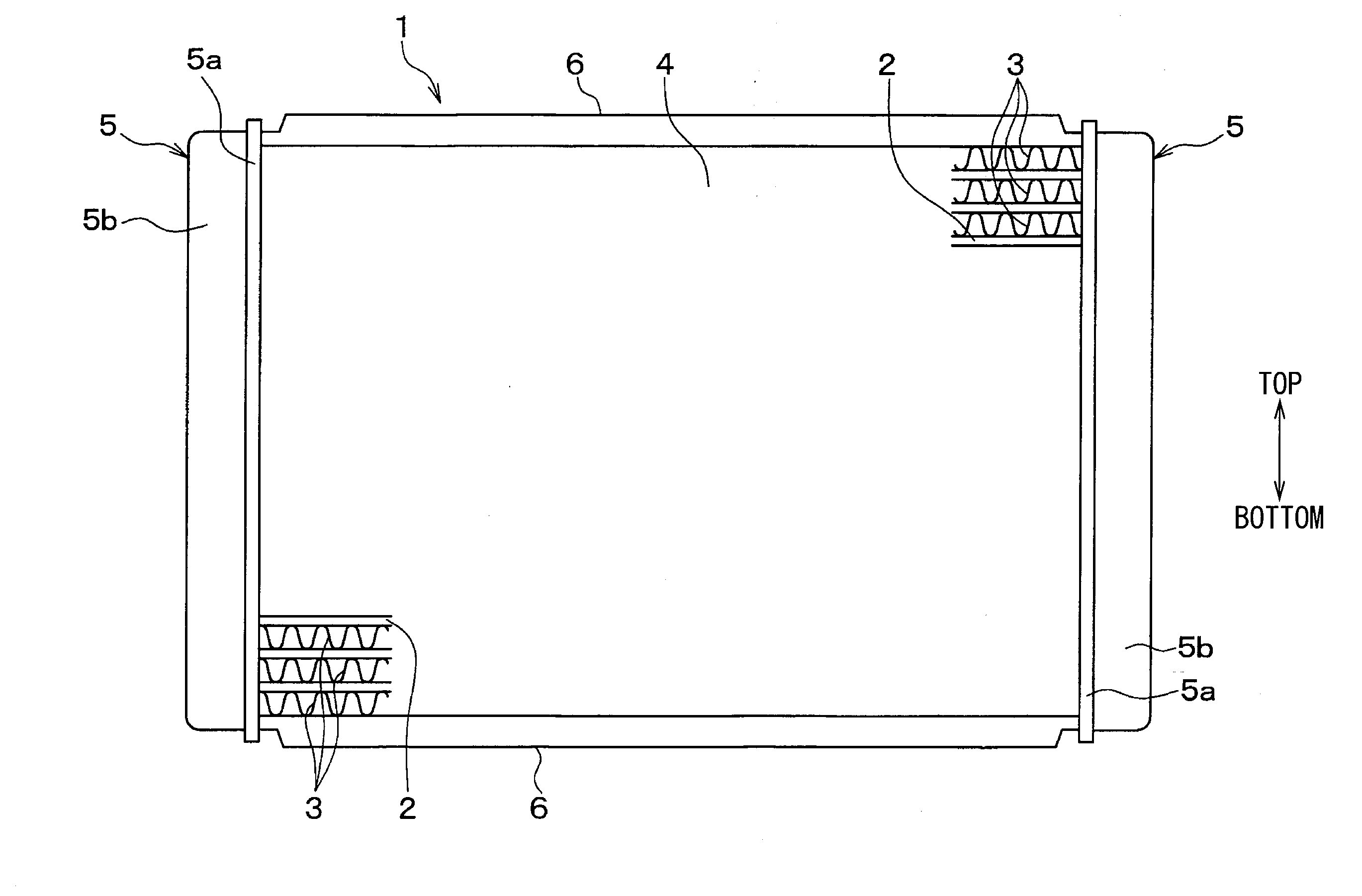

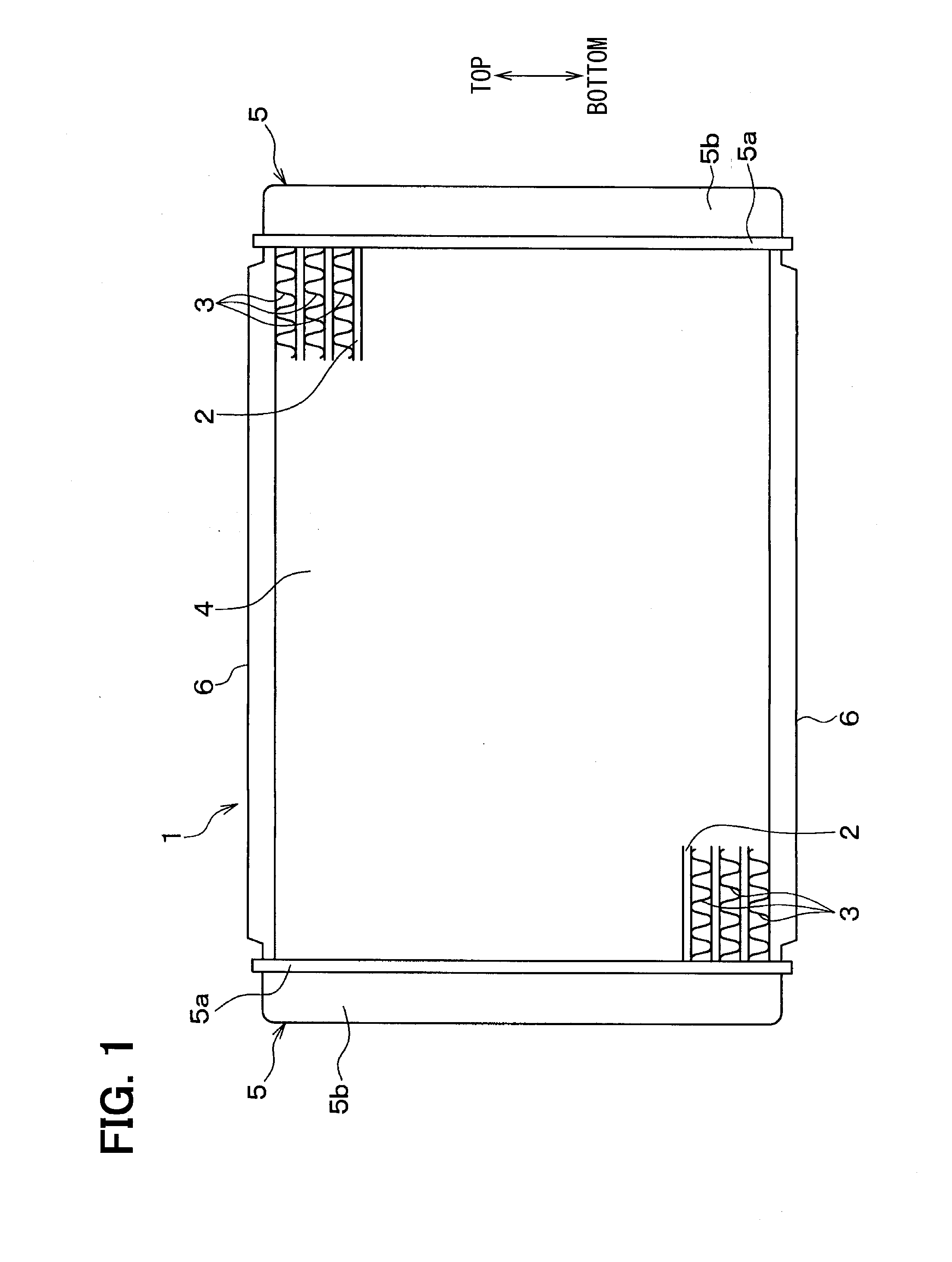

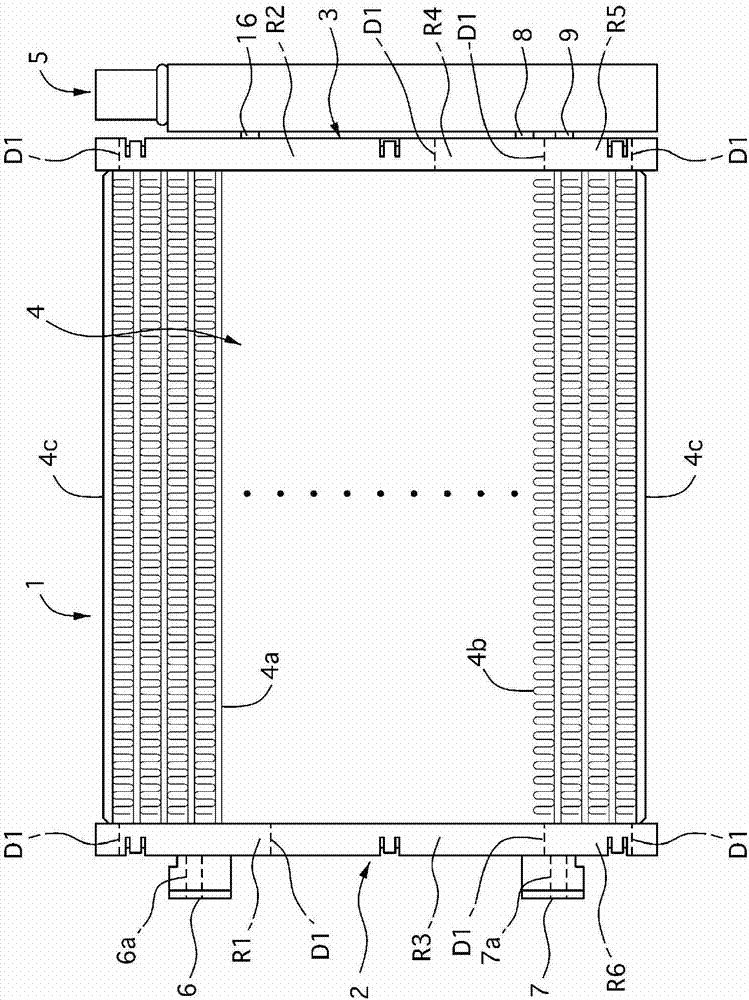

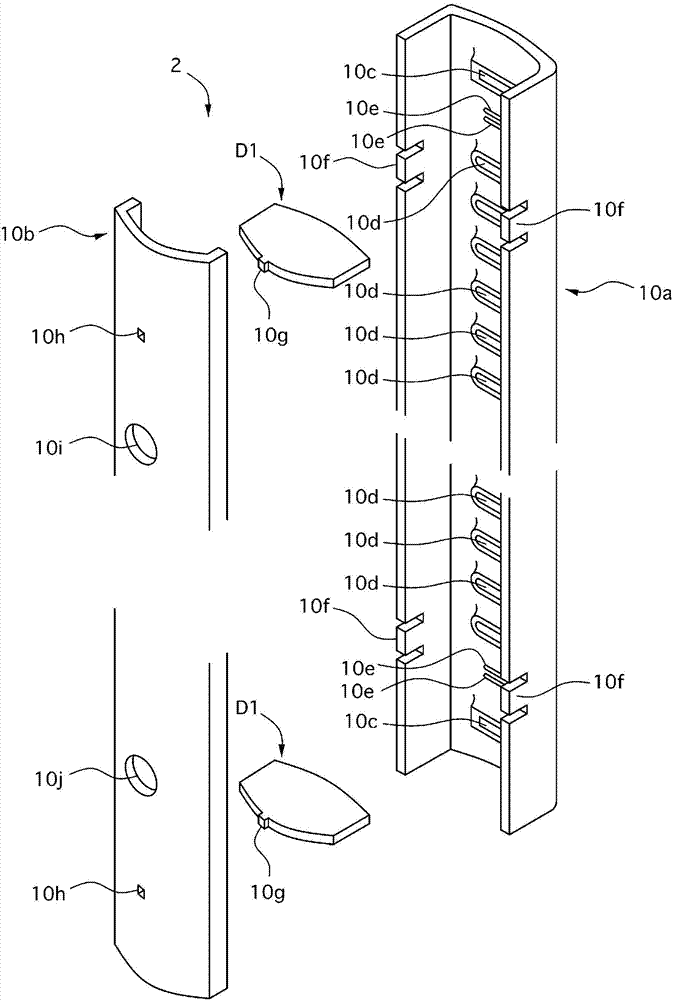

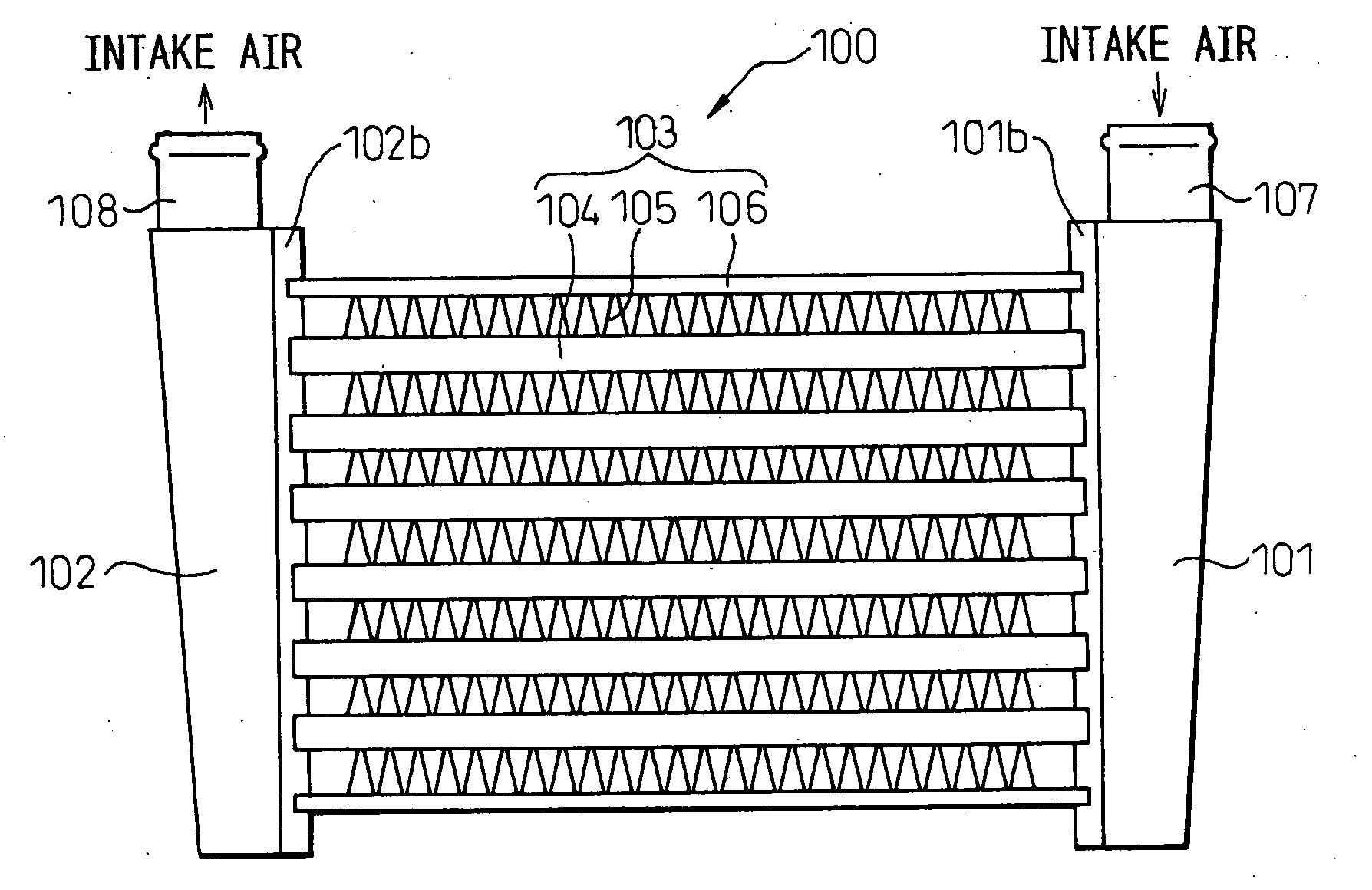

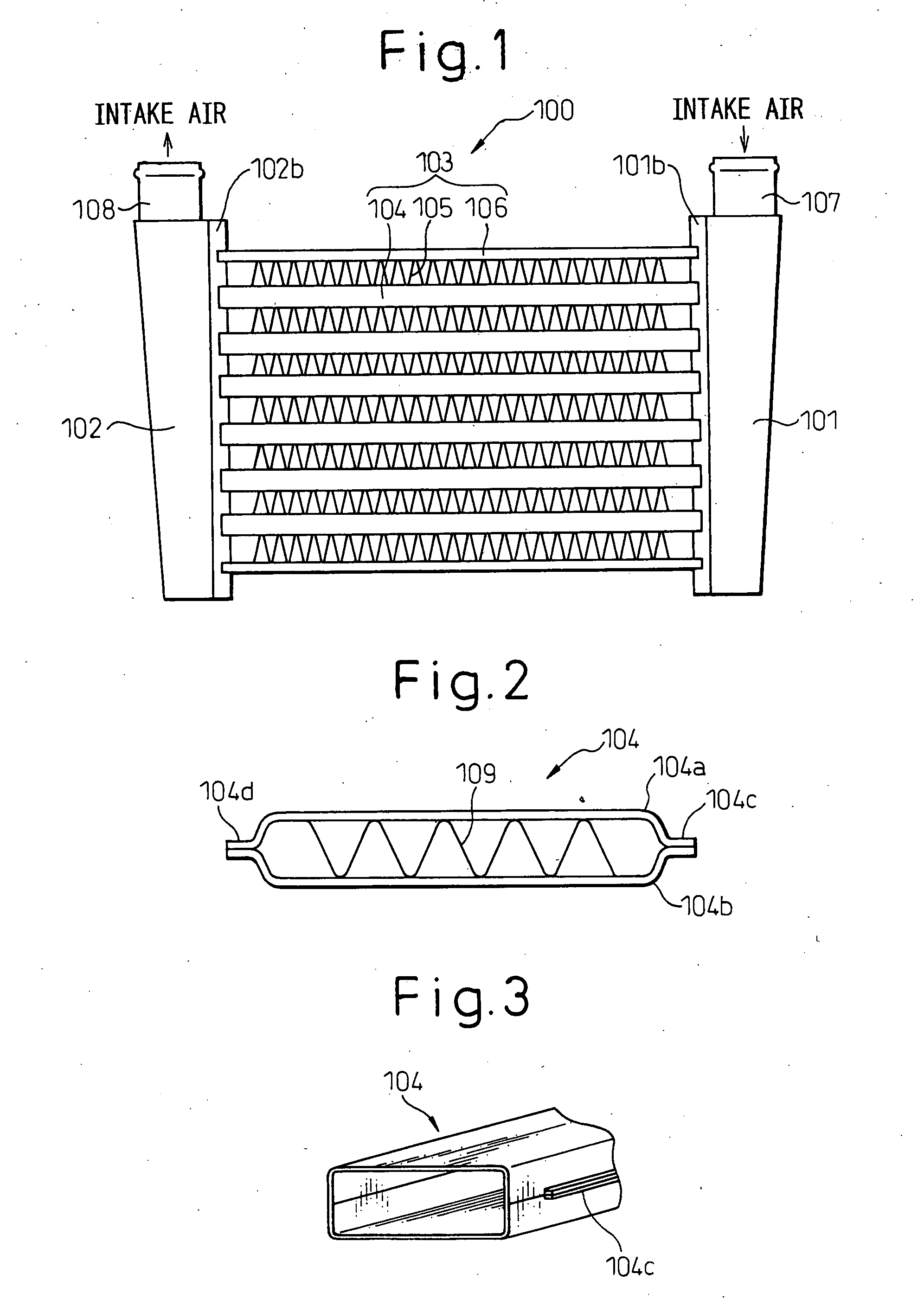

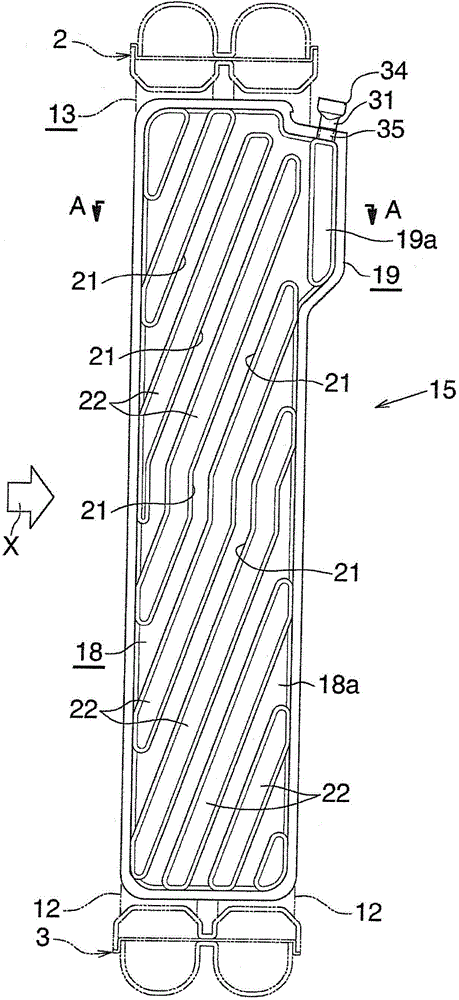

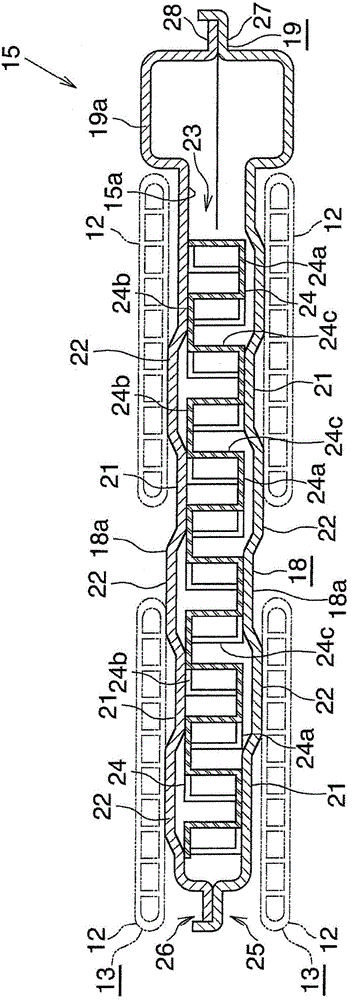

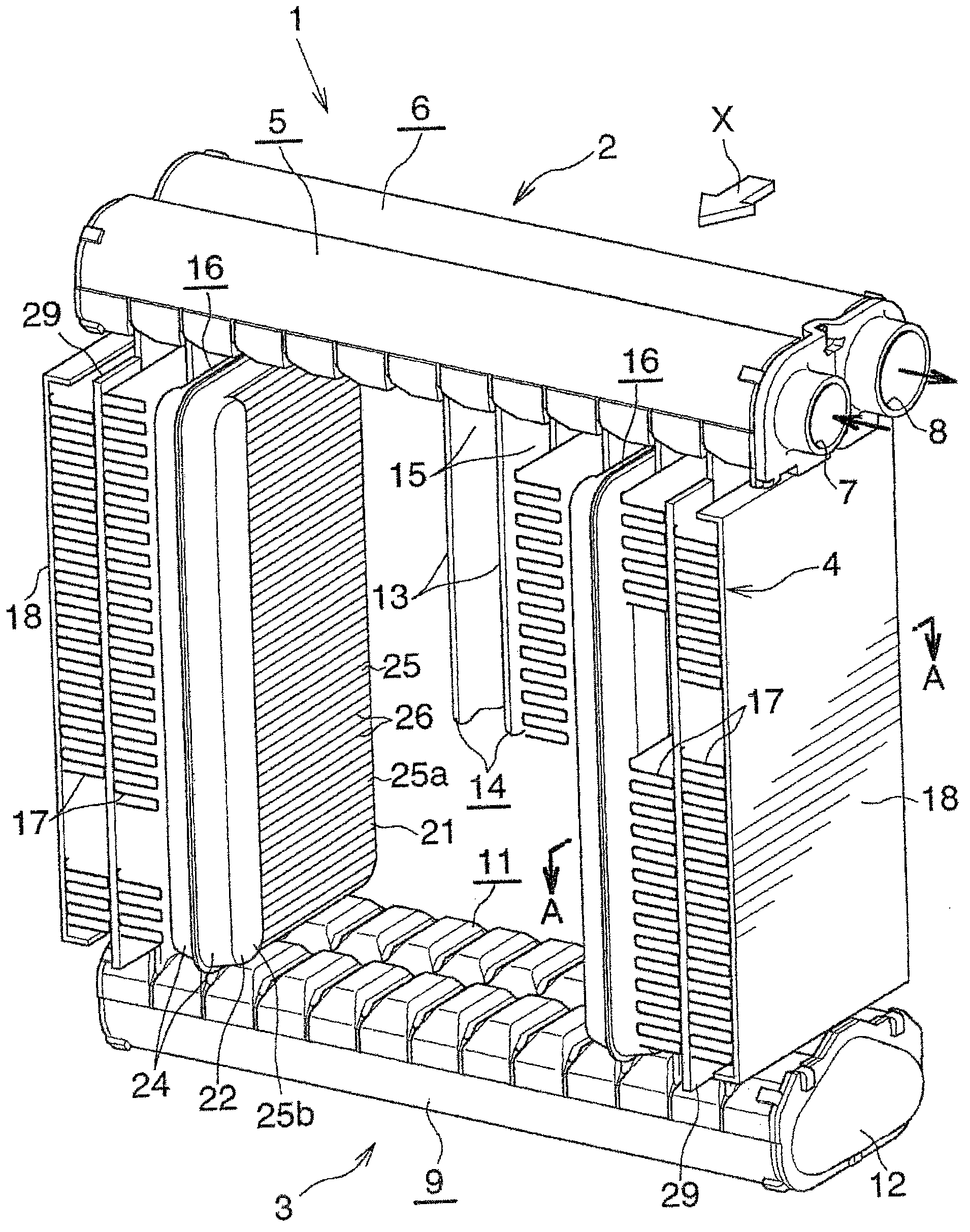

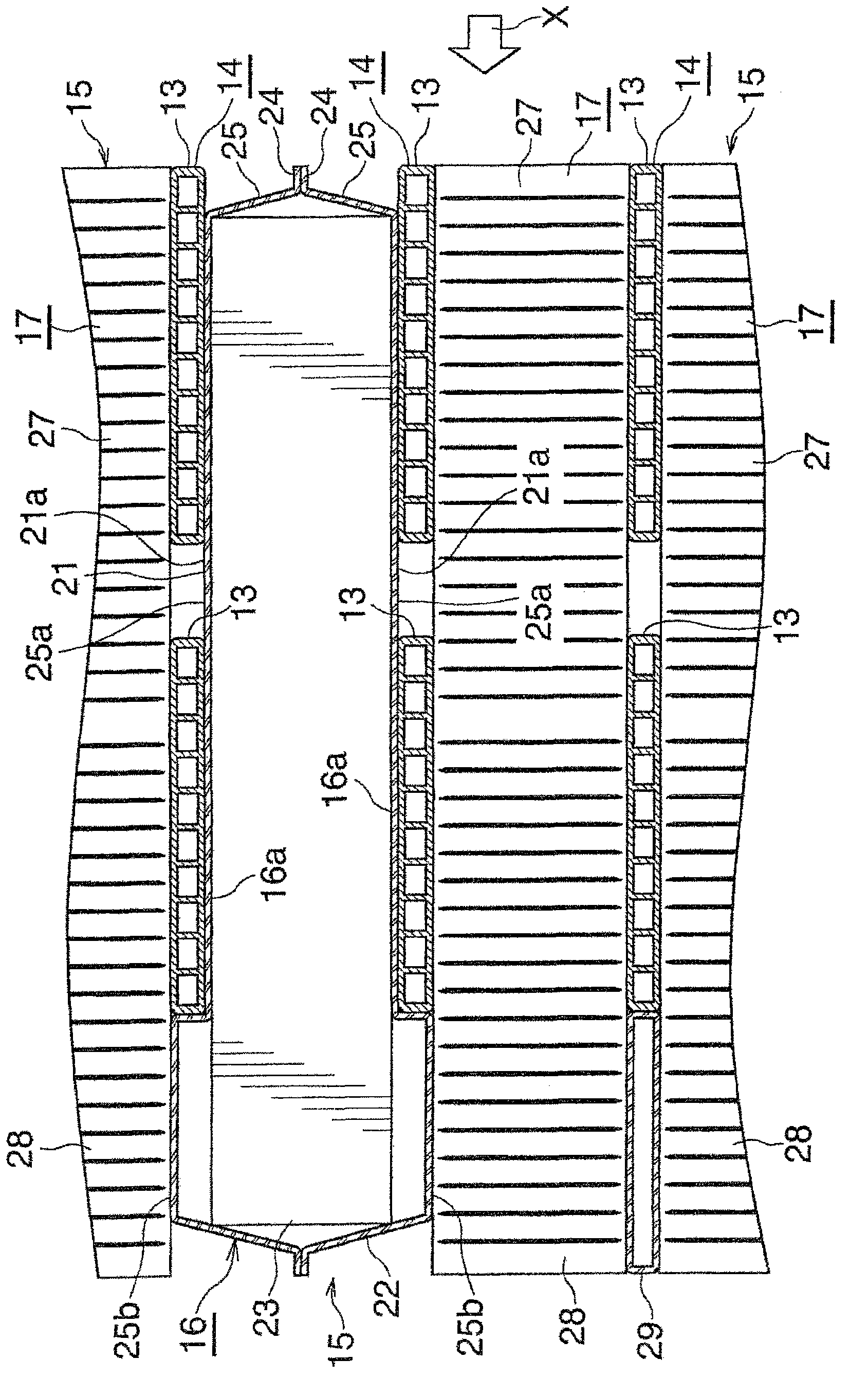

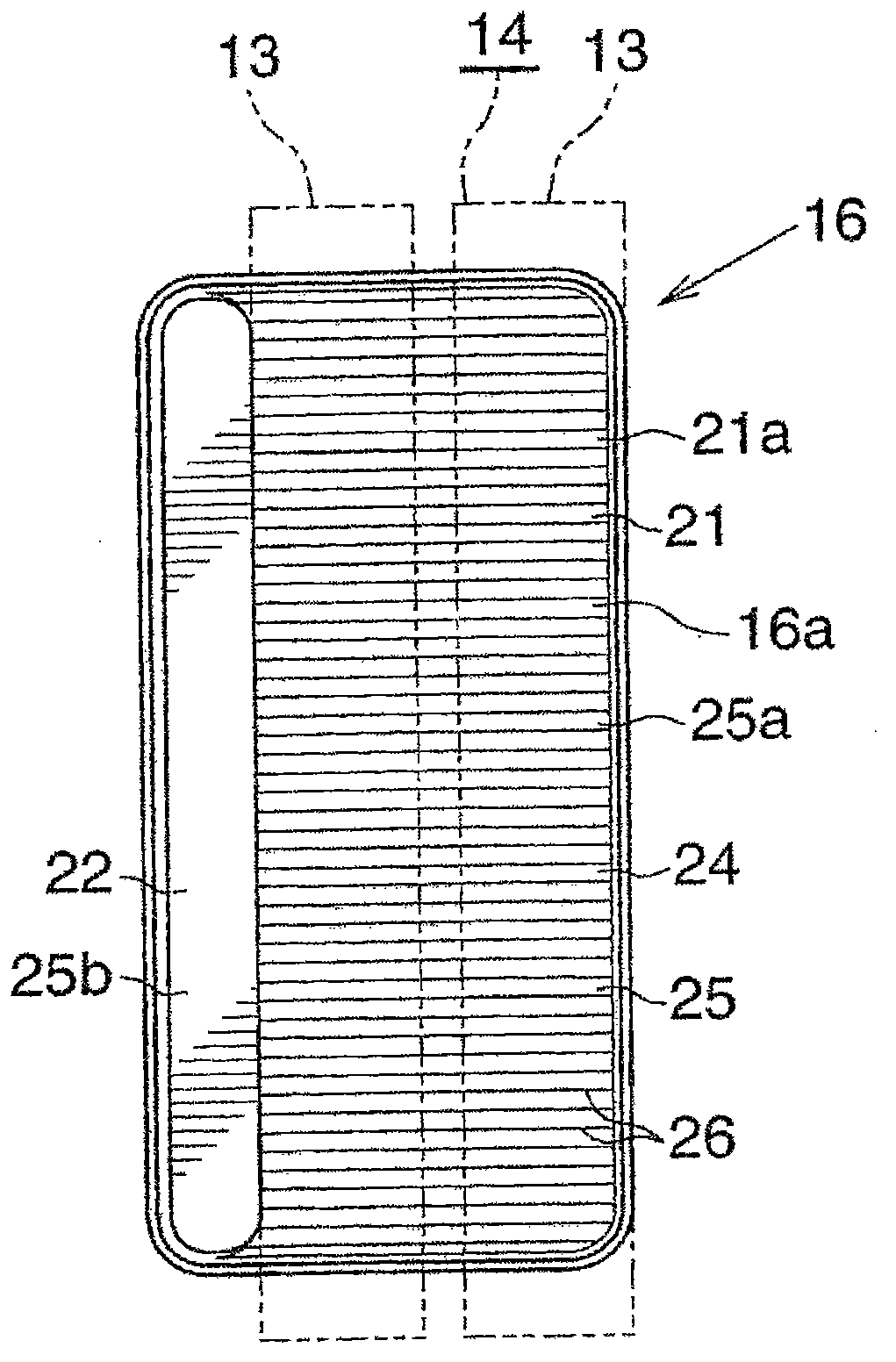

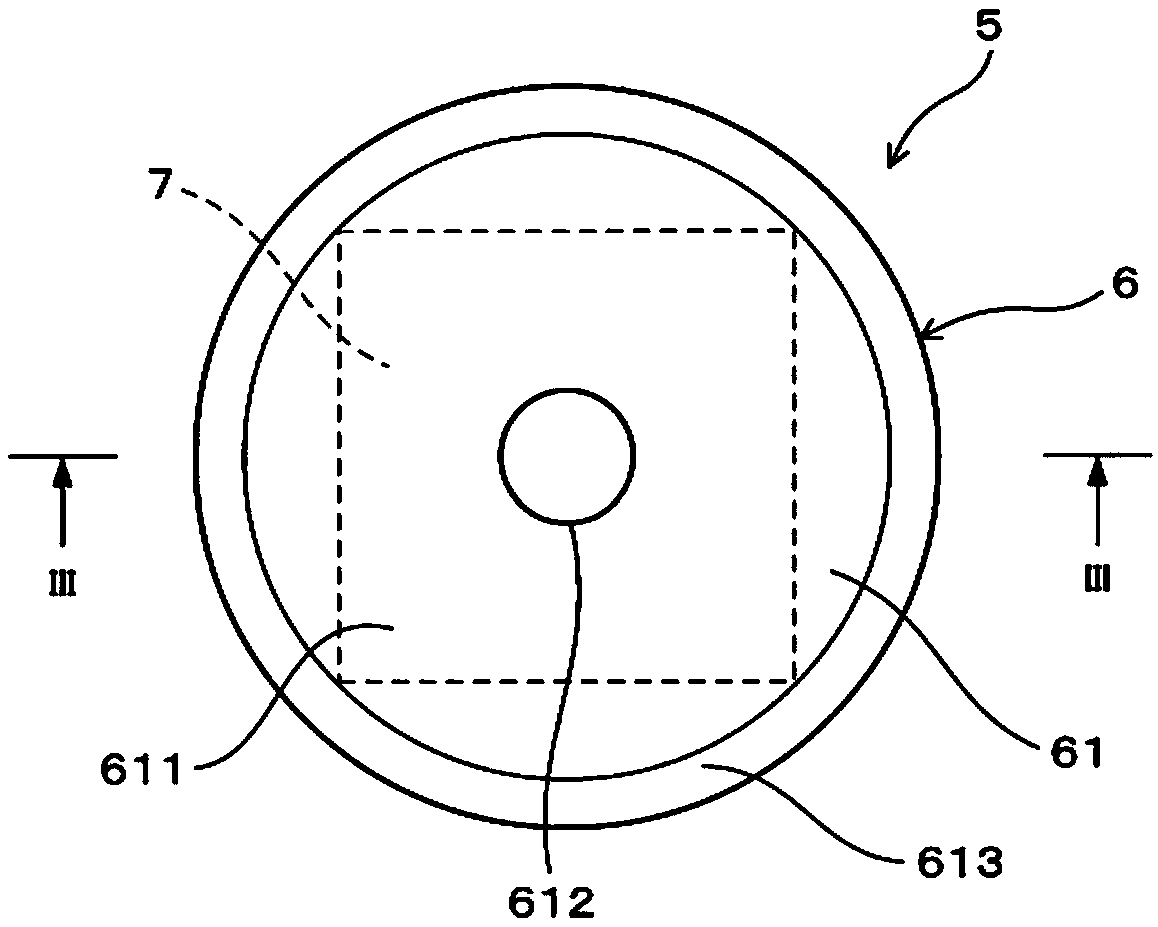

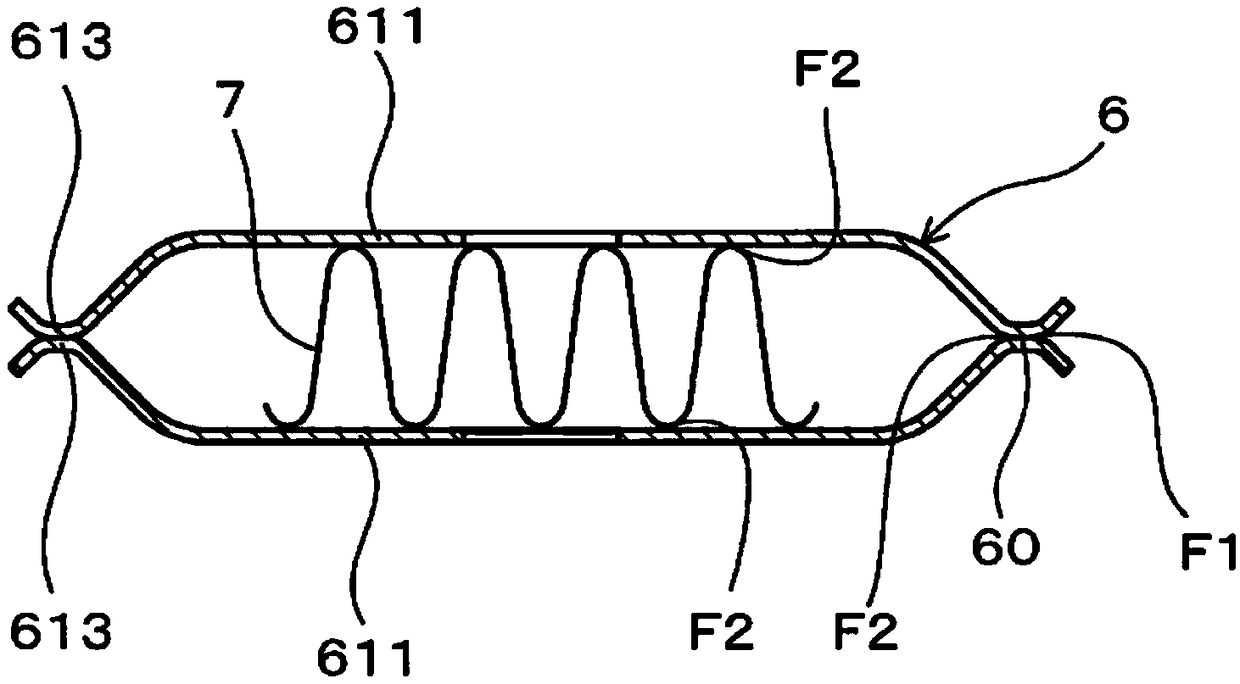

Evaporator with cool storage function

ActiveCN102374705AReduce the pass areaInhibit the increase in ventilation resistanceHeat storage plantsEvaporators/condensersCool storageFront edge

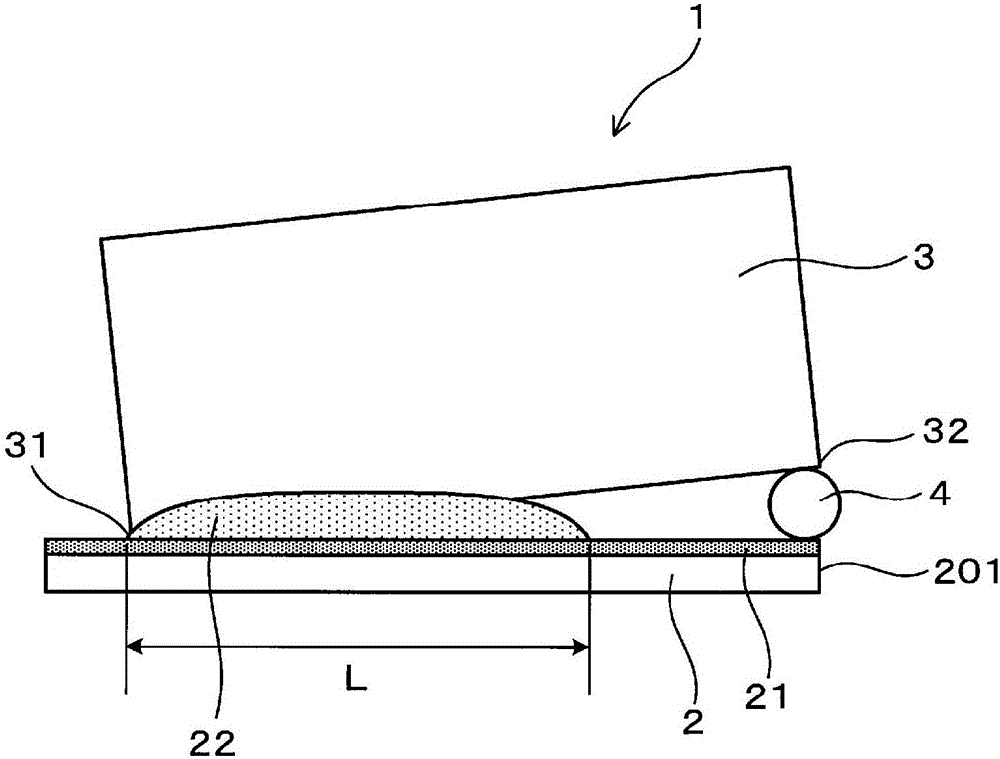

An evaporator with a cool storage function includes a cool storage material container disposed at least one of air-passing clearances formed between adjacent refrigerant flow tubes, and fins disposed in air-passing clearances on opposite sides of the cool storage material container. The cool storage material container includes a container body portion joined to the corresponding refrigerant flow tubes, and an outward extending portion which extends from the front edge of the container body portion and projects frontward in relation to the refrigerant flow tubes. Each of the fins has a fin body portion joined to the