Novel insoluble aluminum brazing flux without corrosion and preparation method thereof

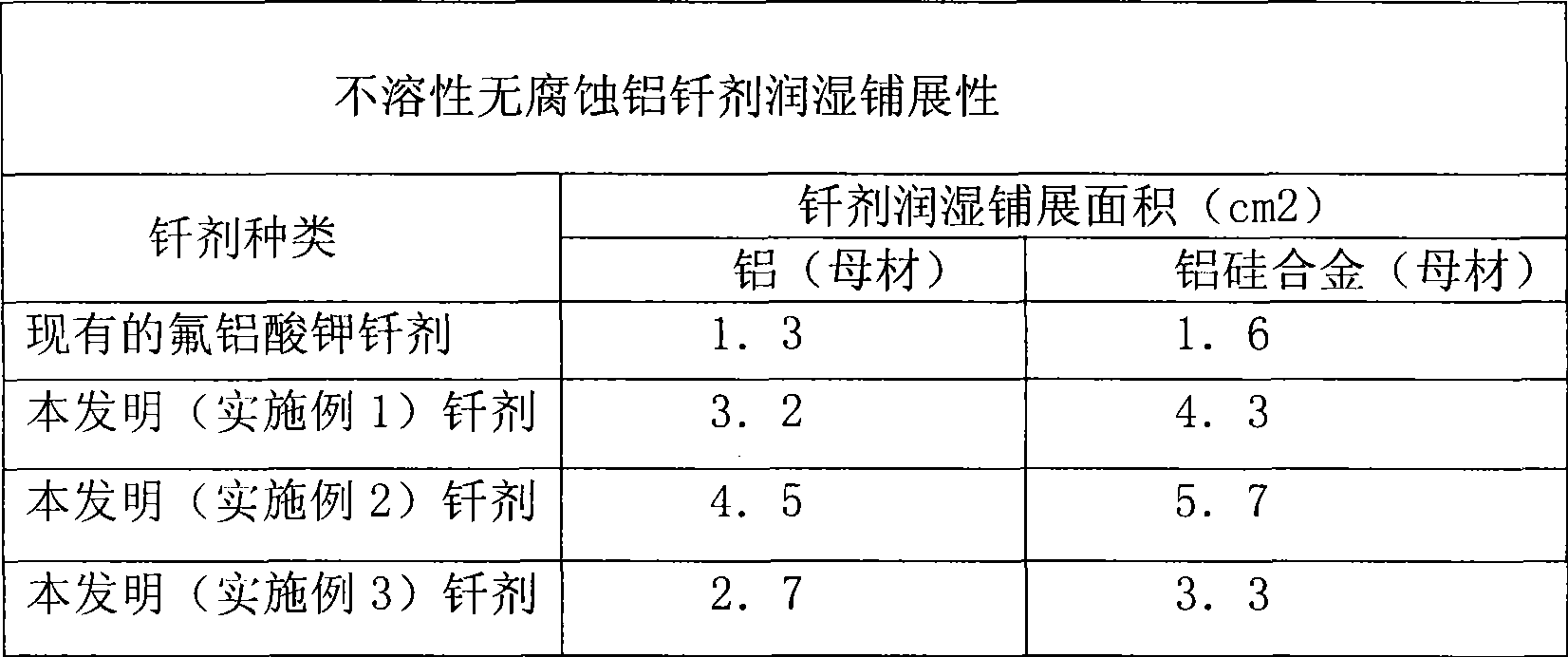

A non-corrosion, aluminum brazing flux technology, applied in the direction of manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problems of poor wettability of solder, increase the difficulty of welding, affect the quality of brazing, etc., to achieve good wettability, Effect of improving brazing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Selection of raw materials

[0039] Raw materials; 98% potassium fluoride, 99% aluminum fluoride, 99% cesium fluoride, 40% fluosilicic acid and 40% hydrofluoric acid.

[0040] (2) Synthesis of aluminum flux

[0041] Weigh 50.5 grams of 99% aluminum fluoride, add 1 kg of water and stir for 0.5 hours, then slowly add 58 ml of 40% hydrofluoric acid, stir for 2 hours, then add 44.8 grams of 98% potassium fluoride, stir for 2 hours , then add 1 gram of 99% cesium fluoride, stir and react for 2 hours, finally add 40% of 2.5 grams of fluorosilicic acid, stir and react for 2 hours, and then let it stand for 24 hours to synthesize a product containing a new type of insoluble non-corrosive aluminum flux .

[0042] (3) Post-processing of the product

[0043] The above synthesized product containing the novel insoluble non-corrosion aluminum brazing flux is centrifugally dehydrated and dried until the water content in the aluminum brazing flux product is 2%, then crushed and...

Embodiment 2

[0046] (1) Selection of raw materials

[0047] Raw materials; 98% potassium hydroxide, 99% aluminum hydroxide, 99% cesium hydroxide, 40% fluosilicic acid and 40% hydrofluoric acid.

[0048] (2) Synthesis of aluminum flux

[0049] Weigh 54.5 grams of 99% aluminum hydroxide, add 1 kg of water and stir for 0.5 hours, then slowly add 138 milliliters of 40% hydrofluoric acid, stir and react for 2 hours, then add 46.8 grams of 98% potassium hydroxide and stir for 2 hours, Then add 0.5 g of 99% cesium hydroxide, stir and react for 2 hours, finally add 40% of 1.25 g of fluosilicic acid, stir and react for 2 hours, then let it stand for 24 hours to synthesize a product containing a new type of insoluble non-corrosion aluminum flux.

[0050] (3) Post-processing of the product

[0051] The above synthesized product containing the novel insoluble non-corrosion aluminum brazing flux is centrifugally dehydrated and dried until the water content in the aluminum brazing flux product is 2%, ...

Embodiment 3

[0054] (1) Selection of raw materials

[0055] Raw materials; 98% potassium oxide, 99% aluminum oxide, 99% cesium oxide, 40% fluosilicic acid and 95% hydrogen fluoride gas. Because the raw material is 95% anhydrous hydrogen fluoride gas, it is necessary to pass 95% hydrogen fluoride gas into water to reach 40% hydrofluoric acid.

[0056] (2) Synthesis of aluminum flux

[0057] Weigh 52.5 grams of 99% alumina, add 1 kg of water and stir for 0.5 hours, add 138 milliliters of 40% hydrofluoric acid, stir for 2 hours, then add 45.8 grams of 98% potassium oxide, stir for 2 hours, then add 99 % cesium hydroxide 0.5 g, stirred and reacted for 2 hours, finally added 40% of 1.25 g of fluosilicic acid, stirred and reacted for 2 hours, and left standing for 24 hours to synthesize a product containing a new type of insoluble non-corrosive aluminum flux.

[0058] (3) Post-processing of the product

[0059] The above synthesized product containing the novel insoluble non-corrosion aluminu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com