Heat exchanger and method of manufacturing the same

a technology of heat exchanger and insulating plate, which is applied in the direction of manufacturing tools, soldering devices, light and heating apparatus, etc., can solve the problems of insufficient melted flux reaching the inner fin to break up (destabilize or disrupt) the oxide film, and the inner fin may be unstable, etc., to achieve strong, effective brazing joints (fillets, easy to prepar

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

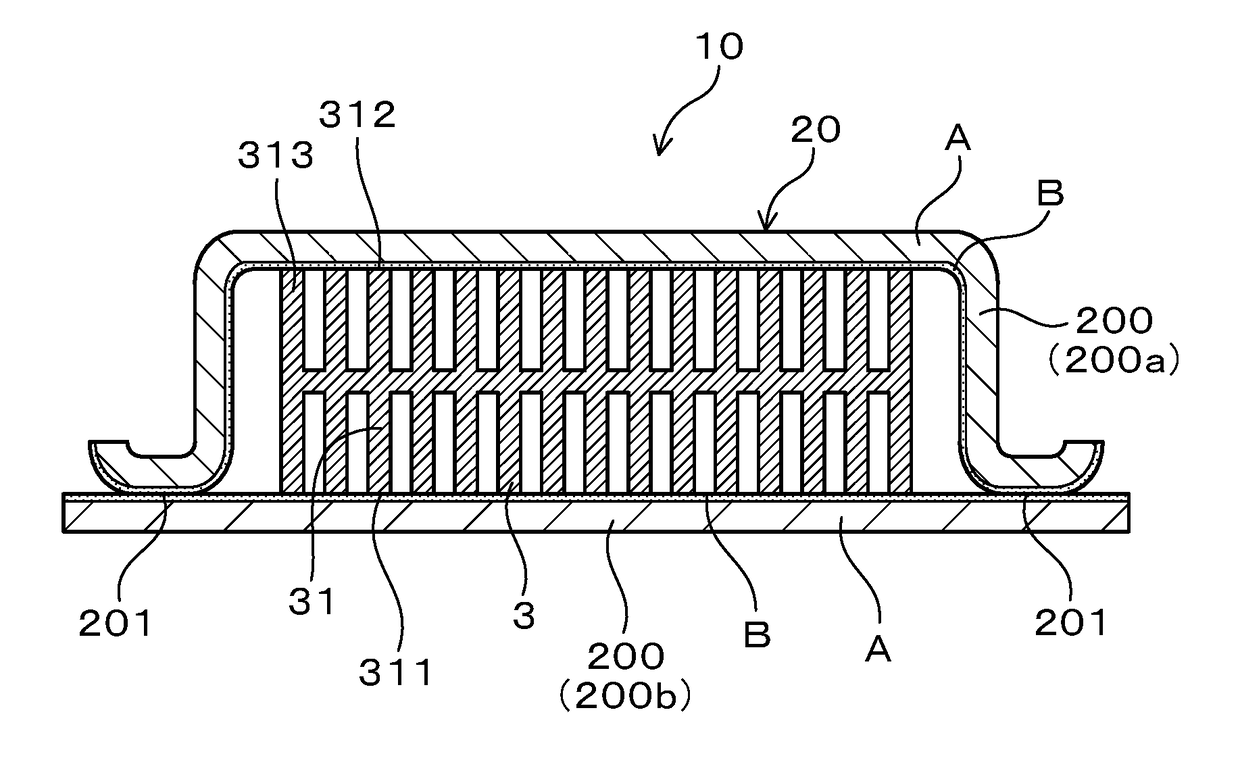

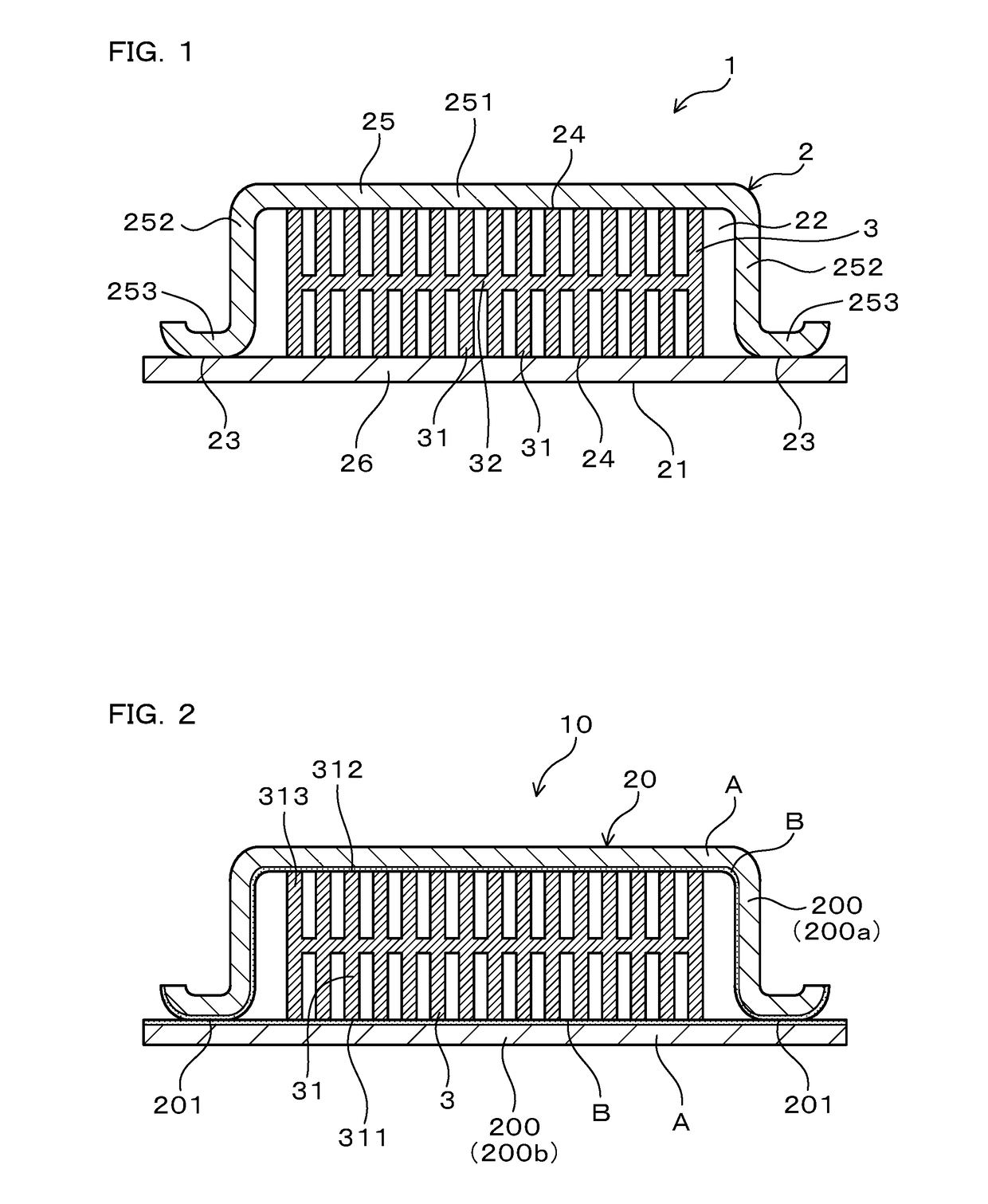

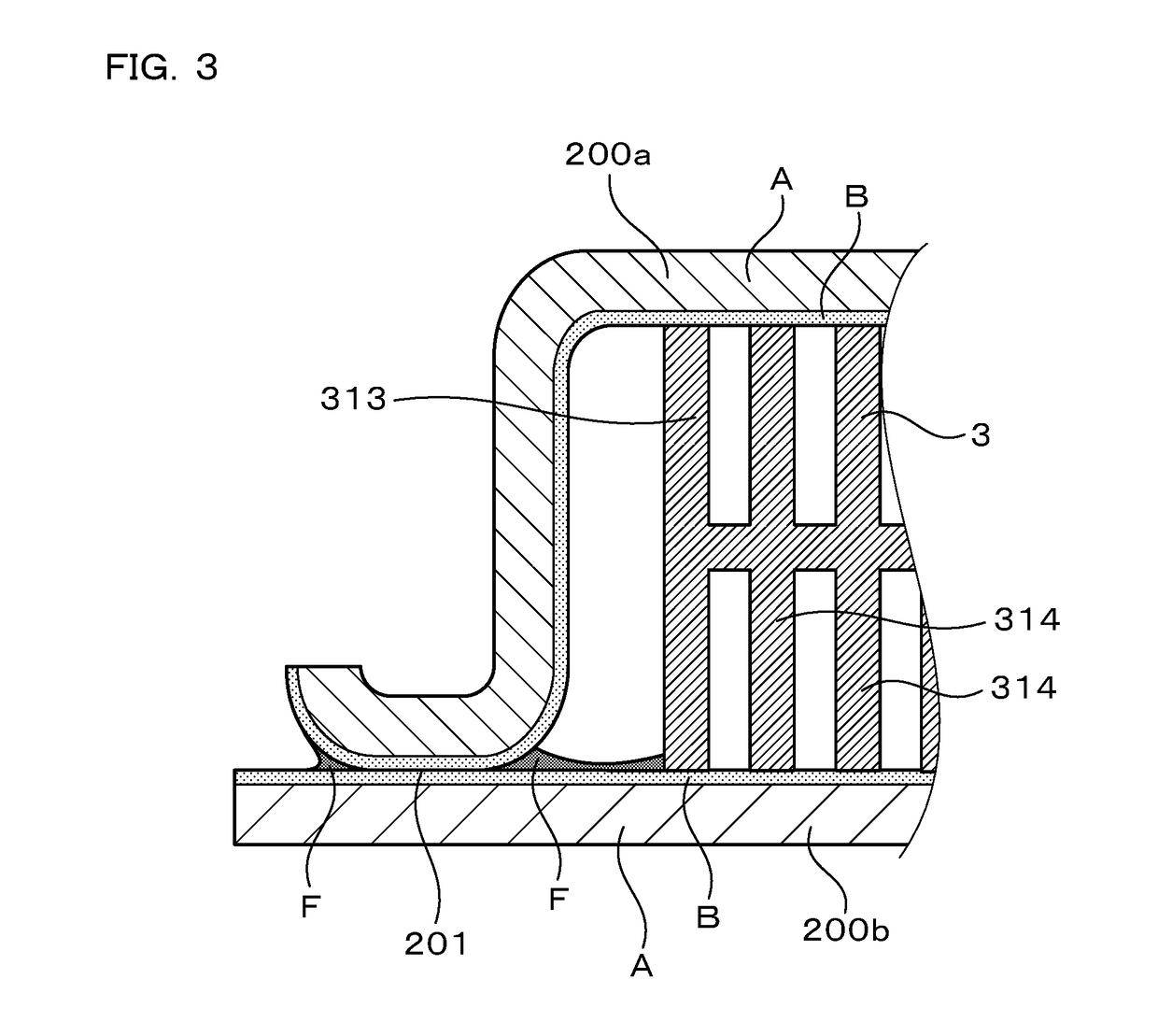

[0093]A representative heat exchanger and a representative method of manufacturing the same will now be explained with reference to the drawings. As shown in FIG. 1, the heat exchanger 1 of the present example comprises: a jacket 2, in which a heat-generating-element