corresponding refrigerant flow tubes, and an outward extending portion which extends from the front edge of the fin body portion body and projects frontward in relation to the refrigerant flow tubes. The outward extending portions of the fins are brazed to opposite sides of the outward extending portion of the cool storage material container.

Owner:MAHLE INT GMBH

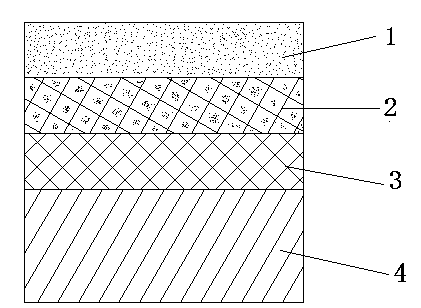

Penetration brazing preparation method of high-content wolfram carbide gradient wear-resisting coating

The invention provides a penetration brazing preparation method of a high-content wolfram carbide gradient wear-resisting coating, comprising the following steps: sequentially sticking a plurality of layers metal wire net flexible compound cloth containing wolfram carbide WC or wolfram carbide-cobalt WC-Co and nickel-chromium alloy powder Ni-Cr on a metal base body by using an epoxy resin binding agent; and carrying out penetration brazing in a vacuum furnace. Compared with the prior art, the Rockwell hardness of a researched coating with the WC content of 70% is HRC64-70 and the wear resistance is obviously improved.

Owner:NANCHANG INST OF TECH

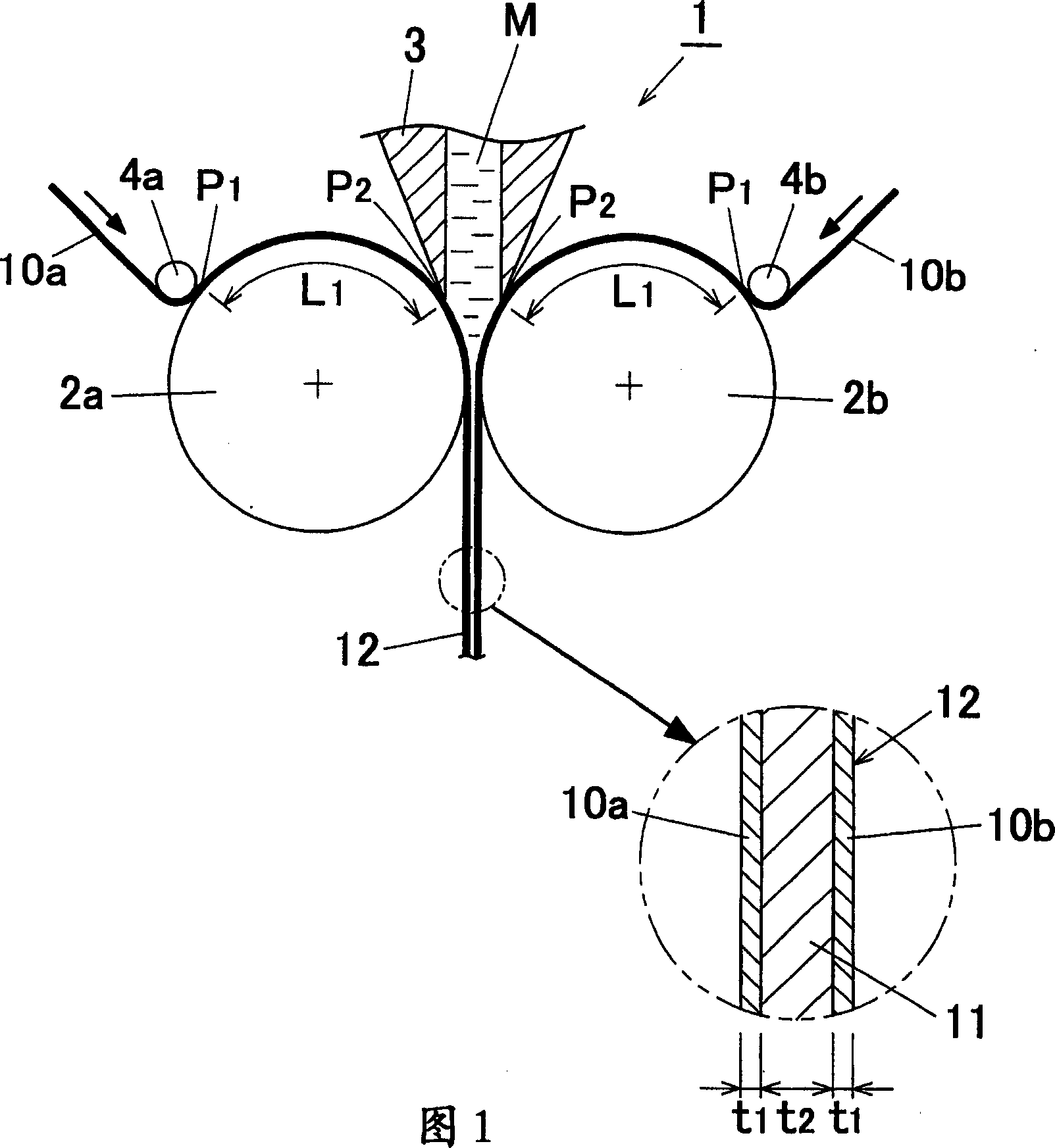

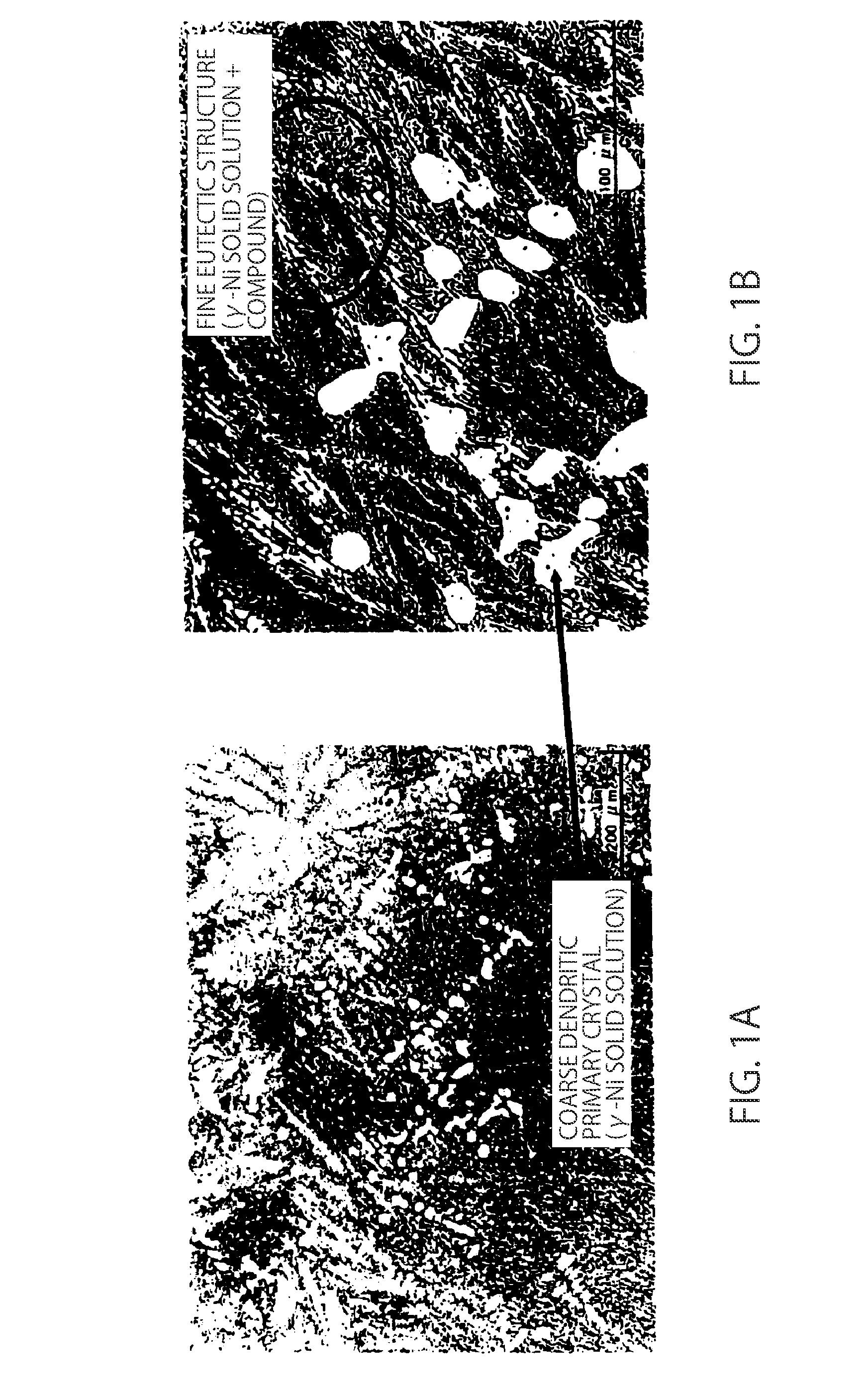

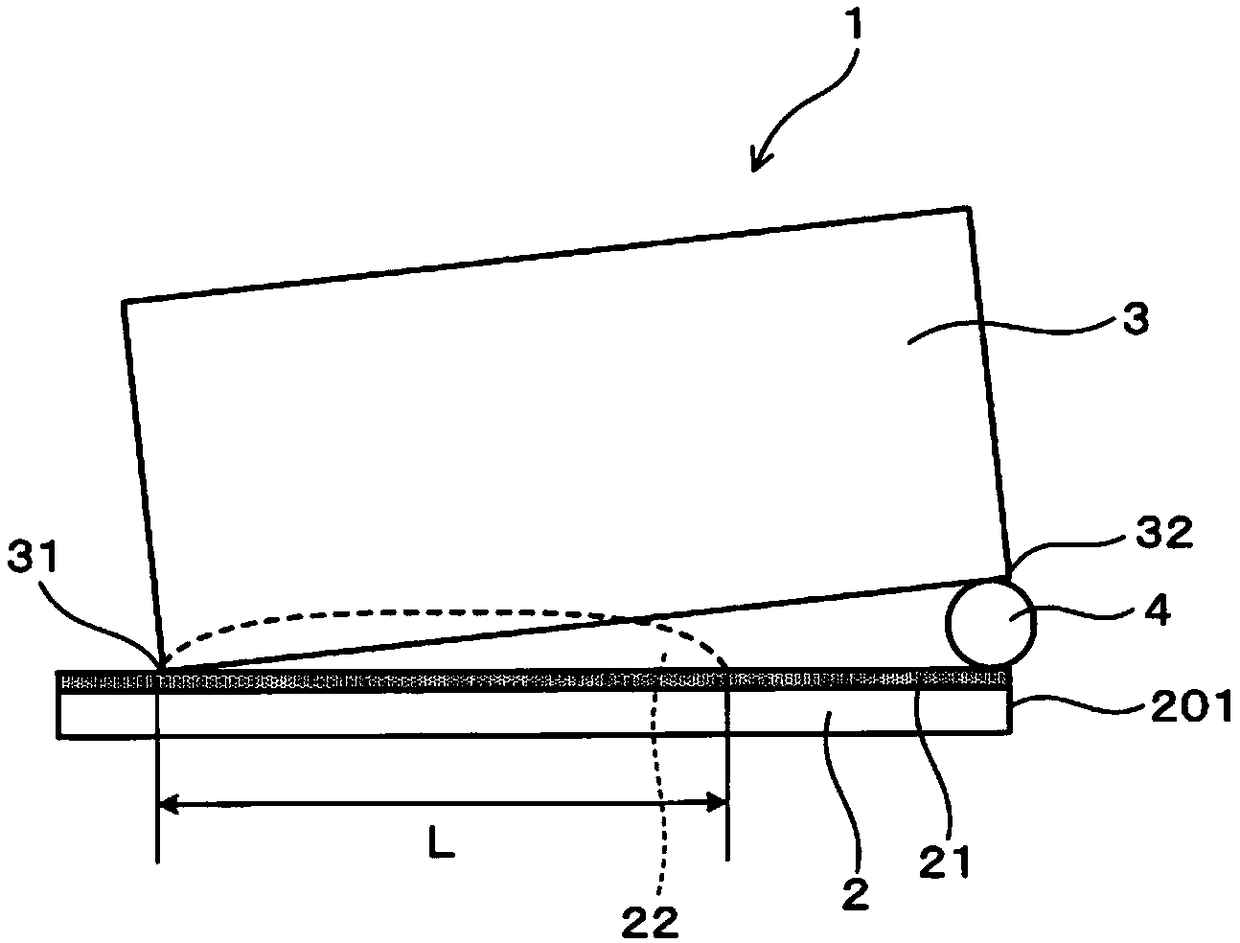

Clad material, method for manufacturing said clad material, and apparatus for manufacturing said clad material

