Heat sink device

A heat dissipation device and heat sink technology, applied in sustainable manufacturing/processing, final product manufacturing, printed circuits, etc., can solve problems such as insufficient thermal conductivity, inability to obtain sufficient heat dissipation performance, and increased material cost to achieve low material cost , heat dissipation performance improvement, thermal stress relaxation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

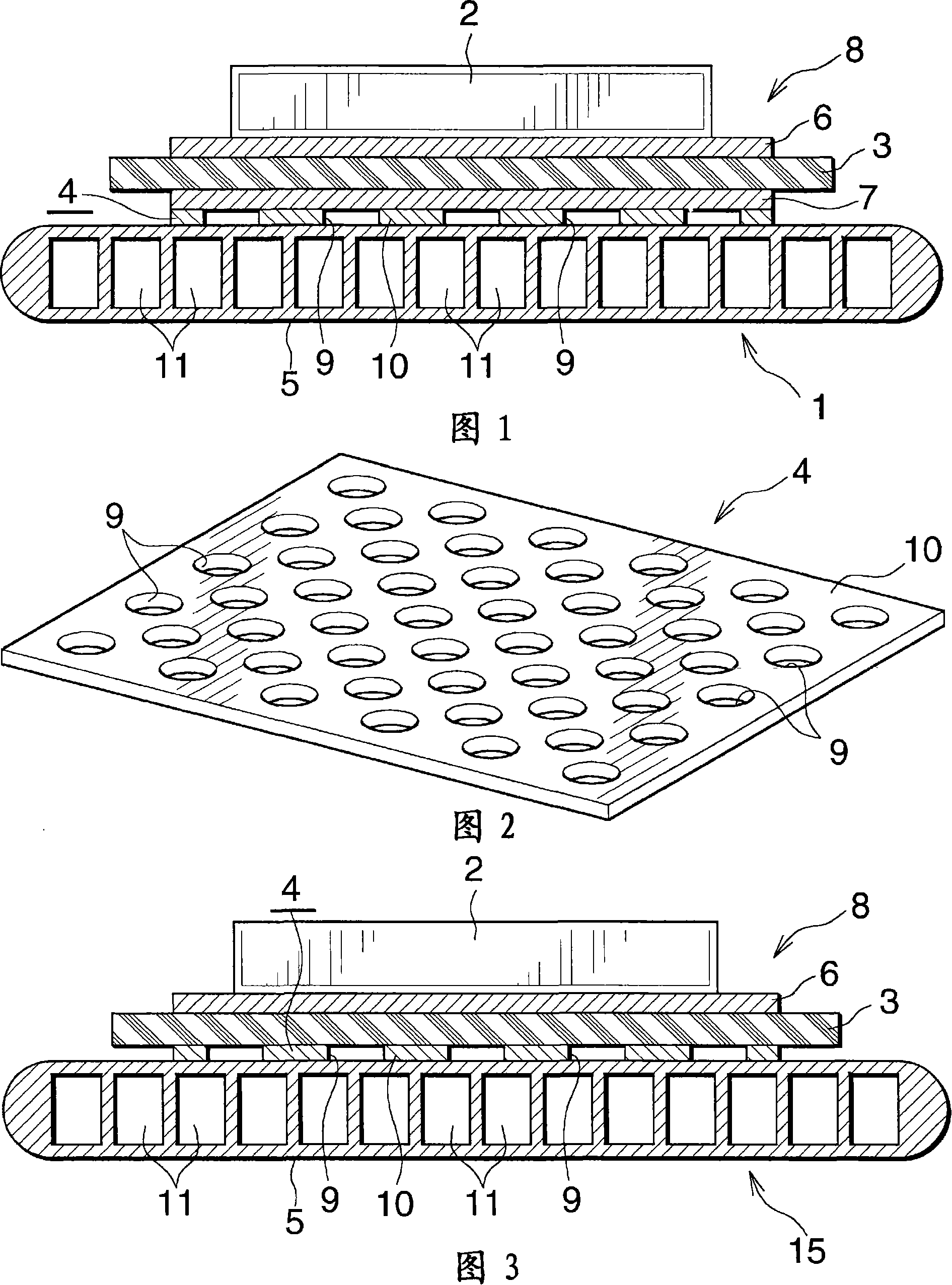

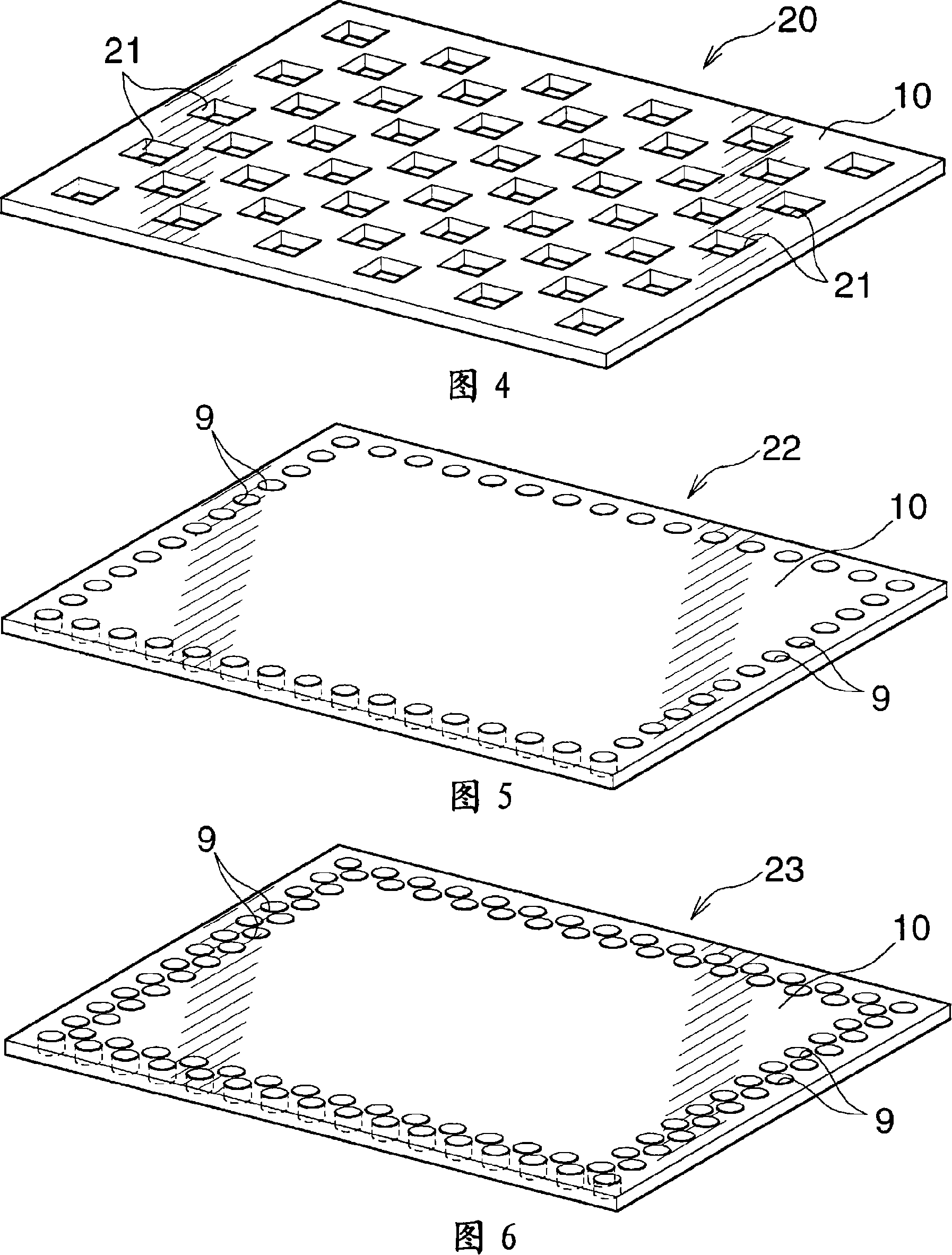

