Cu-Added Ni-Cr-Fe-Based Alloy Brazing Material

a technology of fe-based alloy brazing and cu-added ni-cr-fe-based alloy, which is applied in the direction of manufacturing tools, solvents, other domestic objects, etc., can solve the problem of relatively less available materials, and achieve excellent corrosion resistance and strength, and low melting temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0067]The present invention is explained in detail below with reference to examples.

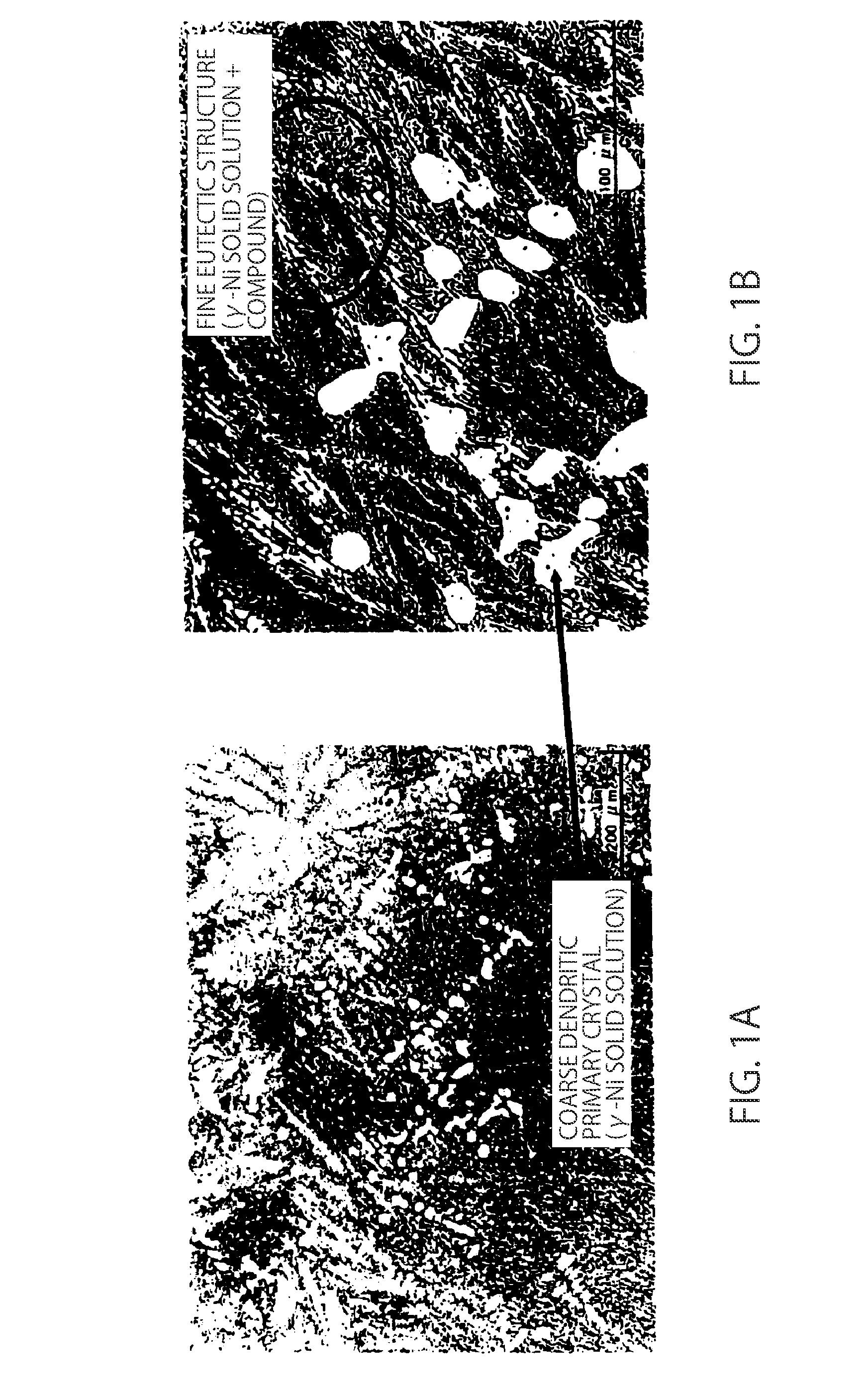

