Patents

Literature

31results about How to "Achieve fusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

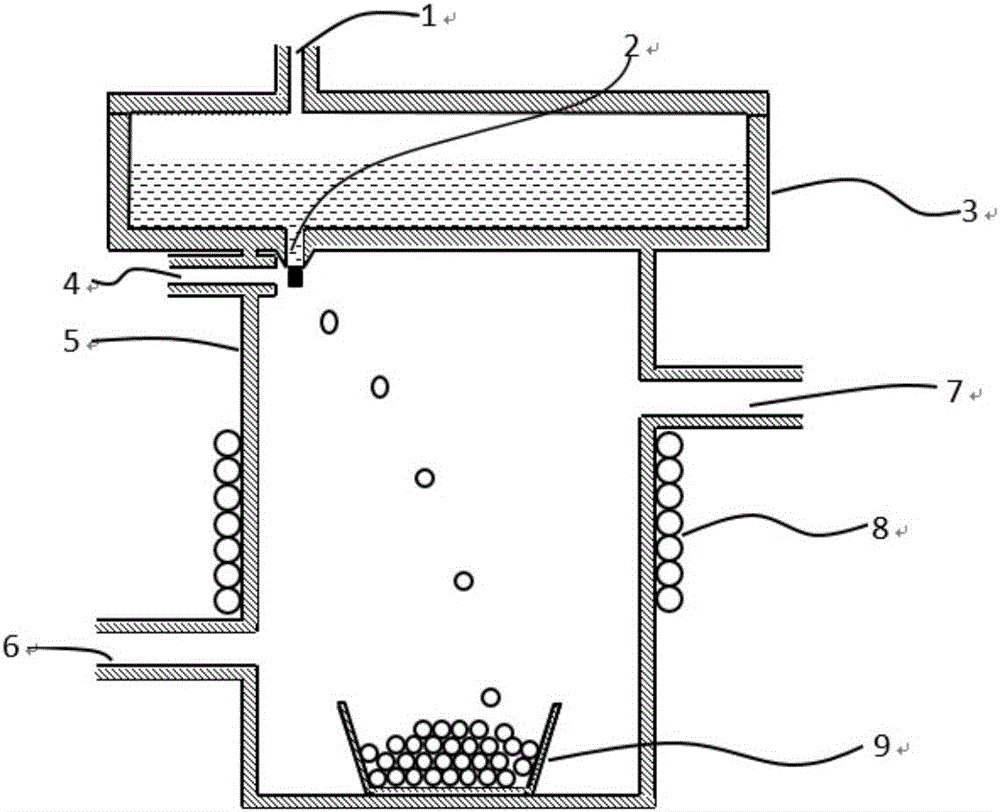

Method and device for manufacturing polyamide three-dimensional object by laser

ActiveCN106626379AAchieve fusionSmall spotAdditive manufacturing apparatus3D object support structuresPolyamideLength wave

The invention discloses a method for manufacturing a polyamide three-dimensional object by laser. The method comprises the steps that a layer of manufacturing material is laid and conveyed onto a bottom plate or a selective fusion layer to form a novel material layer; a laser device emits laser; the laser is guided to selectively irradiate a fusion region on the novel material layer; the fusion region is a cross section position, corresponding the three-dimensional object to be manufactured, on the novel material layer, wherein the laser is generated by the laser device with the wavelength being 400 to 1080nm; the manufacturing material is a mixture of a polyamide powder material and a thermal medium material; the thermal medium material absorbs laser energy and conducts the laser energy to polyamide powder, so that the manufacturing material in the laser irradiation region realizes fusion. The polyamide three-dimensional object with high manufacturing precision can be manufactured according to the method.