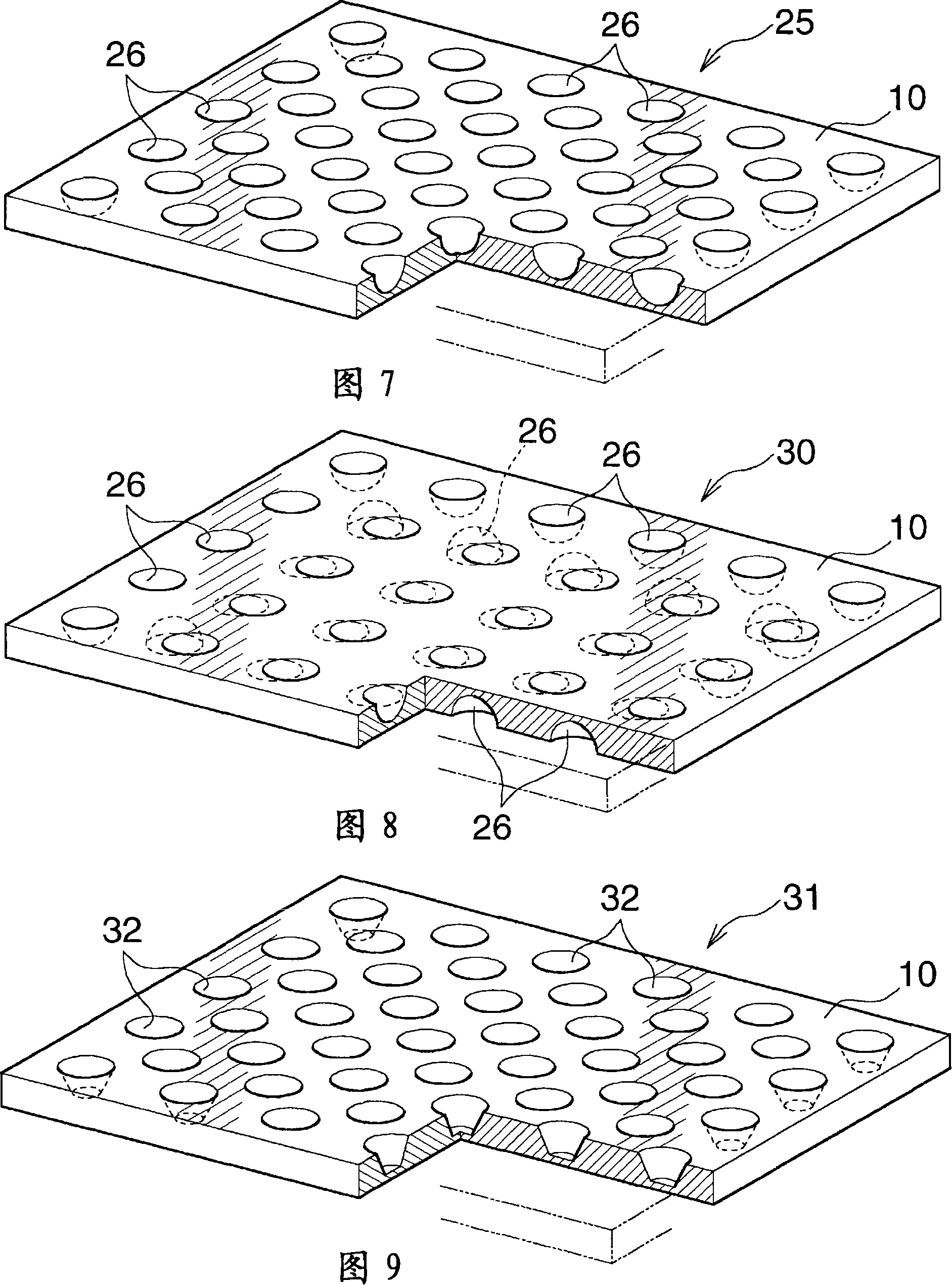

[0057] Embodiments of the present invention will be described below with reference to the drawings. In addition, in the following description, the top and bottom of FIG. 1 are referred to as top and bottom. In addition, in all drawings, the same part and the same component are attached|subjected to the same code|symbol, and repeated description is abbreviate|omitted.

[0058] FIG. 1 shows a part of a power supply module using a heat sink according to a first embodiment of the present invention, and FIG. 2 shows a stress relaxation member.

[0059] In FIG. 1 , the power supply assembly includes: a heat sink (1), and a semiconductor element (2) such as an IGBT mounted on the heat sink (1).

[0060] The heat dissipation device (1) includes: a ceramic insulating substrate (3) whose upper surface is used as a heating element mounting surface, a stress relieving member (4) bonded to the lower surface of the insulating substrate (3), and a stress relieving member (4) bonded to the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com