Heat exchanger and method for manufacturing same

A manufacturing method and heat exchanger technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve problems such as inability to ensure working space, inability to block components to heat up, large liquid reservoir, etc., to achieve Effects of improving pressure resistance, preventing heat damage, and improving brazeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

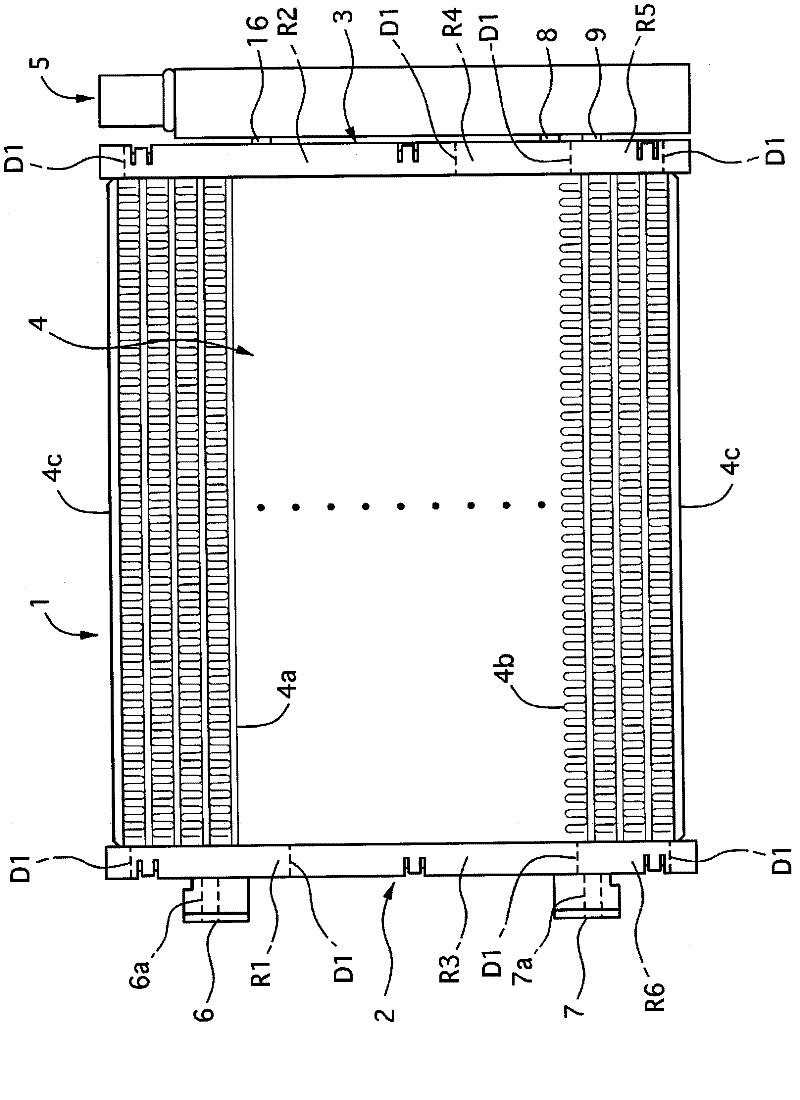

[0048] Next, the heat exchanger and its manufacturing method according to Embodiment 1 of the present invention will be described with reference to the drawings.