Owner:HUNAN FARSOON HIGH TECH CO LTD

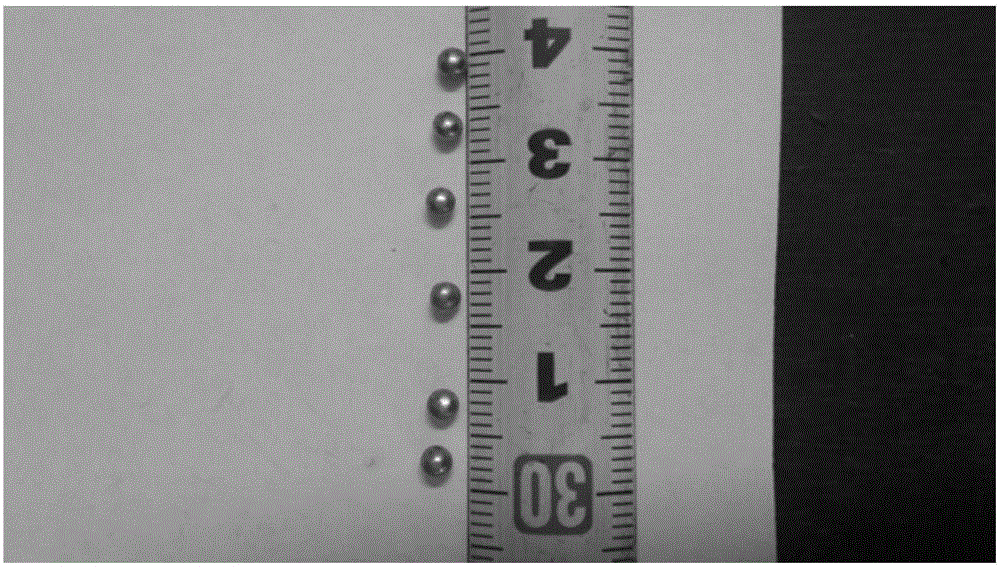

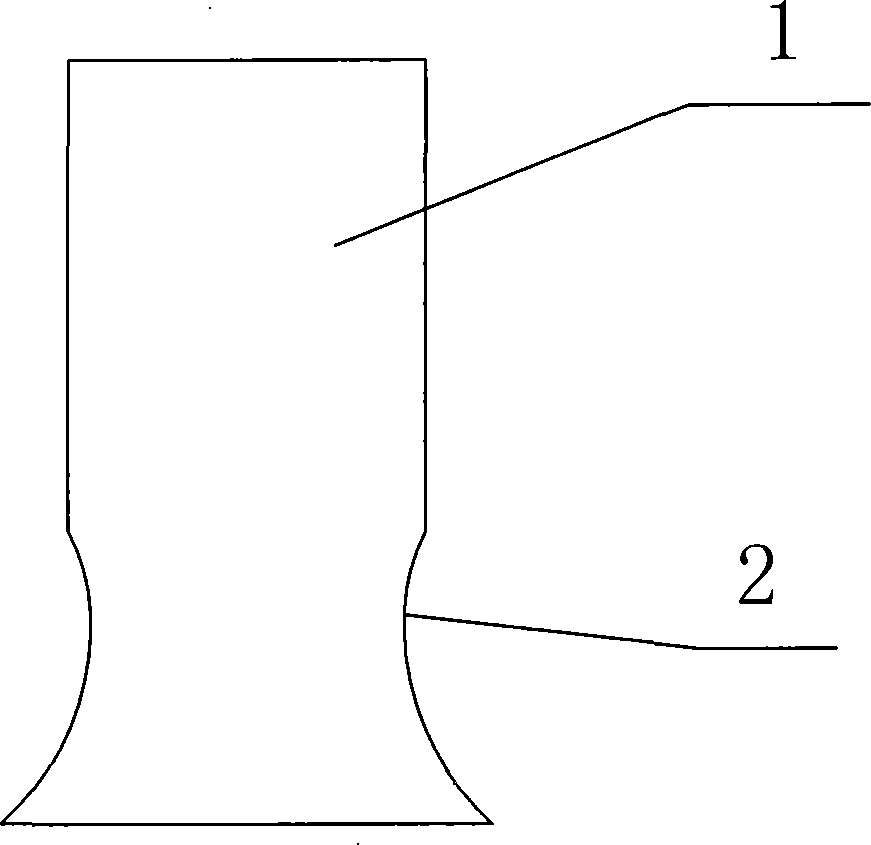

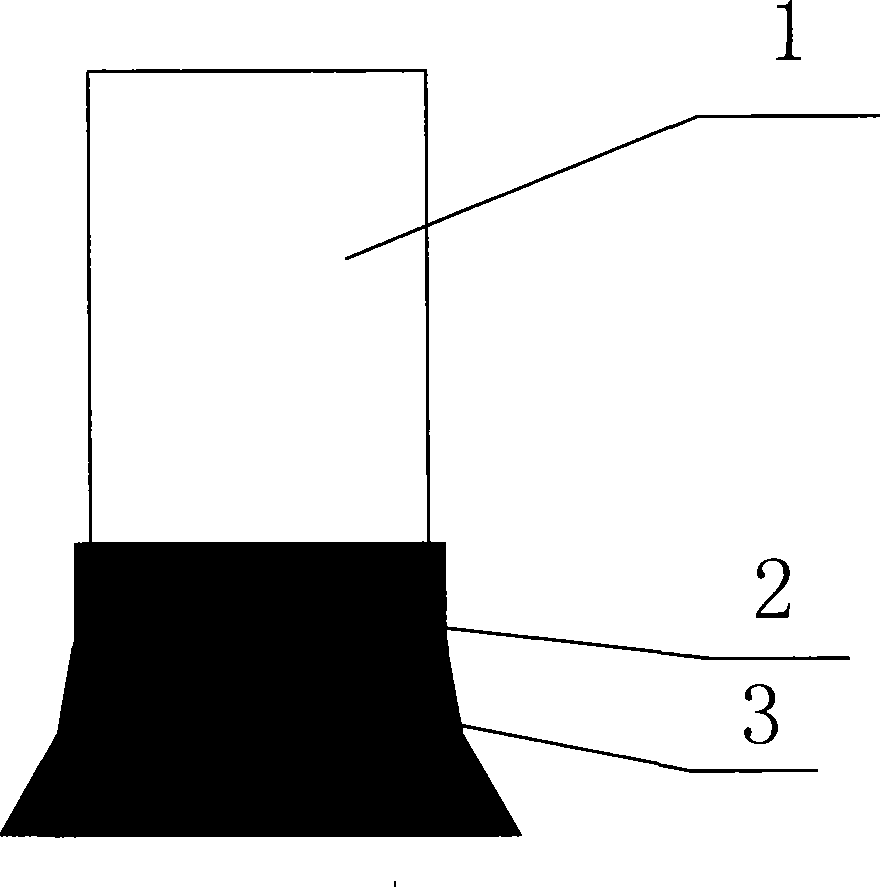

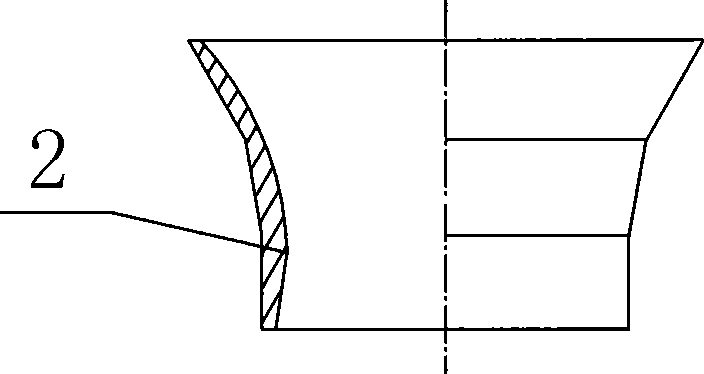

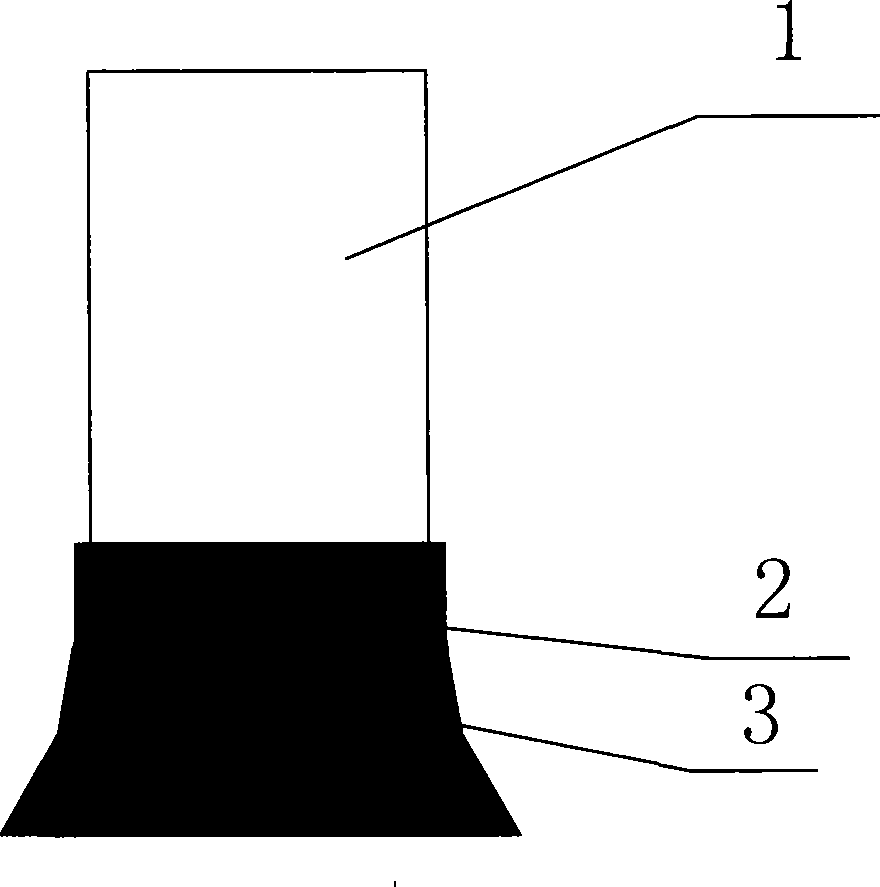

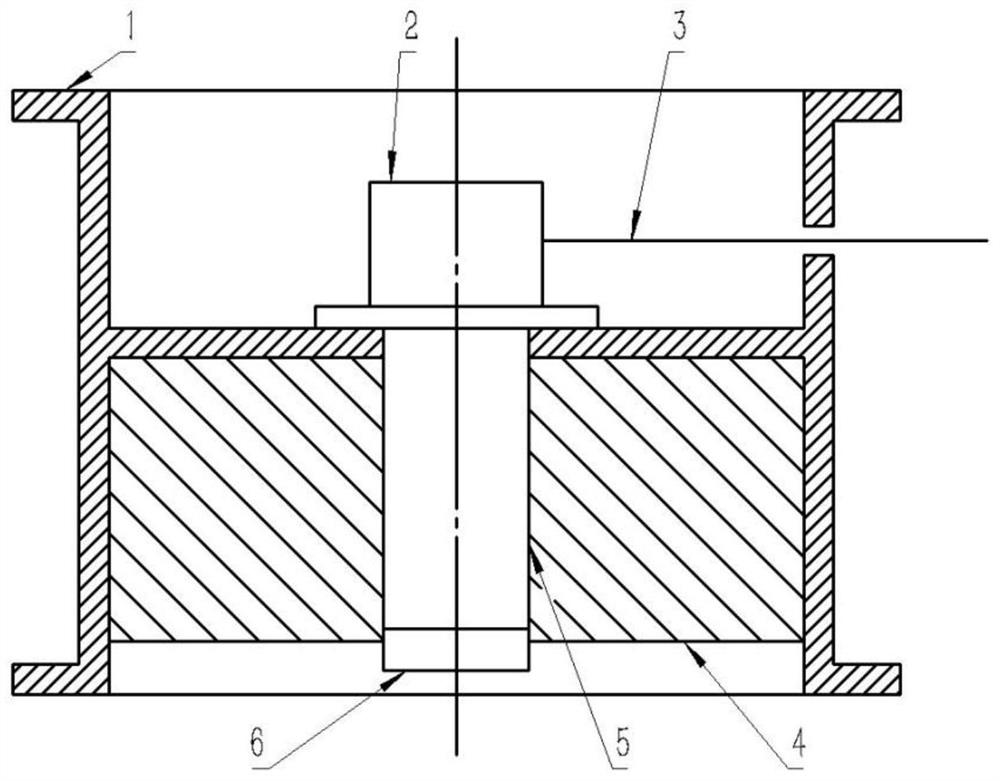

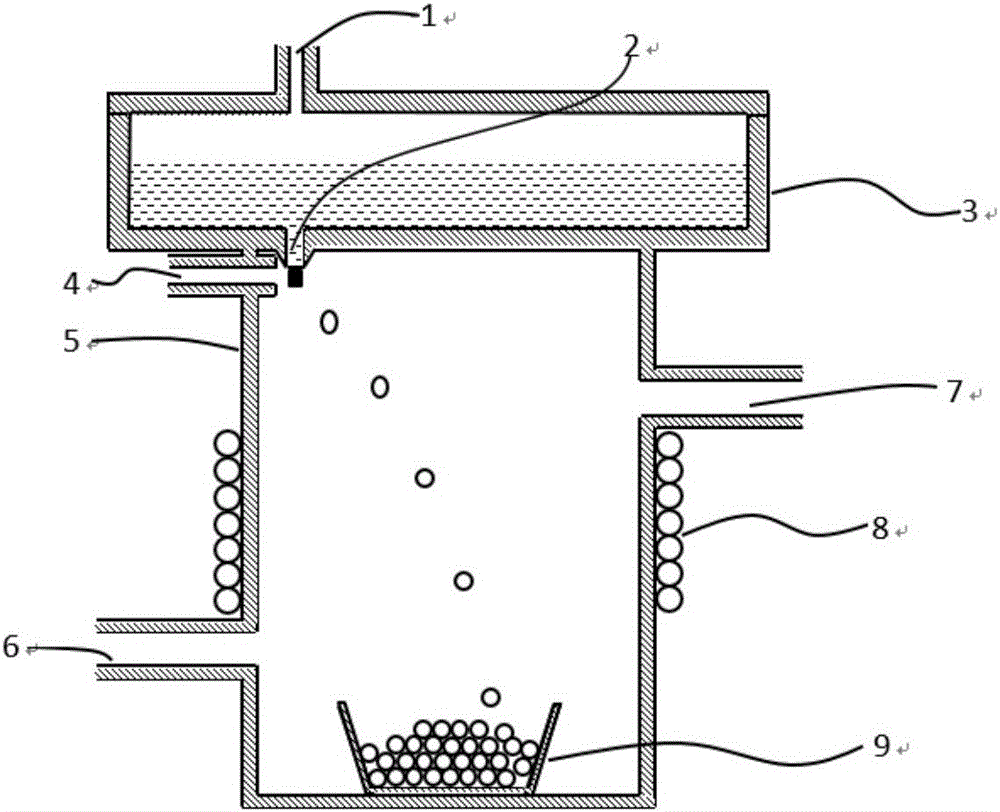

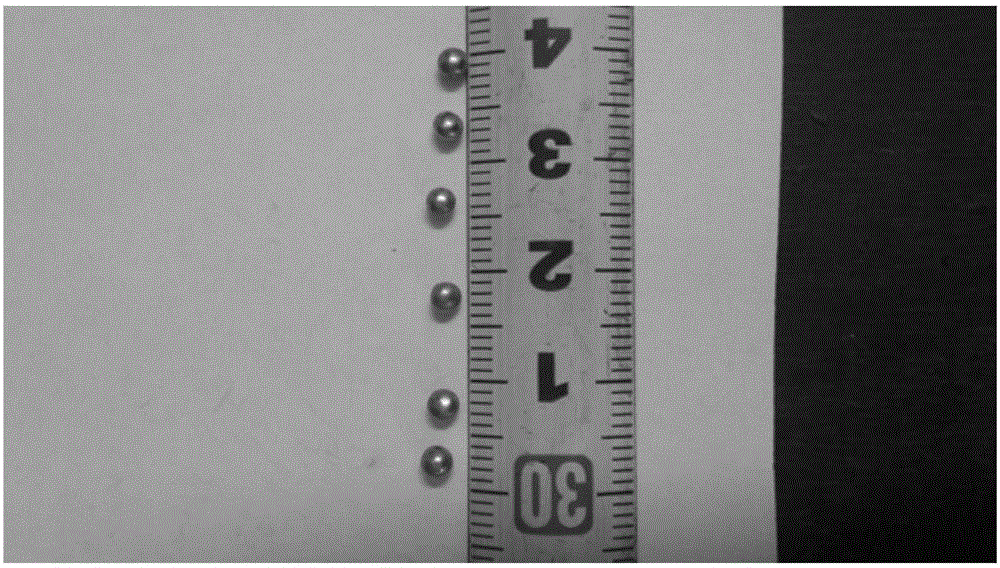

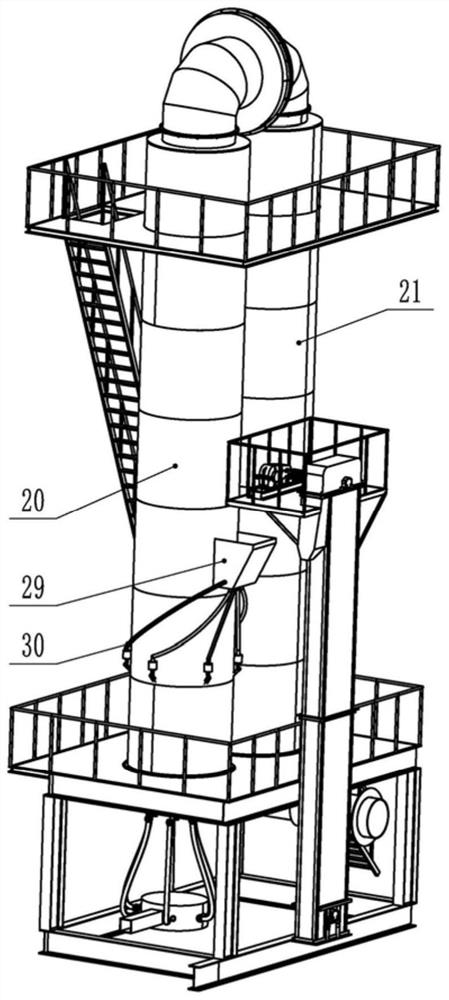

Brittle metal microspheres preparation method based on metal microspheres forming device

The invention discloses a brittle metal microspheres preparation method based on a metal microspheres forming device. The metal microspheres forming device comprises an upper melting chamber and a lower cavity body. The melting chamber is mainly used for melting brittle metal. The molten brittle metal is sprayed into the cavity body by a spray nozzle and cools, solidifies and forms in the cavity body. Prepared brittle metal microspheres are distributed uniformly in particle size with the range being between 1mm and 4mm and the morphology of the prepared brittle metal microspheres is in a standard sphere shape. The method is simple in equipment, strong in operability and capable of continuous production and meeting the industrial production requirements.

