Heat Exchanger

一种换热器、贮液器的技术,应用在换热器外壳、间接换热器、换热器类型等方向,能够解决无法闭塞构件升温、无法确保作业空间、贮液器热质量大等问题,达到提高耐压性、防止热损伤、提高钎焊性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

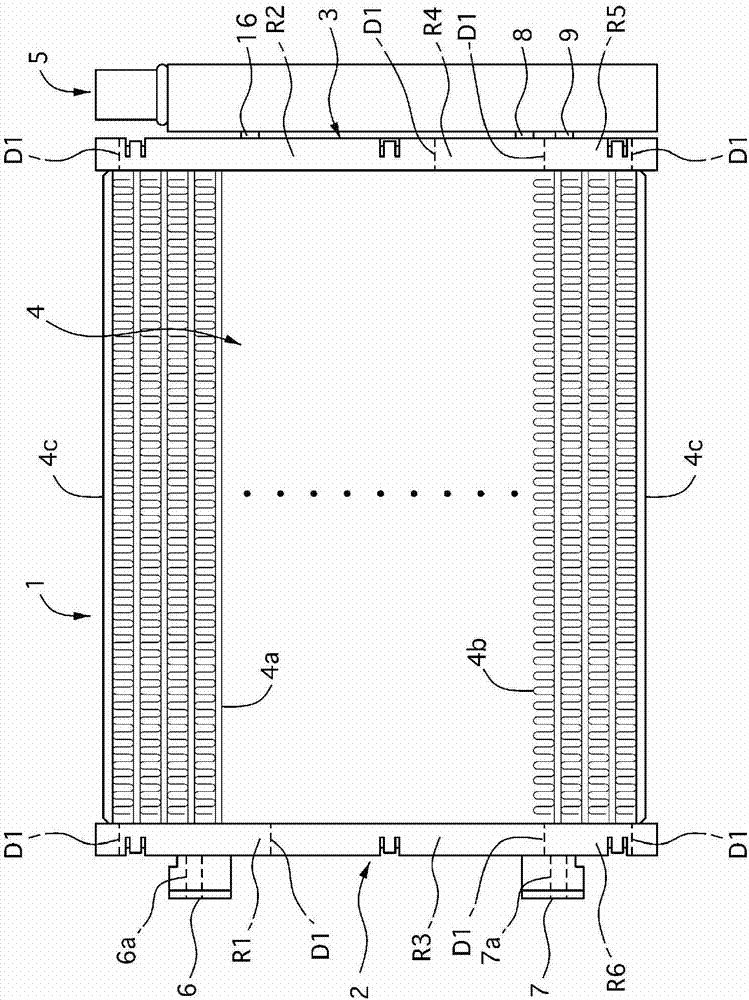

[0049] Hereinafter, the heat exchanger and its manufacturing method according to Embodiment 1 of the present invention will be described based on the drawings.