InactiveCN1933928AControl tensionIncrease cooling rateHeat exchange apparatusMetal rolling arrangementsMeeting placeMolten metal

A method for manufacturing a clad material in which a core material is cast and skin materials are pressure-bonded thereon aims to prevent deterioration of adhesiveness of the core material and the skin materials while keeping sufficient cooling rate of the core material, prevent thickness variation and / or breakage of the skin materials during the manufacturing process, and keep the surface property of the cooling rolls constant. The method for manufacturing a clad material (11) includes the steps of continuously supplying molten metal (M) into a gap between a pair of cooling rollers (2a) (2b) to cast a core material, and cladding skin materials (10a) (10b) on both surfaces of the core material with hot rolling by continuously supplying the skin materials on peripheral surfaces of the cooling rollers so that the skin materials prevent direct contact between the cooling rollers and the molten metal, wherein the skin materials are supplied so as to come into contact with the peripheral surfaces of the cooling rollers, and wherein a contact distance (L1) from a contact starting point (P1) where the skin material begins to come into contact with the cooling roller to a meeting point (P2) where the skin material begins to come into contact with the molten metal is set to 100 times or more of a thickness (t1) of the skin material.

Owner:SHOWA DENKO KK

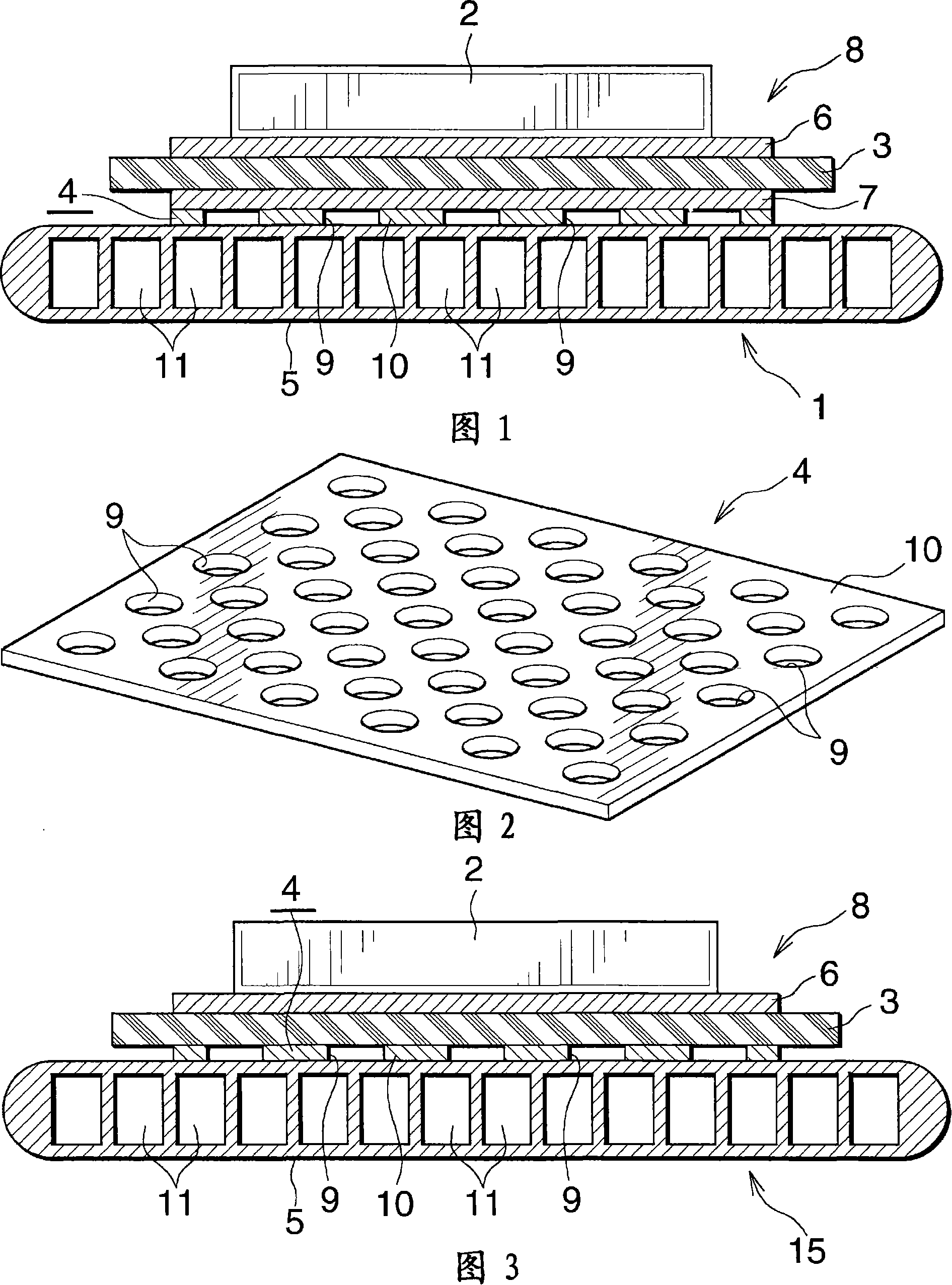

Heat sink device

InactiveCN101156241AImprove thermal conductivityLow costFinal product manufactureSemiconductor/solid-state device detailsOptoelectronicsMetal

A heat sink device (1) is provided with an insulating substrate (3) whose one plane is permitted to be a heat generating body mounting plane, and a heat sink (5) fixed on the other plane of the insulating substrate (3). A metal layer (7) is formed on the plane of the insulating substrate (3), opposite to the heat generating body mounting plane. A stress relaxing member (4), which is composed of an aluminum plate (10) provided with a plurality of through holes (9) and has the through holes (9) as stress absorbing spaces, is arranged between the metal layer (7) of the insulating substrate (3) and the heat sink (5). The stress relaxing member (4) is soldered to the metal layer (7) of the insulating substrate (3) and the heat sink (5). The heat sink device (1) reduces material cost and improves heat sink performance.

Owner:RESONAC HOLDINGS CORPORATION

Soldering flux for brazing diamond cemented carbide sand and preparation method for soldering flux

ActiveCN102814601AImprove solubilityImprove rigidityWelding/cutting media/materialsWelding/soldering/cutting articlesCemented carbideSoldering

The invention provides a soldering flux for brazing a diamond cement carbide. The soldering flux comprises the following components in percentage by weight: 12 to 33% of Na2B4O7, one or two of 5 to 14.8% of KBF4 and 2 to 12% of MF, wherein M is alkali metal, one or two of 0.5 to 10% of CoWO4 and 1 to 15% of CoCl2, one or two of 0.5 to 9% of an oxide of Mo, 0.5 to 5% of the oxide of Ni and 0.5 to 10% of the oxide of W, and the balance of H3BO3. The soldering flux for brazing the diamond cement carbide has a wide scope of application, and can be applied to brazing a cemented carbide such as Co, Mo and Ni and a diamond. Compared with conventional soldering flux, the soldering flux disclosed by the invention can increase an expanding area; a weld joint has a better appearance and high shearing strength, so that a brazing performance is improved.

Owner:HENAN FAMOUS DIAMOND IND CO LTD

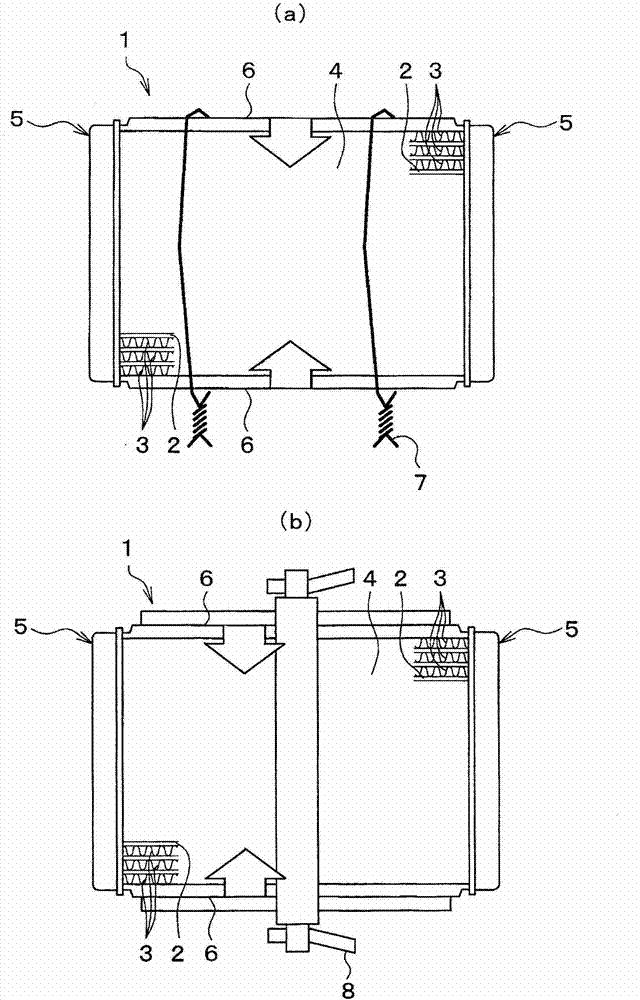

Heat exchanger and method for manufacturing same

InactiveCN102245982ASecure joint workspaceAvoid heat damageEvaporators/condensersSoldering apparatusEngineeringMechanical engineering

Owner:CALSONIC KANSEI CORP

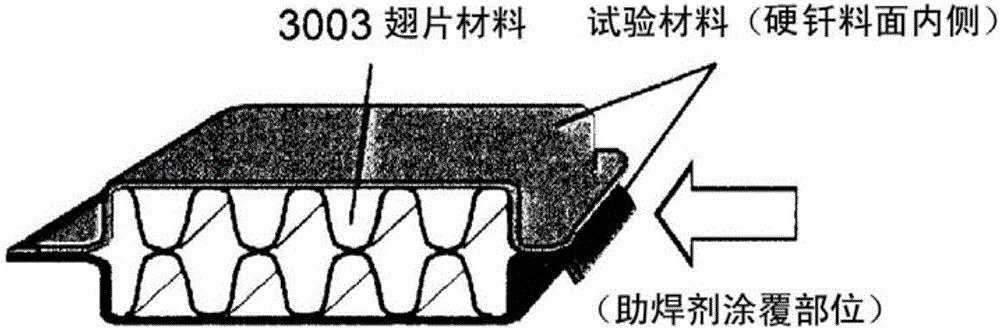

Brazing method

ActiveUS20170320170A1Low stateGood brazingWelding/cutting media/materialsMetal working apparatusFiller metalAtmosphere

A hollow aluminum structure that will be brazed includes at least one brazing sheet having a filler metal layer clad onto a core layer. The core layer is composed of aluminum or an aluminum alloy containing less than 0.2 mass % Mg. The filler metal layer is composed of an aluminum alloy that contains Si: 4.0-13.0 mass % and Bi: 0.01-0.3 mass %, and further contains Li: 0.004-0.08 mass % and / or Be: 0.006-0.12 mass %, the filler metal layer containing less than 0.1 mass % Mg. The hollow aluminum structure is assembled such that the filler metal layer is present at locations that will form both an interior-facing brazed joint and an exterior-facing brazed joint. Then, flux is applied onto the filler metal layer at the location that will form the exterior brazed joint, and the hollow aluminum structure heated in an inert gas atmosphere to form the interior brazed joint and the exterior brazed joint.

Owner:FURUKAWA SKY ALUMINUM CORP

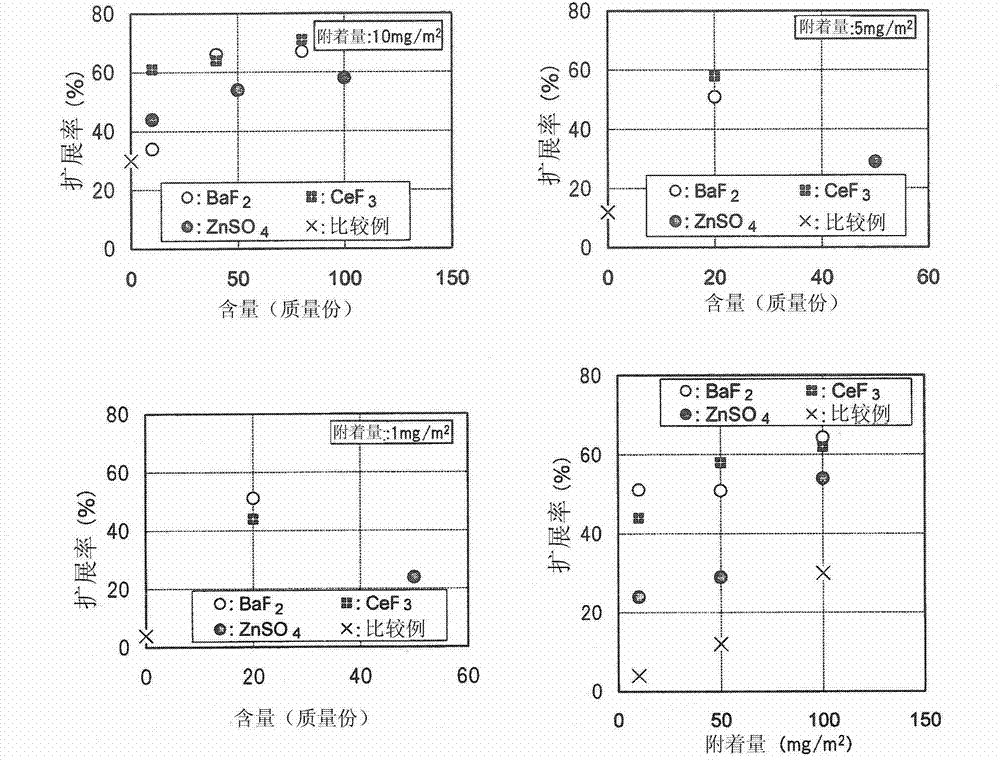

Flux composition and brazing sheet

InactiveCN102950394AImprove wettabilityImprove brazing performanceWelding/cutting media/materialsHeat exchange apparatusFluorideMelting point

Disclosed are: a flux composition which is used for brazing of a magnesium-containing aluminum alloy material, suppresses the formation of high-melting compounds, provides better wettability, and thereby exhibits better brazability even applied in a small mass of coating; and a brazing sheet using the flux composition. The flux composition for brazing of a magnesium-containing aluminum alloy material includes a flux component [A] containing fluorides as principal components; and an additive [B] being at least one selected from the group consisting of CeF3, BaF2, and ZnSO4. The flux component [A] preferably contains KF in a content of 40 percent by mass or more and 60 percent by mass or less; and AlF3 in a content of 40 percent by mass or more and 60 percent by mass or less.

Owner:KOBE STEEL LTD

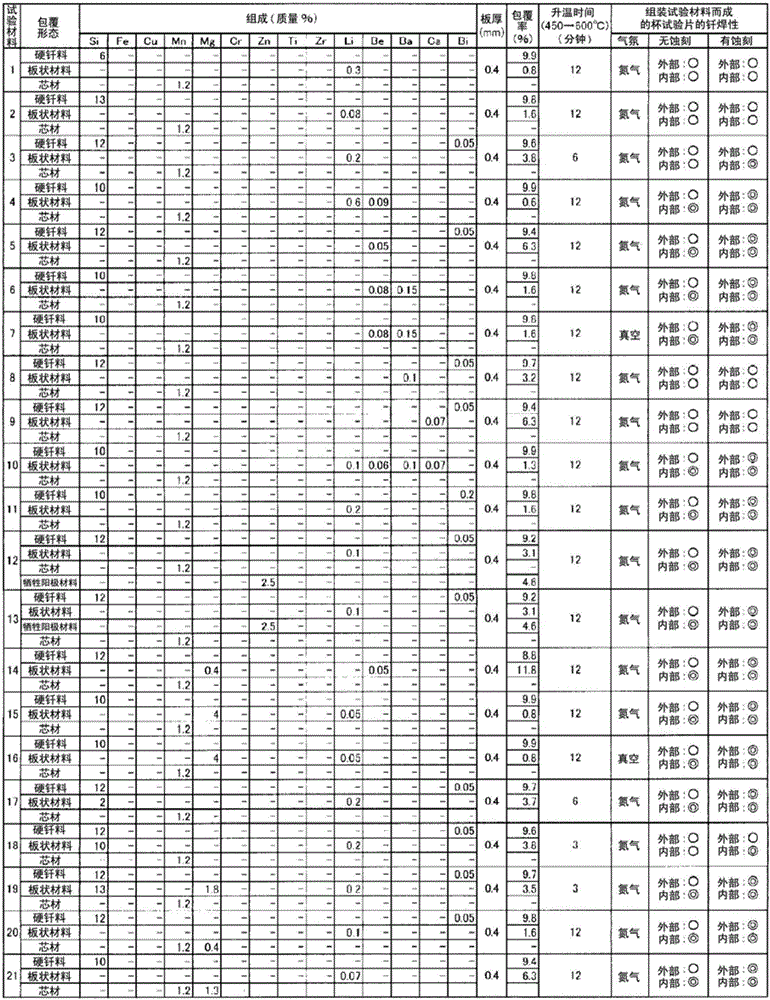

Aluminium alloy brazing sheet

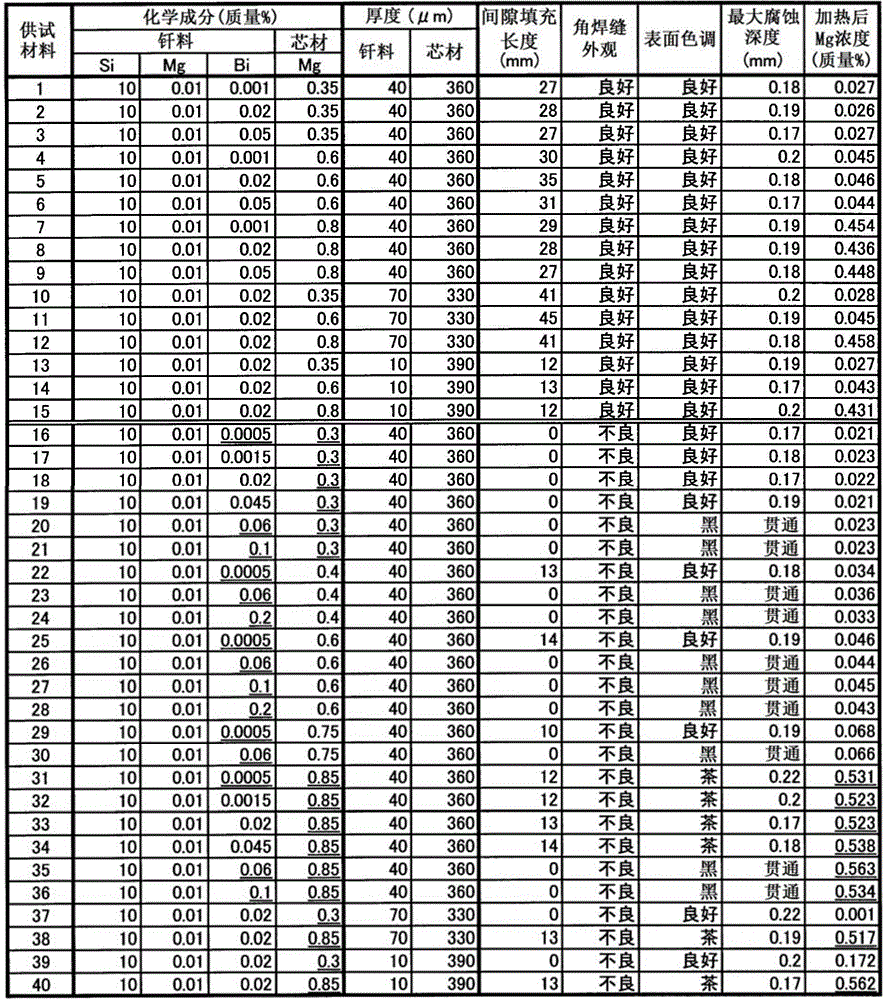

ActiveCN106661677AImprove brazing performanceImprove corrosion resistanceWelding/cutting media/materialsWelding/soldering/cutting articlesChemical composition6111 aluminium alloy

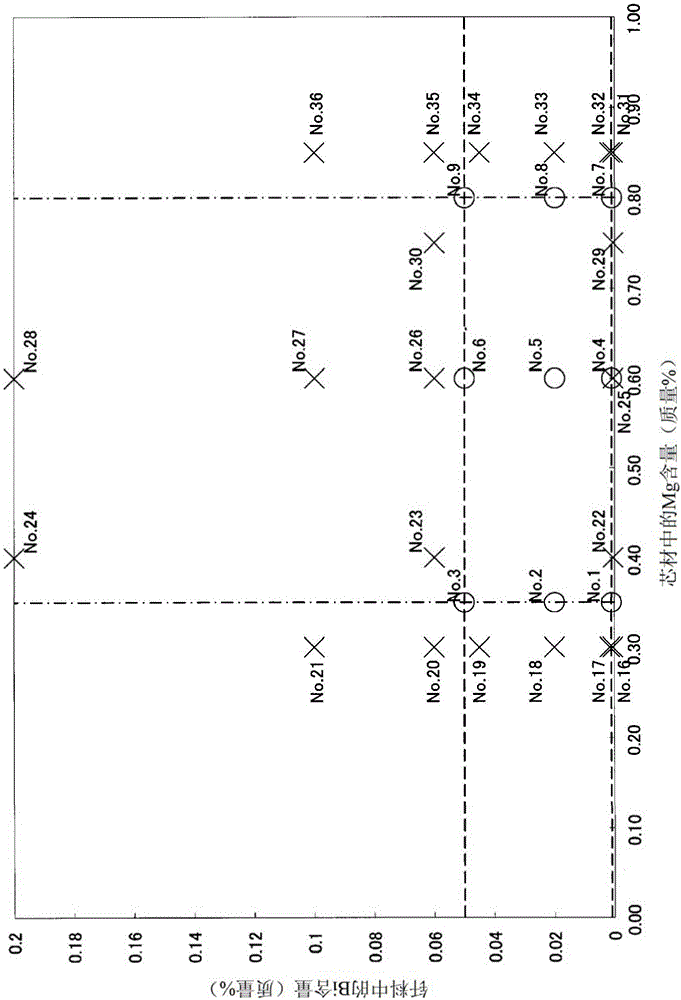

This brazing sheet has a core material and a brazing material clad on one or both sides of the core material, and is used for brazing in an inert gas atmosphere without using a flux. The core material contains 0.35-0.8% (mass%, same hereafter) of Mg, wherein the balance has a chemical composition comprising Al and inevitable impurities. The brazing material contains 6-13% of Si and 0.001-0.05% of Bi, and restricts Mg to less than 0.05%, wherein the balance has a chemical composition comprising Al and inevitable impurities.

Owner:FURUKAWA SKY ALUMINUM CORP

Wire mesh flexible composite fabric for surface modification and preparation method of wire mesh flexible composite fabric

InactiveCN102965602AImprove formabilityImproved formabilitySurface modificationNickel Chromium Alloys

The invention relates to a wire mesh flexible composite fabric for surface modification and a preparation method of the wire mesh flexible composite fabric. The wire mesh flexible composite fabric comprises wolfram carbide (WC) or WC-cobalt (Co), mechanically alloyed nickel-chromium alloy powder, a forming agent and a binding agent. The wire mesh flexible composite fabric for surface modification is made through roll forming. By adopting a mechanical alloying technology, a nanocrystalline technology and a wire mesh technology, the preparation forming property of the flexible fabric is greatly improved, the thickness of the flexible fabric is extremely controlled, and the design idea of gradient coatings of more than two layers can be realized, so that the stress is reduced and the welding texture and the welding property are improved. The WC coating with excellent performance is prepared.