Owner:ZHUZHOU KENENG NEW MATERIAL CO LTD

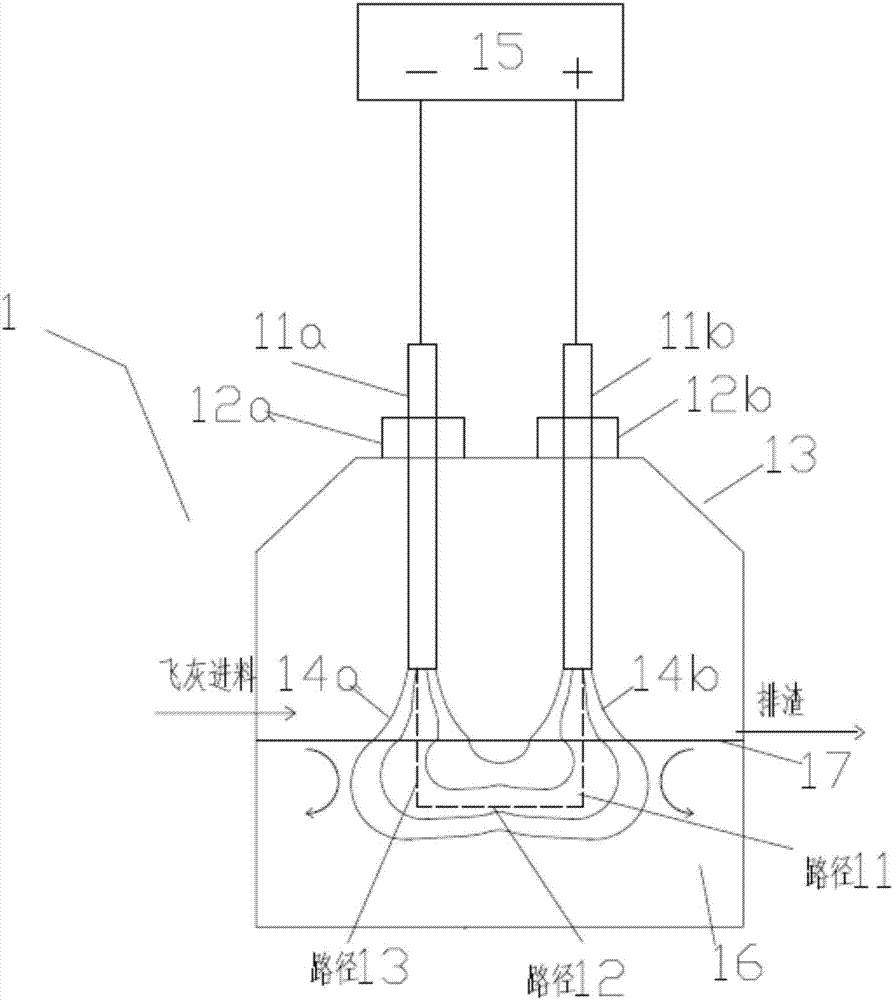

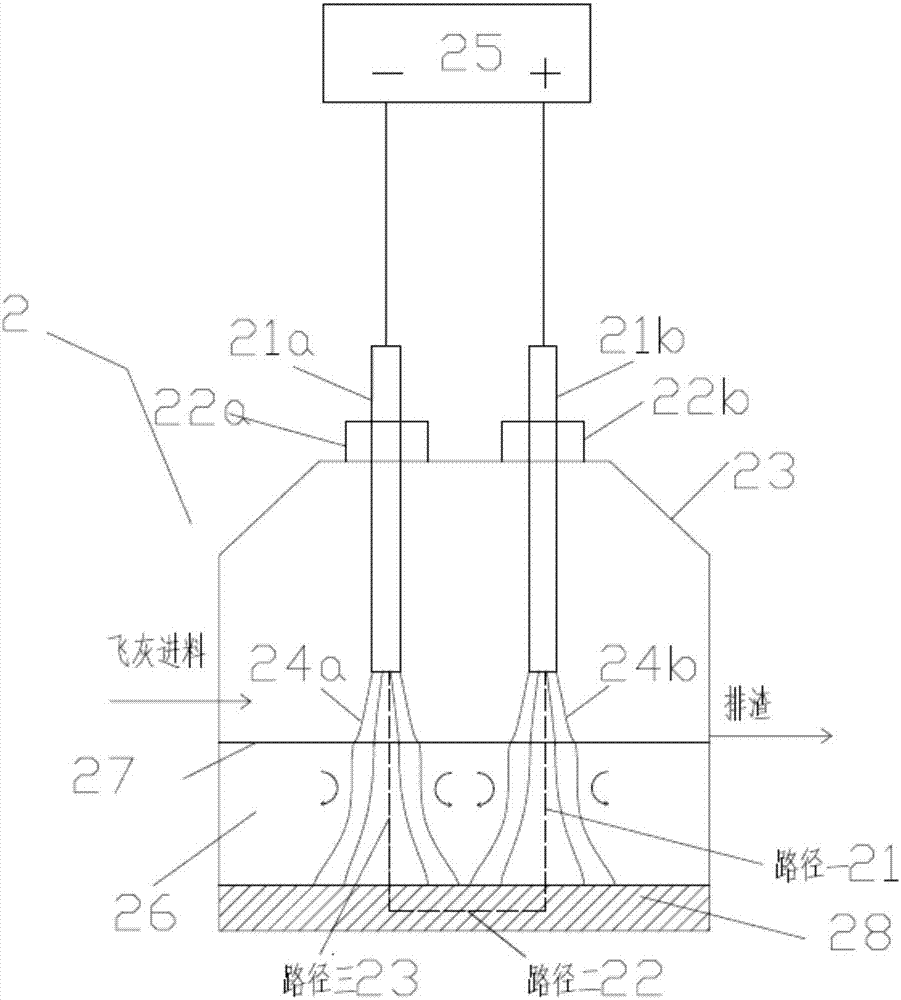

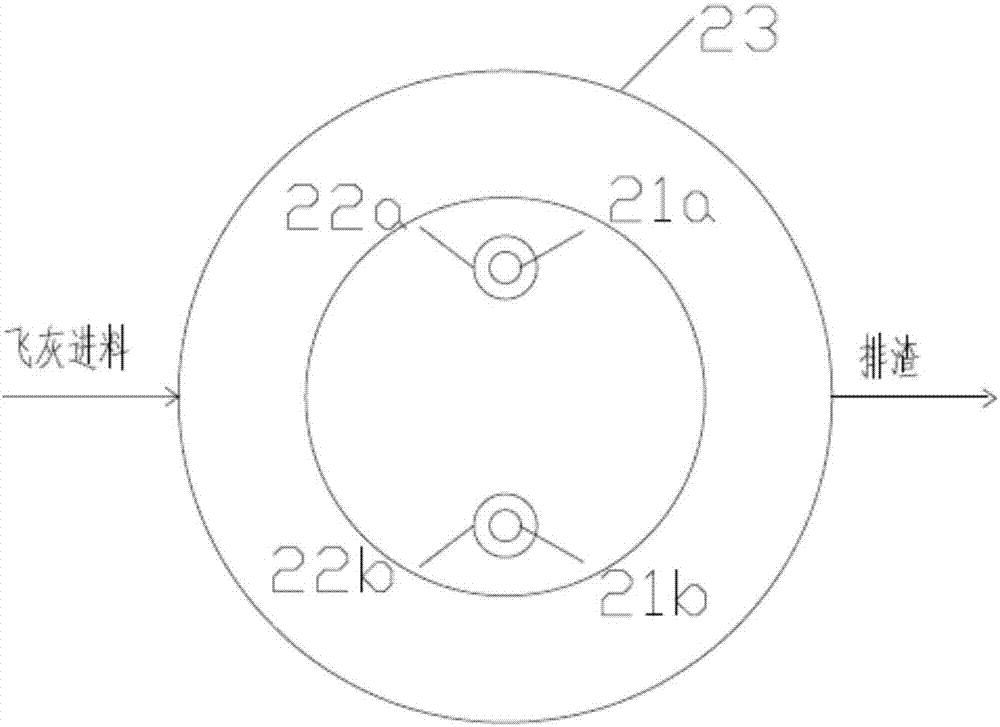

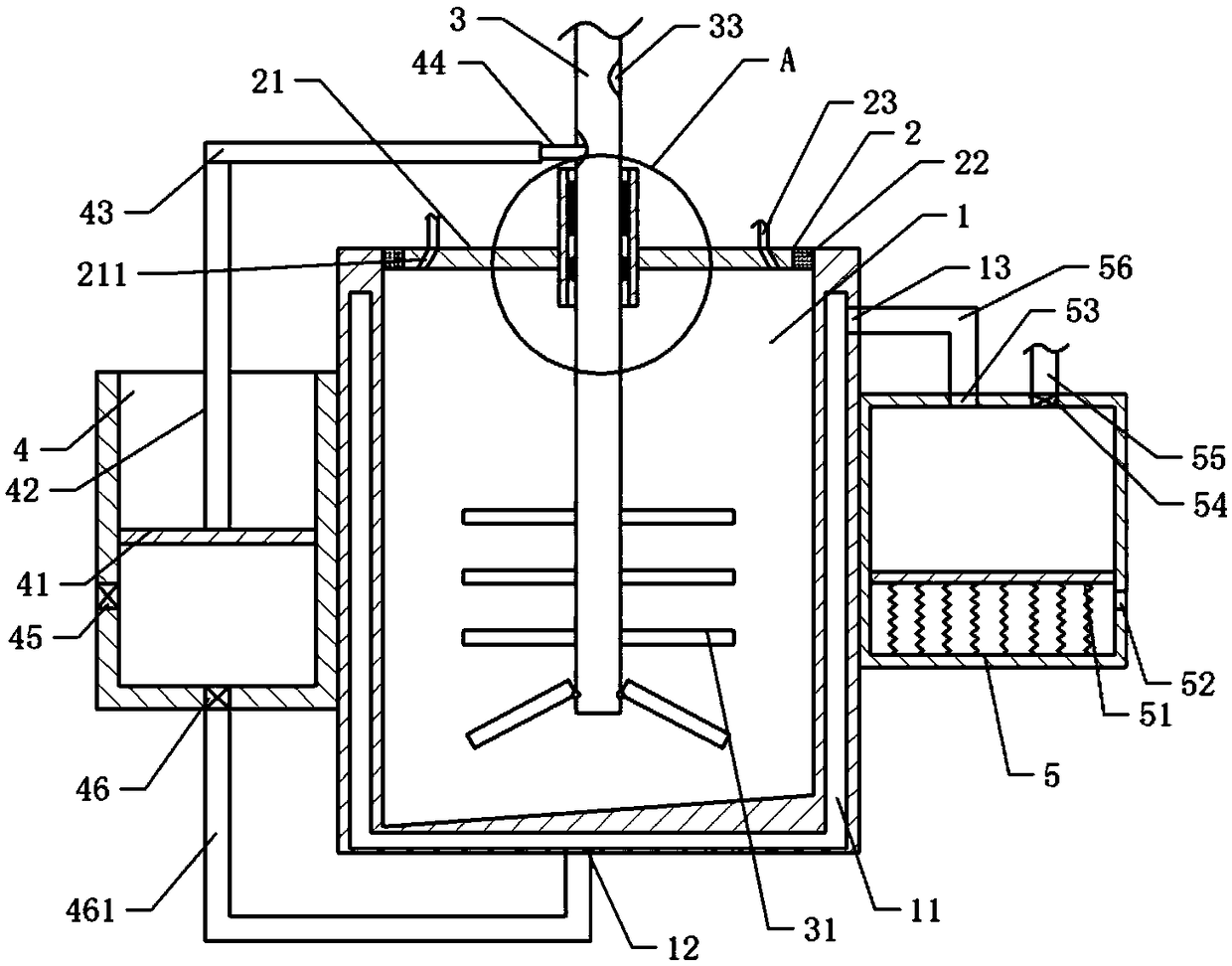

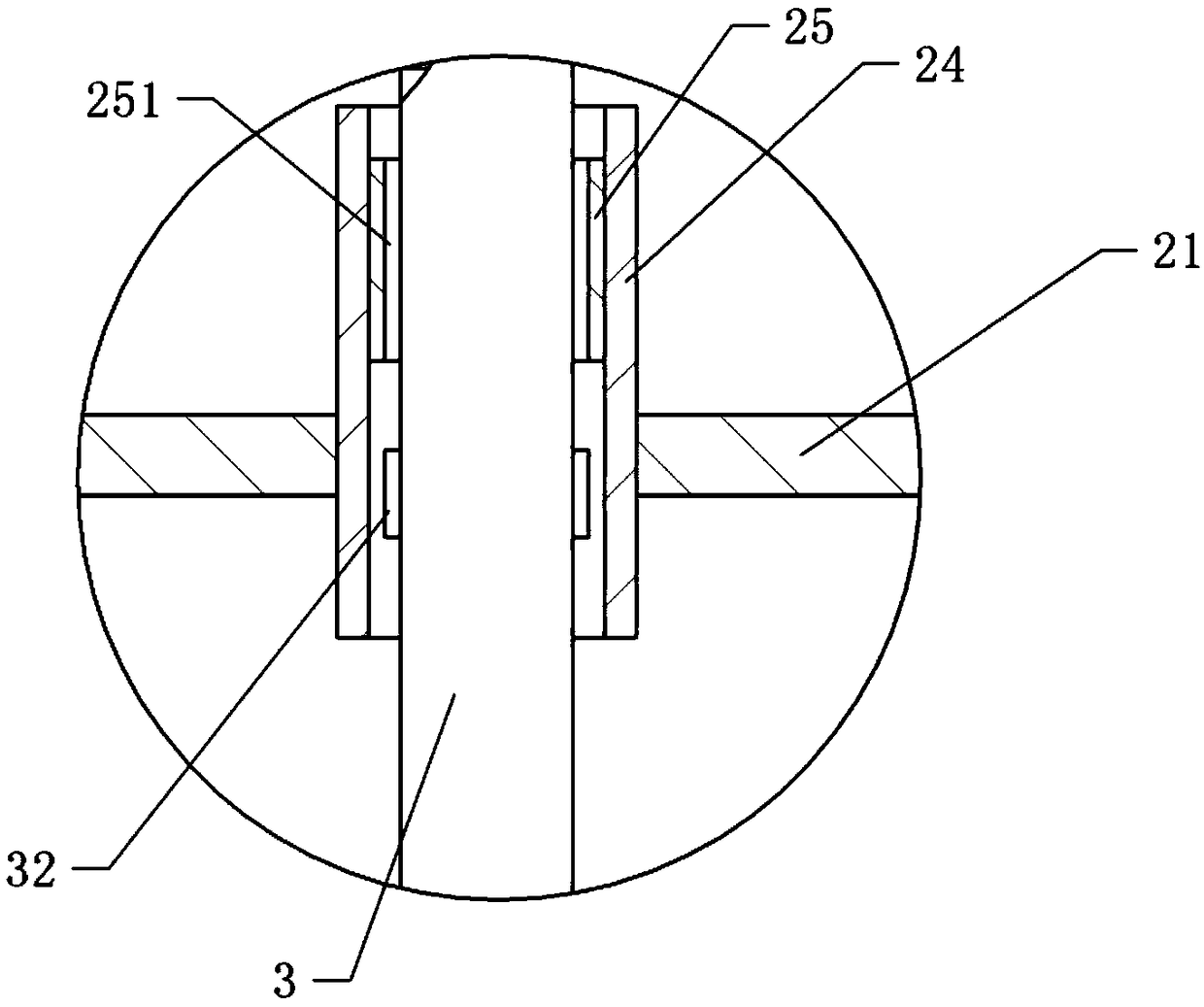

Novel double-electrode direct-current arc system for melting wastes

ActiveCN107020293AAchieve fusionMaximize Melting RateSolid waste disposalTransportation and packagingSlagCurrent distribution

The invention discloses a novel double-electrode direct-current arc system for melting wastes. The novel double-electrode direct-current arc system solves the technical problem of technical defects existed in an existing double-electrode arc technology aiming at the background technology. The adopted technical scheme is characterized in that the novel double-electrode direct-current arc system for melting the wastes comprises a melting furnace, a melting furnace body provided with a fly ash feed inlet and a slag discharge opening, double electrodes vertically inserted into the furnace body, and two lifting systems which are in one-to-one correspondence to the double electrodes and used for adjusting the heights of the double electrodes relative to the surface of a melting pool, wherein the space between the double electrodes vertically inserted into the furnace body is more than two times larger that the height of the melting pool; the two electrodes are connected onto a negative pole and a positive pole of a direct-current power supply; a furnace bottom conductive piece is arranged at the bottom part of the furnace body; and the conductivity of the furnace bottom conductive piece is more than two orders of magnitude higher than the conductivity for melting the wastes. The novel double-electrode direct-current arc system for melting the wastes has the advantages that current distribution in the melting pool is improved, and the fly ash melting pool can be more effectively melted.

