Aluminum material surface local gold plating process

A partial gold-plating and aluminum technology, which is applied in the field of gold plating, can solve the problems of poor bonding between aluminum and gold-plated layers, and the gold-plated layer is easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

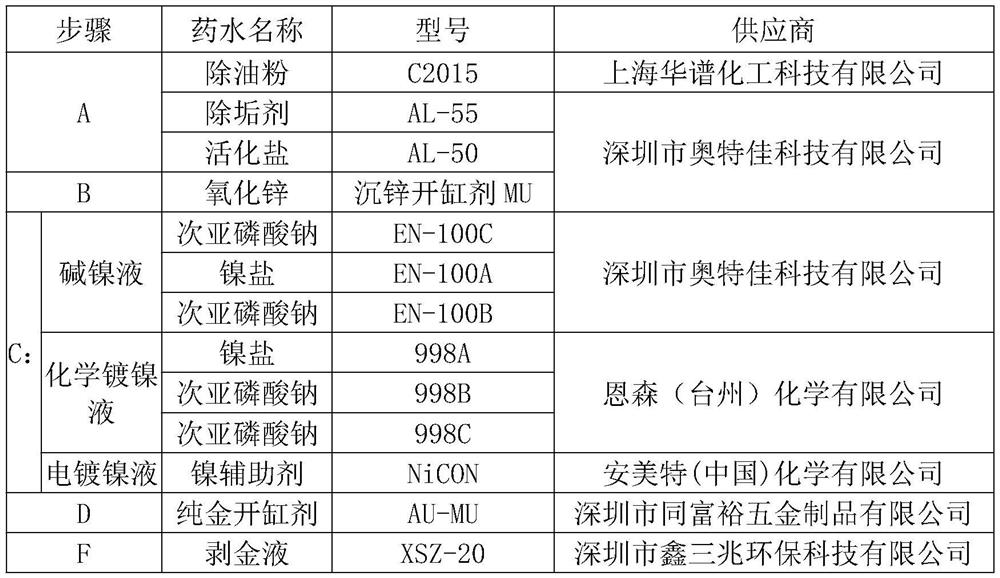

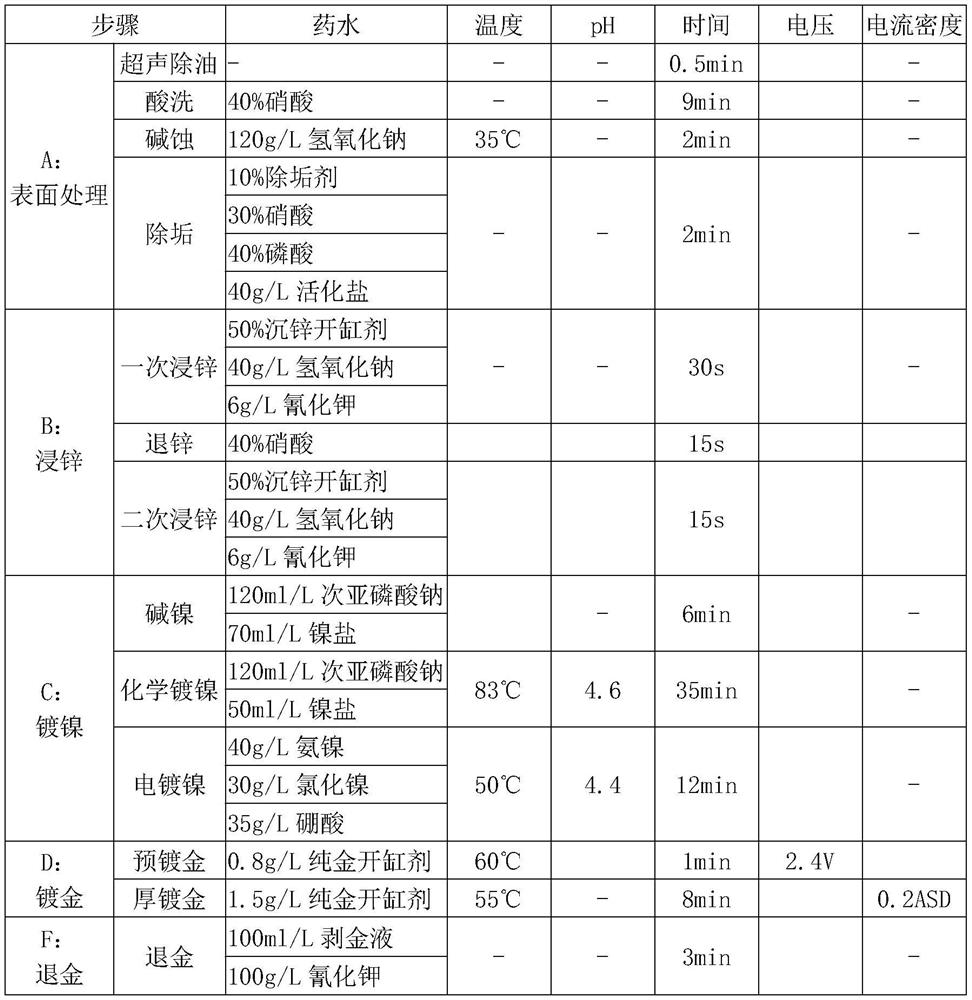

Method used

Image

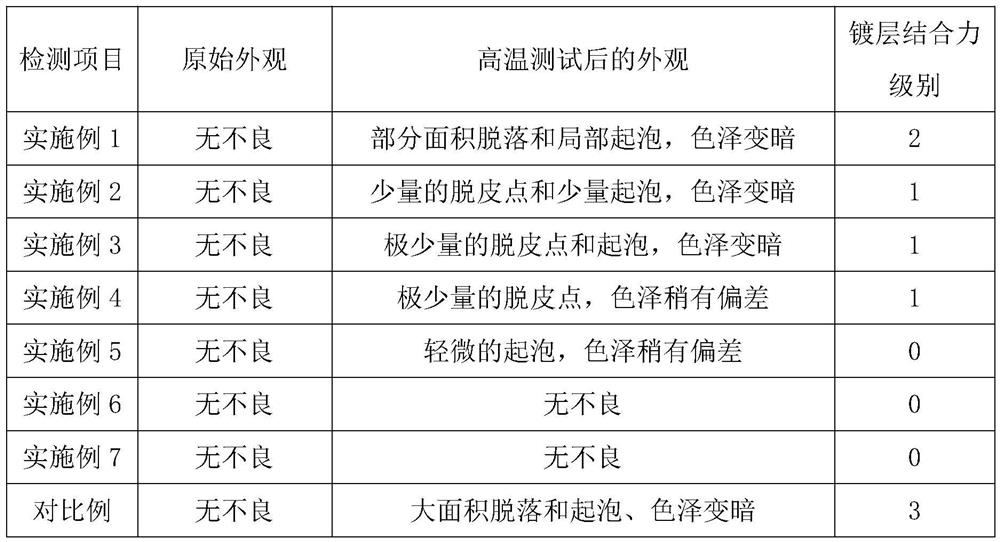

Examples

Embodiment 1

[0055] A partial gold plating process on the surface of an aluminum material is obtained by performing the following steps in sequence:

[0056] A. Surface treatment: Put degreasing powder in the ultrasonic tank, put the aluminum material in the ultrasonic tank to degrease for 0.5min and then wash it with water, and then place the aluminum material in a sodium hydroxide solution with a concentration of 120g / L at 35°C After reacting for 2 minutes in the medium, wash with water, and finally place the aluminum material in the descaling solution for 2 minutes and then wash it with water. The percentage concentration is 10%, the volume percent concentration of nitric acid in the descaling solution is 30%, the volume percent concentration of phosphoric acid in the descaling solution is 40%, and the concentration of the activated salt in the descaling solution is 40g / L.

[0057] B. Zinc dipping: immerse the aluminum material after the surface treatment in step A in the first zinc dip...

Embodiment 2

