Heat exchanger with thermal storage function

一种热交换器、热交换管的技术,应用在加热方式、蓄热设备、间接换热器等方向,达到防止蓄热材料泄漏的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

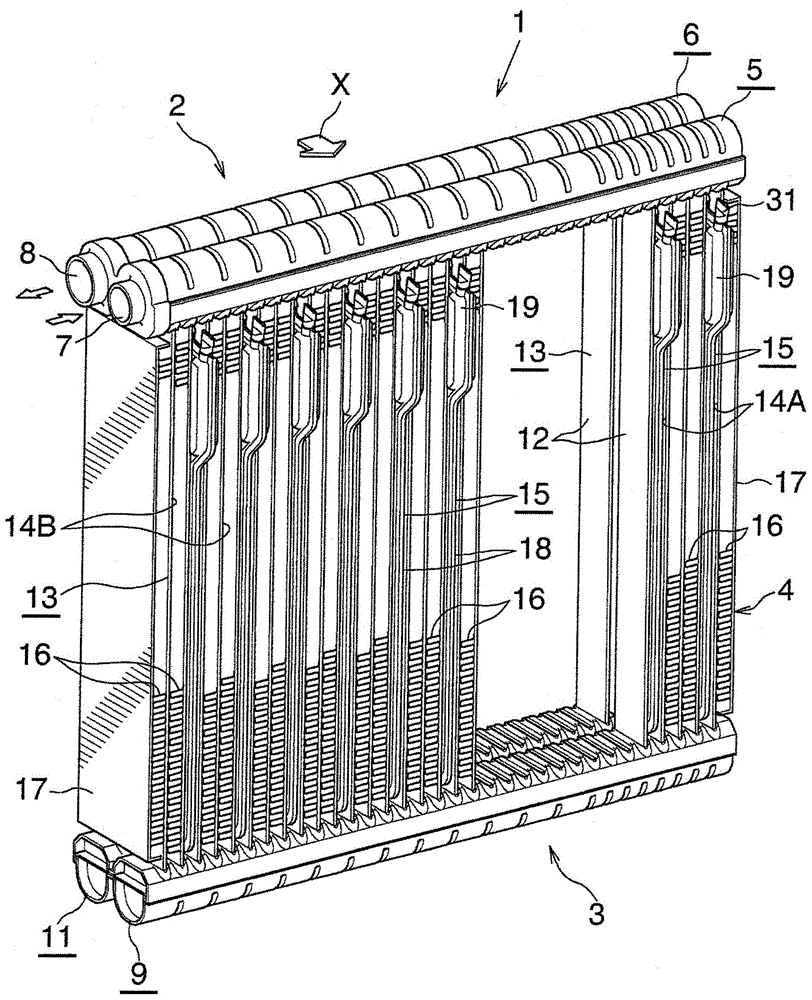

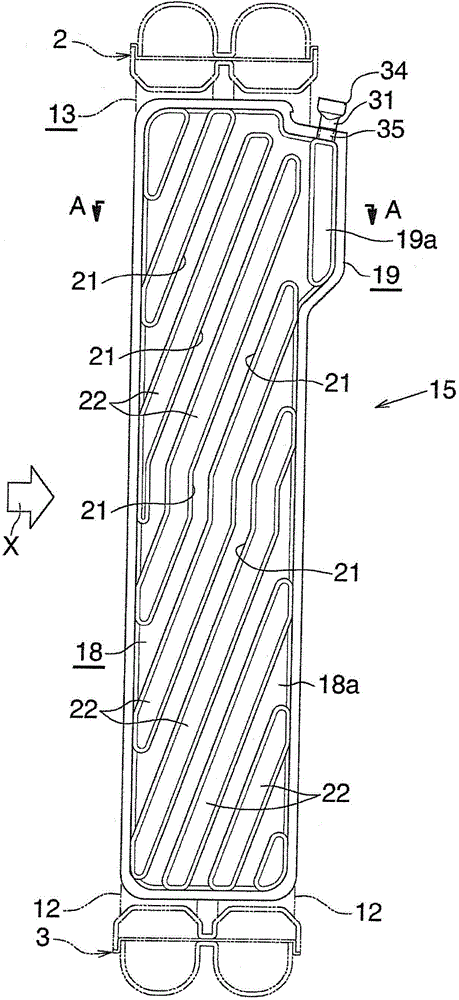

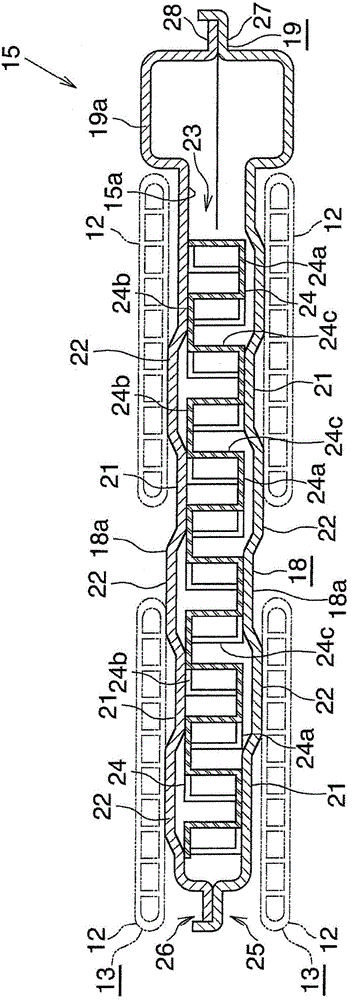

[0047] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In this embodiment, the heat exchanger with a heat storage function of the present invention is applied to an evaporator with a cool storage function having a function of storing cold energy.

[0048] In the following description, the downstream side of the ventilation direction ( figure 1 and figure 2 The direction indicated by the arrow X) is the front, the opposite side is the rear, and the up and down, left and right, that is, when viewed from the front to the rear figure 1 Up and down, left and right are up and down, left and right.

[0049] Furthermore, in the following description, the term "aluminum" includes not only pure aluminum but also aluminum alloys.

[0050] figure 1 Represent the overall structure of the evaporator with cold storage function of the present invention, Figure 2 to Figure 7 Indicates the structure of its main part. in addition, Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com