Owner:JIANGSU TIANYING ENVIRONMENTAL PROTECTION ENERGY COMPLETE EQUIP CO LTD

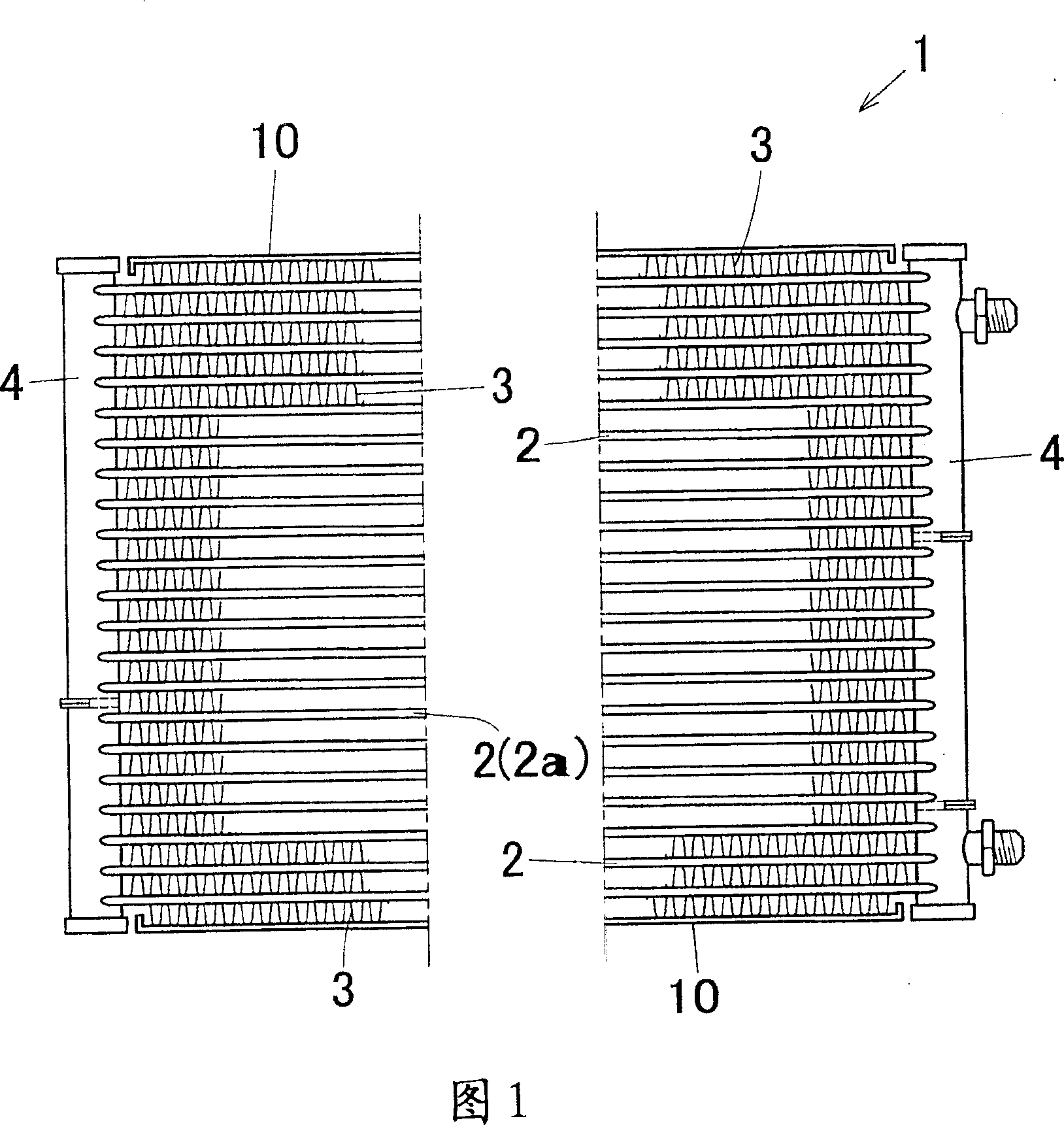

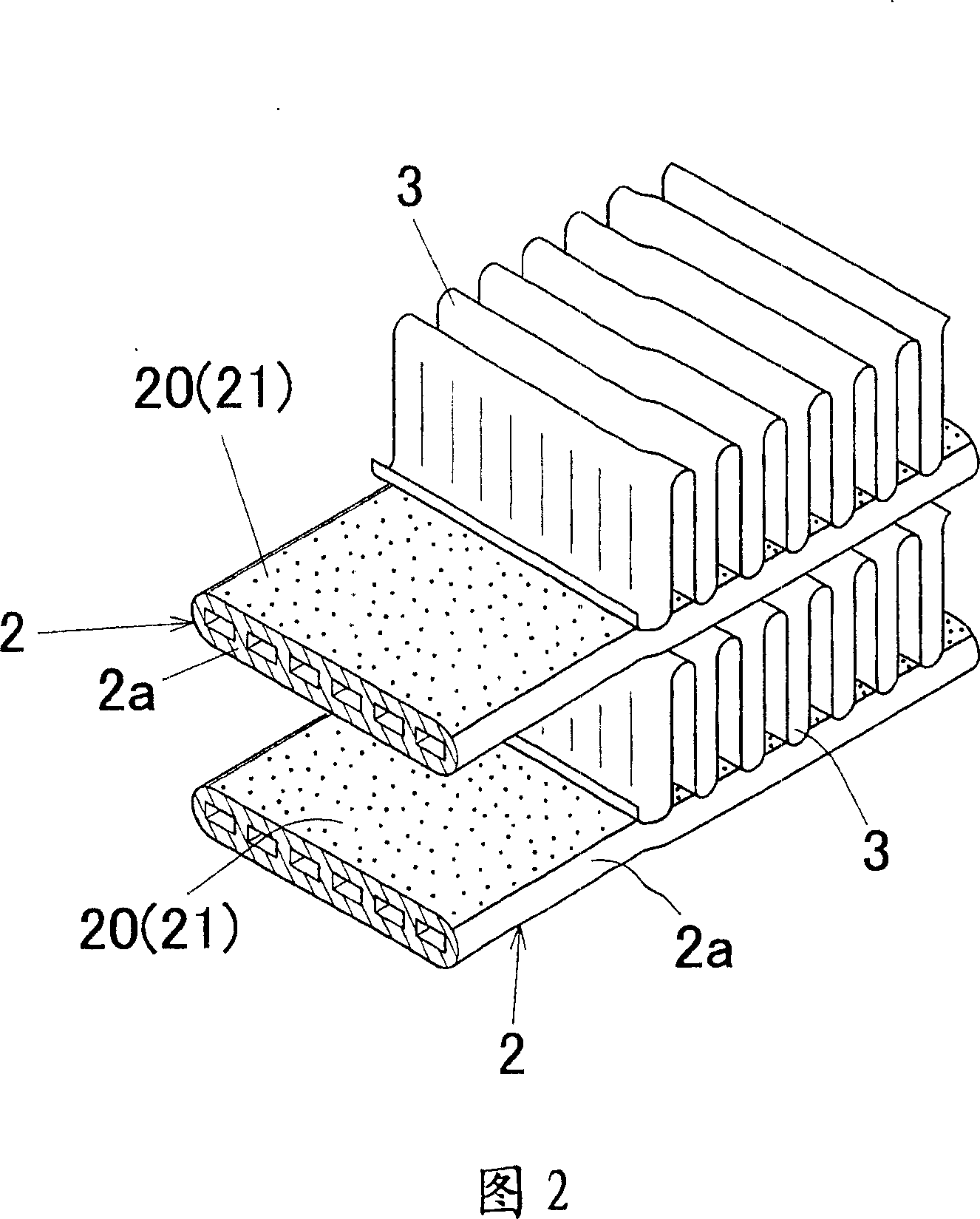

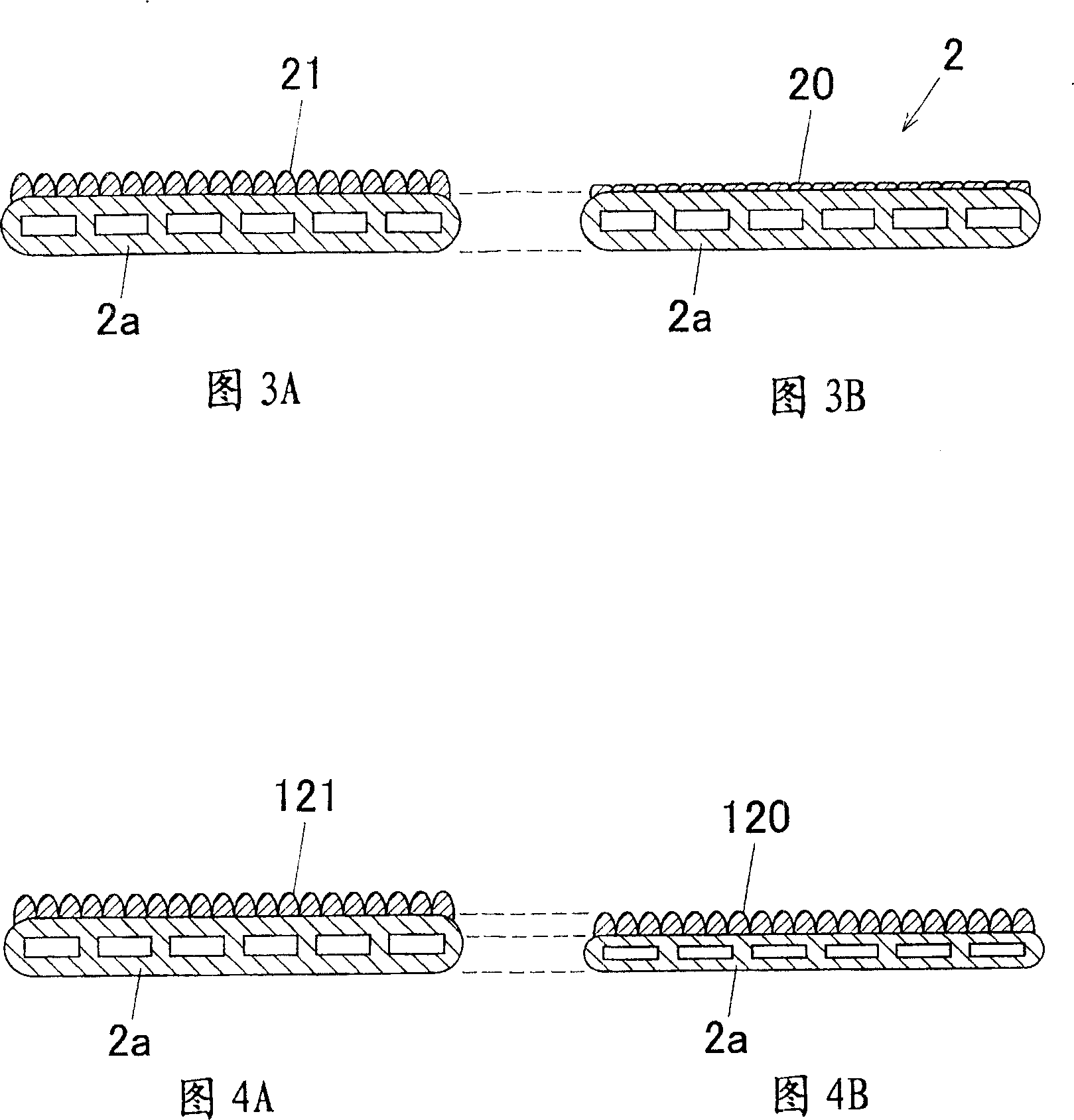

Heat exchanger tube, heat exchanger, and manufacturing method thereof

InactiveCN1964812AAvoid separationEnhanced fill (rate) rateSoldering apparatusStationary conduit assembliesMolten stateThermal spraying

This invention relates to a method of manufacturing an aluminum heat exchanger tube. In forming a thermally sprayed layer 21 on a surface of an aluminum flat tube by thermally spraying Al-Si alloy thermal-spraying particles, quenching the thermally sprayed thermal-spraying particles in a molten state to make them adhere to the tube core 2a. The surface of the thermally sprayed layer 21 is smoothed with, e.g., reduction rolls to form a brazing layer 20. With this method, brazing defects due to fin detachment, erosion to the tube of the brazing material, etc., can be prevented, resulting in good brazing performance.