Owner:NANCHANG INST OF TECH

Terminal electrod composition for multilayer ceramic capacitor

InactiveCN1518007AImprove adhesionImprove sintering performanceFixed capacitor electrodesFixed capacitor dielectricFritCeramic capacitor

The present invention relates to terminal electrode compositions for multilayer ceramic capacitors. More specifically, it relates to terminal electrode compositions for multilayer ceramic capacitors, which compositions are made of a conductive-based powder and a glass frit and can be fired at a low temperature in a nitrogen atmosphere.

Owner:EI DU PONT DE NEMOURS & CO

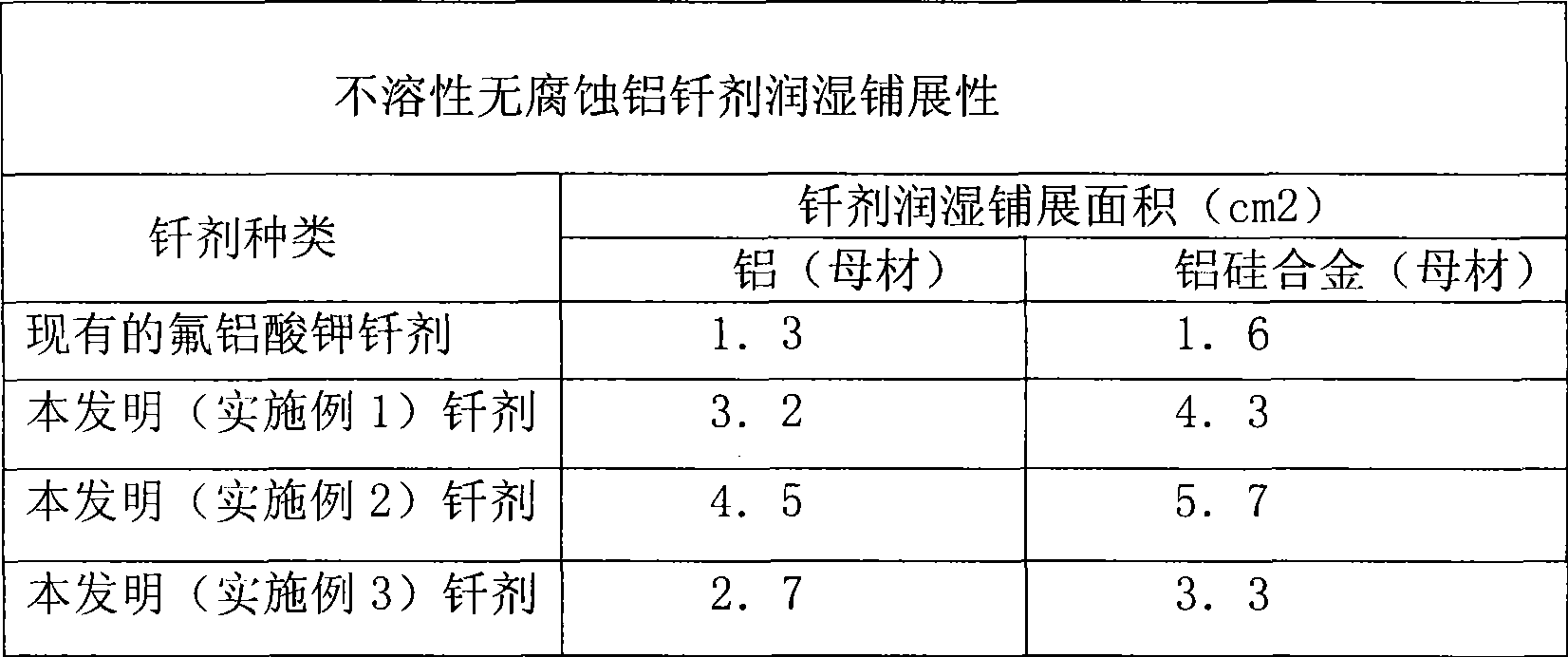

Novel insoluble aluminum brazing flux without corrosion and preparation method thereof

InactiveCN101486137AImprove wettabilityEfficient removalWelding/cutting media/materialsSoldering mediaHydrofluoric acidPotassium

The invention relates to novel insoluble non-corrosive aluminum soldering flux and a preparation method thereof, belongs to insoluble non-corrosive aluminum soldering flux and preparation technology thereof, and in particular to insoluble non-corrosive aluminum soldering flux containing a potassium composition, an aluminum composition, a cesium composition, a silicon composition and a fluorine composition and preparation thereof. The insoluble non-corrosive aluminum soldering flux solves the problems of poor wettability of solder, increase of the welding difficulty and influence of the braze welding quality during braze welding because aluminum is active and compact and stable oxide is easy to form on the surface of the solder. The preparation method adopts a technical proposal that the preparation method comprises the following steps: firstly, making the aluminum composition react with hydrofluoric acid, and adding the potassium composition and the cesium composition in turn; secondly, adding hydrofluosilicic acid into the mixture for reaction after the reaction is over; and thirdly, performing dehydration, drying, crushing and sieving through 20 mu m sieve, and preparing the insoluble non-corrosive aluminum soldering flux. The insoluble non-corrosive aluminum soldering flux has the advantages of convenient use, protection of brazing metals and the solder from being continuously oxidized during heating, improvement of the wettability of the solder on the surfaces of substrate metals, promotion of flowing of the solder, filling of joint gaps, formation of braze welding seams with clean and compact surfaces, and the like, and can be widely applied to braze welding of aluminum workpieces and aluminum alloy workpieces.

Owner:TIANJIN UNIV

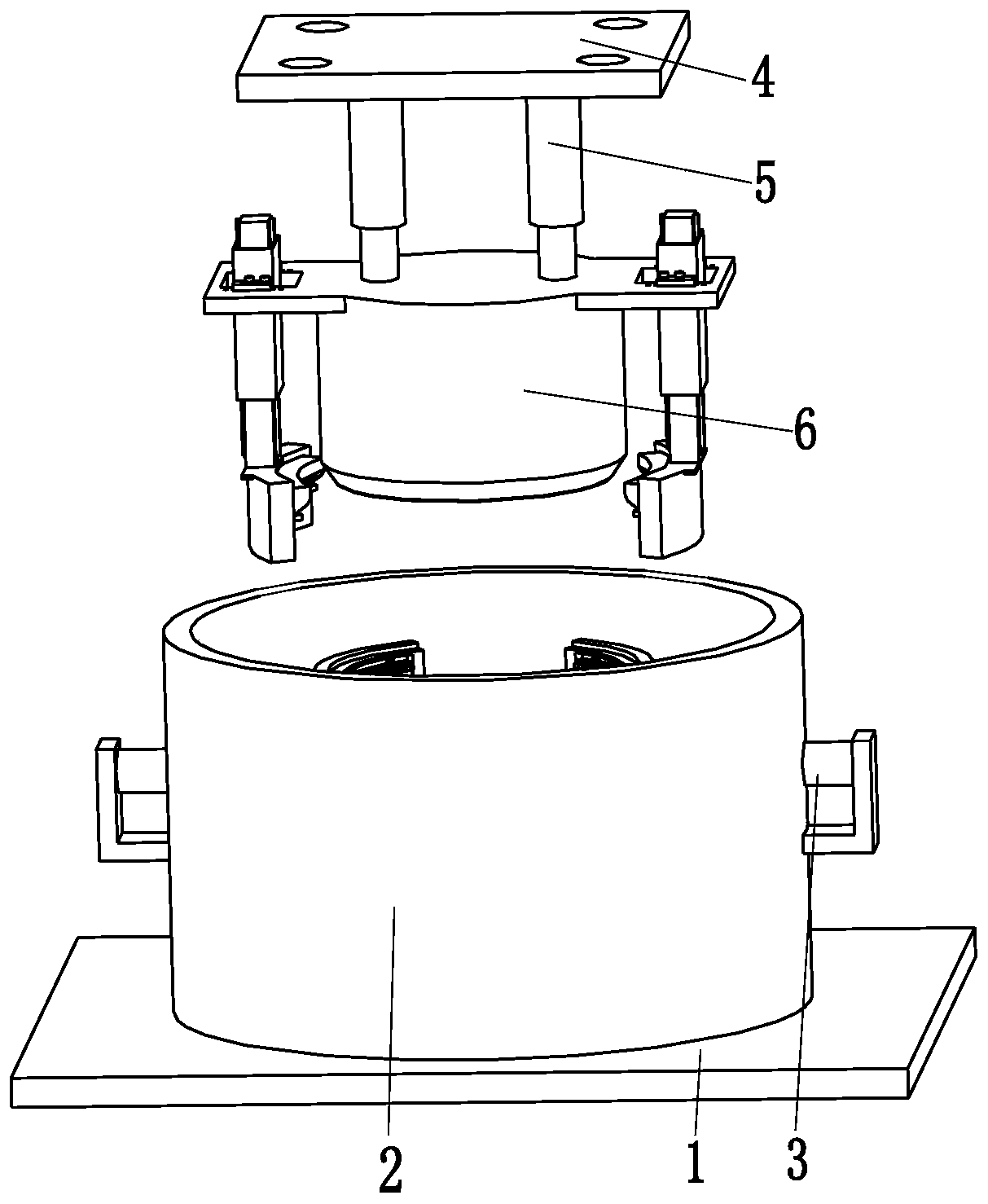

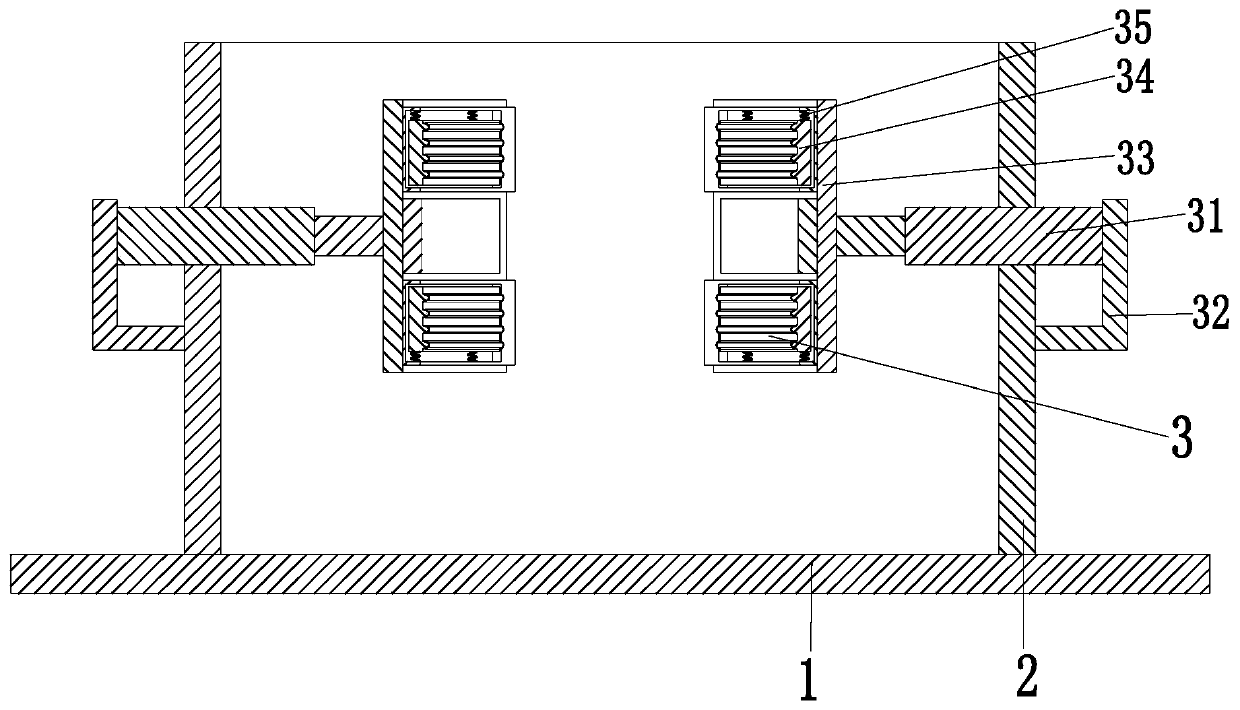

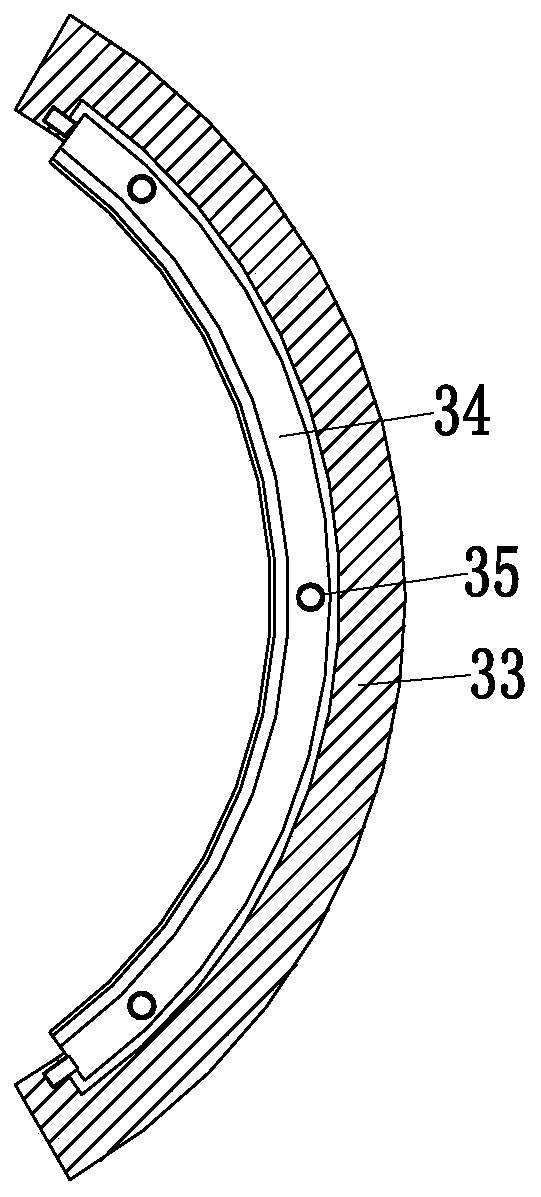

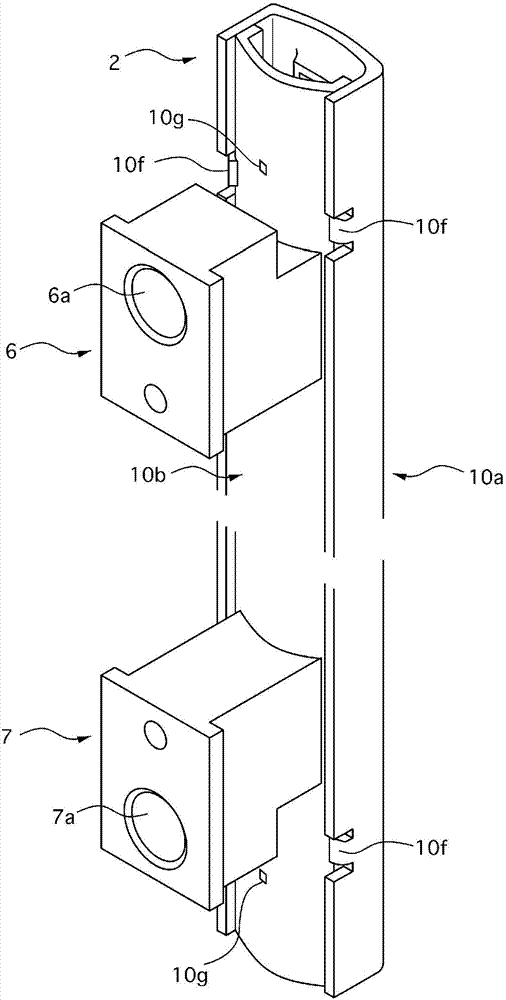

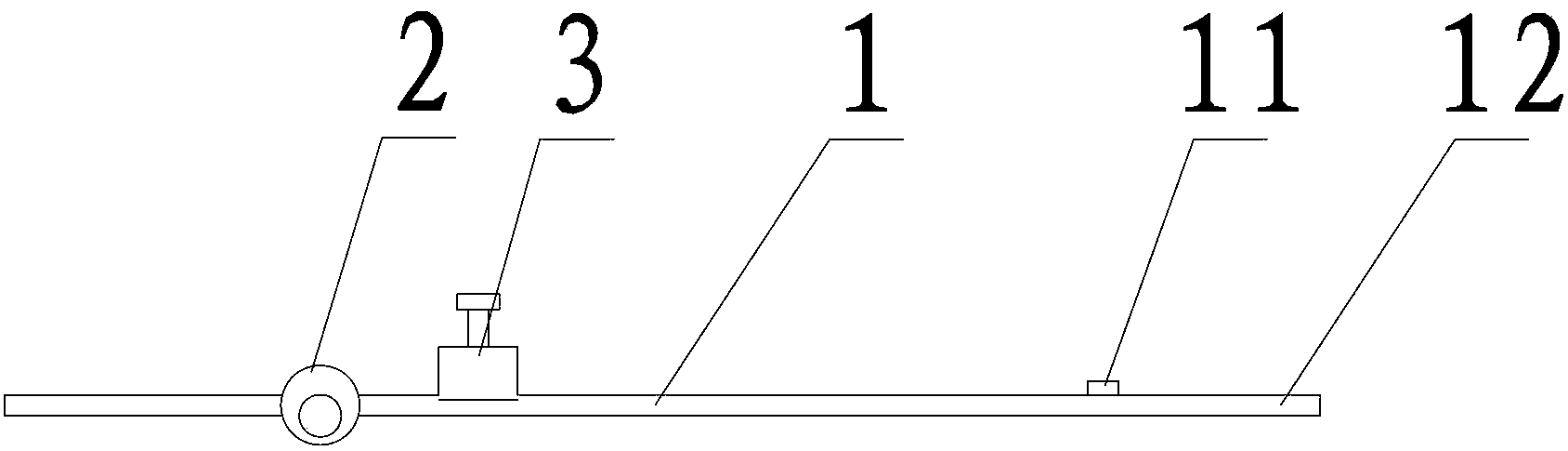

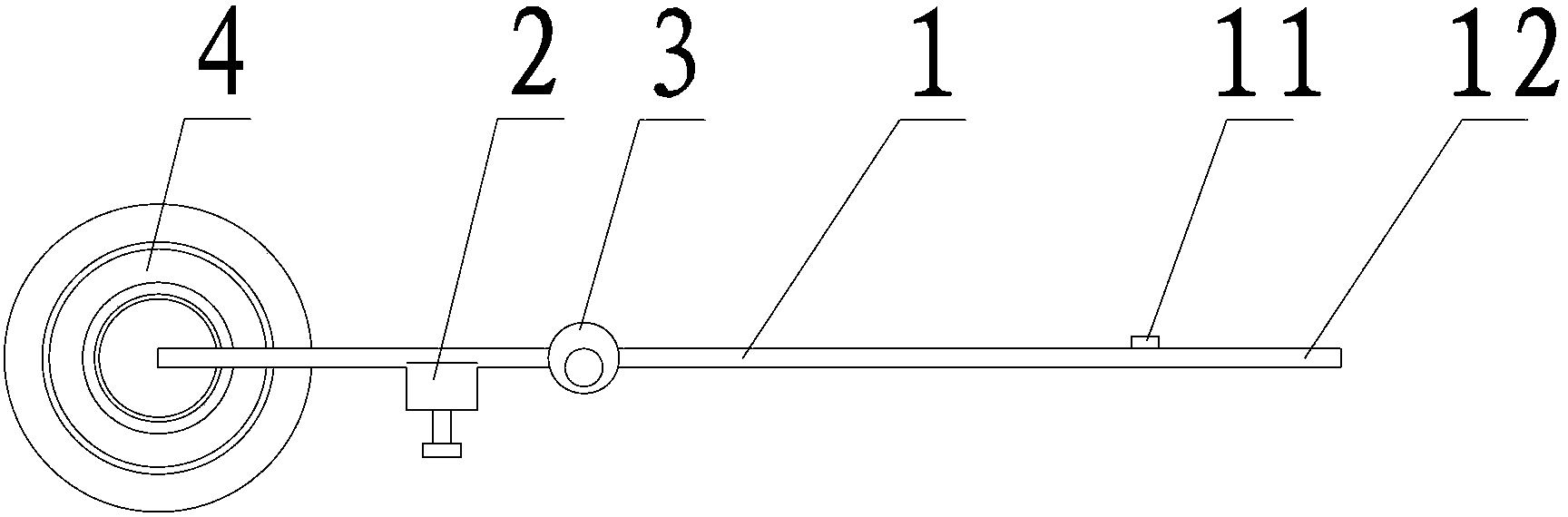

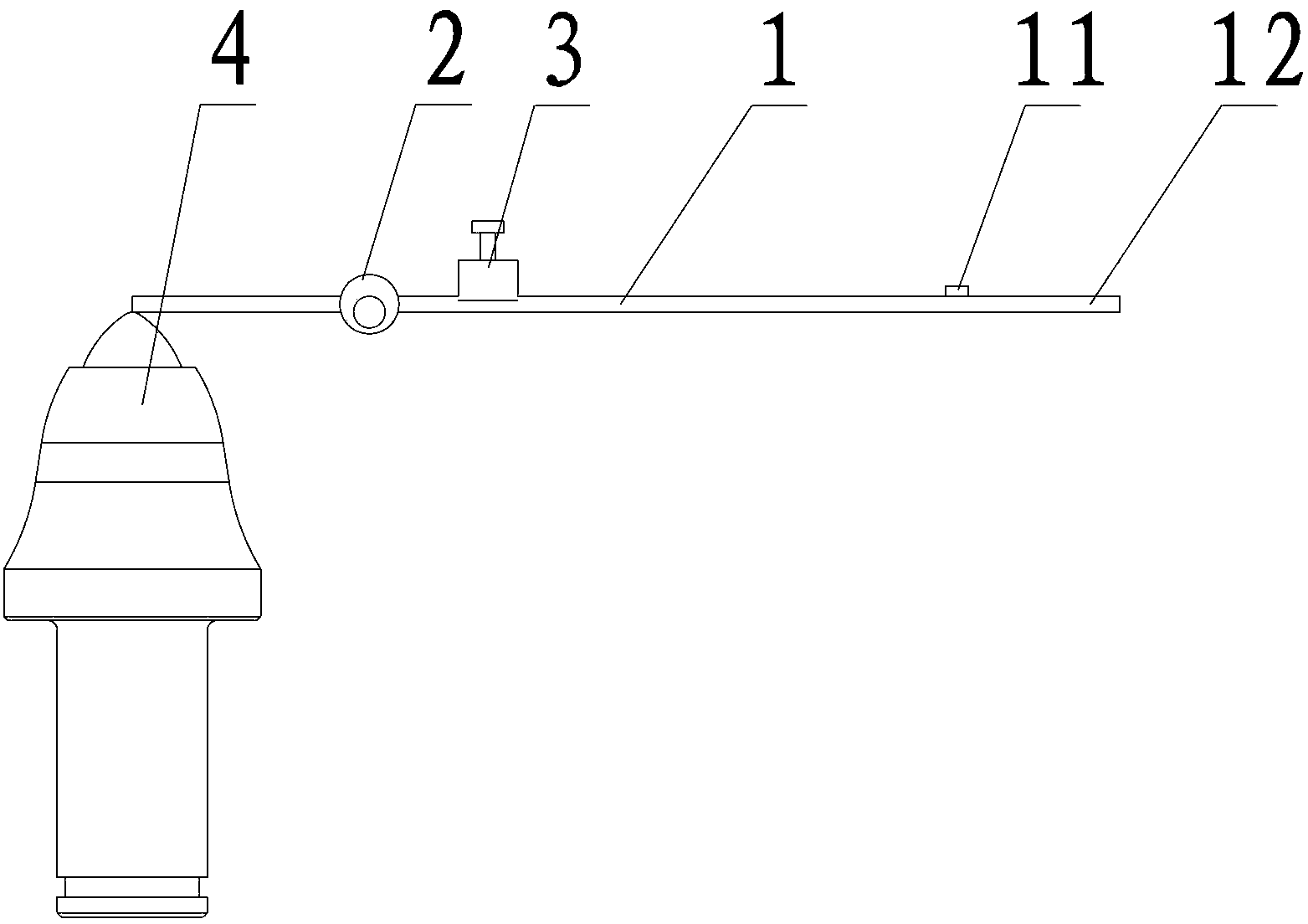

Positioning and assembling die for ceramic shell of vacuum switch tube

ActiveCN110060894AQuick positioning correctionImprove stabilityElectric switchesSoldering auxillary devicesEngineeringVacuum switch

The invention relates to a positioning and assembling die for a ceramic shell of a vacuum switch tube. The positioning and assembling die comprises a supporting plate, a placement sleeve, clamping devices, a lifting plate, a positioning air cylinder and an alignment device, wherein the placement sleeve is arranged on the top of the supporting plate, and the left end and the right end of the placement sleeve are provided with the clamping devices respectively; the alignment device is positioned above the placement sleeve; the top of the alignment device is connected with the lower end of the positioning air cylinder; the lifting plate is installed on the upper end of the positioning air cylinder, and mounting holes are uniformly formed in the lifting plate; and the alignment device comprises an alignment clamping sleeve, a locking clamping jaw, a buffer spring, an adjusting column, a clamping-pressing column, a clamping-pressing spring, a laminating plate, a pushing column and a pushingspring. According to the positioning and assembling die, the problems can be solved as follows: the welding effect of the switch tube is poor due to the fact that a certain error exists in manual operation in the prior art, a three-jaw chuck easily causes damage to the ceramic shell and the three-jaw chuck cannot be attached to the appearance of the ceramic shell when the ceramic shell is lockedby the three-jaw chuck.