[0063] A partial gold plating process on the surface of an aluminum material, the difference from Example 1 is that step A specifically includes: putting degreasing powder in an ultrasonic tank, putting the aluminum material in the ultrasonic tank for degreasing for 0.5 min, and then washing the aluminum material with water. Put it in a nitric acid solution with a concentration of 40% by volume to react for 9 minutes, then place the aluminum material in a sodium hydroxide solution with a concentration of 120g / L at 35°C for 2 minutes, wash it with water, and finally put the aluminum material in a descaling After reacting in the solution for 2 minutes, wash with water, wherein the descaling solution is the same as in Example 1.

Embodiment 3

[0065] A partial gold-plating process on the surface of an aluminum material, the difference from Example 2 is that step B specifically includes: immersing the aluminum material after the surface treatment in step A into the first zinc dipping solution, washing it with water after reacting for 30 seconds, and then immersing the aluminum material in the annealing solution. Rinse with water after reacting in the zinc solution for 15s, and finally immerse the aluminum material in the second zinc dipping solution and react for 15s before washing with water. Wherein the first zinc dipping solution and the second zinc dipping solution are mixed solutions containing 50% zinc oxide, 40g / L sodium hydroxide and 6g / L potassium cyanide, and the zinc stripping solution is nitric acid with a concentration of 40% by volume solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com