Owner:SHOWA DENKO KK

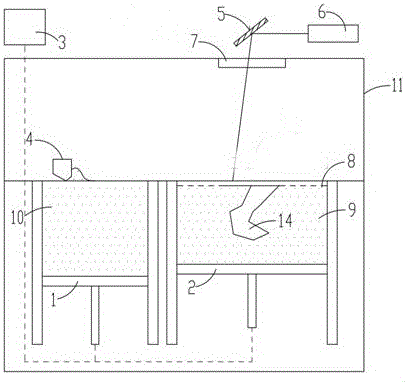

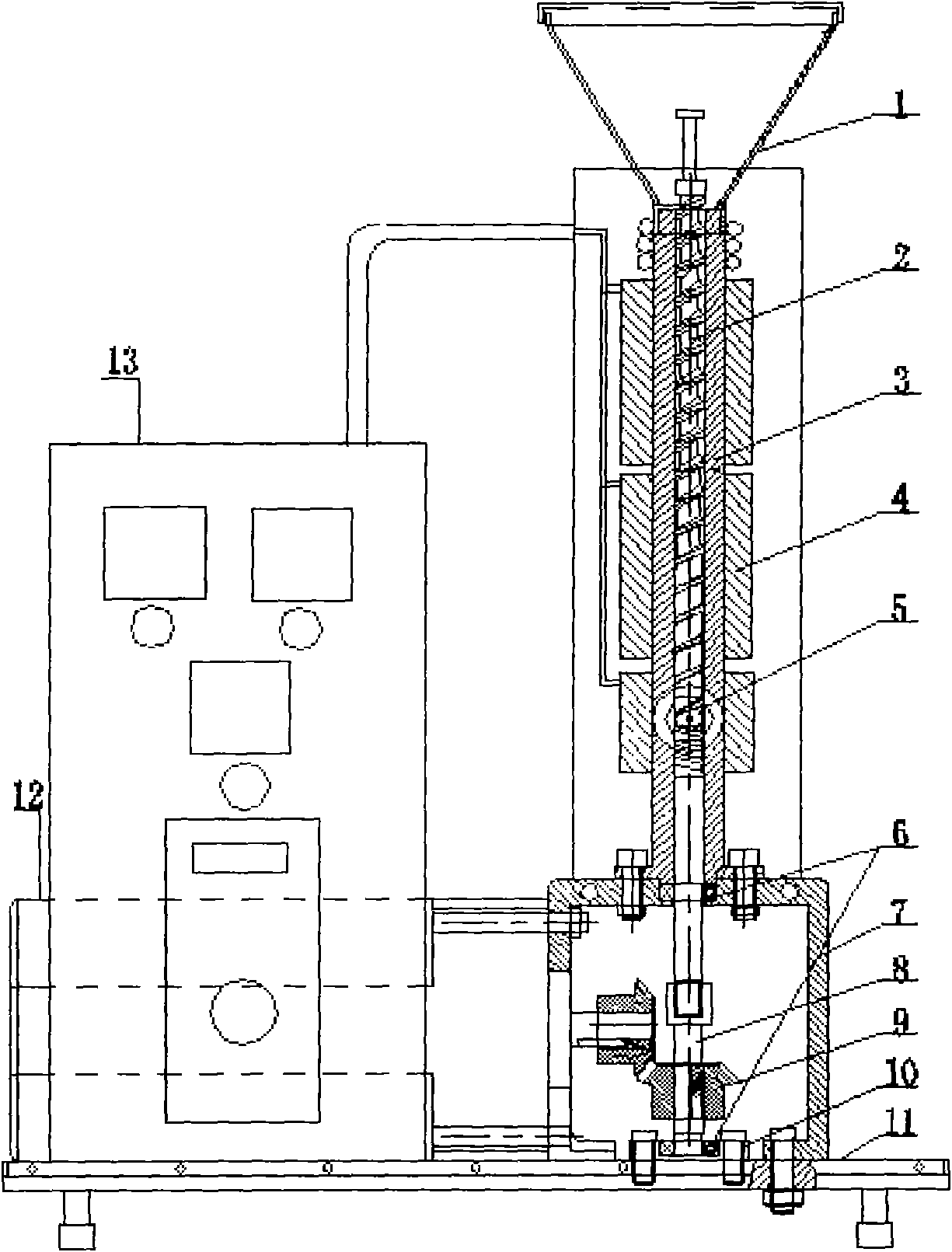

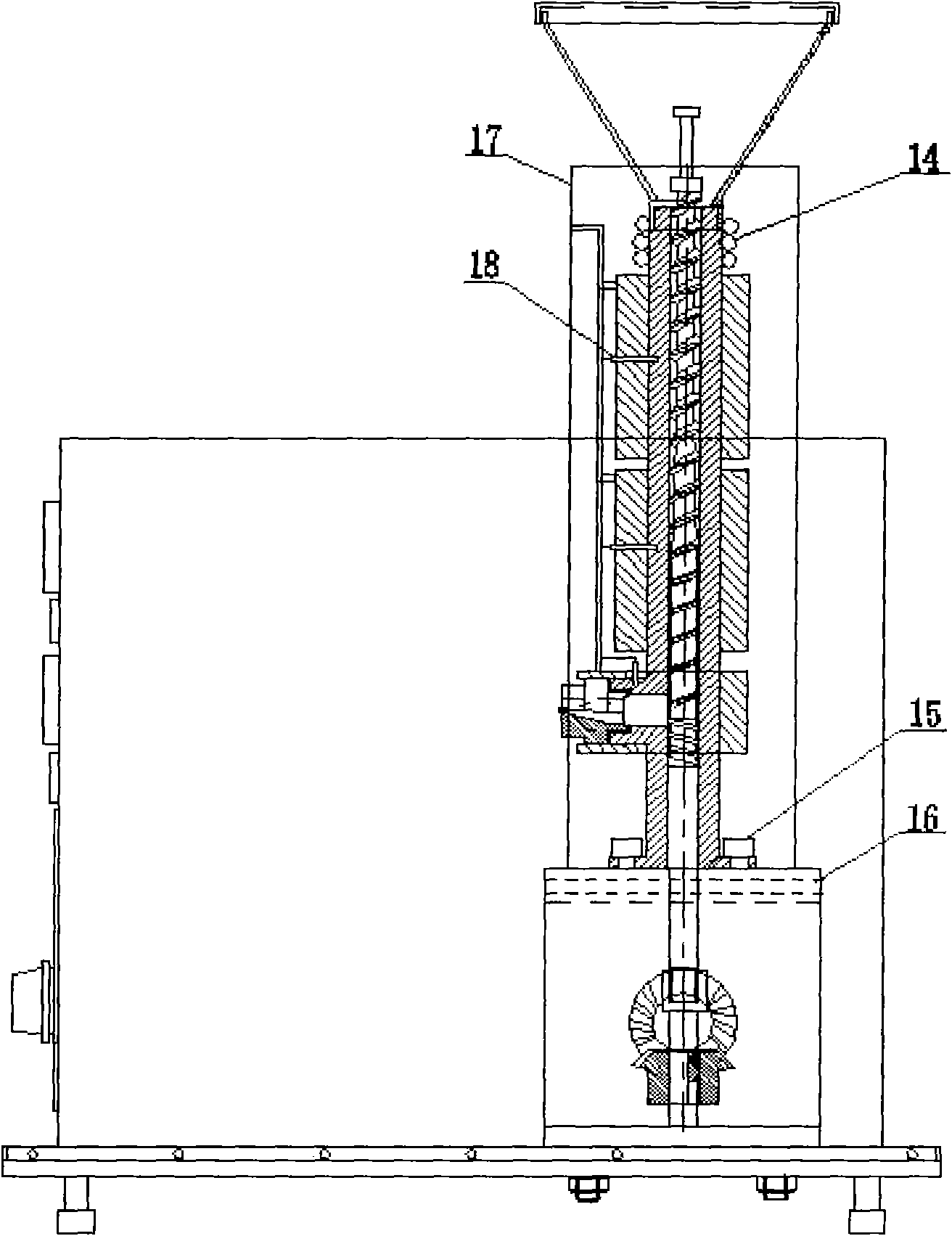

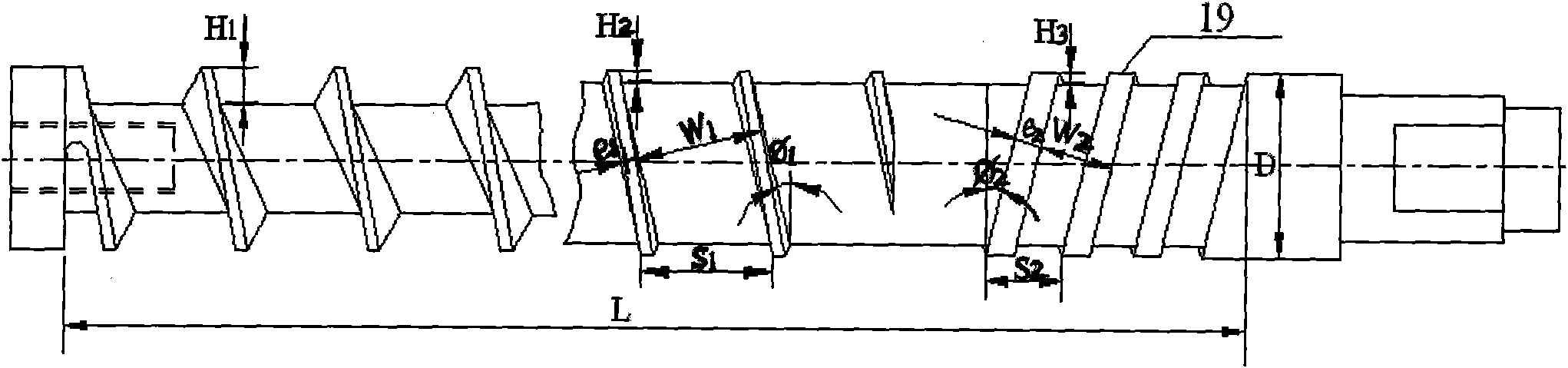

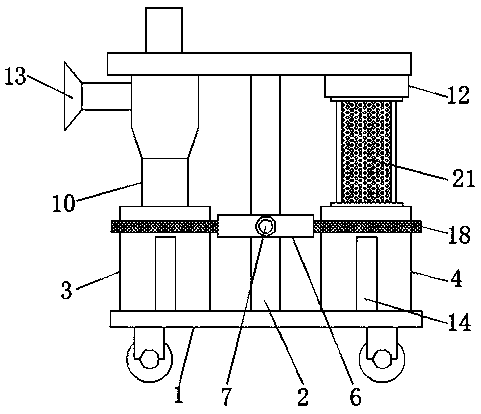

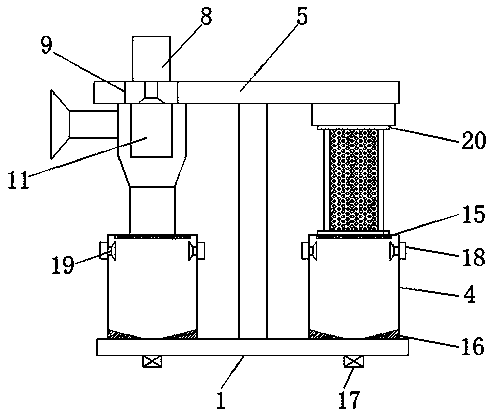

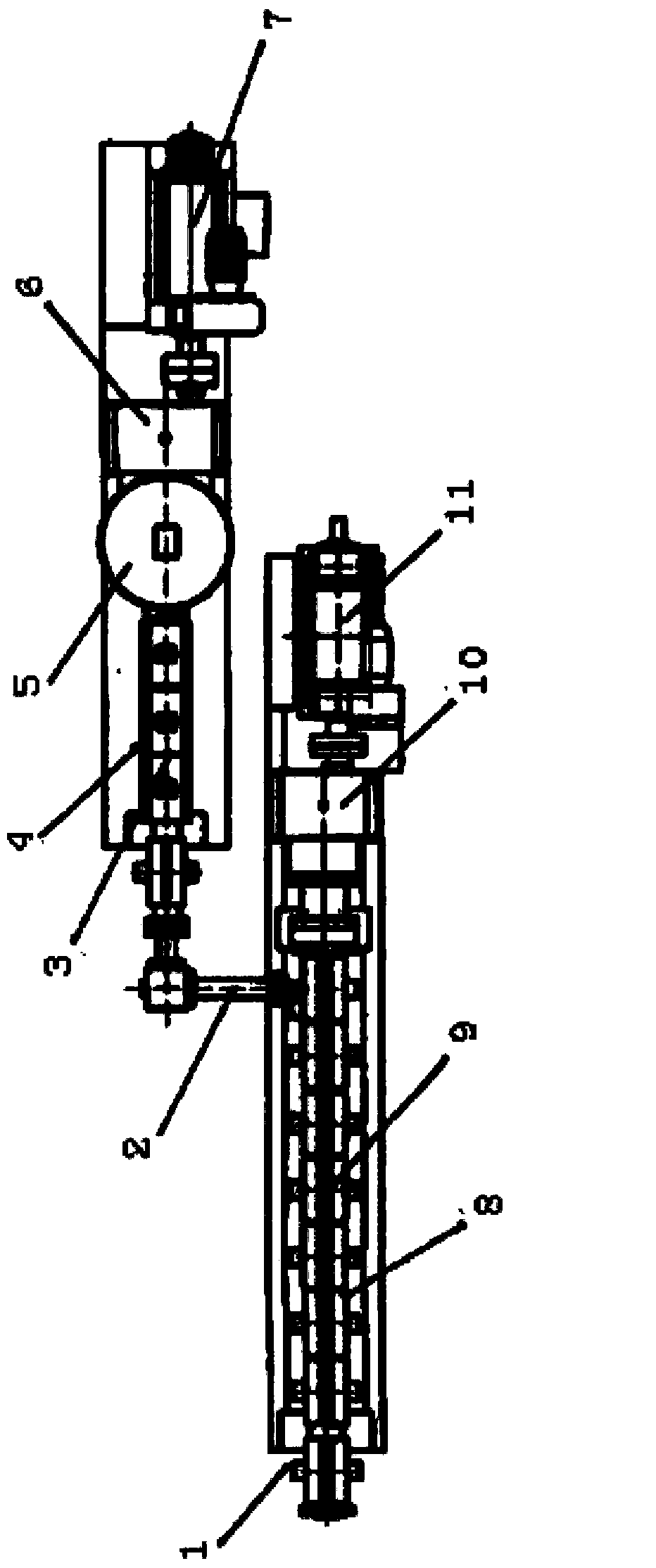

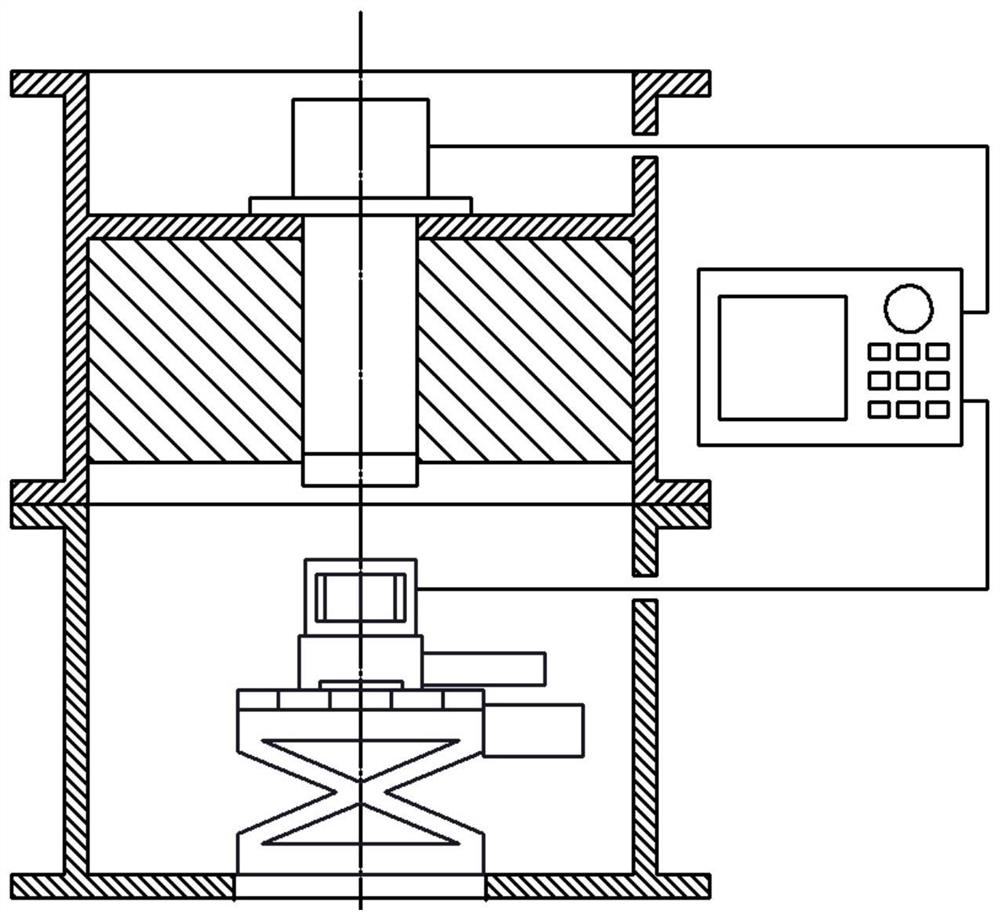

Small micro high-temperature mixing extrusion vertical testing machine

InactiveCN101650361AHigh degree of automationIncrease working temperatureMaterial testing goodsIn planeDrive shaft

The invention discloses a small micro high-temperature mixing extrusion vertical testing machine which is used for researching special micro high-temperature resistant macromolecule materials for laboratories and enterprises, is small testing equipment with the characteristics of high processing temperature, large torque, small volume, high control precision and the like and comprises a charging hopper, a small threaded rod, a machine cylinder, a heating sleeve, a machine head, a flange, a driving shaft, an oblique gear, a speed regulating motor, a control cabinet and the like. The charging hopper and the machine cylinder of the testing machine are connected by a thread screw and are positioned on a same axes; the small threaded rod and the machine cylinder are in vertical structures and the driving part is arranged on one end with largest root diameter of the threaded rod, i.e. the end part of the extrusion section of the threaded rod, thereby enabling the threaded rod to load the torque to the maximum. The threaded rod and the driving shaft of the testing machine are in plane contact by a slot, and the threaded rod stops rotating in the process of high-temperature melting mixingextrusion and is pulled out instantly. The testing machine is suitable for researching the micro melting mixing extrusion and the formation of all thermoplastic macromolecules, in particular special heat resistant macromolecule materials.

Owner:BEIHANG UNIV

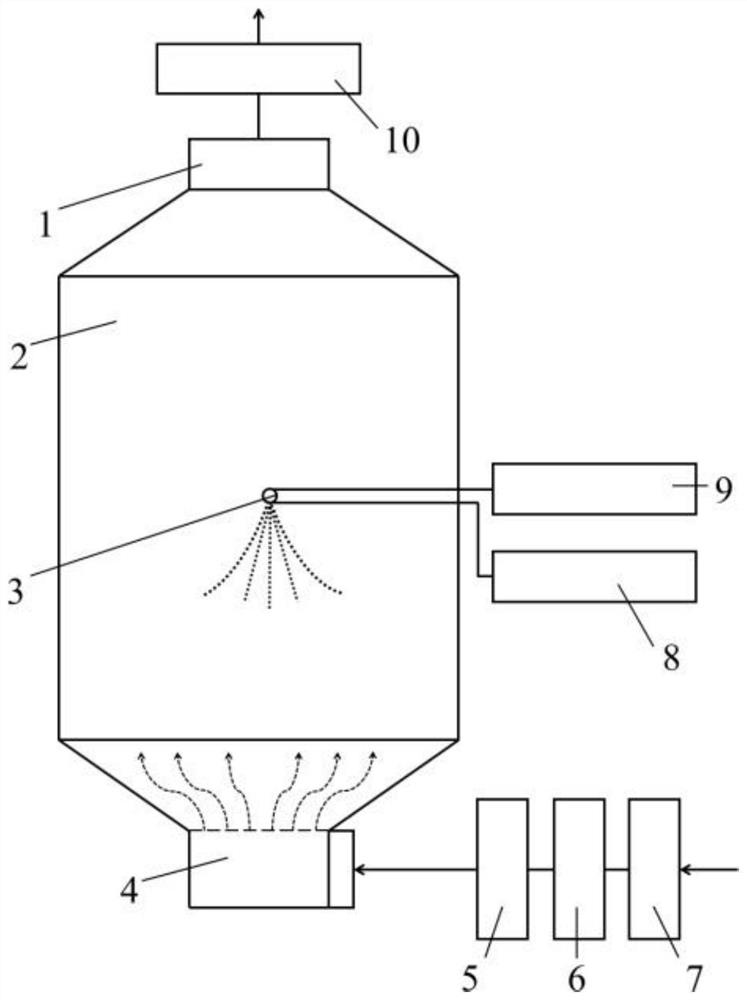

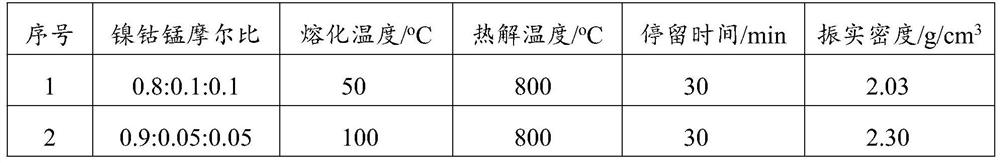

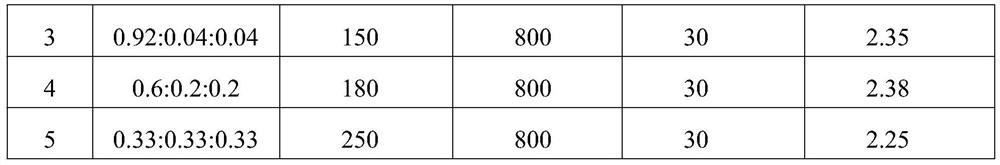

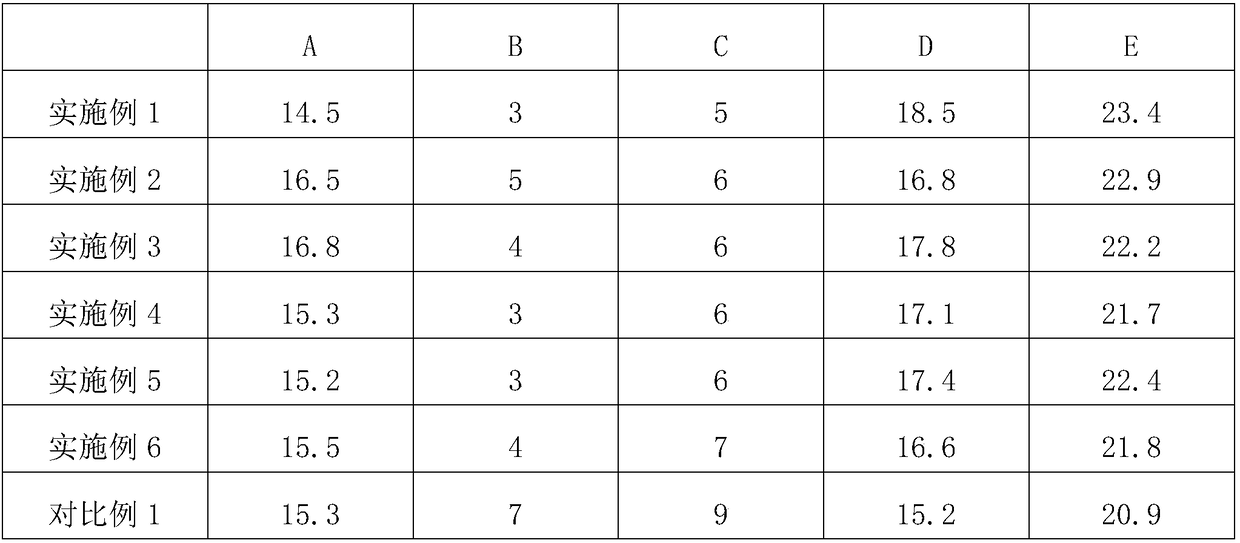

High-tap-density multi-element oxide precursor and preparation method and preparation system thereof

ActiveCN112919552ASolve the problem of low tap densityHigh tap densityCell electrodesSecondary cellsFluidized bedPhysical chemistry

The invention relates to the technical field of powder material preparation methods, in particular to a high-tap-density multi-element oxide precursor and a preparation method and a preparation system thereof. The preparation method comprises the steps that S1, metal salt containing crystal water is added into a liquid feeding device according to the stoichiometric ratio of all metal elements in the multi-element oxide to be stirred, heated and melted, and sub-molten salt liquid is obtained; S2, the sub-molten salt liquid is atomized through a two-fluid atomizer to form atomized liquid drops, and the atomized liquid drops are brought into a fluidized bed pyrolyzing furnace through compressed gas for pyrolysis; and S3, a pyrolysis product is collected in the step S2 through a dust collector to obtain the high-tap-density multi-element oxide precursor. According to the method, sub-molten salt liquid, double-fluid atomization and fluidized bed pyrolysis are combined, efficient preparation of the high-tap-density multi-element oxide precursor is achieved, and the precursor is uniform in element distribution, uniform in particle size, high in purity and good in spherical morphology.