Owner:JINHUA MINGZHENG TECH CO LTD

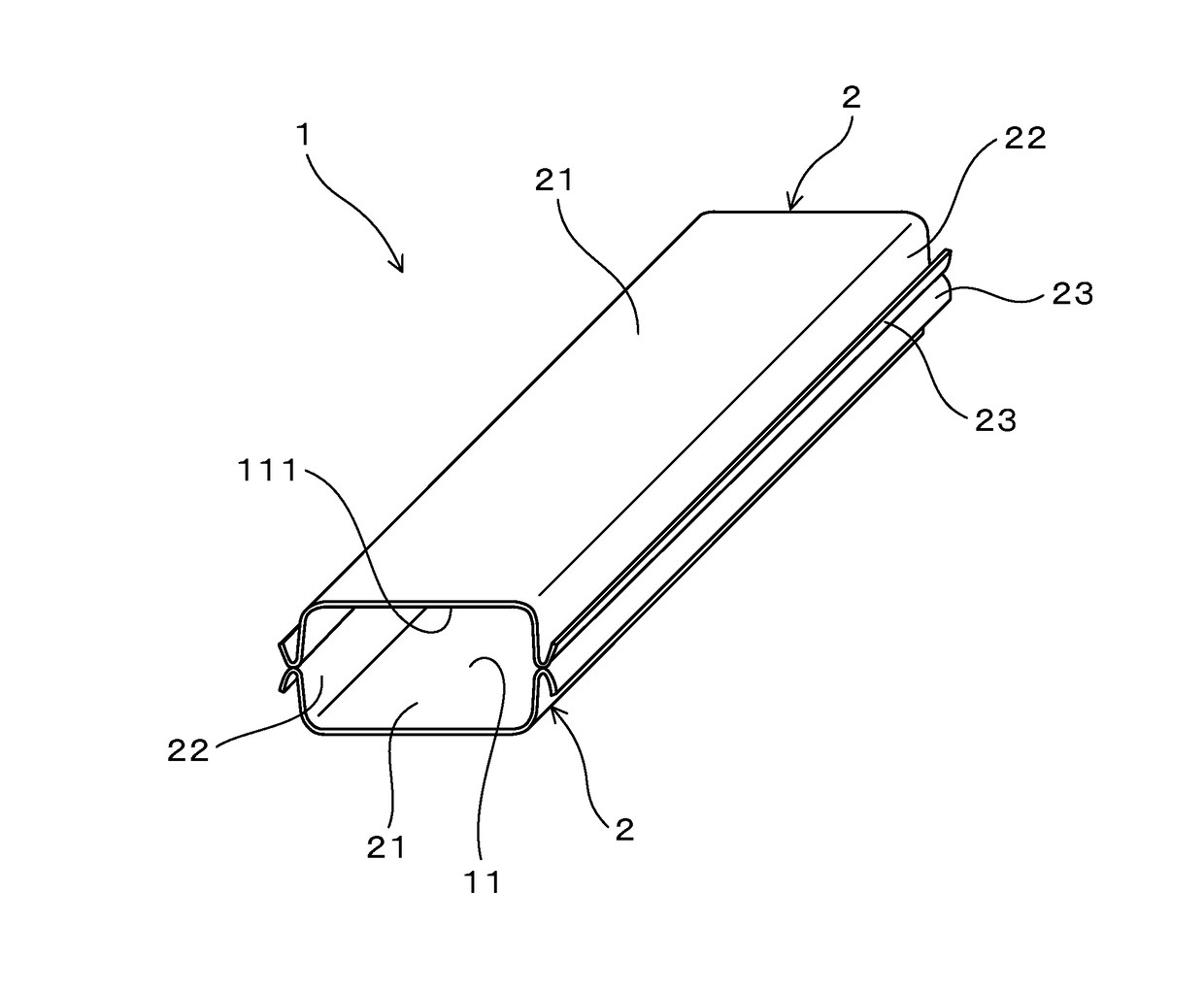

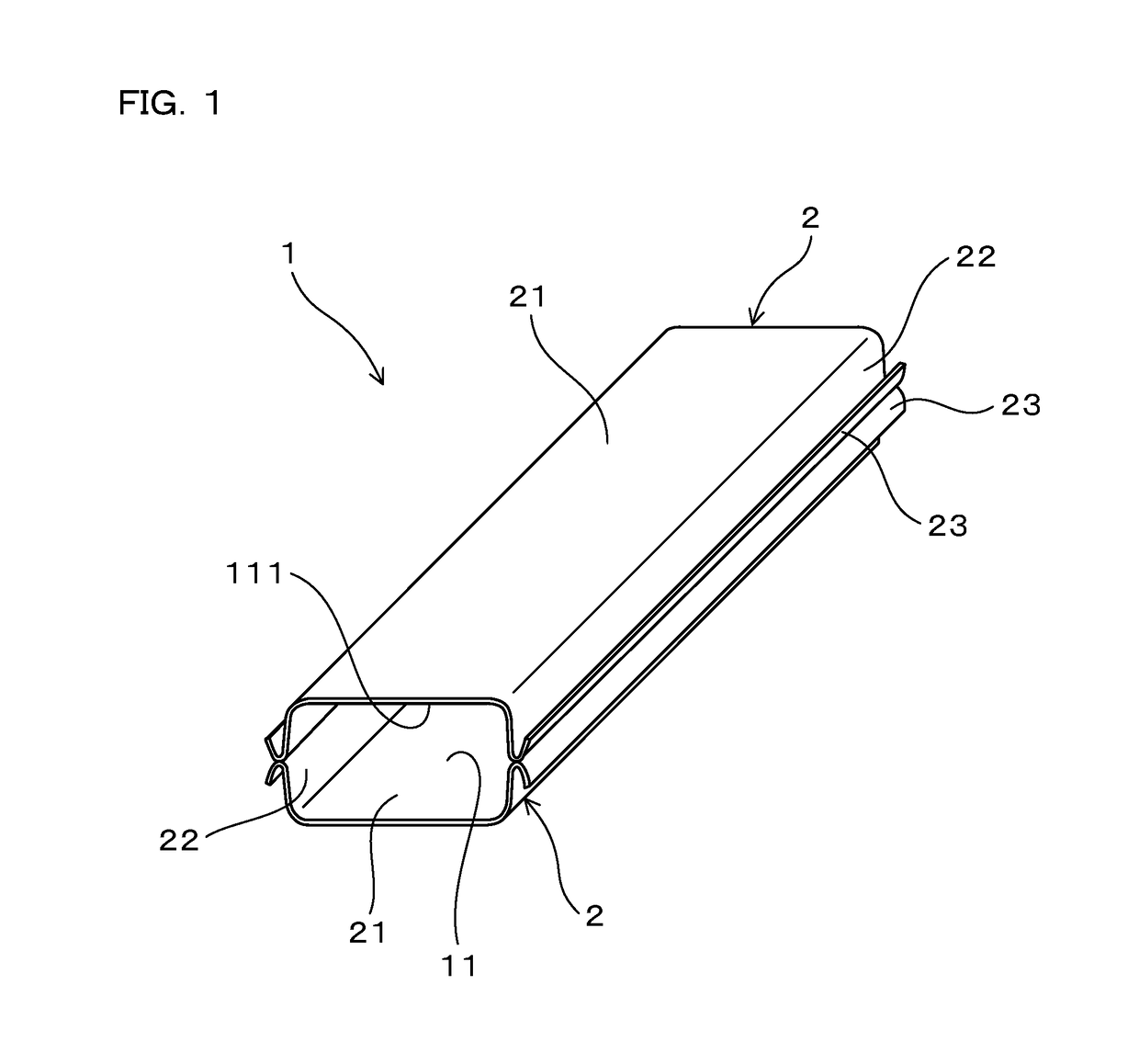

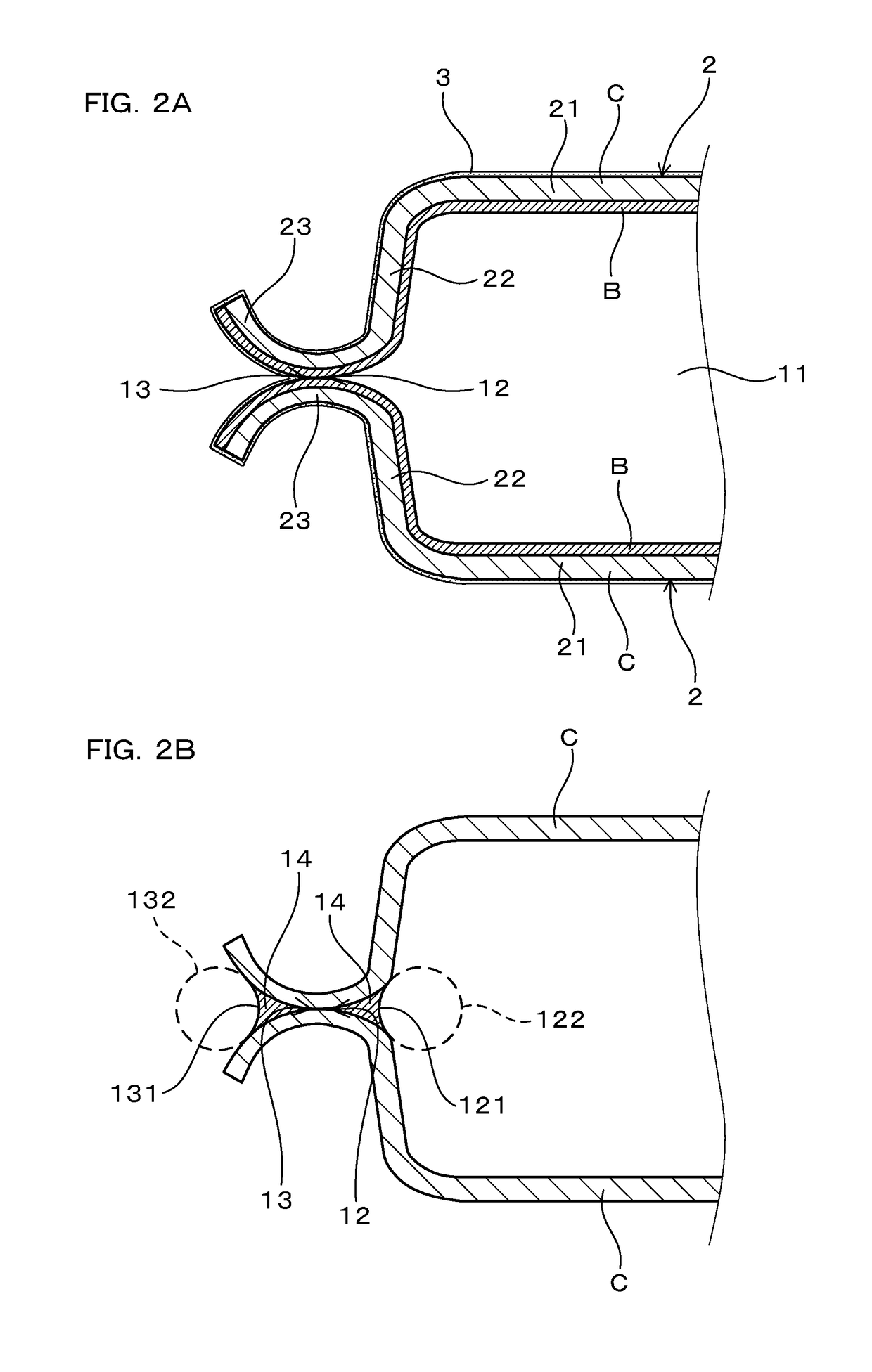

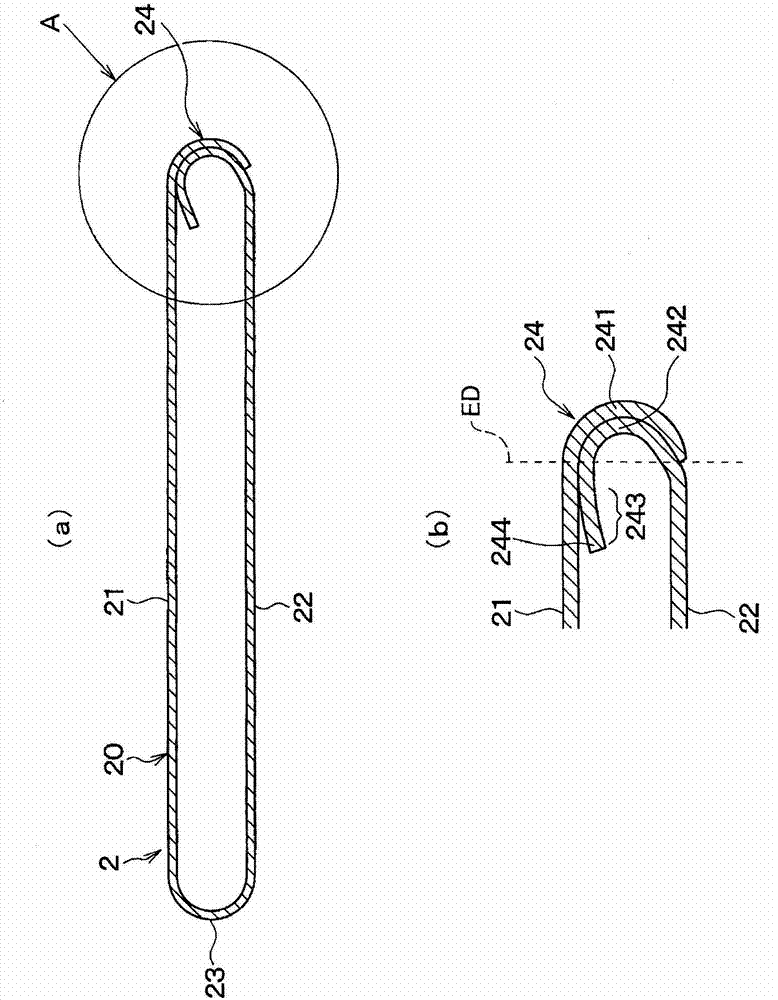

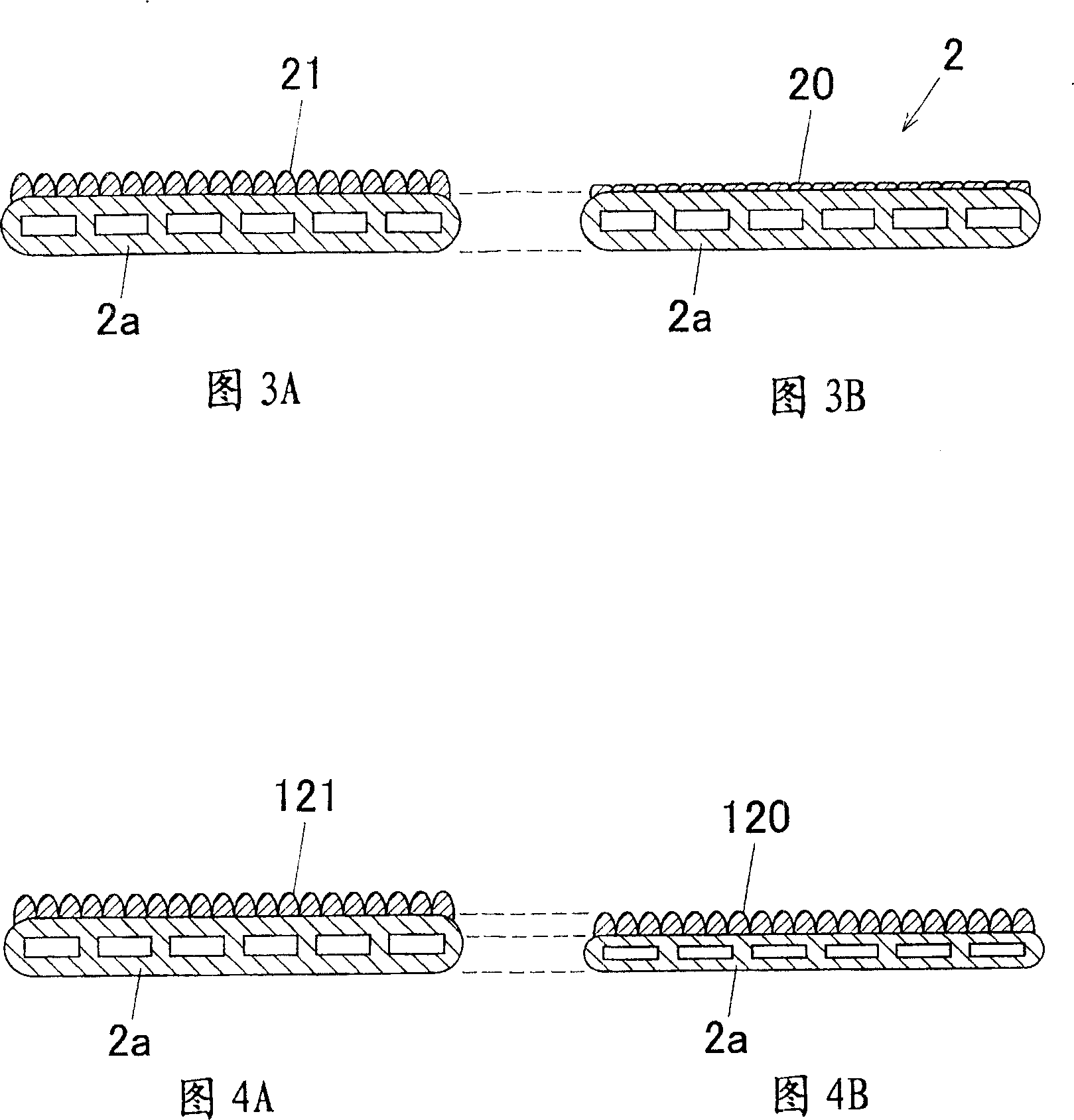

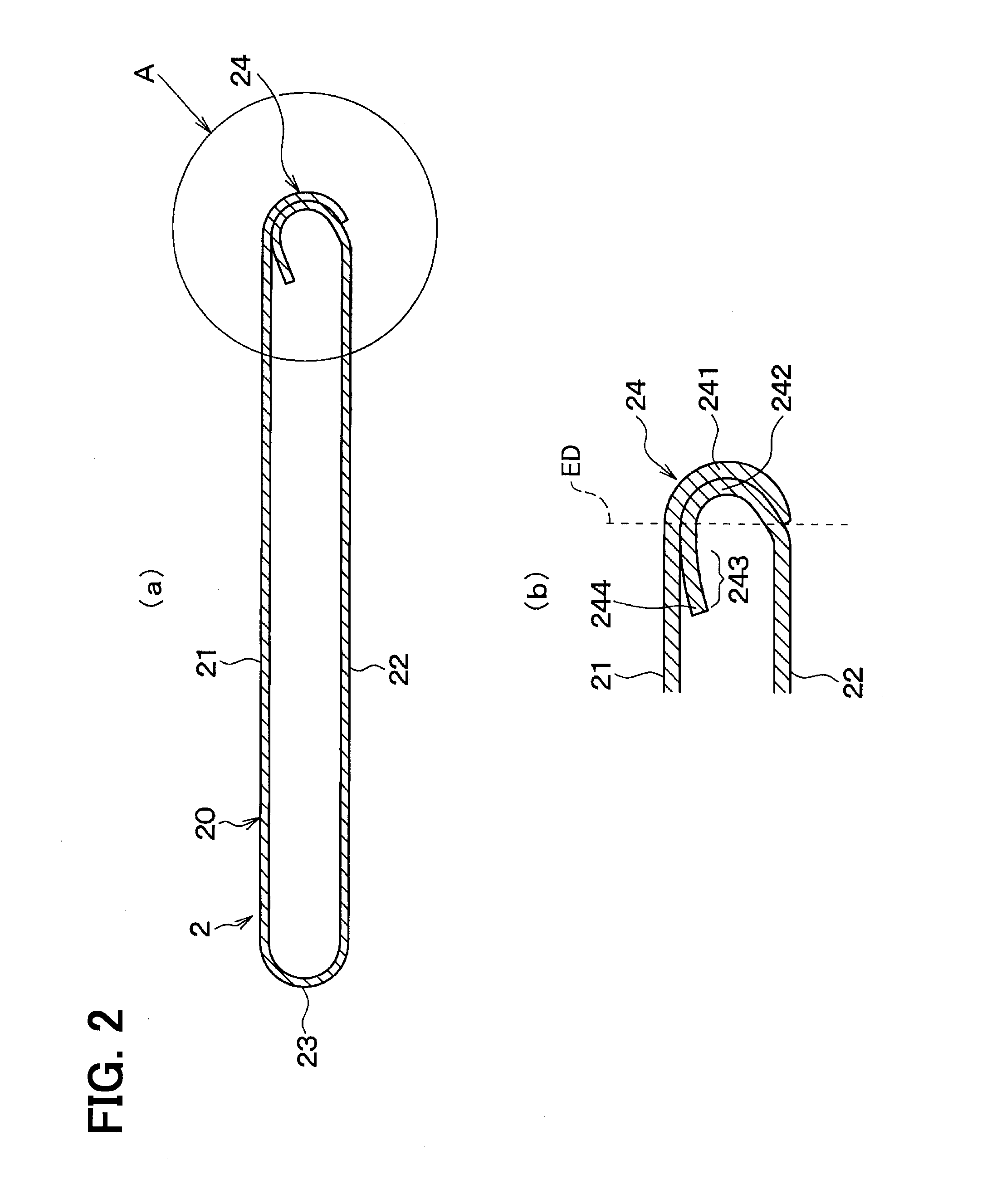

Tube for heat exchanger

InactiveCN103201582AGuaranteed adhesionImprove brazing performanceSoldering apparatusStationary conduit assembliesLong axisEngineering

A tubular member (20) that constitutes a tube for a heat exchanger comprises a pair of flat sections (21, 22) that are aligned in parallel so as to face one another in the short-axis direction of the channel cross section, and a pair of curved sections (23, 24) that face one another in the long-axis direction of the channel cross section and connect the pair of flat sections (21, 22) to one another. One of the curved sections (23, 24) constitutes a joint part at which an outer wall portion (241), which extends from an end of the pair of flat sections (21, 22) and constitutes a part of the outer wall of the tubular member (20), and an inner wall portion (242), which extends from an end of the pair of flat sections (21, 22) and constitutes a part of the inner wall of the tubular member (20), overlap and are joined by brazing. The inner wall portion (242) is joined in a manner such that the portion facing the outer wall (241) is closely adhered thereto, and the leading end (244) facing the flat section (21) is spaced apart from the flat section (21).

Owner:DENSO CORP

Heat exchanger tube, heat exchanger, and manufacturing method thereof

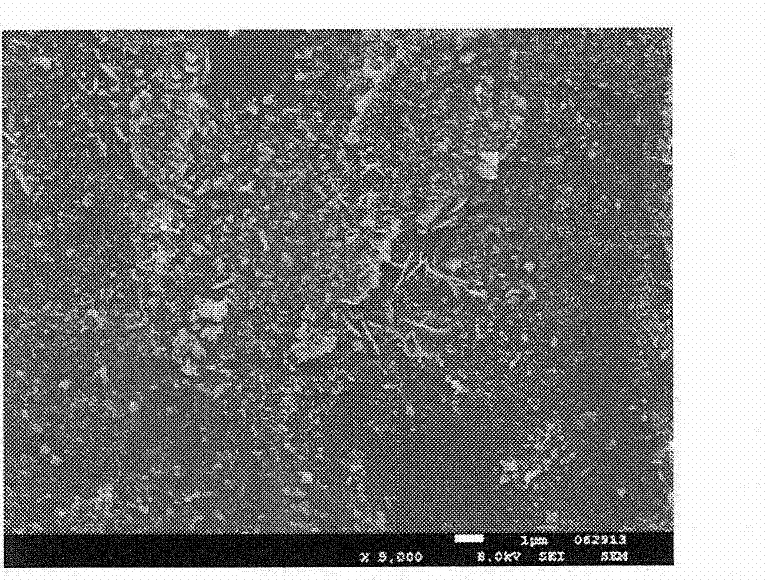

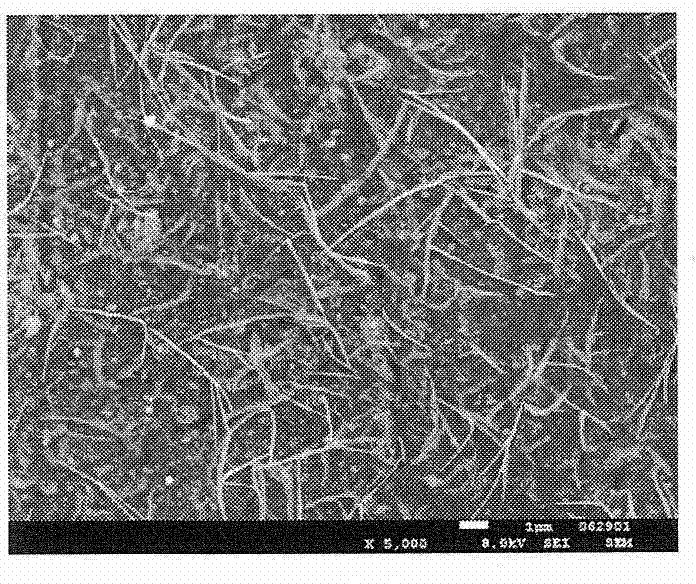

InactiveCN1964812AAvoid separationEnhanced fill (rate) rateSoldering apparatusStationary conduit assembliesMolten stateThermal spraying

This invention relates to a method of manufacturing an aluminum heat exchanger tube. In forming a thermally sprayed layer 21 on a surface of an aluminum flat tube by thermally spraying Al-Si alloy thermal-spraying particles, quenching the thermally sprayed thermal-spraying particles in a molten state to make them adhere to the tube core 2a. The surface of the thermally sprayed layer 21 is smoothed with, e.g., reduction rolls to form a brazing layer 20. With this method, brazing defects due to fin detachment, erosion to the tube of the brazing material, etc., can be prevented, resulting in good brazing performance.

Owner:SHOWA DENKO KK

Tube for heat exchanger

InactiveUS20130220585A1Improve brazing performanceSoldering apparatusStationary conduit assembliesEngineeringMechanical engineering

A cylindrical member of a tube for a heat exchanger is made of a pair of flat plate portions, and a pair of curved portions for connecting the pair of flat plate portions to each other. One of the pair of curved portions constructs a bonded portion in which an outer wall portion and an inner wall portion are bonded to each by brazing in a state where the outer wall portion and the inner wall portion overlap each other. The inner wall portion has a portion opposite to the outer wall portion put into close contact with the outer wall portion and is bonded to the one flat plate portion in a state where a tip end portion of the inner wall portion opposite to the one flat plate portion is separated from the one flat plate portion.

