Brazing sheet, manufacturing method therefor, and aluminum structure brazing method

A technology of aluminum structure and brazing method, applied in the direction of manufacturing tools, chemical instruments and methods, welding/welding/cutting articles, etc., capable of solving problems such as deterioration of flux residue surface treatment, flux clogging, and cost burden problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

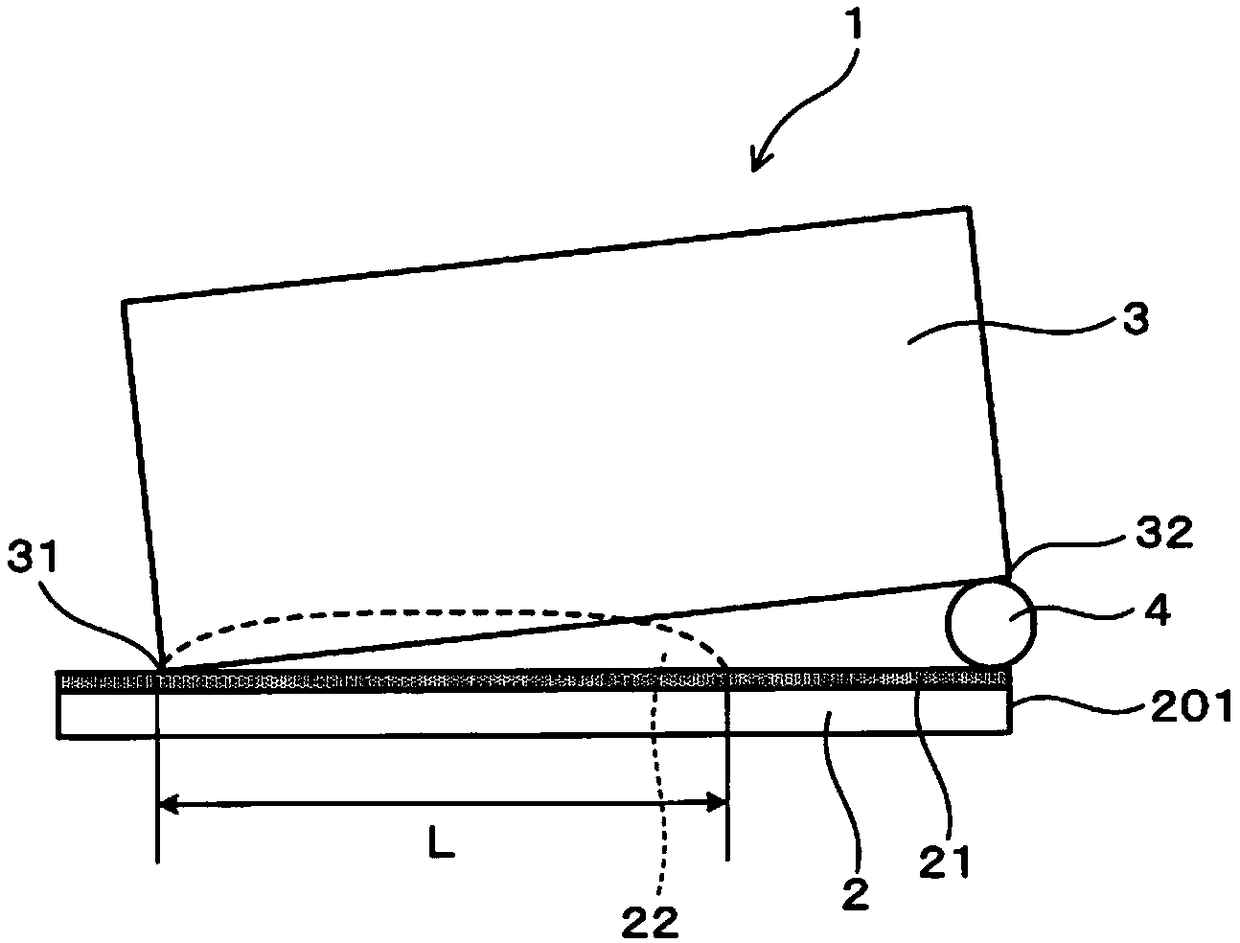

[0106] This example is an example of a gap filling test using the above-mentioned test materials. Test body for gap filling test (refer to figure 1 ) is produced by the following method. First, a horizontal plate 2 having a width of 25 mm and a length of 60 mm was taken from the test material. In addition, unlike the horizontal plate 2, a vertical plate 3 having a width of 25 mm, a length of about 55 mm, and a thickness of 1 mm made of a JIS A3003 alloy was prepared. After the horizontal plate 2 and the vertical plate 3 were degreased with acetone, they were figure 1 Assembled as shown, test body 1 was produced.