Owner:CENT SOUTH UNIV

Method for shaping throat liner lining

The invention discloses a forming method for throat insert lining; wherein, a clamp is arranged on the terminal of the inner core mold with the stable shape and structure, according to the inner structure of throat insert lining; the high melting point metal material sprayed coating layer is sprayed on the outer flank of the inner core mold by the art of air plasma spraying, according to the thickness demand of throat insert lining; the compatibility of the sprayed coating layer material and the inner core mold material is low; the separation of the sprayed coating layer material and the inner core mold material is easy; the outer profile of the sprayed coating layer is finish-machined, the inner core mold is separated from and the acquired sprayed coating layer is the product of throat insert lining, according to the exterior shape and structure of throat insert lining and the thickness demand of each part. The forming method for throat insert lining has the advantages of simple technology, easy manufacture, realizing the near-size forming, low raw material cost, simplifying the subsequent processing procedures, and resolving the problems of high temperature resistant thin wall irregular parts forming of difficult machining and easy broken of shaped product.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

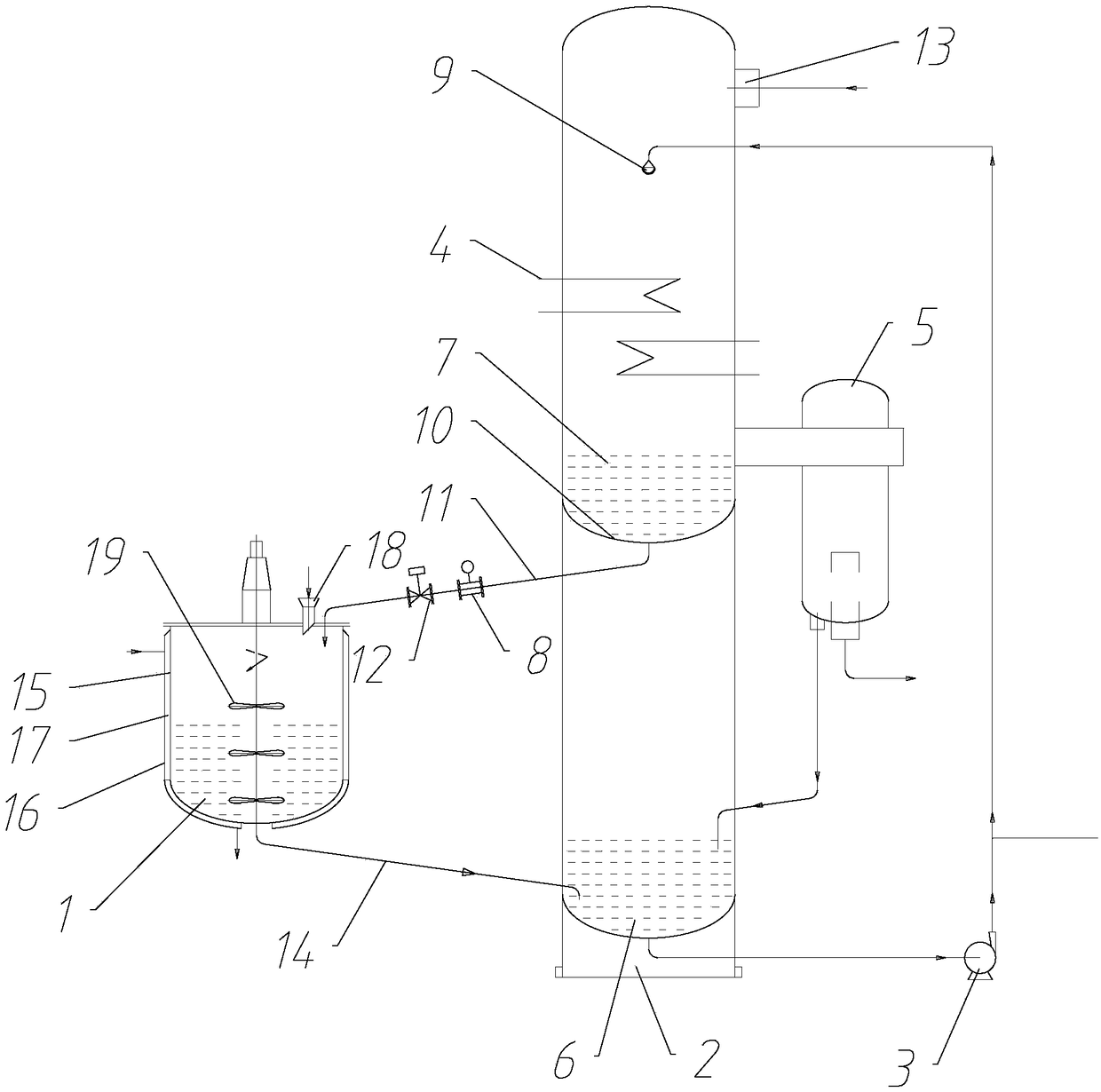

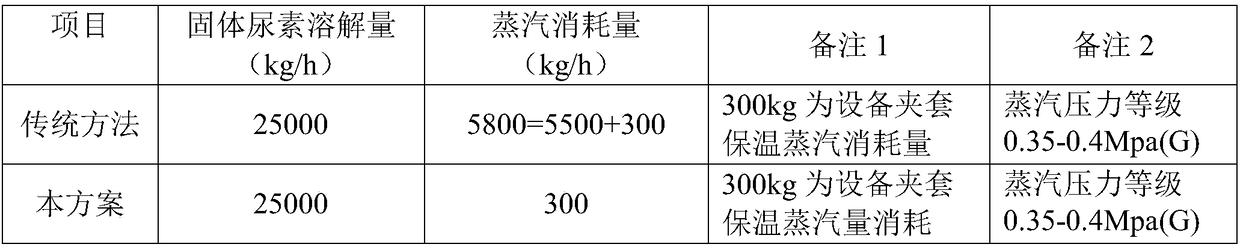

Energy-saving device and method for dissolving solid urea in production of melamine

The invention belongs to the technical field of solid urea melting equipment, and provides an energy-saving device for dissolving solid urea in production of melamine. The energy-saving device comprises a urea melting tank and a liquid urine washing tower, wherein a middle sealing head is arranged in the liquid urine washing tower; a middle tower reactor is arranged on the middle sealing head in the liquid urine washing tower; a bottom tower reactor is arranged at a bottom end of the liquid urine washing tower; a liquid urine spraying head and a high temperature process gas inlet are formed ina top end of the liquid urine washing tower; the bottom tower reactor is connected with the urea melting tank, and is further communicated with the liquid urine spraying head by a liquid urine circulation pump; one side of the middle tower reactor is communicated with the bottom tower reactor by a gas-liquid separator; a molten urea lead-out pipeline is arranged on the middle sealing head; and the middle tower reactor is communicated with the urea melting tank by the molten urea lead-out pipeline. The energy-saving device and method provided by the invention solve technical problems that dissolution of solid urea consumes a large amount of steam and the production costs are increased.

Owner:辛集市九元化工有限责任公司

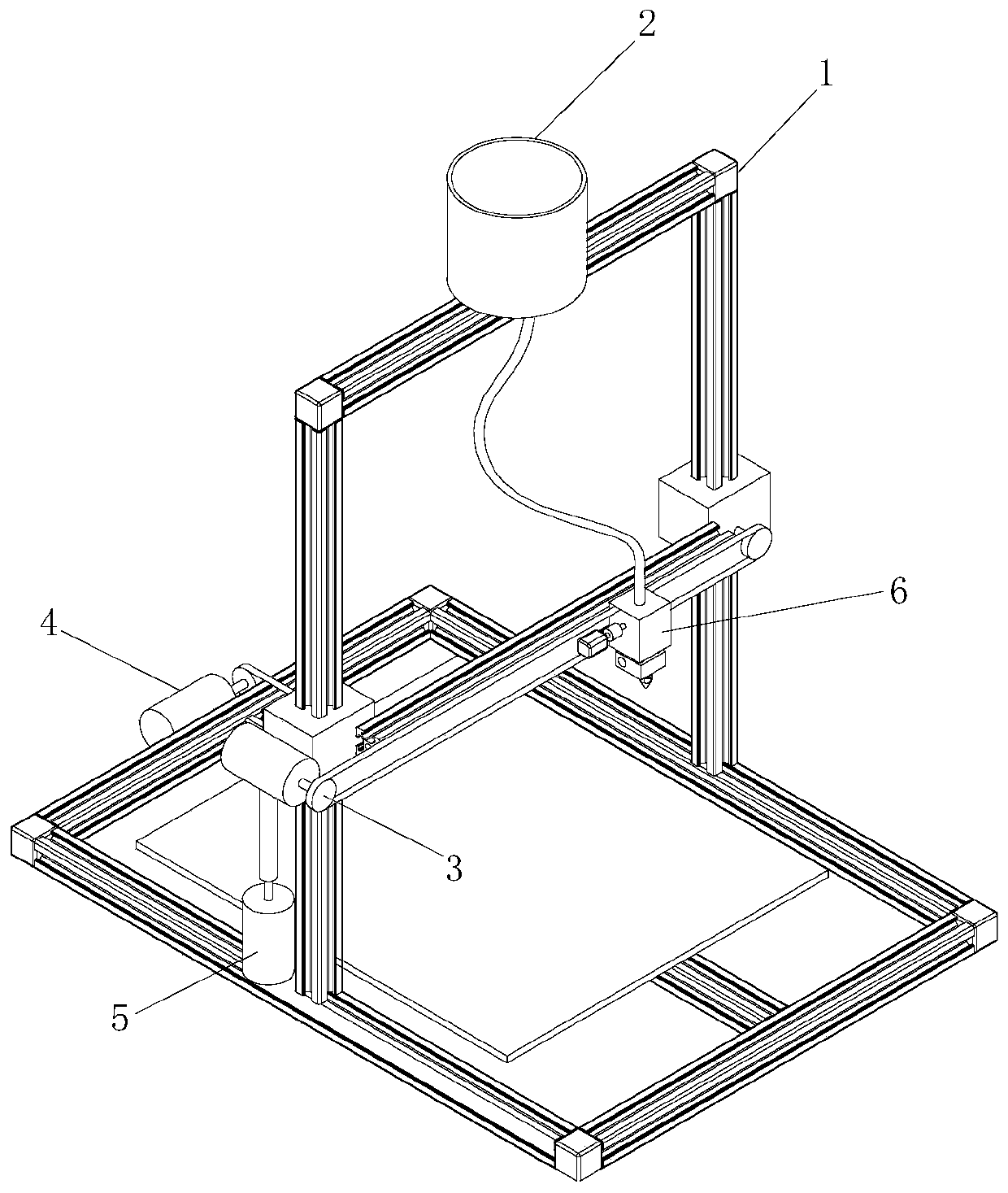

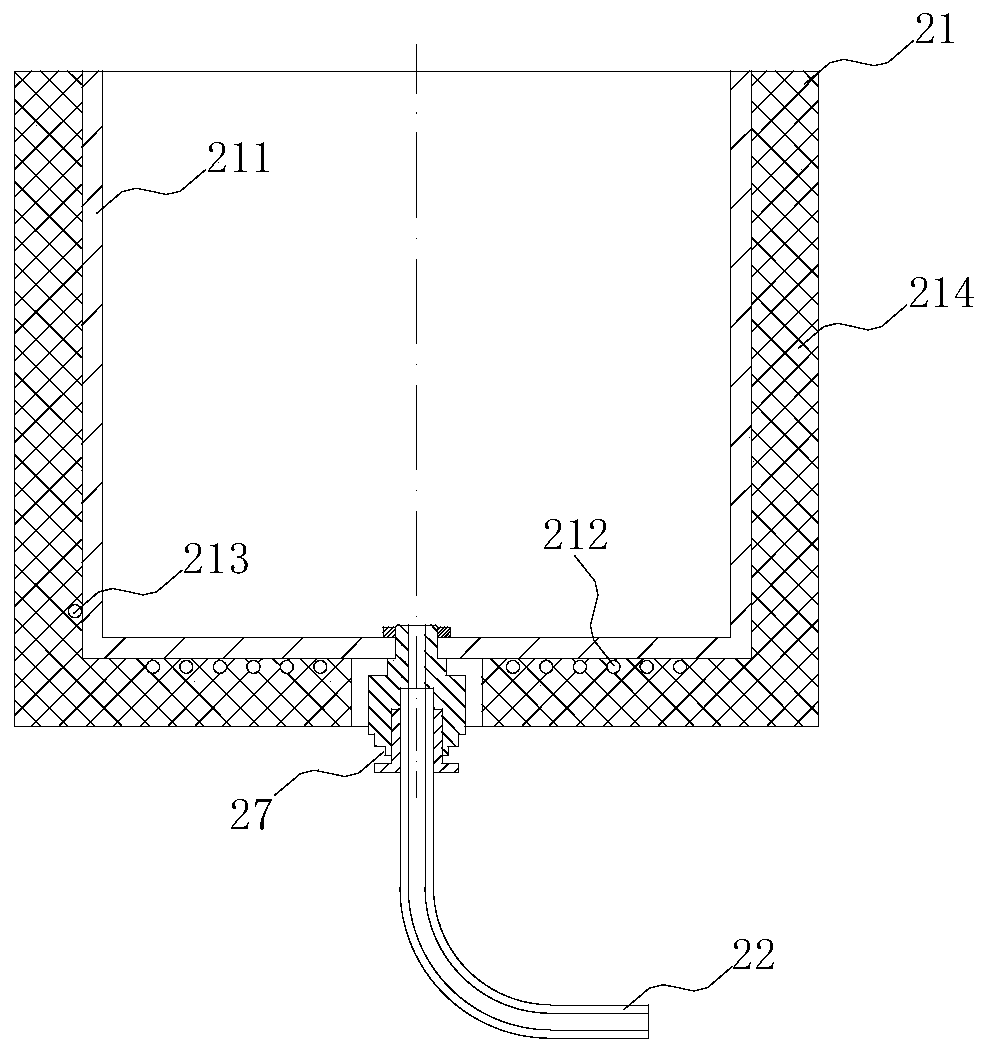

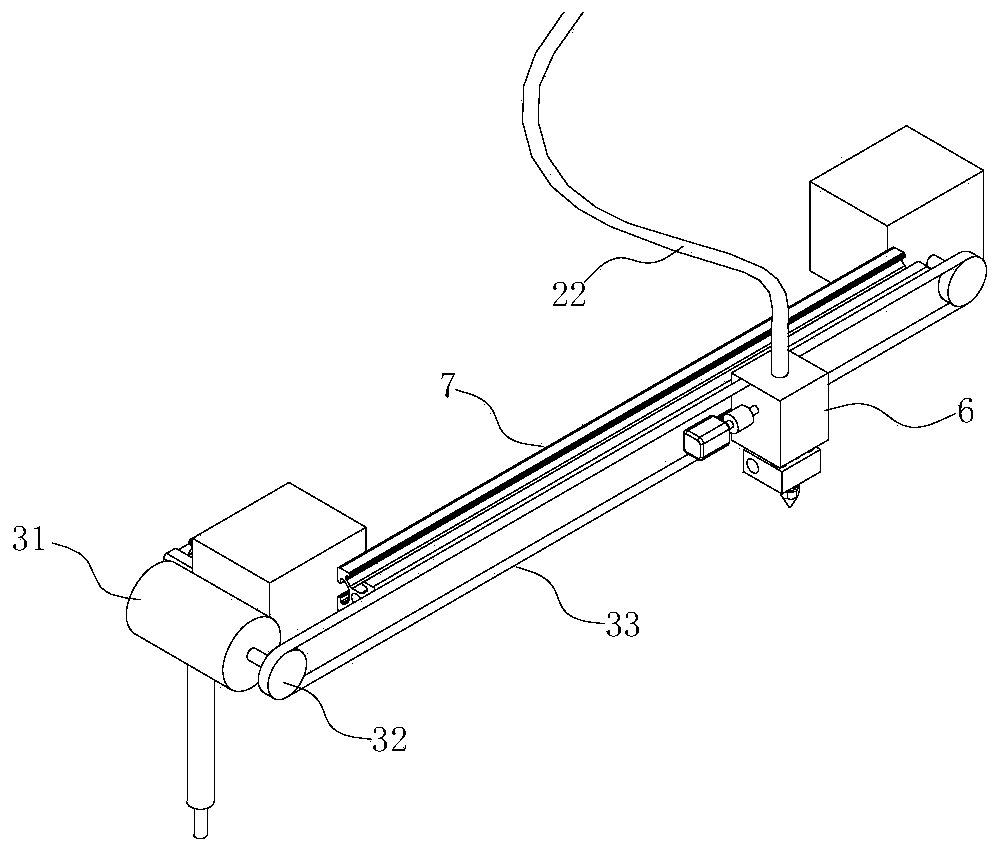

3D printer of wax part

PendingCN111531882ALow costSimple structureManufacturing enclosuresManufacturing heating elementsParaffin waxInvestment casting