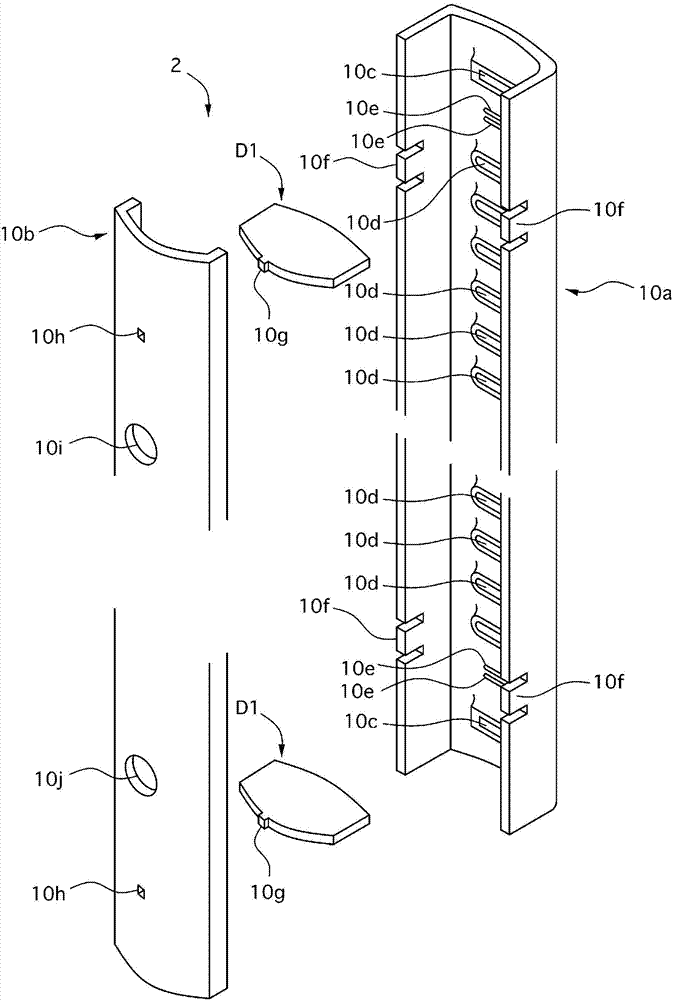

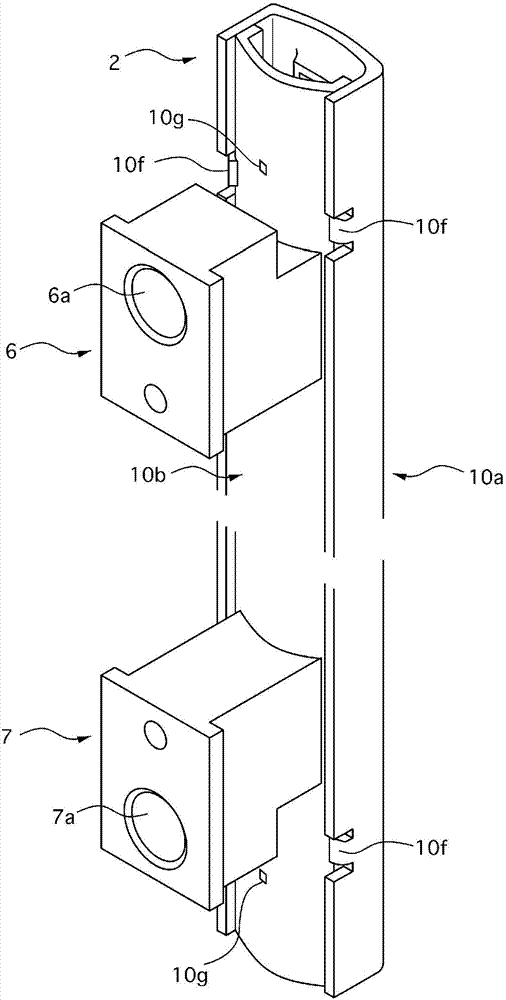

[0050] figure 1 Is a front view showing the heat exchanger of Example 1, figure 2 It is an exploded perspective view of the box used in the heat exchanger of Example 1, image 3 Is a three-dimensional view of the box, Figure 4 Yes figure 2 , image 3 The exploded perspective view of the box, Figure 5 It is a perspective view of the box.

[0051] Image 6 It is an exploded perspective view of the accumulator used in the heat exchanger of Example 1, Figure 7 Is a three-dimensional view of the reservoir, Figure 8 It is an exploded perspective view of the intermediate member and the reservoir of Example 1, Picture 9 Is description Image 6 , Figure 7 Side sectional view of the lower interior of the reservoir, Picture 10 Yes Picture 9 Sectional view of S10-S10.

[0052] Picture 11 Is description Image 6 , Figure 7 Sid...

Embodiment 2

[0209] Hereinafter, a heat exchanger and its manufacturing method according to Embodiment 2 of the present invention will be explained based on the drawings.

[0210] In the second embodiment, the same reference numerals are given to the same constituent members as in the first embodiment, and the description of the members is omitted, and only the differences are described in detail.

[0211] Figure 25 It is a figure explaining the high frequency induction heating in the heat exchanger of Example 2 and its manufacturing method.

[0212] Such as Figure 25 As shown, in the heat exchanger and the manufacturing method of the second embodiment, the black body paint 50 is applied to the vicinity of the junction of the closing member 15 in advance, and an infrared temperature sensor 51 capable of measuring the surface temperature of the black body paint 50 is provided.

[0213] In addition, the temperature detected by the infrared temperature sensor 51 is sequentially sent to the controlle...

Embodiment 3

[0225] Hereinafter, a heat exchanger and its manufacturing method according to Embodiment 3 of the present invention will be described based on the drawings.

[0226] In the heat exchanger of the third embodiment and the manufacturing method thereof, the same constituent members as those of the first embodiment are denoted by the same reference numerals and the description thereof is omitted, and only the differences are described in detail.

[0227] Figure 26 It is a perspective view of the accumulator used in the heat exchanger of Example 3.

[0228] Such as Figure 26 As shown, in the heat exchanger of Example 3, the total length of the first divided member 11 of the accumulator 5 is formed to be significantly shorter than the second divided member 12.

[0229] In addition, a bracket member 60 having the same shape as the first divided member 11 but shorter than the first divided member 11 is brazed at a position corresponding to the holding member 16 on the outer periphery of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com