Tube for heat exchanger

A technology of heat exchanger and heat exchange medium, which is used in heat exchanger fixing, heat exchange equipment, indirect heat exchanger, etc., can solve the problems of unstable brazing performance of flat tubes, and achieve the effect of improving brazing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

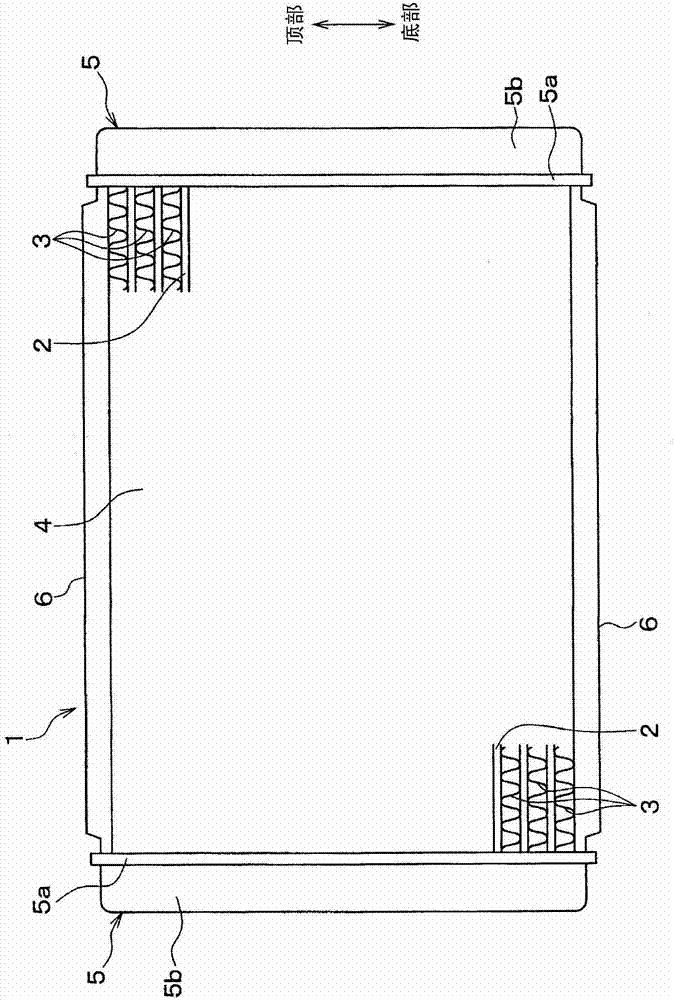

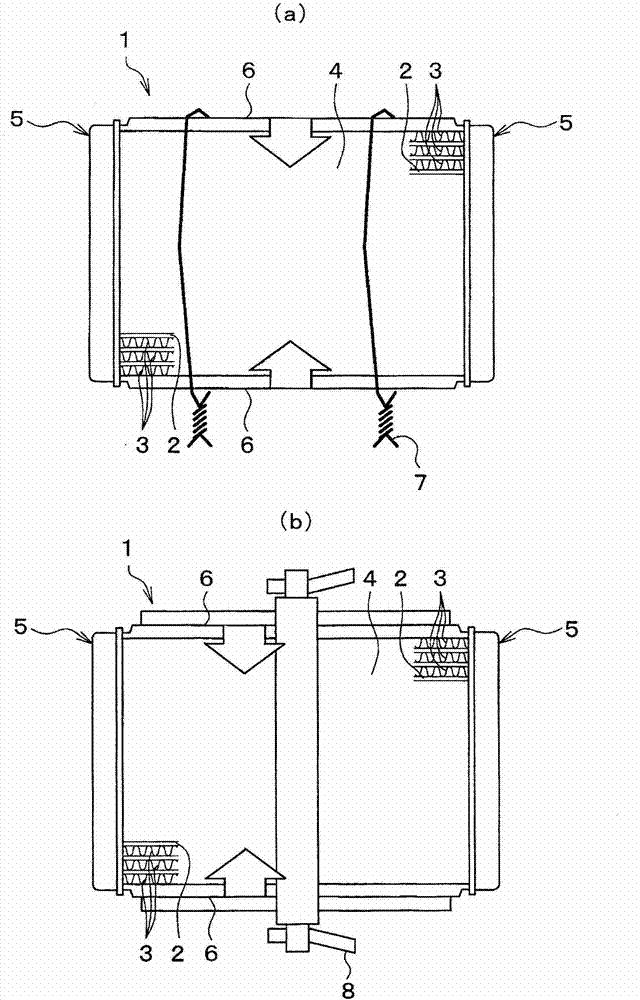

[0035] The following will be based on Figure 1-7 The first embodiment of the present invention is described. figure 1 It is a front view of the radiator 1 according to this embodiment.

