Aluminum alloy brazing sheet and brazing method

一种钎焊板、铝合金的技术,应用在焊接介质、焊接设备、金属加工等方向,能够解决添加量限制、耐腐蚀性不良影响、硬钎料表面的氧化覆膜破坏作用缺乏等问题,达到钎焊性提高、稳定钎焊性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

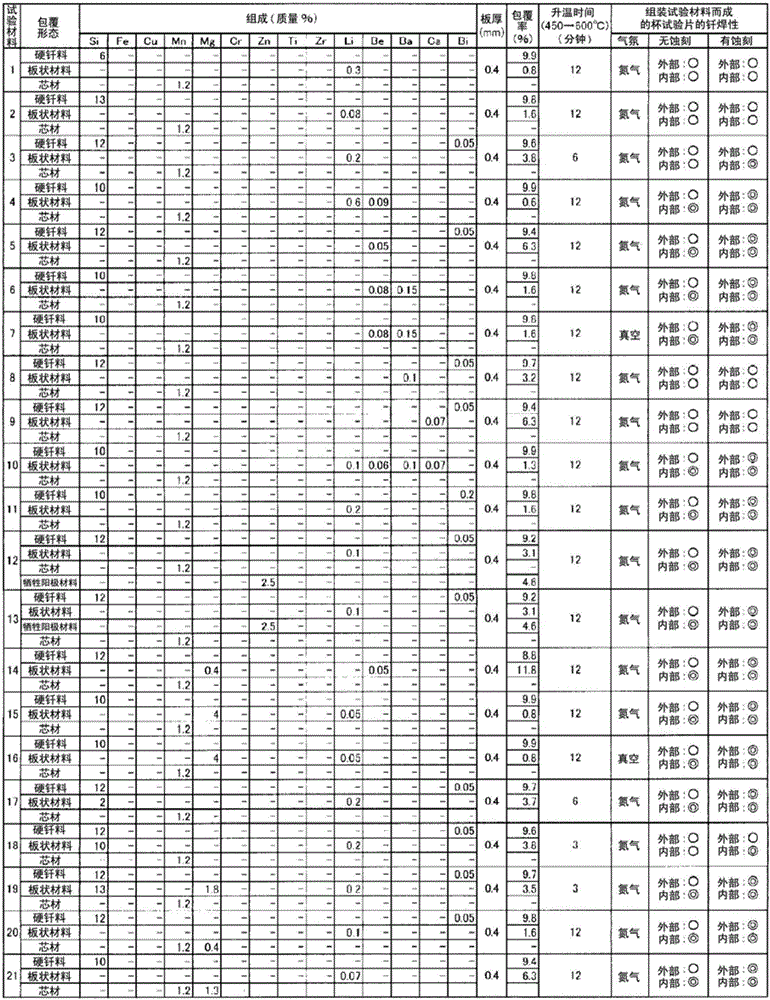

[0060] The brazing material, core material, plate material, and sacrificial anode material having the compositions shown in Table 1 were respectively cast by continuous casting, and the obtained ingot was coated with a size of 163 mm in length, 163 mm in width, and 27 mm in thickness for the core material. . For the brazing filler metal, the obtained ingot was hot-rolled to a thickness of 3 mm, and cut into a size of 163 mm in length and 163 mm in width.

[0061] For the plate-shaped material, the obtained ingot was hot-rolled to a thickness of 3 mm, then cold-rolled to a thickness of 0.25 to 2 mm, and cut to a size of 163 mm in length and 163 mm in width. A part of the sheet material is prepared as a cut product of an ingot. For the sacrificial anode material, the obtained ingot was hot rolled to a thickness of 3 mm, then cold rolled to 1.5 mm, and cut into a size of 163 mm in length and 163 mm in width.

[0062] According to the conventional method, the prepared brazing ma...

Embodiment 2

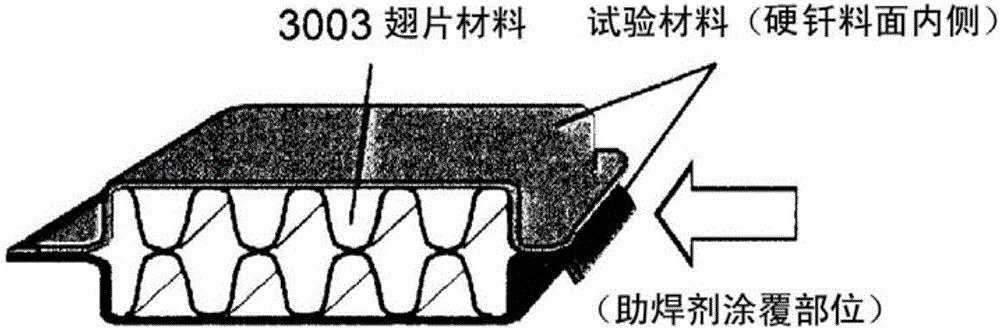

[0078] The brazing material, the core material, the plate material, and the sacrificial anode material having the composition shown in Table 3 were respectively cast by continuous casting, and a soft clad plate material with a thickness of 0.4 mm was produced in the same manner as in Example 1, which was used as a test The material is pressurized into a cup shape, degreased with acetone only (no etching), or degreased with acetone, and then etched with a weak acid (with etching), and a 0.1mm-thick 3003 alloy that will be degreased is installed inside fins obtained by sheet forming, assembled into figure 1 The cup test piece shown. On the outside of the flared joint of the cup test piece ( figure 2 arrow part) coated with alcohol diluted flux (in the form of KF and AlF 3 Fluoride flux of the basic composition), in a nitrogen gas furnace, brazing heating was performed under the same conditions as in Example 1, and in the same manner as in Example 1, the brazing joint state o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com