Heat exchanger tube, heat exchanger, and manufacturing method thereof

A technology of heat exchanger tubes and heat exchanger tubes, applied in heat exchange equipment, manufacturing tools, indirect heat exchangers, etc., can solve problems such as volume rate deterioration, and achieve prevention of poor brazing, high quality, and deformation prevention. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

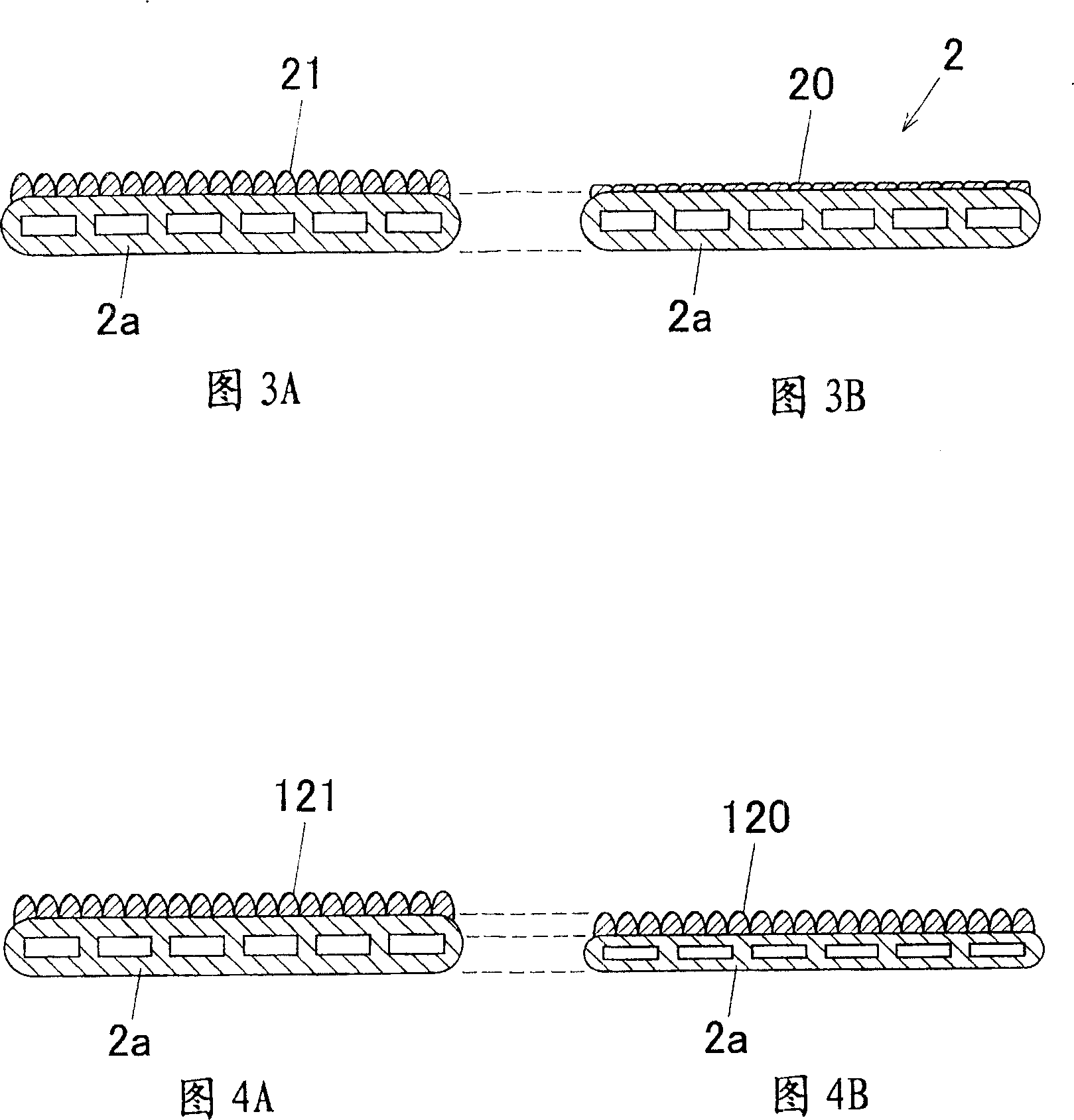

[0169] As shown in Table 1, an Al alloy extruded material (Cu: 0.4% by mass, Mn: 0.21% by mass; the rest is Al) was used to extrude a flat sheet with a width of 16 mm, a height of 3 mm, and a wall thickness of 0.5 mm through an extruder. Porous extruded tube (core part). The surface roughness of the obtained die portion was 10 μm.

[0170] The Al—Si alloy was thermally sprayed onto the upper and lower surfaces of the extruded tube by thermal spray guns of an arc thermal sprayer arranged on the upper and lower sides of the extruder outlet. In this thermal spraying method, the thermal spraying distance was adjusted to 120 mm in an air atmosphere.

[0171] The molten thermal spray particles to be sprayed onto the die attach to the die by cooling from the thermal spray temperature to the temperature of the die by being cooled by the tube when the thermal spray particles reach the core. This is achieved by the core absorbing heat.

[0172] In Table 1, in terms of the degree of c...

example 2

[0177] As shown in Table 1, an extruded tube with a surface roughness Ry of 10 μm was thermally sprayed in a nitrogen atmosphere by arc spraying at a thermal spraying temperature of 5500° C. and a thermal spraying distance of 60 mm. The pipe member having the thermally sprayed layer was pressed with a calender roll to form a brazing layer having a brazing material filling rate of 50%, a thickness of 15 μm, and a surface roughness Ry of 37 μm. Thus, a heat exchanger tube was fabricated in the same manner as above. In this tube, the average equivalent diameter of Si crystals was 0.1 µm.

[0178] Then, a heat exchanger was manufactured using this heat exchanger tube in the same manner as in the above example.

example 3

[0180] As shown in Table 1, an extruded pipe with a surface roughness Ry of 7 μm was thermally sprayed in a nitrogen atmosphere at a thermal spraying temperature of 4800° C. and a thermal spraying distance of 60 mm by arc spraying method. The pipe member having the thermally sprayed layer was pressed with a calender roll to form a brazing layer having a brazing material filling rate of 60%, a thickness of 20 μm, and a surface roughness Ry of 35 μm. Thus, a heat exchanger tube was fabricated in the same manner as above. In this tube, the average equivalent diameter of Si crystals was 0.5 µm.

[0181] Then, a heat exchanger was manufactured using this heat exchanger tube in the same manner as in the above example.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com