mounting surface 21, on which one or more heat-generating elements is (are) to be mounted, is provided (defined) on an outer surface thereof and a coolant passageway 22, through which a coolant circulates (flows), is provided (defined) in the interior; and an inner fin 3 disposed in the coolant passageway 22. The jacket 2 is preferably composed of a plate material having a chemical composition that contains Mg: 0.40-1.0 mass %, the remainder being Al and unavoidable impurities. However, other elements optionally may be added to the alloy composition of the jacket 2, as was discussed above and will be further discussed below. The inner fin 3 is formed by extruding an aluminum alloy having a chemical composition that pref...

experimental examples

[0108]The following experimental examples are additional examples (both inventive and comparative) of the heat exchanger 1 in which the chemical compositions of the core layer A, the filler-material layer B, and the aluminum alloy that constitutes the inner fin 3 have been variously modified. It is noted that the components of the heat exchangers 1 manufactured in the present examples have the same shape as in the above-described working example. It is noted that the reference numbers and letters used in the following experimental examples are the same as were used in FIG. 1 to FIG. 3 to indicate the same structural elements, etc. as in the working example, except as otherwise explained.

[0109]In the present examples, the clad plates 200 and the inner fin 3 were manufactured as described below.

[0110]Clad Plates 200

[0111]Aluminum alloys (A1-A7) having the chemical compositions listed in Table 1 were cast into ingots. The resulting ingots were heated to 560° C. and a homogenization tre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com