Owner:DENSO CORP

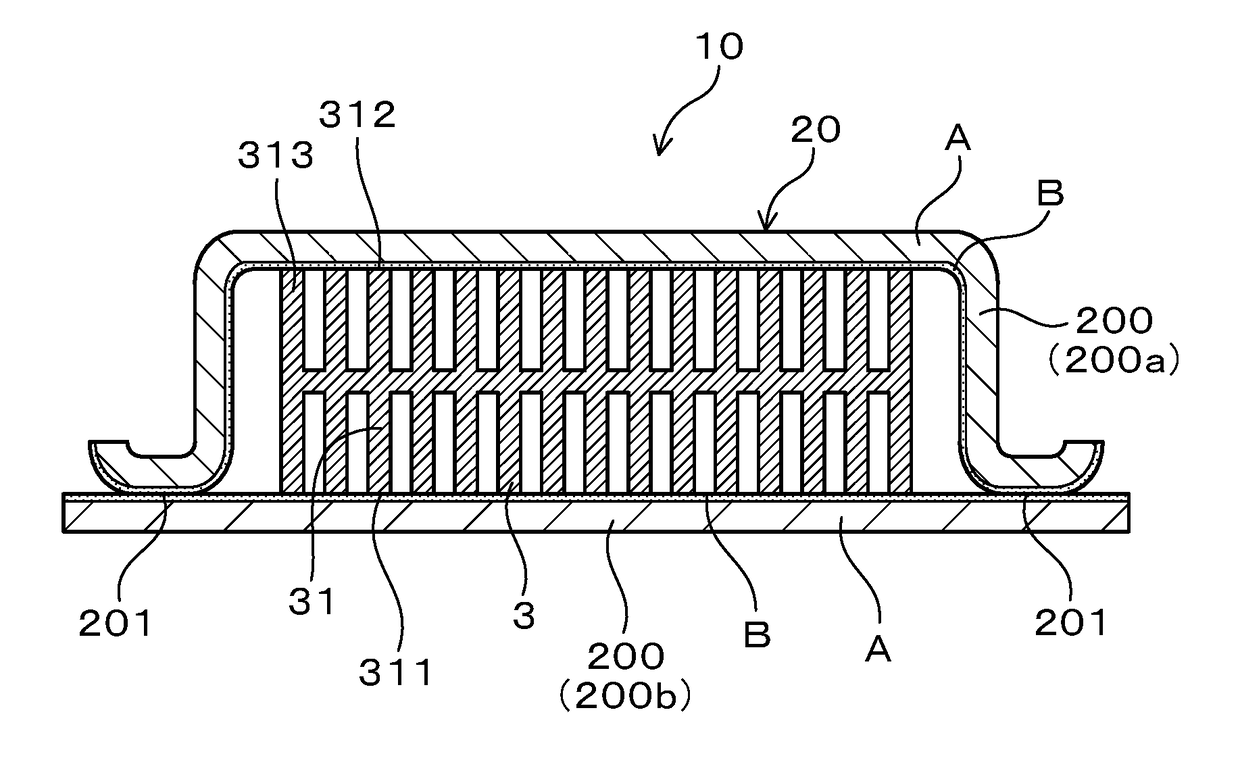

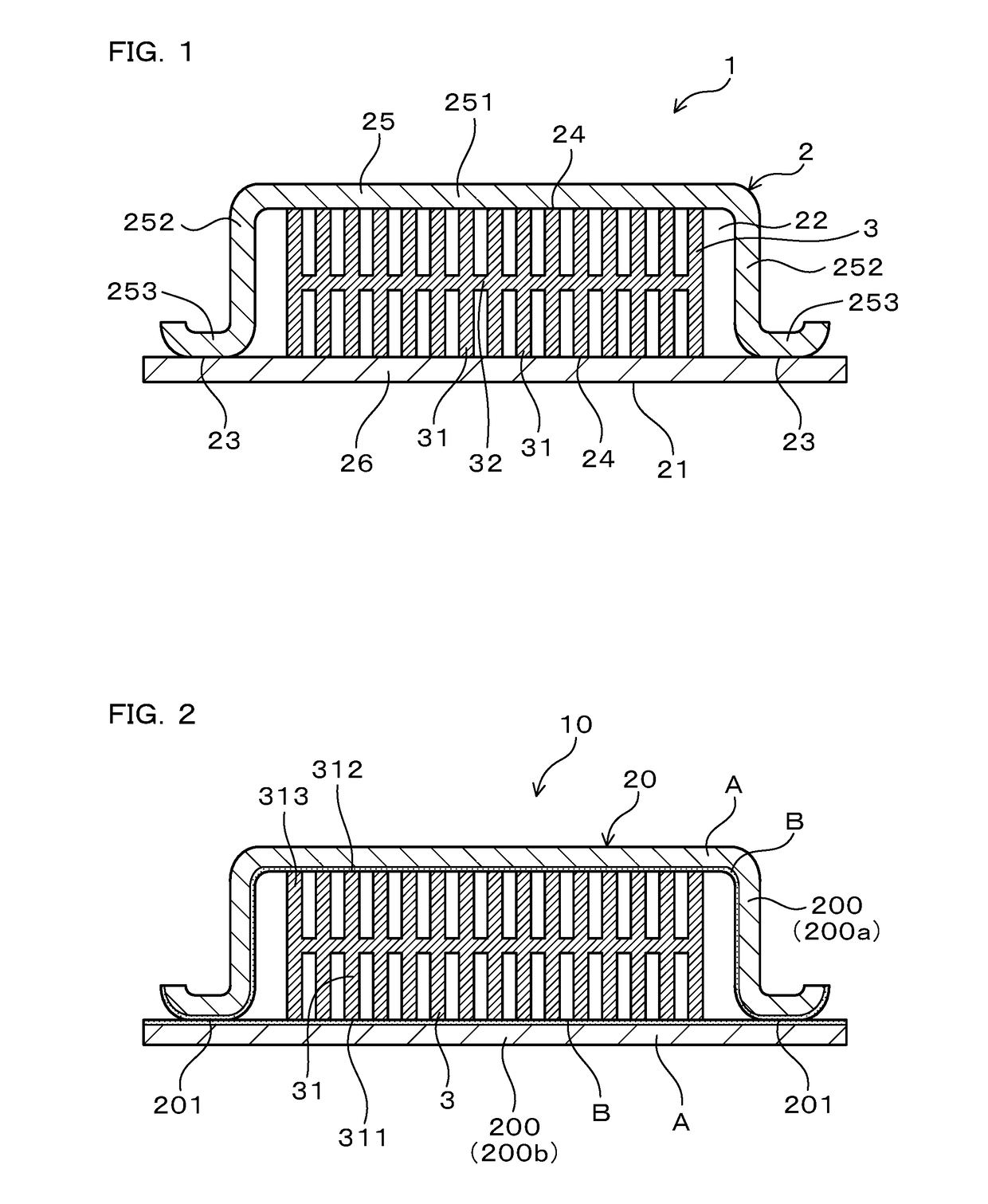

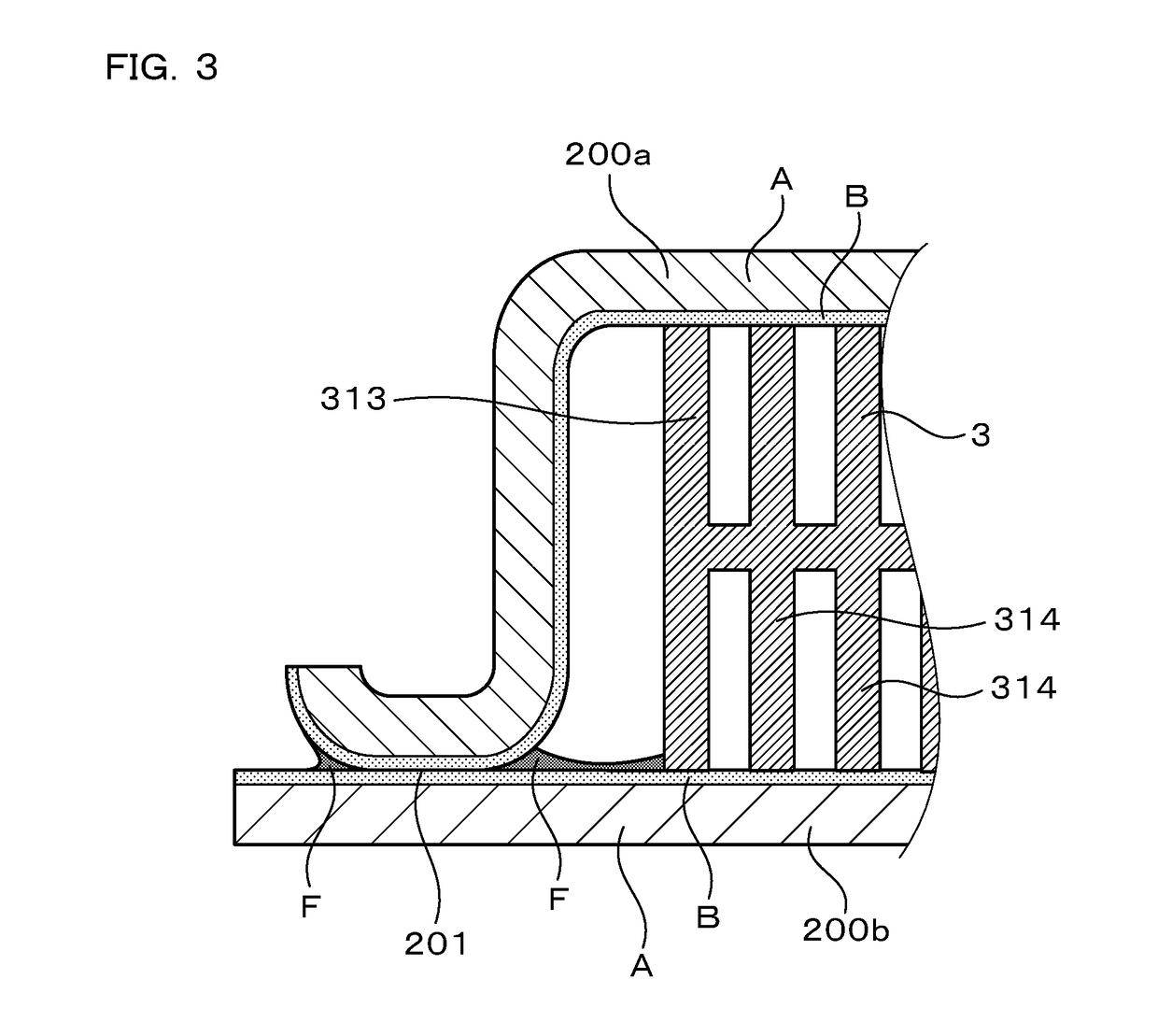

Heat exchanger and method of manufacturing the same

InactiveUS20170205160A1Strong and effective brazed jointEasy to prepareStationary conduit assembliesWelding/cutting media/materialsFiller metalHeat exchanger

A method for manufacturing a heat exchanger (1) includes joining an inner fin (3) to a hollow structure (20) formed from at least two clad plates (200a, 200b) by heating and brazing a filler metal layer (B). Each clad plate has a core layer (A) composed of an aluminum alloy that contains Mg: 0.40-1.0 mass %. The filler metal layer is composed of an aluminum alloy that contains Si: 4.0-13.0 mass %, and further contains Li: 0.0040-0.10 mass %, Be: 0.0040-0.10 mass %, and / or Bi: 0.01-0.30 mass %. The inner fin is composed of an aluminum alloy that contains Si: 0.30-0.70 mass % and Mg: 0.35-0.80 mass %. A flux (F) that contains cesium (Cs) is applied along a contact part (201), and the vicinity thereof, of the at least two clad plates prior to the heating. A heat exchanger (1) may be manufactured according to this method.

Owner:FURUKAWA SKY ALUMINUM CORP

Aluminum alloy brazing sheet and brazing method

InactiveCN106794556AImprove brazing performanceStable solderabilityWelding/cutting media/materialsWelding/soldering/cutting articlesImpurityAtmosphere

The purpose of the invention of the present application is to provide an aluminum alloy brazing sheet able to achieve excellent brazing properties by effectively weakening an oxide film on a brazing surface. This aluminum alloy brazing sheet is obtained by cladding a brazing material, which contains 6-13% of Si, with the remainder consisting of Al and unavoidable impurities, on one or both surfaces of an aluminum alloy core material and is used to braze aluminum in an inert gas atmosphere or in a vacuum, wherein the aluminum alloy brazing sheet is characterized in that cladding is effected by interposing a plate-like material between the core material and the brazing material, the plate-like material containing one or more elements selected from among 0.05% or more of Li, 0.05% or more of Be, 0.05% or more of Ba, 0.05% or more of Ca and 0.4% or more of Mg, with the remainder consisting of Al and unavoidable impurities.

Owner:UACJ CORP

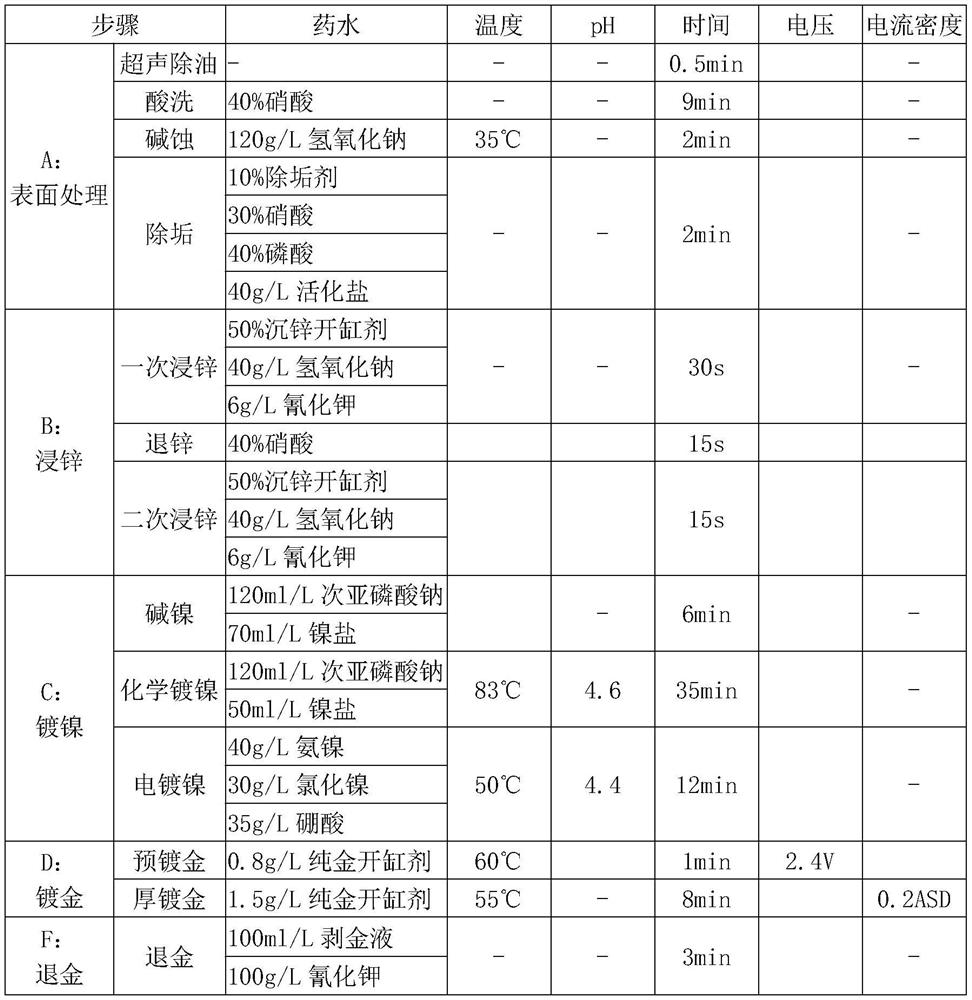

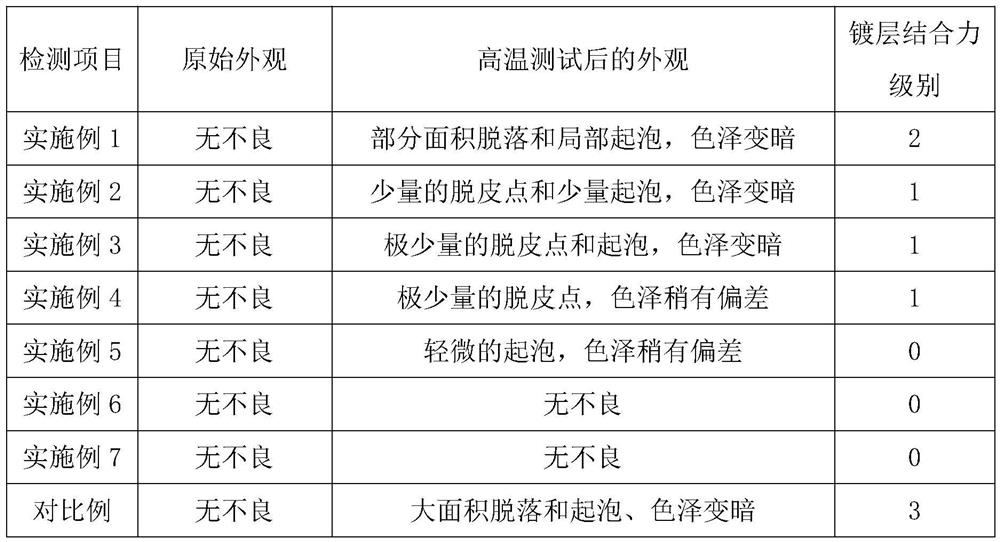

Aluminum material surface local gold plating process

InactiveCN112126929AImprove brazing performanceImprove bindingLiquid/solution decomposition chemical coatingSuperimposed coating processGold platingNickel coating

The invention relates to the field of gold plating technologies, in particular to an aluminum material surface local gold plating process. The process comprises the following steps of removing impurities on the surface of an aluminum material; immersing the aluminum material treated in the step A into a zinc dipping solution, reacting until a zinc coating is formed on the surface of the aluminum material, and performing washing with water; immersing the aluminum material subjected to zinc immersion in the step B into a nickel plating solution, reacting until a nickel plating layer is formed onthe surface of the aluminum material, and performing washing with water; immersing the aluminum material subjected to nickel plating in the step C into a gold plating solution, reacting until a goldplating layer is formed on the surface of the aluminum material, performing washing with water, and performing drying; dividing the surface of the aluminum material plated with gold in the step D intoa gold plating area and a non-gold plating area, and wrapping the surface of the gold plating area with a layer of shielding material; and immersing the aluminum material subjected to local shieldinginto a gold stripping mixed solution, reacting until the gold plating layer of the non-gold-plating area of the aluminum material disappears, performing washing with water after the nickel plating layer is completely exposed, and performing drying to obtain a local gold-plating plated part. The process has the effect of improving the binding force between the plating layer and the plated part.

Owner:深圳市海里表面技术处理有限公司

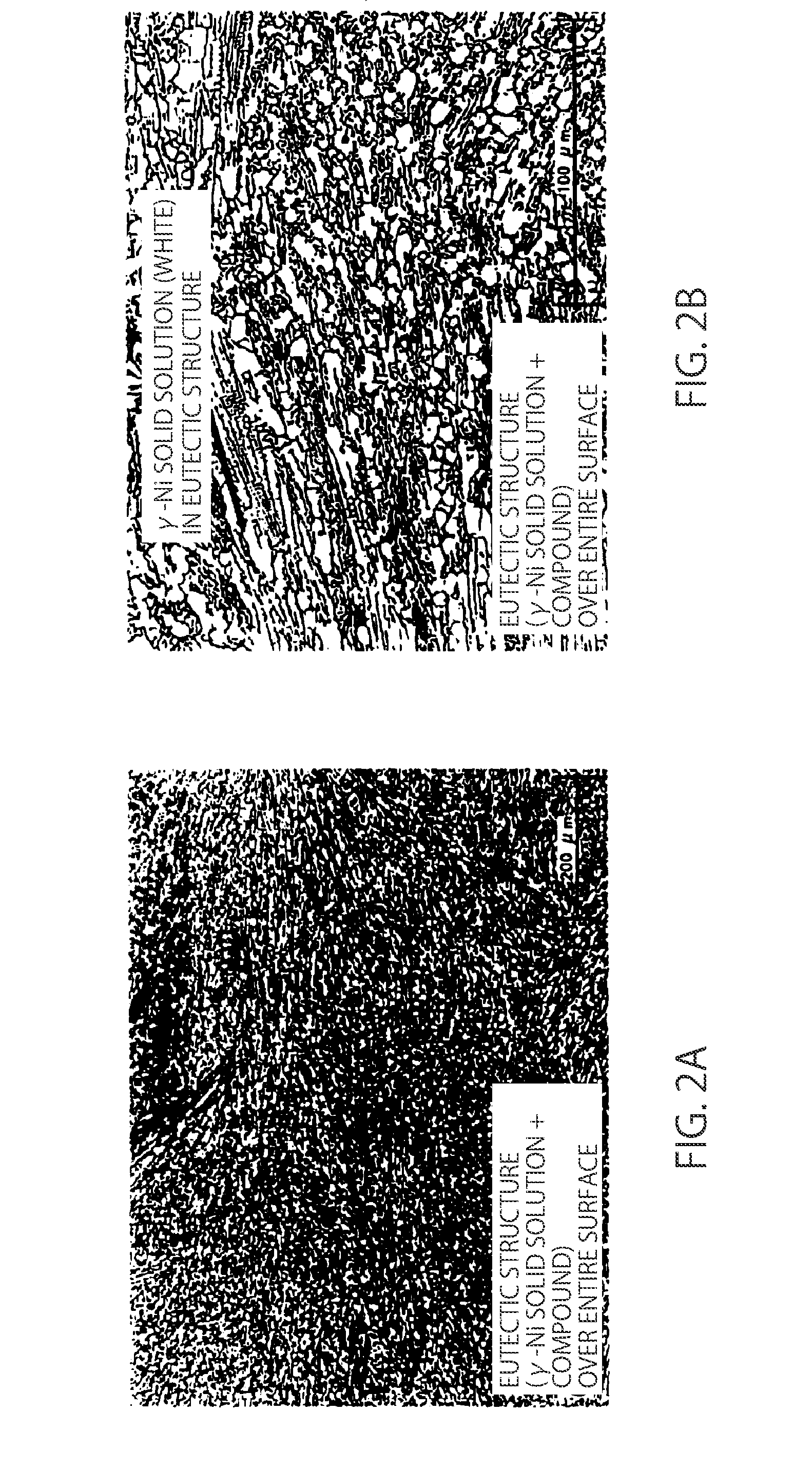

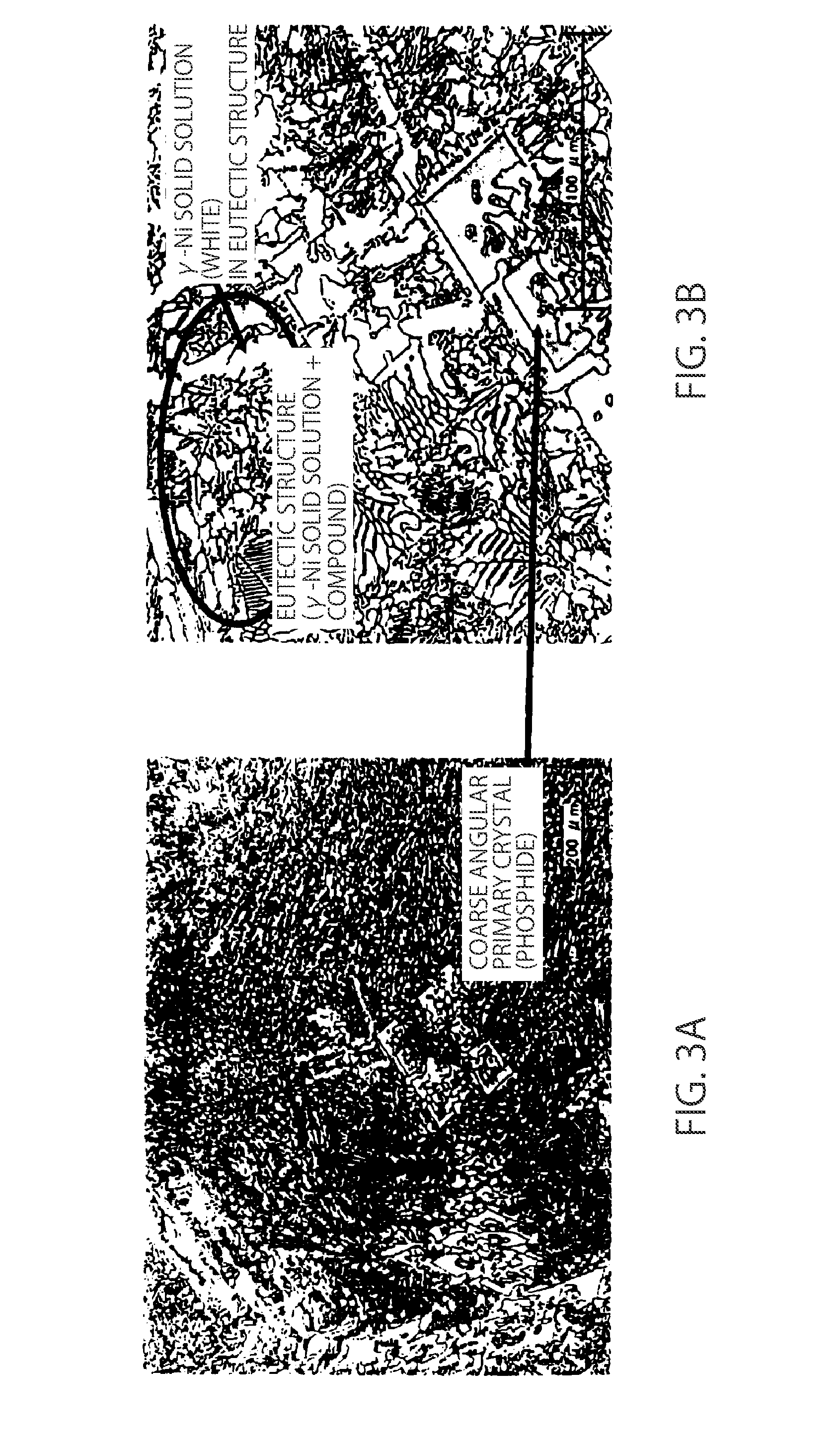

Cu-Added Ni-Cr-Fe-Based Alloy Brazing Material

InactiveUS20160175992A1Lower melting temperatureImprove corrosion resistanceWelding/cutting media/materialsHeat exchange apparatusFilling materialsCopper

There is provided a Ni—Cr—Fe-based alloy brazing filler material to which Cu is added, and which has a low melting temperature, and is inexpensive and excellent in corrosion resistance and in strength, for use in manufacture of stainless-steel heat exchangers or the like, specifically, a Ni—Cr—Fe-based alloy brazing filler material, including, in mass %, Cr: 15 to 30%; Fe: 15 to 30%; Cu: 2.1 to 7.5%; P: 3 to 12%; and Si: 0 to 8%; and the balance being Ni and unavoidable impurities, wherein the total content of Cr and Fe is 30 to 54%, and the total content of P and Si is 7 to 14%.