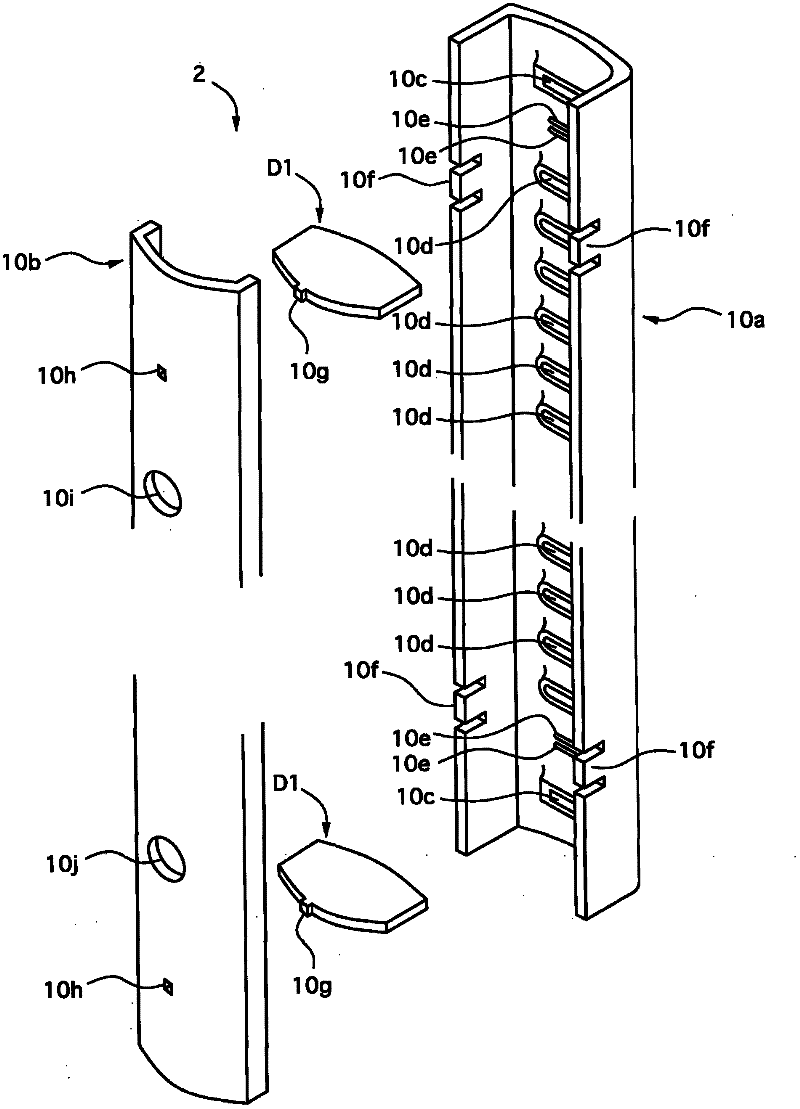

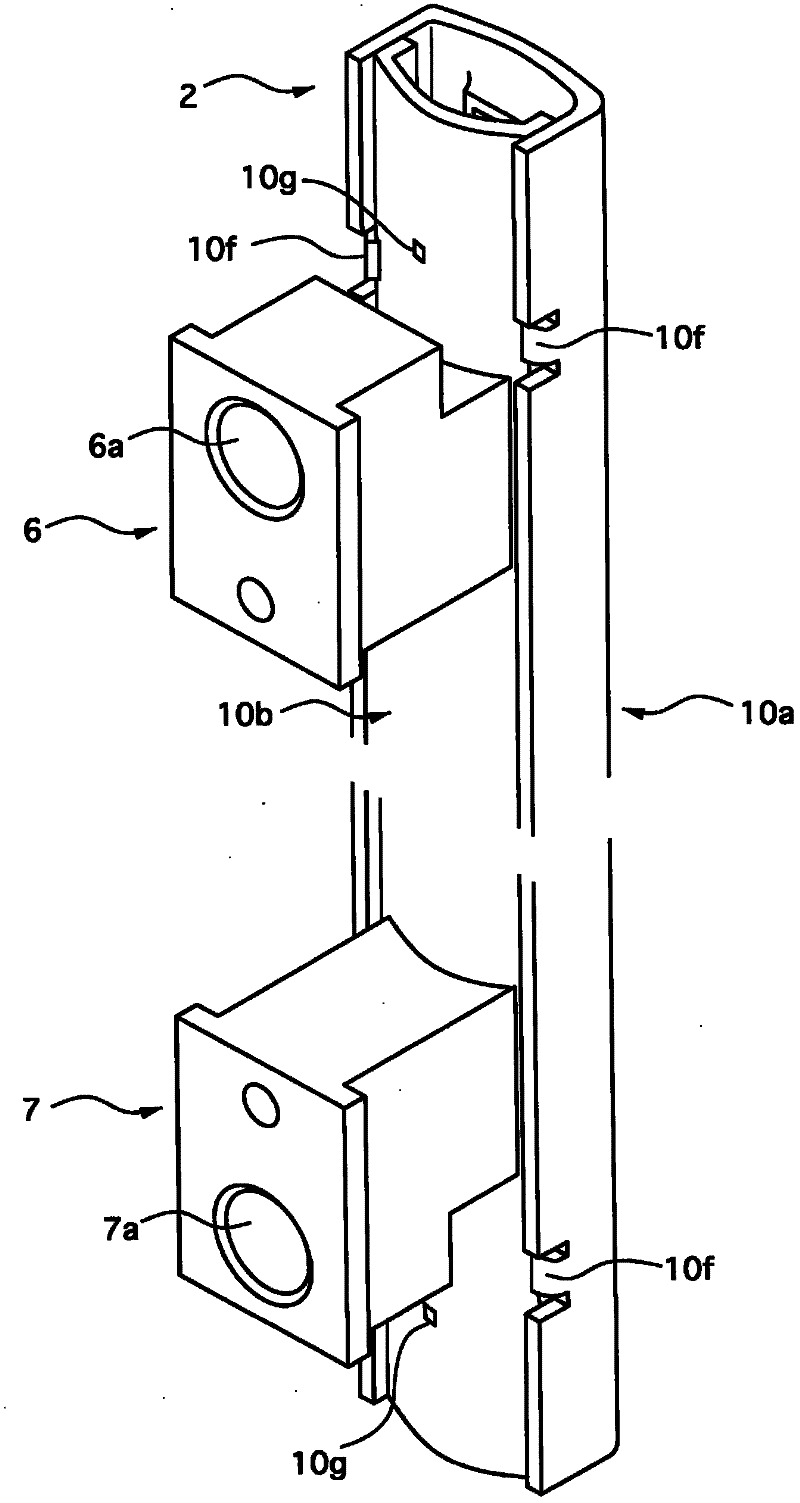

[0049] figure 1is a front view showing the heat exchanger of Example 1, figure 2 It is an exploded perspective view of the box used in the heat exchanger of Example 1, image 3 is a perspective view of the box, Figure 4 yes figure 2 , image 3 The exploded perspective view of the box, Figure 5 is a perspective view of the box.

[0050] Figure 6 It is an exploded perspective view of the liquid reservoir used in the heat exchanger of Example 1, Figure 7 is a perspective view of the reservoir, Figure 8 It is an exploded perspective view of the intermediate member and the liquid reservoir of Embodiment 1, Figure 9 is description Figure 6 , Figure 7 A side sectional view of the lower interior of the reservoir, Figure 10 yes Figure 9 Cutaway view of the S10-S10.

[0051] Figure 11 is descriptio...

Embodiment 2

[0207] Next, the heat exchanger and its manufacturing method according to Embodiment 2 of the present invention will be described with reference to the drawings.

[0208] In Embodiment 2, the same reference numerals are assigned to the same constituent members as in Embodiment 1, and descriptions of these members are omitted, and only differences are described in detail.

[0209] Figure 25 It is a figure explaining the high-frequency induction heating in the heat exchanger of Example 2 and its manufacturing method.

[0210] Such as Figure 25 As shown, in the heat exchanger and its manufacturing method of Example 2, a black body paint 50 is applied in advance near the junction of the closing member 15, and an infrared temperature sensor 51 capable of measuring the surface temperature of the black body paint 50 is installed.

[0211] In addition, the temperatures detected by the infrared temperature sensor 51 are sequentially sent to the controller 33 .

[0212] In addition...

Embodiment 3

[0223] Next, the heat exchanger and its manufacturing method according to Embodiment 3 of the present invention will be described with reference to the drawings.

[0224] In the heat exchanger and its manufacturing method of Example 3, the same reference numerals are assigned to the same components as those of Example 1, and description thereof will be omitted, and only differences will be described in detail.

[0225] Figure 26 It is a perspective view of the accumulator used in the heat exchanger of Example 3.

[0226] Such as Figure 26 As shown, in the heat exchanger of Example 3, the overall length of the first divided member 11 of the accumulator 5 is formed much shorter than that of the second divided member 12 .

[0227] In addition, a bracket member 60 having the same shape as the first divided member 11 but shorter than the first divided member 11 is brazed at a position corresponding to the holding member 16 on the outer periphery of the second divided member 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com