The invention provides a 3D printer of a wax part and relates to the technical field of additive manufacturing. The 3D printer structurally comprises a machine frame, a consumable extrusion system anda spatial motion system. The consumable extrusion system comprises a paraffin wax container, a wax liquid conveying pipe, a positive displacement pump, a heating block, an extrusion head and a cooling fan. The paraffin wax container can be fixed to the machine frame, the wax liquid conveying pipe is connected with the paraffin wax container and the positive displacement pump, an outlet of the positive displacement pump is connected with the heating block, and an outlet of the heating block is connected with the extrusion head. The spatial motion system comprises a first direction motion mechanism, a second direction motion mechanism, a third direction motion mechanism and a printing trolley. The positive displacement pump, the heating block, the extrusion head and the cooling fan are arranged on the printing trolley. The 3D printer uses industrial paraffin wax as a consumable and prints the wax part through a fused deposition modeling process. By the adoption of the 3D printer of thewax part, the cost of the printer can be greatly reduced, the structure of the printer is simplified as well, the price of the consumable is lowered, and the 3D printer is widely applied to the fieldssuch as investment casting and new product development.

Owner:QINGDAO HUANGHAI UNIV

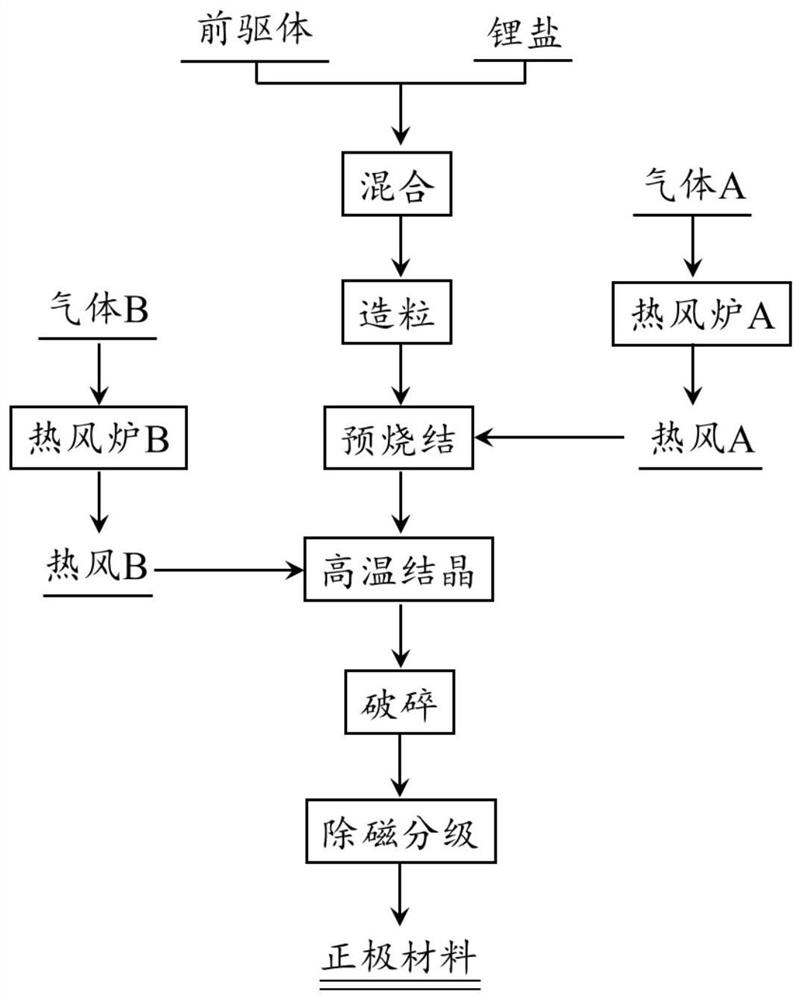

Method for preparing positive electrode material of lithium ion battery through fluidized sintering

PendingCN113526481AAchieve decompositionAchieve fusionSecondary cellsPositive electrodesElectrical batteryPhysical chemistry

The invention provides a method for preparing a lithium ion battery positive electrode material through fluidized sintering. The method comprises the following steps: step 1, mixing materials; step 2, granulating; step 3, carrying out fluidized pre-sintering; step 4, performing high-temperature crystallization; step 5, crushing the materials; and step 6, demagnetizing and grading the materials. In the invention, a large amount of waste gas generated by the precursor and the lithium salt is discharged in time through fluidized pre-sintering, and meanwhile decomposition of the precursor, fusion of the lithium salt and a preliminary combination reaction of the precursor and the lithium salt are achieved; secondly, a fluxing agent which is easy to knot and generates alkali corrosion does not exist in the high-temperature crystallization kiln, so that the problem that the anode material of the lithium ion battery is knot in a dynamic kiln is solved; no decomposable gas product is formed in the high-temperature crystallization kiln, and the atmosphere in the kiln is stable and easy to control; meanwhile, the mass and heat transfer process is enhanced, the production energy consumption is obviously reduced, and the product consistency and the batch stability are obviously improved; therefore, the lithium ion battery positive electrode material is prepared by a large-scale, continuous and short-time sintering method.