[0036] In this embodiment, the flat tube (tube for heat exchanger) 2 is applied for exchanging heat between engine cooling water (heat exchange medium) and air (atmosphere) for cooling the vehicle engine (internal combustion engine) 的radiator 1.

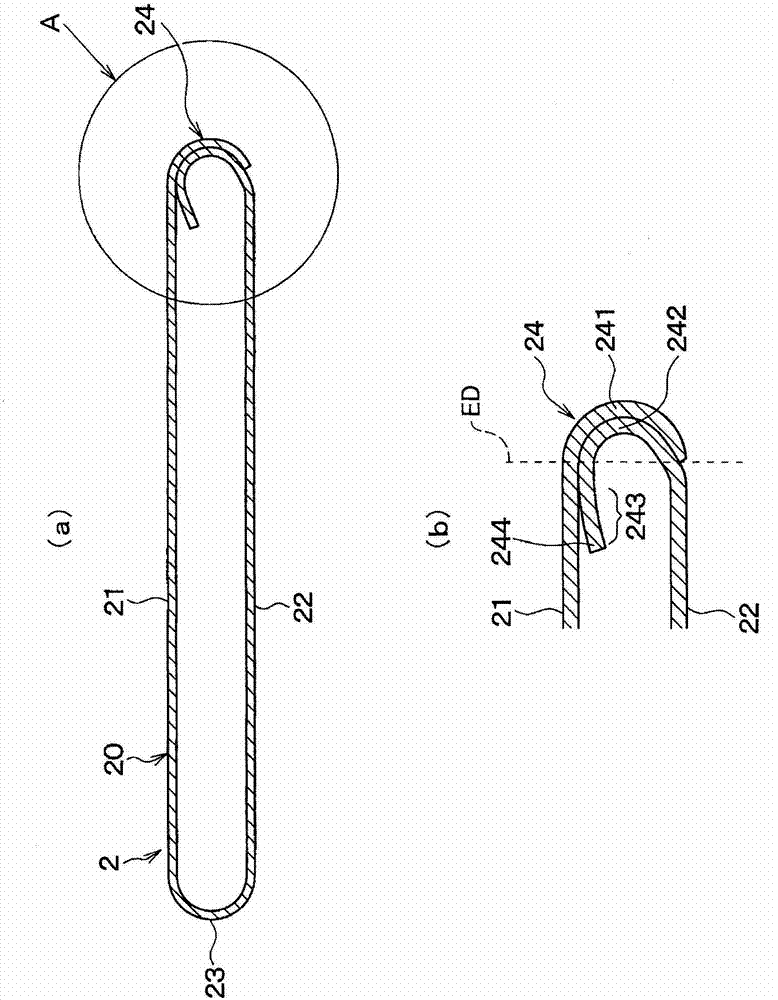

[0037] figure 1 The flat tube 2 in is the tube through which engine cooling water flows. The flat tube 2 is formed into a flat shape so that the direction of air flow (perpendicular to figure 1 The direction of the paper plane) is aligned with the long radius direction. Further, a plurality of flat tubes 2 along figure 1 The vertical directions are arranged parallel to each other, so that the longitudinal direction of the flat tube and figure 1 Align in the horizontal direction. A detailed description of the flat tube 2 is provided later.

[0038] Outer ...

no. 2 example

[0063] Next, based on Figure 8 (a) and Figure 8 (b) The second embodiment of this embodiment is described. Here, Figure 8 (a) and Figure 8 (b) is a cross-sectional view showing the cross section of the flow passage of the flat tube 2 of this embodiment. Figure 8 (a) shows the entire flow passage section of the flat tube 2, and Figure 8 (b) shows Figure 8 A partial enlarged view of part B in (a). In this embodiment, descriptions of components similar or equivalent to those in the first embodiment will be omitted or simplified.

[0064] The flat tube 2 of this embodiment has an extension portion 243 in which the inner wall portion 242 extends from a portion opposite to the outer wall portion 241 to the first curved portion 23. In the extension portion 243, the portion (radiating fin portion 243a) opposed to the respective flat plate portions 21, 22 in the short radius direction of the flat tube 2 is formed in a corrugated shape to serve as an inner radiating fin for increasi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com