Owner:SANYO SPECIAL STEEL COMPANY

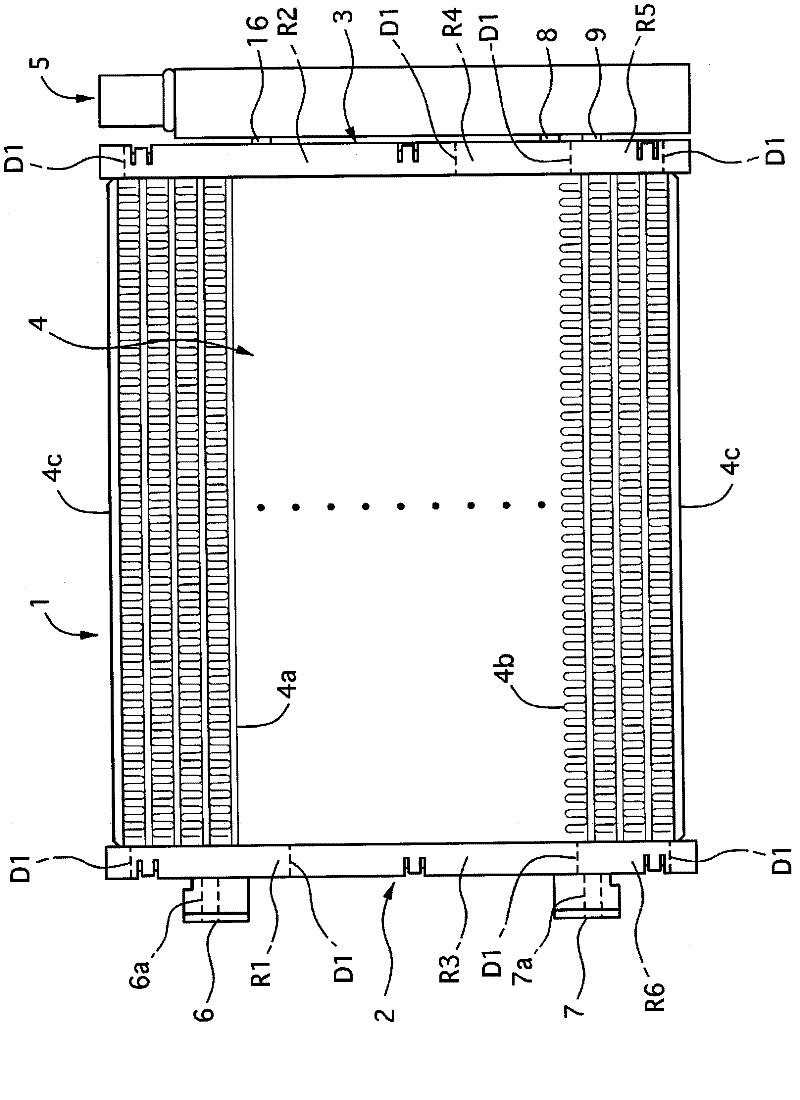

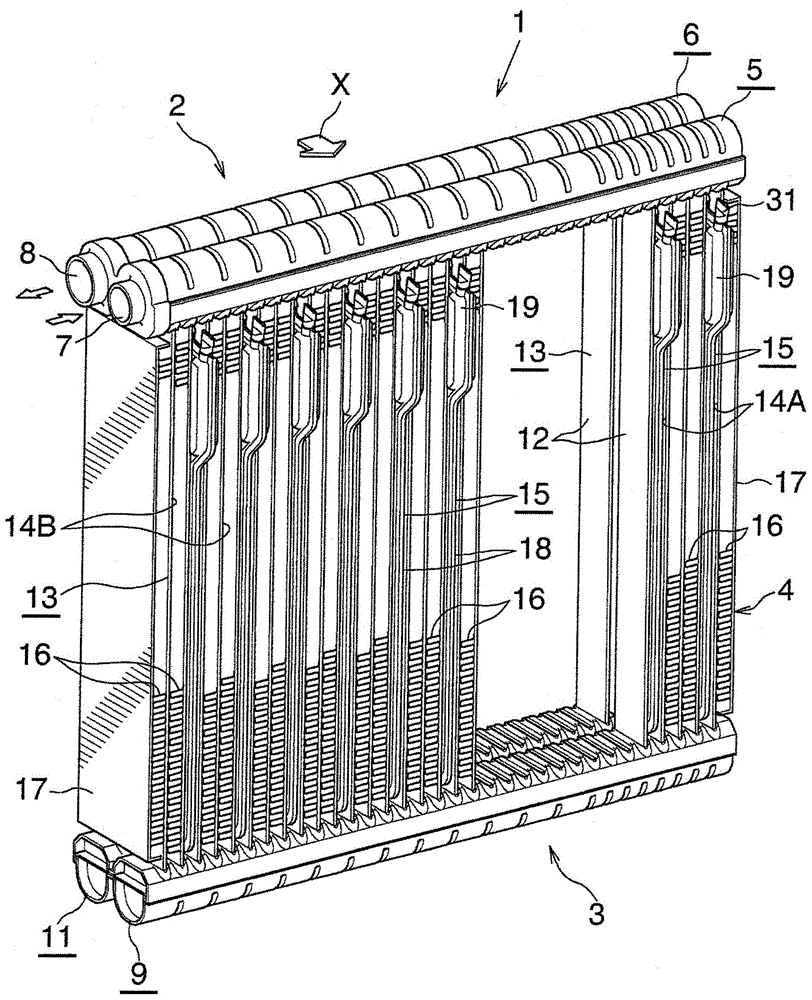

Heat Exchanger

ActiveCN103090695ASecure joint workspaceAvoid heat damageEvaporators/condensersSoldering apparatusMechanical engineeringHeat exchanger

A heat exchanger 1 includes a pair of tanks 2 and 3 arranged a certain distance apart from each other, a plurality of tubes 4a whose both end portions are connected with the pair of tanks 2 and 3, a long receiver tank 5 arranged along and adjacently to the tank 3 and communicatably connected with the tank 3, and a reception member 20 contained in the receiver tank 5. An upper opening end portion 13b has an opening portion at one side in a longitudinal direction of the receiver tank 5 and having a reduced diameter, and a block member 15 blocks the upper opening end portion 13b. An entire of the heat exchanger 1 except the reception member 20 and the block member 15 are integrally formed by a brazing process. The reception member 20 is inserted through the upper opening end portion 13b and arranged in the receiver tank 5 after the brazing process, and then the block member 15 is joined by brazing with the upper opening end portion 13b after the reception member 20 is inserted and arranged therein.

Owner:CALSONIC KANSEI CORP

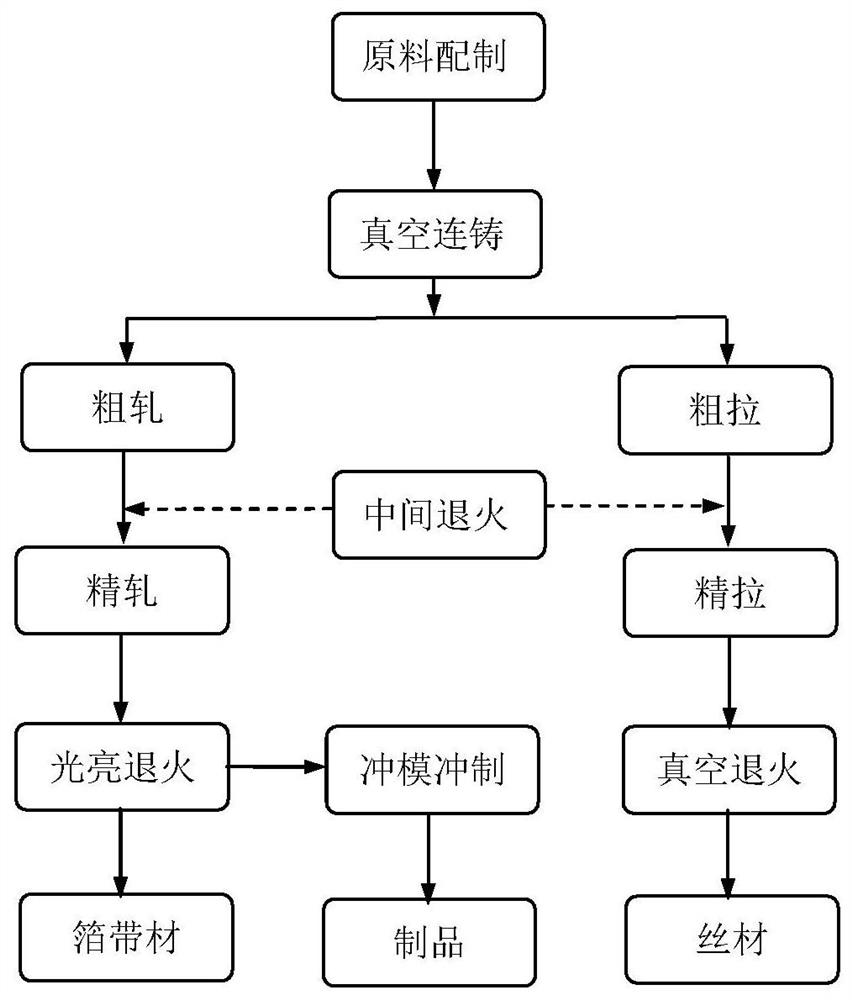

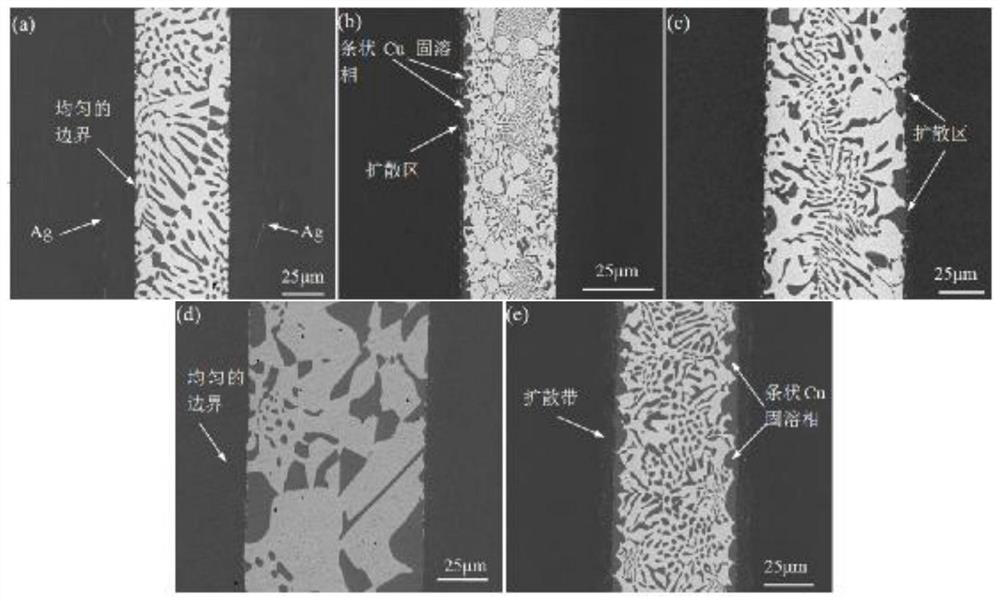

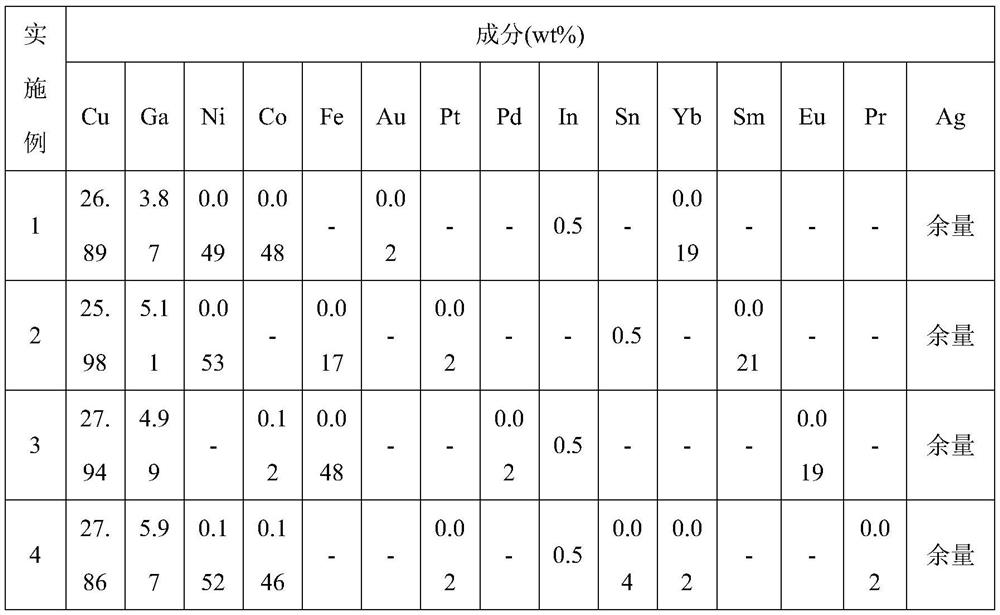

Silver-based brazing filler metal alloy, preparation method of silver-based brazing filler metal alloy, and preparation methods of foil strip and wire

ActiveCN112059468ASolve the problem of high welding temperature and inconsistent melting pointEliminates nickel plating processWelding/cutting media/materialsSoldering mediaUltimate tensile strengthFiller metal

The invention discloses a silver-based brazing filler metal alloy. The silver-based brazing filler metal alloy comprises the following components of, in percentage by mass, 26%-28% of Cu; 3.5%-5.5% ofGa; at least two of the following elements of 0.001%-0.5% of Ni; 0.001%-0.5% of Co; 0.001%-0.5% of Fe; at least one of the following elements of 0.001%-0.5% of Au; 0.001%-0.5% of Pt; 0.001%-0.5% of Pd; at least one of the following elements of 0.001%-0.5% of In; 0.001%-0.5% of Sn; at least one of the following elements of La, Ce, Pr, Nd, Sm, Eu, Er, Yb, Y and Sc; and the balance Ag. The inventionfurther provides a preparation method of the silver-based brazing filler metal alloy and preparation methods of a foil strip and a wire. When the silver-based brazing filler metal alloy is used for welding a vacuum electronic device, a nickel plating process is omitted, and environmental pollution is prevented; meanwhile, the problems of high welding temperature and inconsistent melt flow pointsof Ag-28Cu-xNi alloy are solved; and the brazing filler metal alloy is good in brazing manufacturability and good in wettability, the brazing rate of kovar alloy, stainless steel and the like is higher than 95%, and the shear strength sigma b of a brazed joint is larger than or equal to 285 MPa.

Owner:KUNMING INST OF PRECIOUS METALS

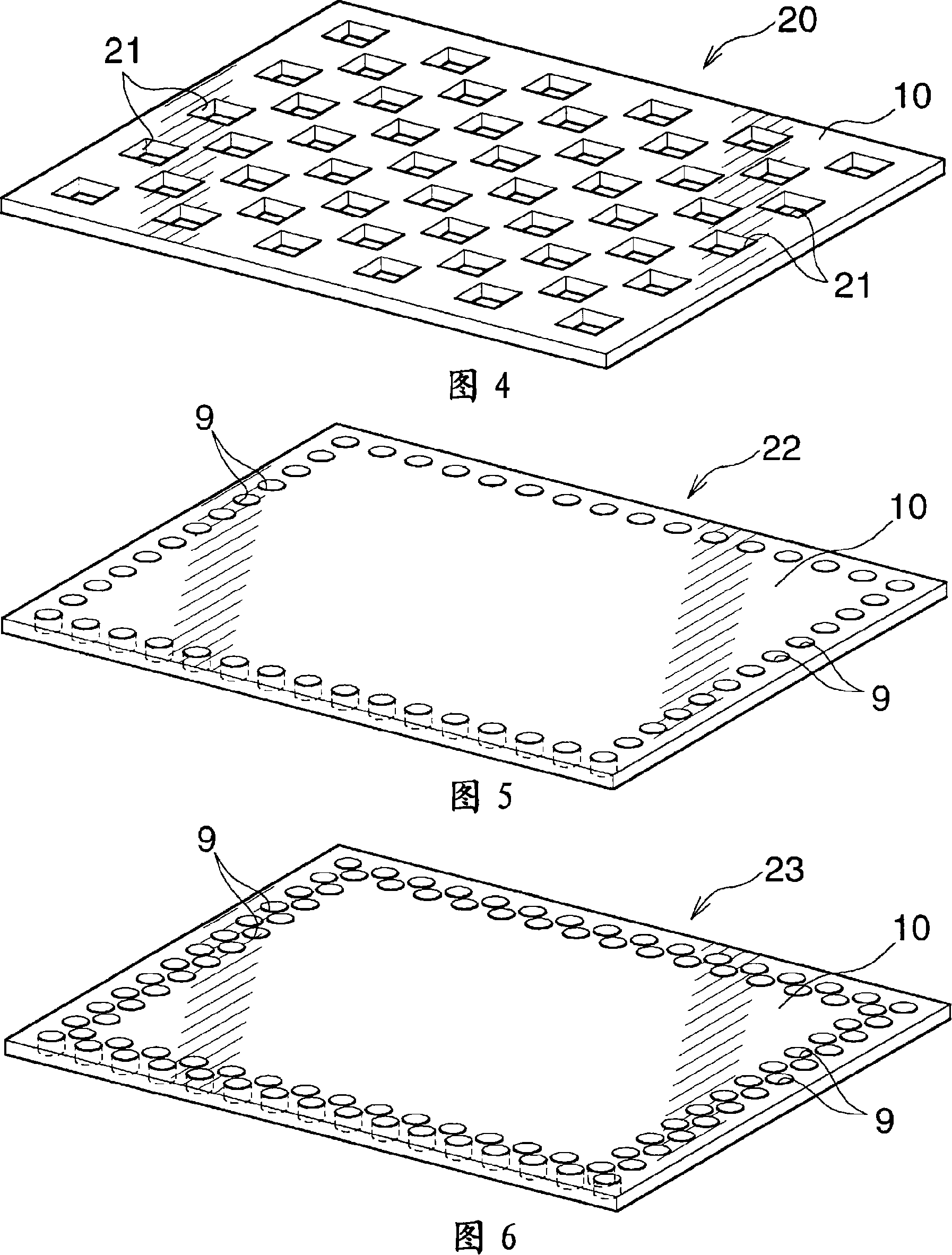

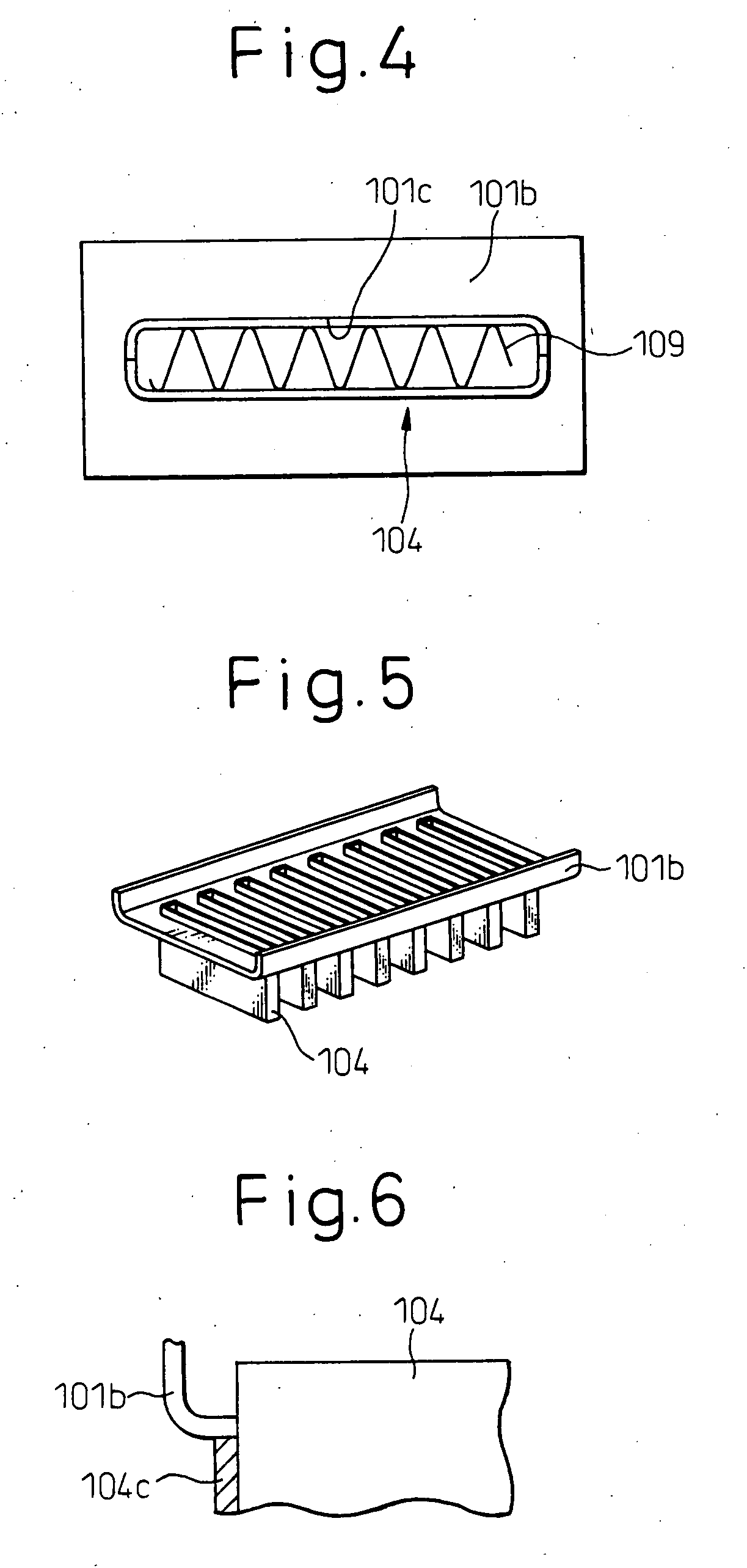

Heat exchanger

InactiveUS20070187081A1Excellent brazeabilityManufactured smallInternal combustion piston enginesStationary conduit assembliesMechanical engineeringHeat exchanger

A heat exchanger comprising: a plurality of tubes inside of which a fluid passes; fins which are joined to the outer surfaces of the tubes and promote heat exchange between a fluid passing around the tubes and the fluid passing through inside the tube; and tank sections comprising core plates having insertion holes formed for the tubes to be inserted therein and tank bodies having the core plates joined thereto for distributing or collecting the fluid to be passed through the tubes; the tube comprises a first and a second tube plates joined in opposition to each other and inner fins disposed between the first and second tube plates, and that the portion of the tube to be inserted into the insertion hole of the core plate has generally the same outer shape as the periphery of the insertion hole, and that the portions of the first and second tube plates not to be inserted into the insertion hole of the core plate have overlapping sections which overlap each other in laminating direction of the tubes.