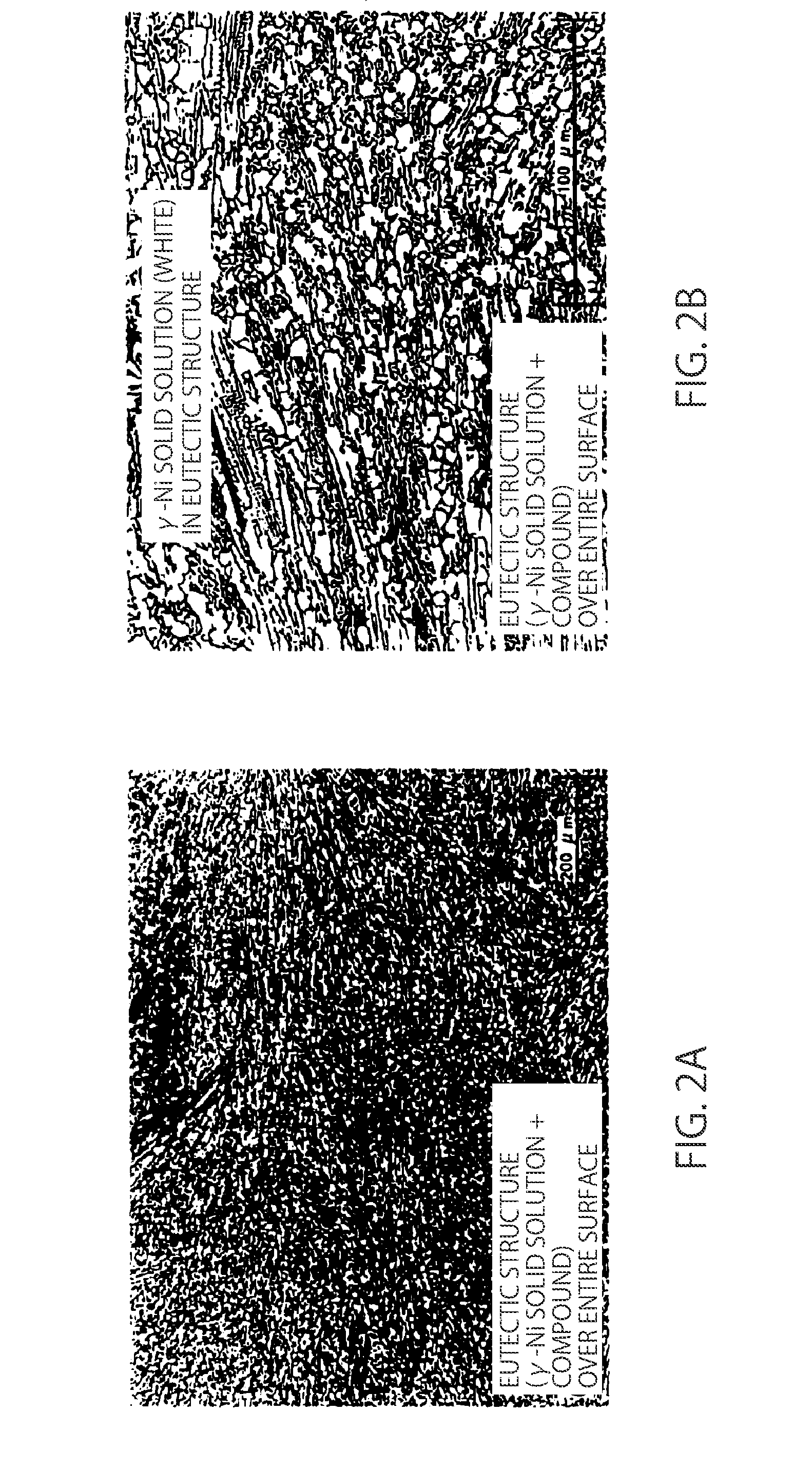

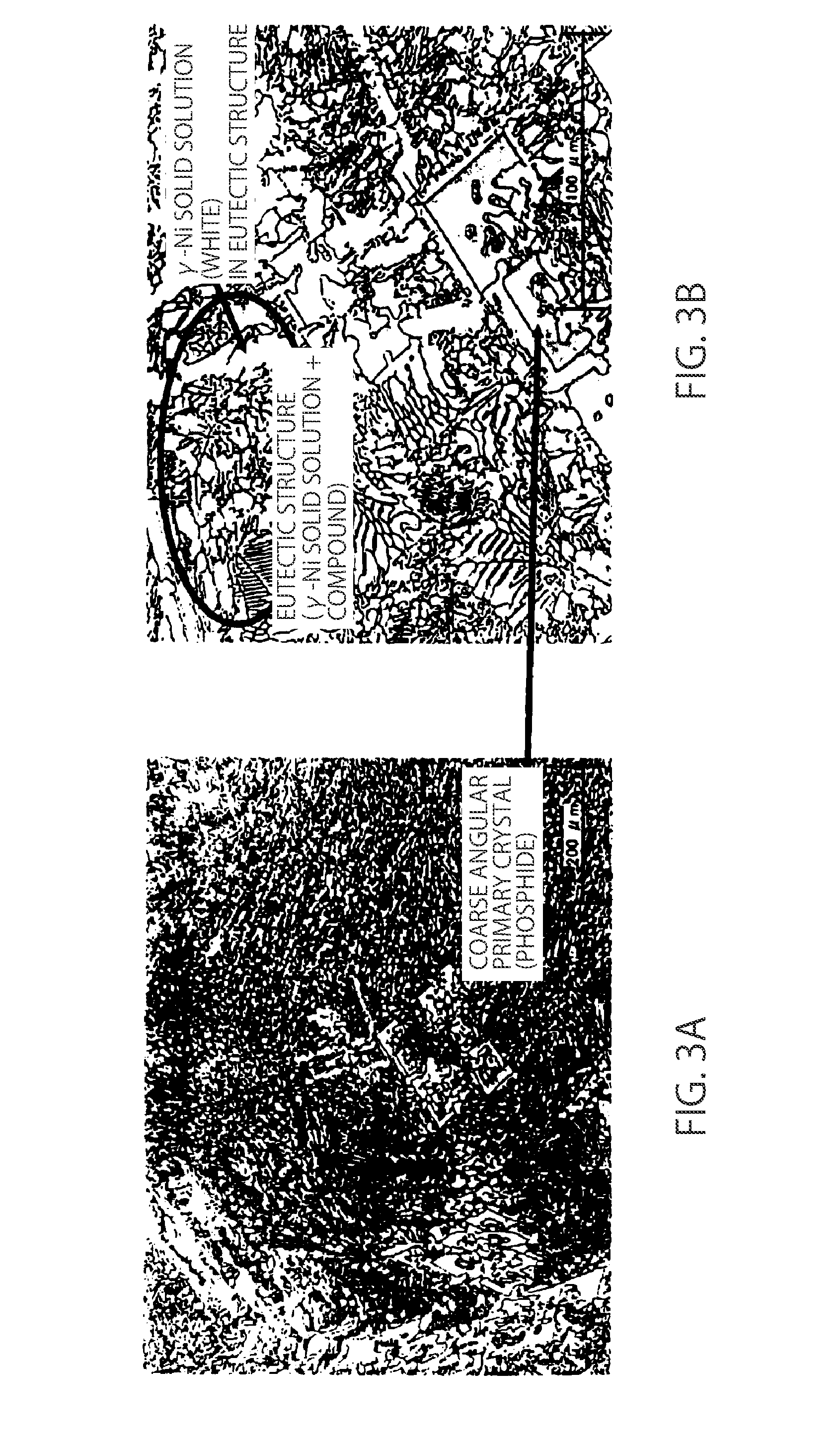

[0068]First, in order to examine in detail the amount of added Cu influencing various properties including bending strength, the bending strength, liquidus line, and solidus line of Ni-30% Cr-20% Fe-x % Cu-7% P-3% Si were evaluated with a test piece cut out of a produced centrifugal cast steel. Furthermore, SUS304 as a base material was brazed with a specimen cut out of the centrifugation cast steel. The bending strength and corrosion resistance of the brazed test piece were evaluated (Experiment A).

[0069]Then, centrifugal cast steels in which each alloy composition was varied were produced, the bending strength, liquidus line, and solidus line of a test piece cut out of each centrifugal cast steel were evaluated, and the bending strength and corrosion resistance of a test piece obtained by brazing SUS304 as a base material with a specimen cut out of the centrifugal cast steel were evaluated (Experim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com