[0107] Such as figure 1 As shown, the vertical plate 3 is arranged in a direction perpendicular to the horizontal plate 2 , and one end 31 of the vertical plate 3 in the longitudinal direction is in contact with the solder 21 of the horizontal plate 2 . In addition, a spacer 4 made of a stainless steel round wire with a diameter of 1.6 mm is interposed between t...

Embodiment 2

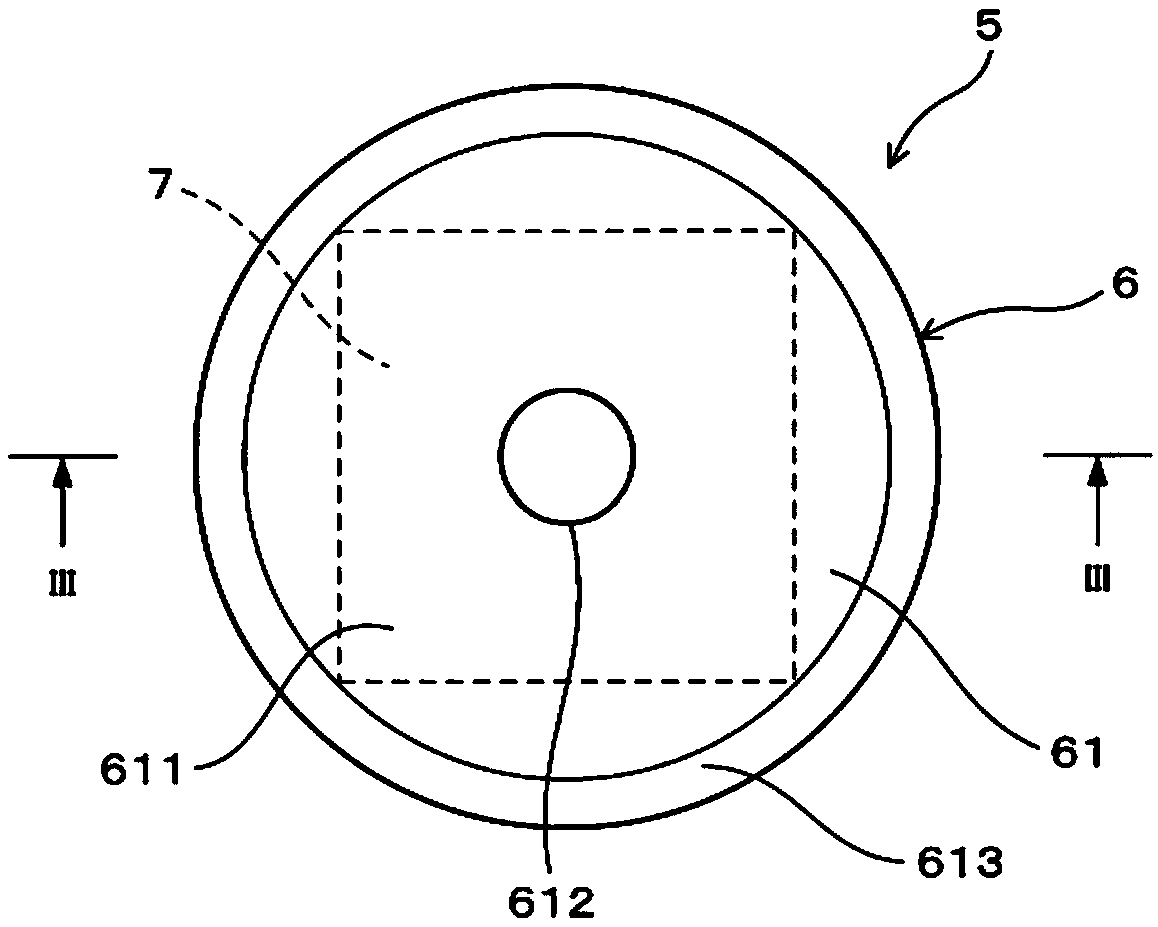

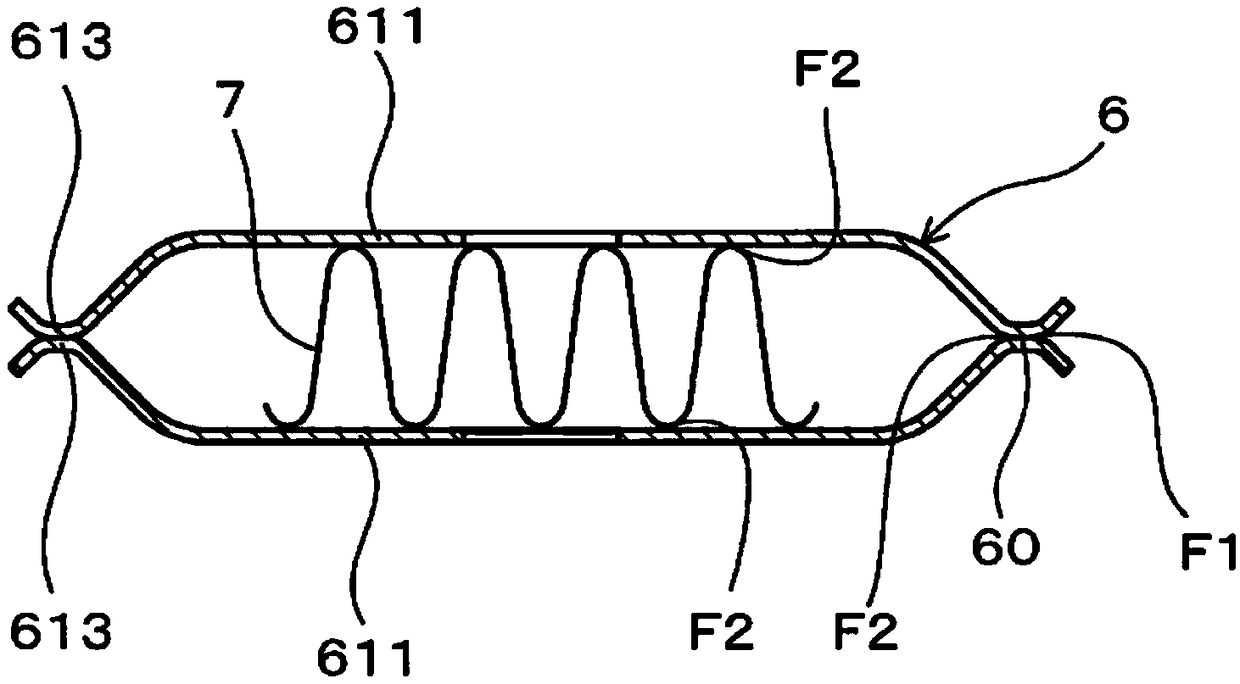

[0129] This example is an example in which a hollow member was produced using the above-mentioned test material, and the brazability of an aluminum structure including the hollow member was evaluated. The test body of this example was produced by the following method. Perform press processing on the test material, and produce figure 2 and image 3 The circular cup 61 is shown. The diameter of the cup-shaped body 61 is 30 mm, and a vent hole 612 with a diameter of 5 mm is formed in the center of the bottom 611 of the cup-shaped body 61 . A flange 613 is formed on the outer peripheral portion of the cup body 61 . In addition, the cup-shaped body 61 is formed so that the solder is inside.

[0130] A corrugated fin 7 made of a JIS A3003 alloy is prepared separately from the cup 61 .

[0131] After degreasing the cup-shaped body 61 and corrugated fins 7, two cup-shaped bodies 61 and corrugated fins 7 are combined to assemble figure 2 and image 3 Test body 5 shown. The te...

Embodiment 3

[0149] This example is an example of evaluating the corrosion resistance of a brazing sheet after brazing. In this example, a test body of 150 mm in length and 50 mm in width collected from the test material was hung in a brazing furnace so that the longitudinal direction was parallel to the vertical direction, and brazing was performed under the same conditions as in Example 1. After the brazing is completed, the lower part of the test body where the molten solder has accumulated is cut off.

[0150] Thereafter, a salt spray test was performed by a method based on JIS Z2371. The test conditions are test solution: 5% NaCl aqueous solution, pH: 6.8, test temperature: 35°C. The cross section of the corroded portion generated after the test was observed to evaluate the corrosion resistance. In the "corrosion resistance" column in Table 6, the symbol "A+" was entered when the corrosion resistance was excellent, and the symbol "A" was entered when the corrosion resistance was goo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com