Owner:DENSO CORP

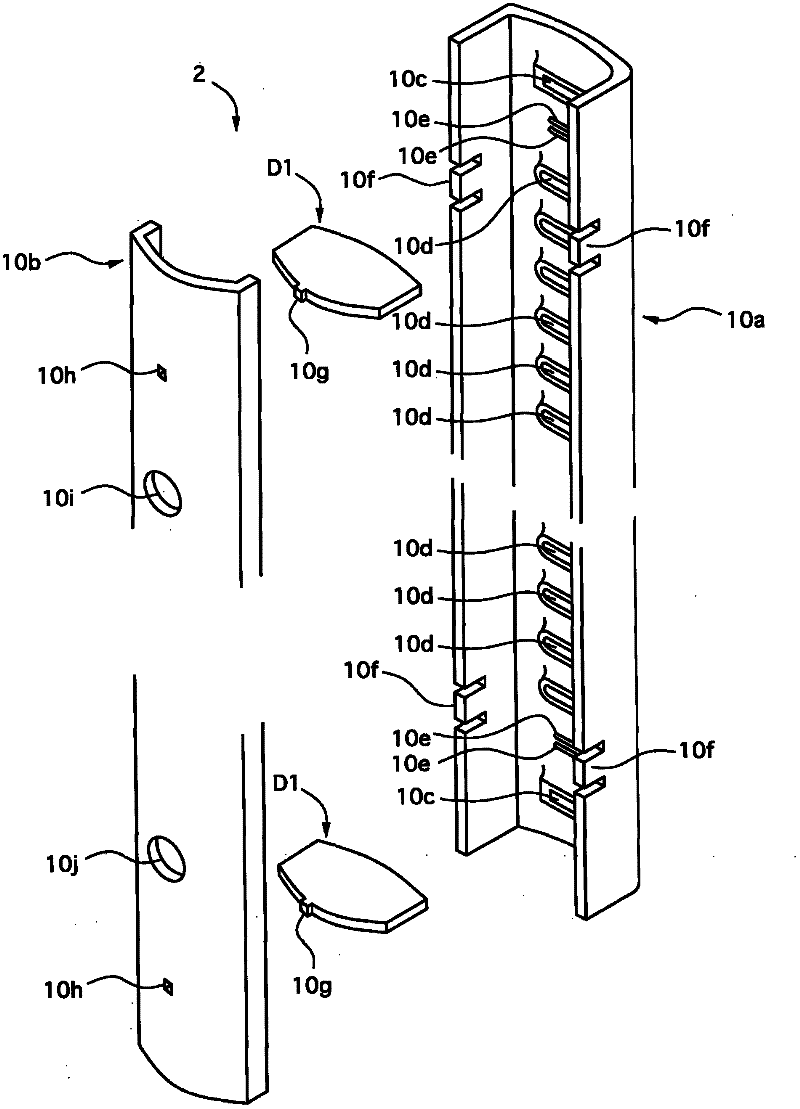

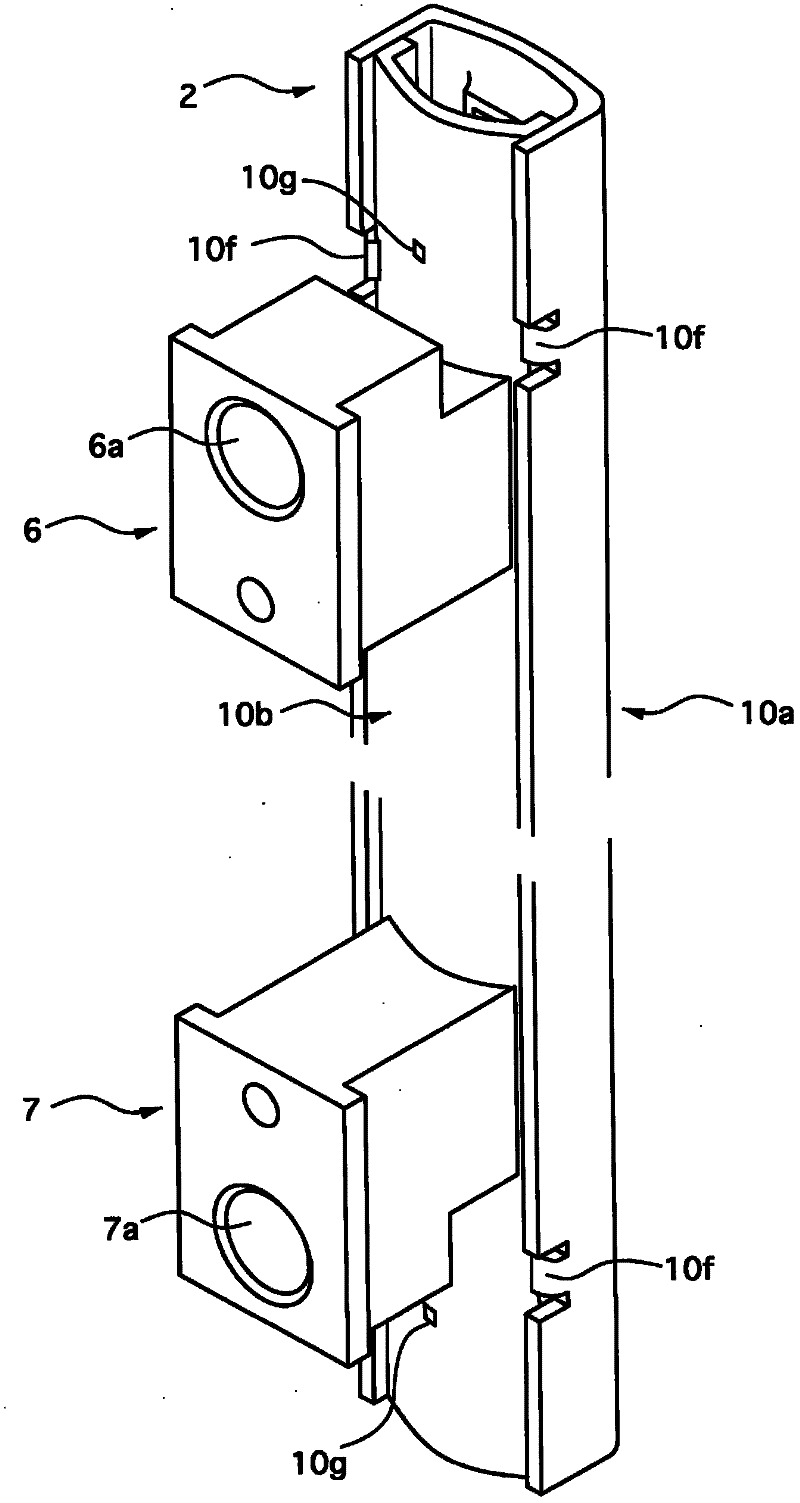

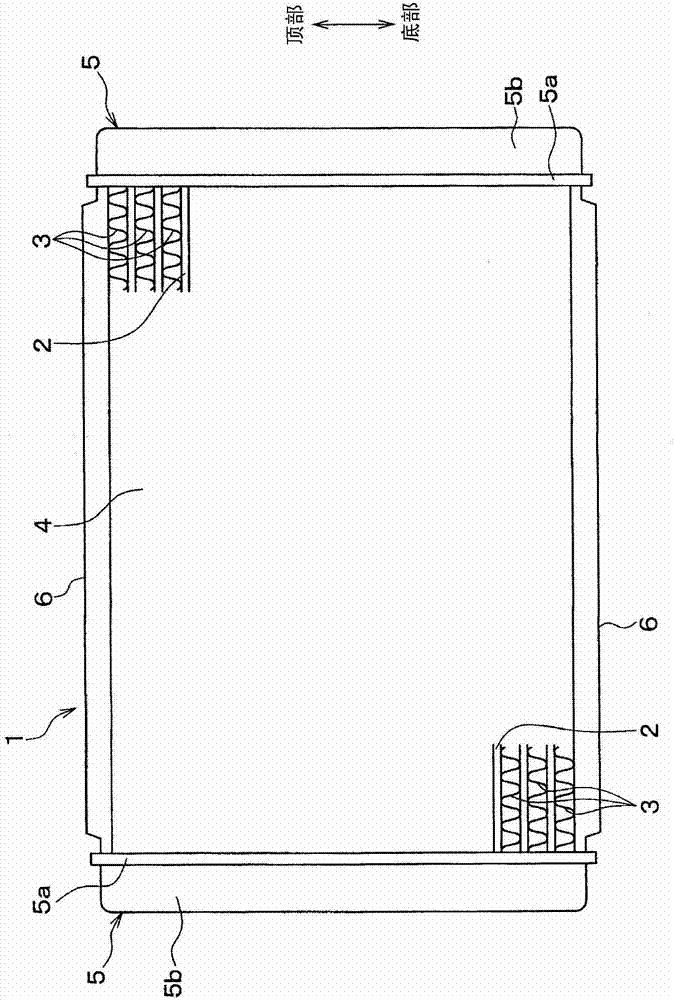

Heat exchanger with thermal storage function

InactiveCN104613681APrevent leakageAvoid misalignmentHeat storage plantsEvaporators/condensersPlate heat exchangerCool storage

Owner:KEIHIN THERMAL TECH CORP

Aluminum alloy radiating fin for heat exchanger

The invention relates to an aluminum alloy radiating fin for a heat exchanger. The aluminum alloy radiating fin comprises the composition by the weight percentage: 0.3-0.5% of silicon, 1.8-2.0% of manganese, 0.05-0.08% of nickel, 0.3-0.5% of copper, 0.01-0.03% of magnesium, 0.1-0.3% of iron, 1.5-2.0% of zinc, 0.001-0.0015% of yttrium, 0.01-0.03% of titanium, 0.0001-0.00015% of boron, and the balance being aluminum and inevitable impurities. Wall thinning and weight lightening of the aluminum alloy radiating fin for the heat exchanger become possible, and in addition, the reliability of a heat radiating fin material and the heat exchanger is improved.

Owner:吴高峰

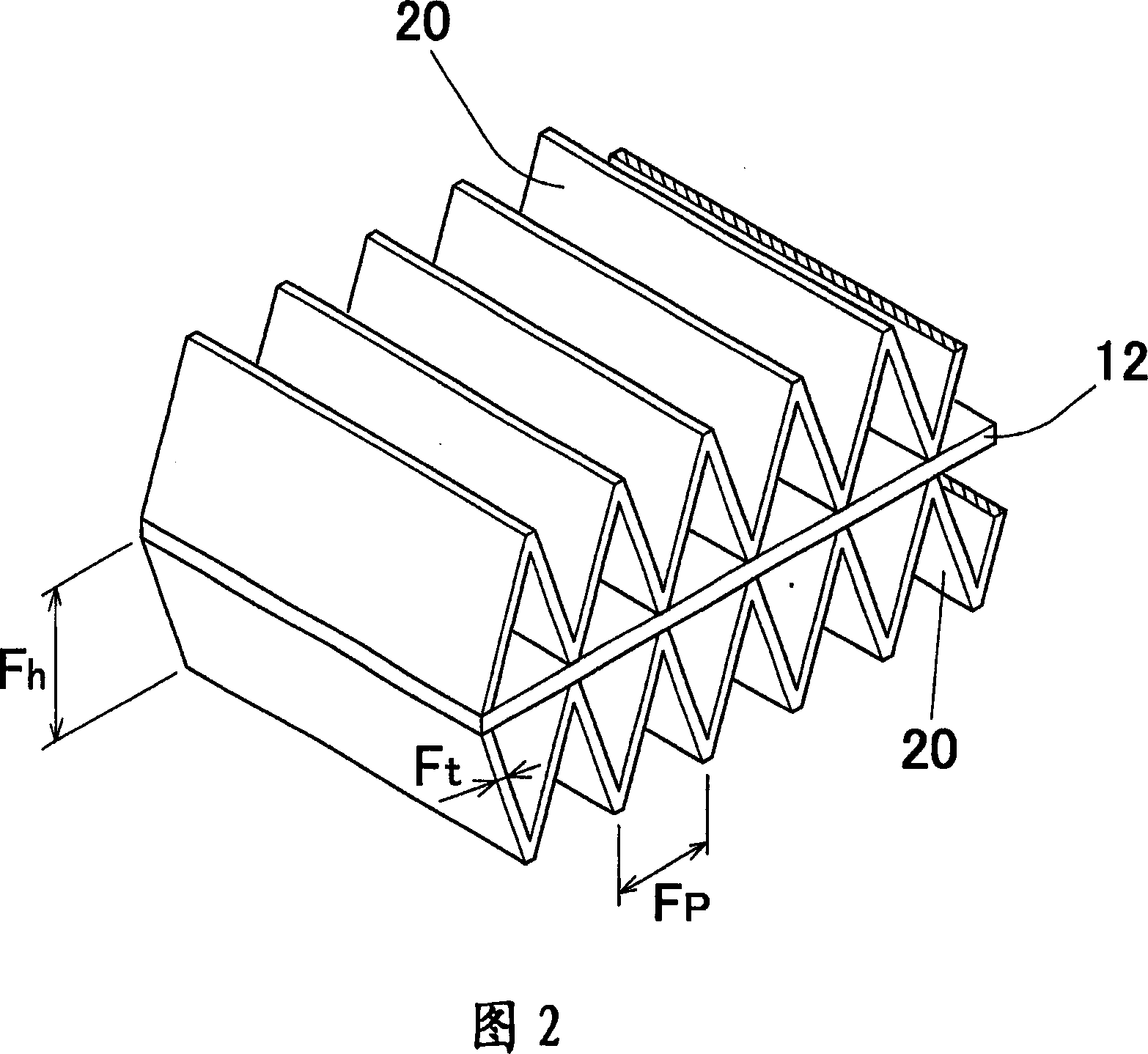

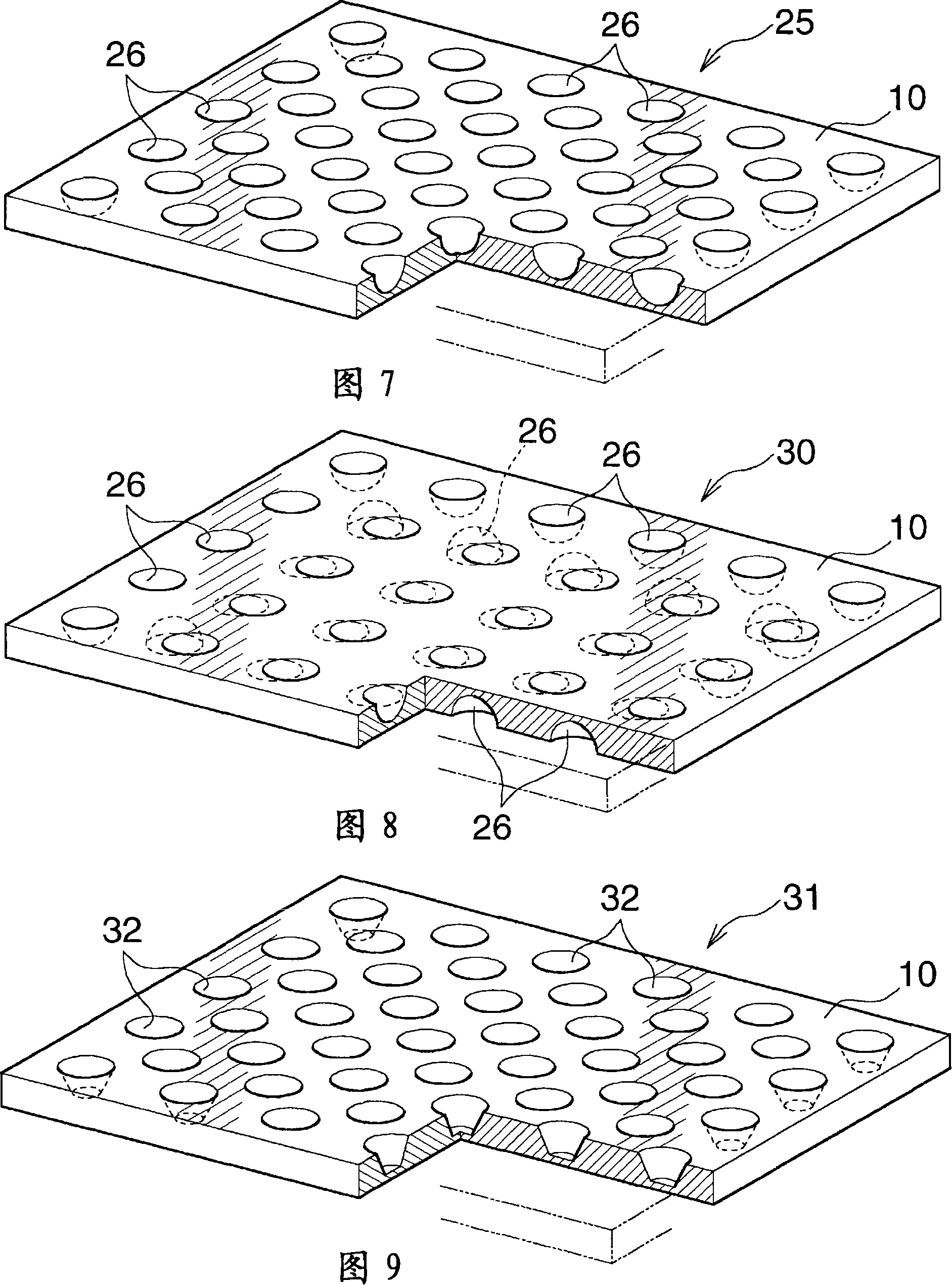

Method of manufacturing evaporator with cool storage function

InactiveCN103252628AImprove brazing performanceEasy to spreadEvaporators/condensersSoldering apparatusCool storageMetallic materials

In a method of manufacturing an evaporator with a cool storage function, a plurality of flat refrigerant flow tubes and a plurality of container forming assemblies are disposed such that a width direction of each of the plurality of flat refrigerant flow tubes and a width direction of each of the plurality of container forming assemblies coincide with a vertical direction. Peripheral edge portions of container forming plates are brazed together to prepare each of the cool storage material containers. The flat refrigerant flow tubes and the cool storage material containers are brazed together.

Owner:MAHLE INT GMBH

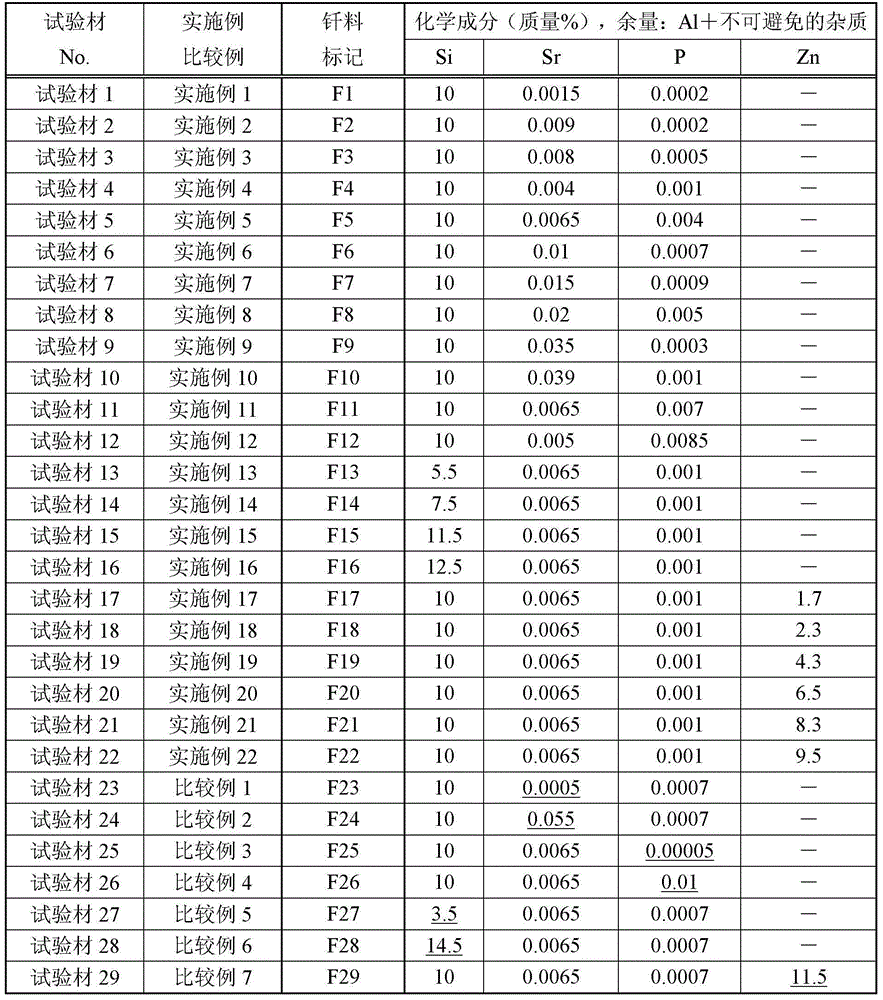

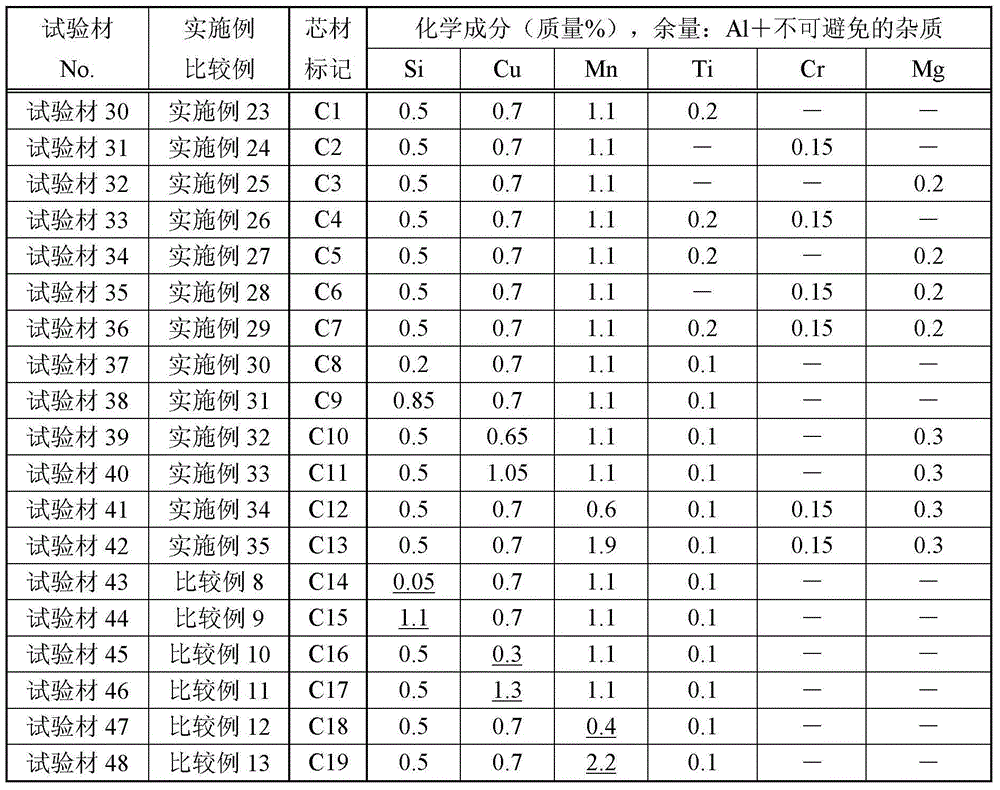

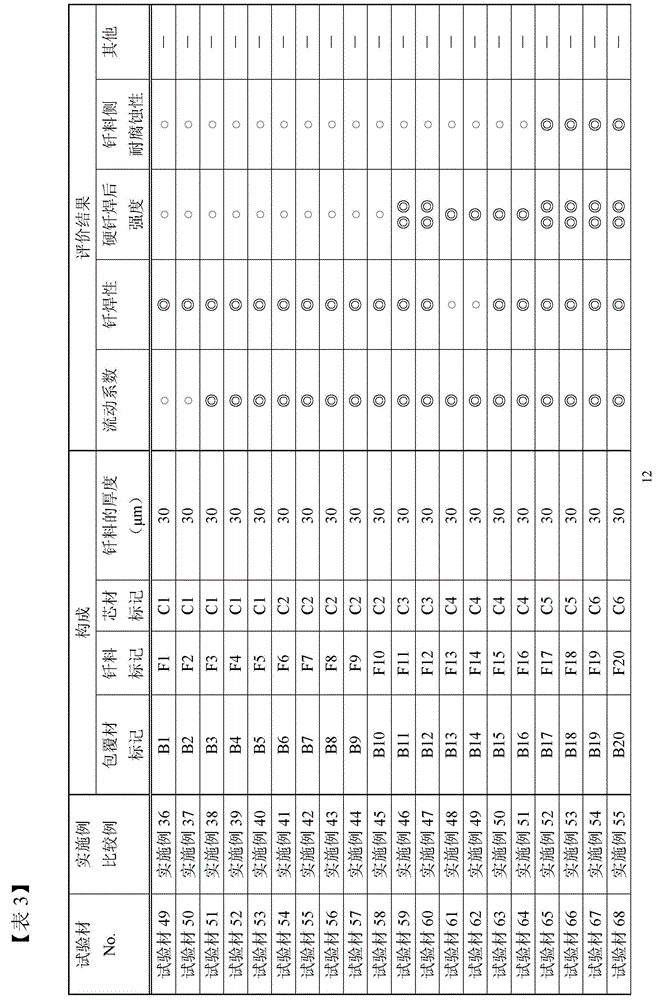

Aluminum alloy brazing filler metal and brazing plate

InactiveCN104070304AGood liquidityLess solder thicknessWelding/cutting media/materialsSoldering mediaForeign matterFiller metal

The invention discloses an aluminum alloy brazing filler metal constituted by Si in a range from 4.0 to 13.0wt%, Sr 0.001 to 0.050wt%, P 0.0001 to 0.0090 wt%, and other aluminum alloy formed by A1 and other inevitable foreign matters and a brazing plate using the same. The aluminum alloy brazing filler metal has advantages of excellent, strength, hard-solder performance, and anti-corrosion performance.

Owner:KOBE STEEL LTD

Flux composition and brazing sheet

InactiveUS20160059362A1Excellent brazeabilityImprove brazing performanceWelding/cutting media/materialsSoldering mediaFluorideSingle component

This brazing flux composition for an aluminum alloy is characterized by containing [A] a flux component containing KAlF4 and [B] a fluoride that does not contain K and that contains elements other than group 1 elements and group 2 elements: being in a particle form of single component of [B] the fluoride; and the added amount (C) (mass %) of [B] the fluoride with respect to [A] the flux component and the average particle size (d) (μm) satisfying formula (1),0.83C−0.19d<43 (1).

Owner:KOBE STEEL LTD

Brazing auxiliary device and brazing device for cutting bit

InactiveCN103433589AEasy dischargeImprove brazing performanceSoldering auxillary devicesEngineeringMechanical engineering

The invention relates to a brazing auxiliary device and a brazing device for a cutting bit. The brazing auxiliary device comprises a pressure bar device for discharging gas to a brazing part; the pressure bar device is provided with a plurality of vibrating devices. The embodiment of the invention is mainly used for achieving a certain auxiliary effect on discharge of gas in a solder after completion of brazing; the pressure bar device which is in contact with the solder after brazing is arranged and a plurality of vibrating devices are arranged on the pressure bar device, so that the pressure bar device can be driven to generate a plurality of vibrations in different directions through the vibrating devices, the end part of the pressure bar device is in contact with the solder, the vibrations in a plurality of directions are transferred to the solder to quicken the discharge of the gas in the solder, improve the brazing effect and save the brazing time.

Owner:SANY HEAVY EQUIP

Brazing sheet, manufacturing method therefor, and aluminum structure brazing method

PendingCN109072352AImprove brazing performanceLess quantityWelding/cutting media/materialsHeat exchange apparatusImpurityMaterials science

Provided are: a brazing sheet that can be used for both brazing performed using flux and brazing performed without using flux; a manufacturing method therefor; and a brazing method. The brazing sheetcomprises: a core made of an aluminum material; an intermediate material that contains Mg: 0.40-3.0 mass%, the balance having chemical components made of Al and unavoidable impurities, and that is laminated on the core; and a brazing material that contains Si: 6.0-13.0 mass% and limits Mg to less than 0.050 mass%, the balance having chemical components made of Al and unavoidable impurities, and that is laminated on the intermediate material. The Mg content in the intermediate material M [mass%], the thickness of the intermediate material ti [[mu]m], and the thickness of the brazing material tf[[mu]m] satisfy the relationship in expression (1). tf>=10.15*ln(M*ti)+3.7 (1).

Owner:FURUKAWA SKY ALUMINUM CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com