Owner:CENT SOUTH UNIV

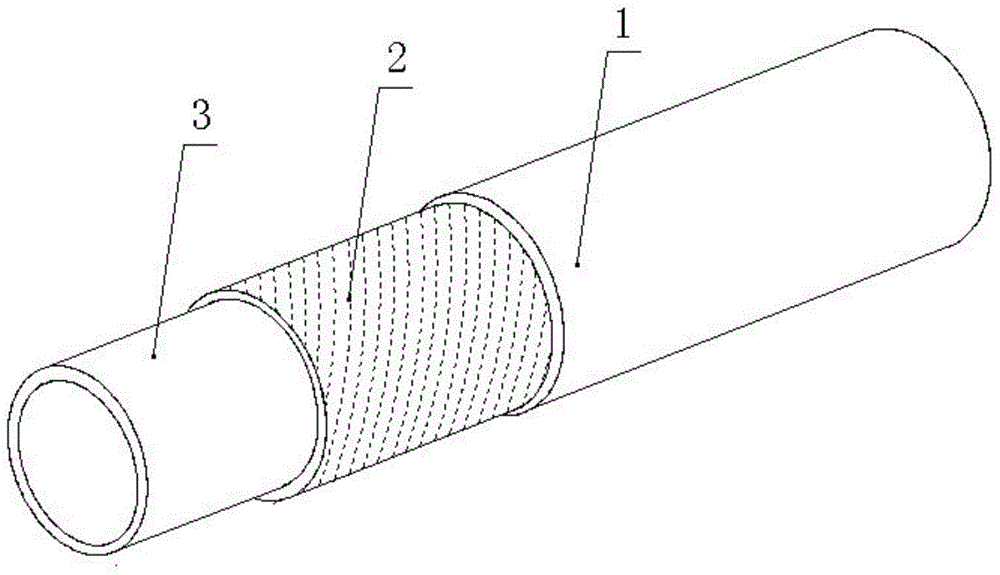

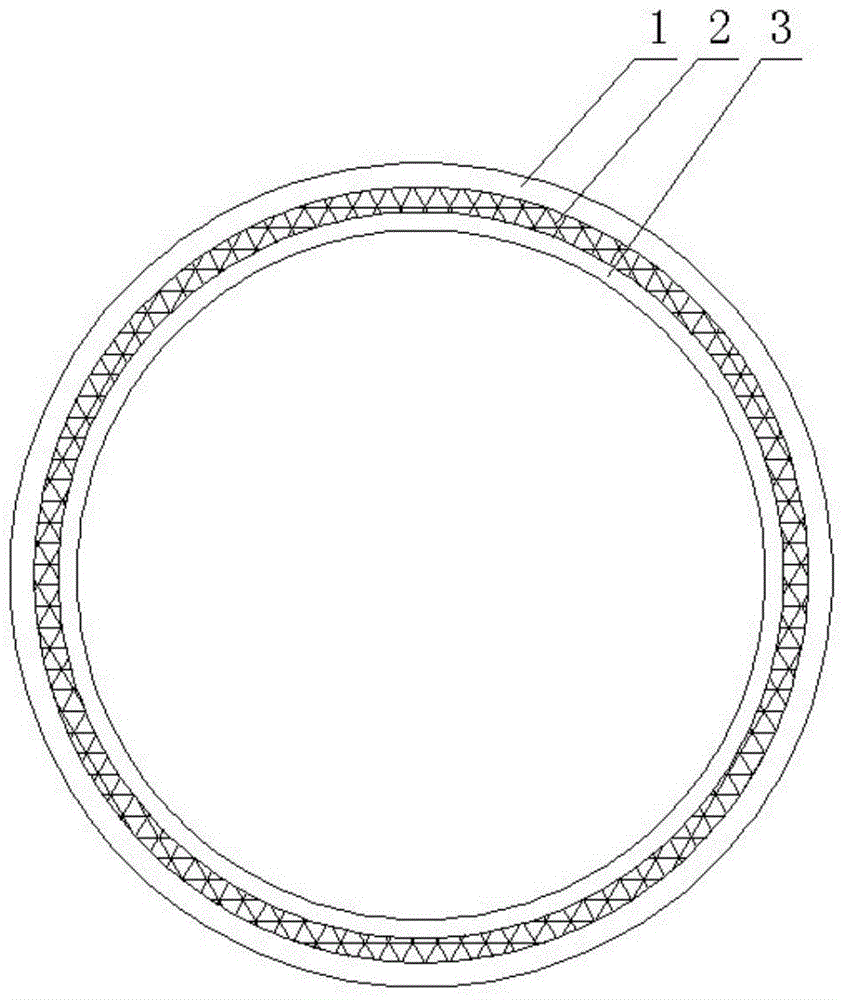

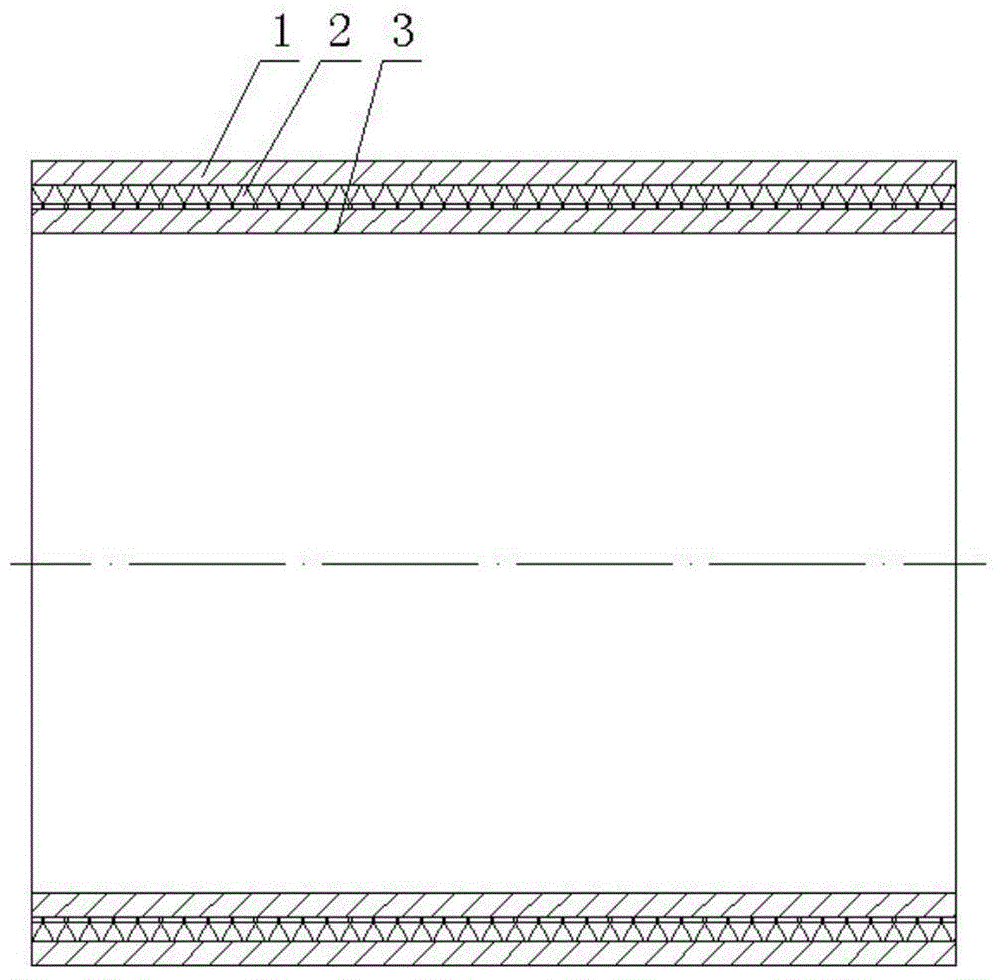

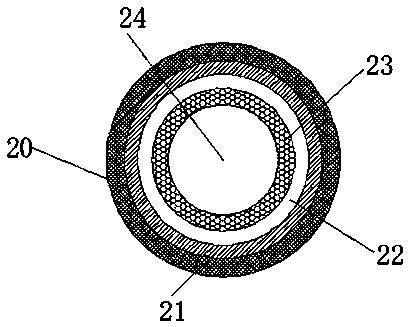

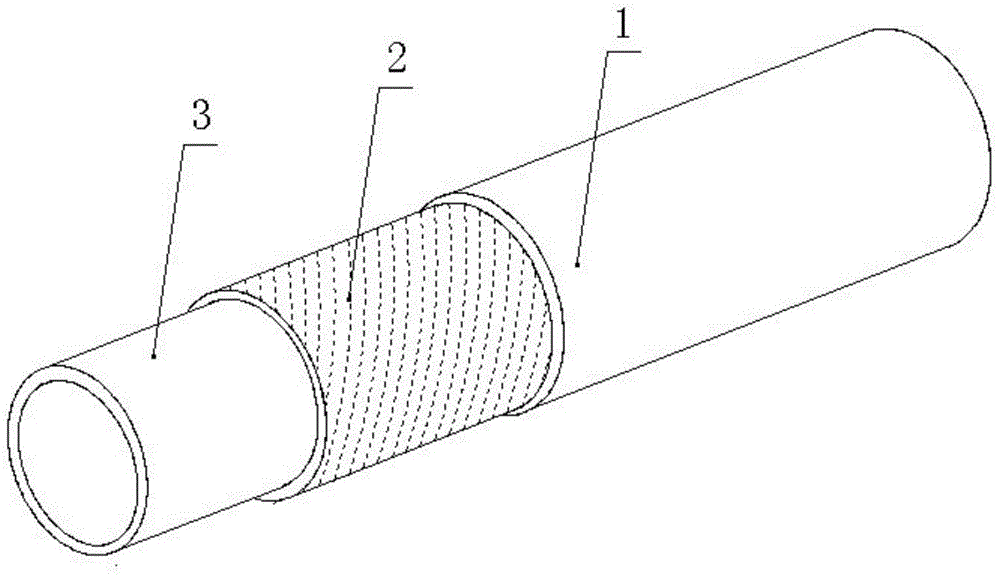

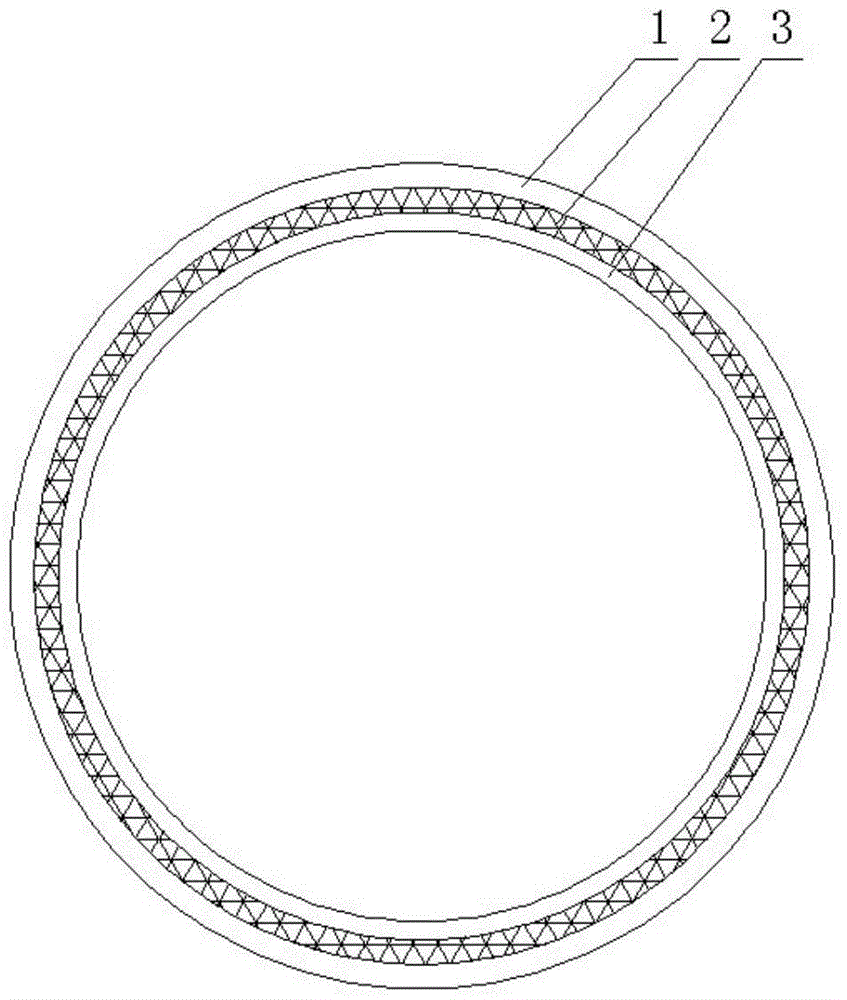

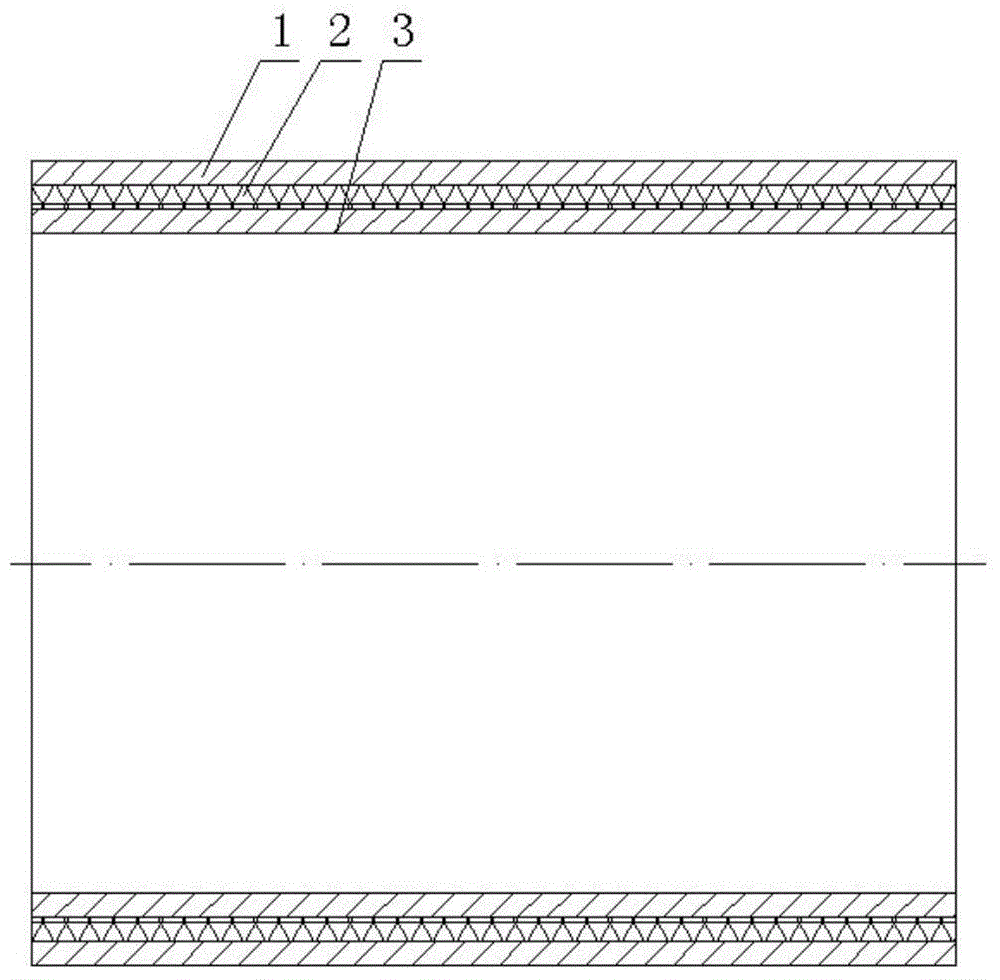

Three-layer composite liquid crystal polymer enhanced pipe

ActiveCN104527143AImprove heat resistance and pressure resistanceIncreased tensile strength and modulus of elasticitySynthetic resin layered productsRigid pipesLubricationCorrosion

The invention discloses a three-layer composite liquid crystal polymer enhanced pipe. The composite liquid crystal polymer enhanced pipe is characterized by sequentially and coaxially covering an outer functional material layer, an intermediate thermotropic liquid crystal polymer engineering plastic enhanced layer and an inner functional material layer; the intermediate thermotropic liquid crystal polymer engineering plastic enhanced layer forms a spiral directional array in an equal distance on the outer edge of the inner layer of a pipe along a flowing direction. According to the composite liquid crystal polymer pipe, liquid crystal winding molding is carried out by using a special device and utilizing the strength and the pressure resistance property of the liquid crystal, as well as the high intensity and high flexibility and self-fusion property of polyethylene, so that the use of inner layer materials and outer layer materials under special work conditions such as abrasion resistance, corrosion resistance, flame retardant, anti-static electricity and super-lubrication can be realized, the heatproof property and pressure resistance levels of the pipeline can be improved based on the property of the liquid crystal polymer, and the water delivery requirement of the pressure of 20 MPa can be realized at maximum.

Owner:HEBEI WANGYUAN PIPES

Dust removal device of electric automation equipment for easy cleaning

The invention discloses a dust removal device of electric automation equipment for easy cleaning. The device comprises a moving base, and a support rod, a first dust collecting can, and a second dustcollecting can are disposed on the moving base. The support rod is connected to the middle of the upper surface of the moving base through a rivet. The first dust collecting can is connected to the left side of the upper surface of the moving base through a rivet. The second dust collecting can is connected to the right side of the upper surface of the moving base through a rivet. The upper end ofthe support rod is provided with a ventilation channel and a connection pipe. The ventilation channel is connected with the upper end of the support rod through a rivet. The connection tube is connected with the middle of the support rod through a rivet. A water pipe joint is disposed on the connection tube. The automatic flushing of the first dust collecting can and the second dust collecting can on the dust removal device can be achieved, thereby speeding up cleaning speed of the first dust collecting can and the second dust collecting can and reducing the labor intensity of an operator during washing the first dust collecting can and the second dust collecting can.

Owner:邢二江

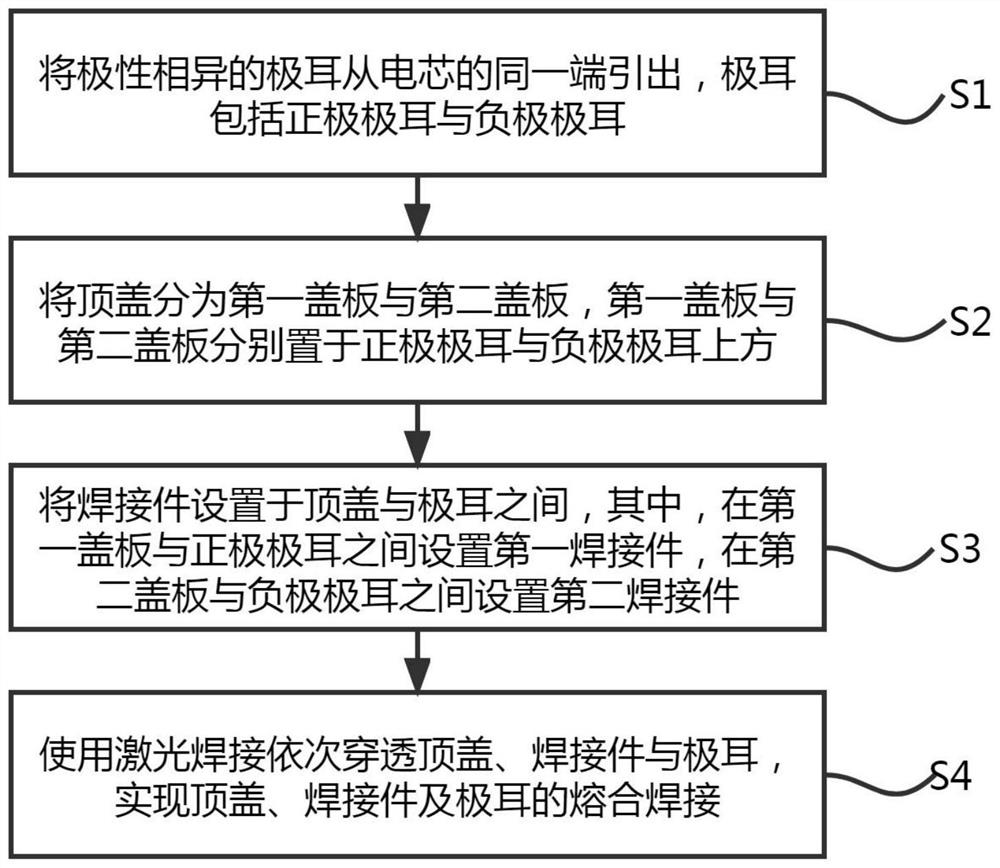

Welding method, preparation method and welding structure of cylindrical battery

PendingCN114824600AAchieve fusionAvoid it happening againCell component detailsLaser solderingFusion welding

The invention belongs to the technical field of lithium ion batteries, and particularly relates to a welding method, a preparation method and a welding structure of a cylindrical battery, the welding method comprises the following steps: step 1, tabs with different polarities are led out from the same end of a battery cell, and the tabs comprise a positive tab and a negative tab; 2, dividing the top cover into a first cover plate and a second cover plate, wherein the first cover plate and the second cover plate are respectively arranged above the positive pole lug and the negative pole lug; step 3, arranging welding pieces between the top cover and the electrode lugs, arranging a first welding piece between the first cover plate and the positive electrode lug, and arranging a second welding piece between the second cover plate and the negative electrode lug; and 4, laser welding is used for sequentially penetrating through the top cover, the welding piece and the electrode lug, and fusion welding of the top cover, the welding piece and the electrode lug is achieved. By arranging the welding piece between the top cover and the tab, the welding piece, the tab and the top cover can form a continuous solid solution in the welding process, and generation of intermetallic compounds is prevented, so that the welding performance is improved.

Owner:JIANGSU ZENIO NEW ENERGY BATTERY TECH CO LTD

Method for shaping throat liner lining

The invention discloses a forming method for throat insert lining; wherein, a clamp is arranged on the terminal of the inner core mold with the stable shape and structure, according to the inner structure of throat insert lining; the high melting point metal material sprayed coating layer is sprayed on the outer flank of the inner core mold by the art of air plasma spraying, according to the thickness demand of throat insert lining; the compatibility of the sprayed coating layer material and the inner core mold material is low; the separation of the sprayed coating layer material and the inner core mold material is easy; the outer profile of the sprayed coating layer is finish-machined, the inner core mold is separated from and the acquired sprayed coating layer is the product of throat insert lining, according to the exterior shape and structure of throat insert lining and the thickness demand of each part. The forming method for throat insert lining has the advantages of simple technology, easy manufacture, realizing the near-size forming, low raw material cost, simplifying the subsequent processing procedures, and resolving the problems of high temperature resistant thin wall irregular parts forming of difficult machining and easy broken of shaped product.

Owner:XIAN AEROSPACE COMPOSITE MATERIALS INST

Method and device for laser manufacturing polyamide three-dimensional objects

ActiveCN106626379BAchieve fusionSmall spotAdditive manufacturing apparatus3D object support structuresPolyamideLaser fabrication

The invention discloses a method for manufacturing a polyamide three-dimensional object by laser. The method comprises the steps that a layer of manufacturing material is laid and conveyed onto a bottom plate or a selective fusion layer to form a novel material layer; a laser device emits laser; the laser is guided to selectively irradiate a fusion region on the novel material layer; the fusion region is a cross section position, corresponding the three-dimensional object to be manufactured, on the novel material layer, wherein the laser is generated by the laser device with the wavelength being 400 to 1080nm; the manufacturing material is a mixture of a polyamide powder material and a thermal medium material; the thermal medium material absorbs laser energy and conducts the laser energy to polyamide powder, so that the manufacturing material in the laser irradiation region realizes fusion. The polyamide three-dimensional object with high manufacturing precision can be manufactured according to the method.

Owner:HUNAN FARSOON HIGH TECH CO LTD

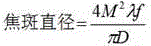

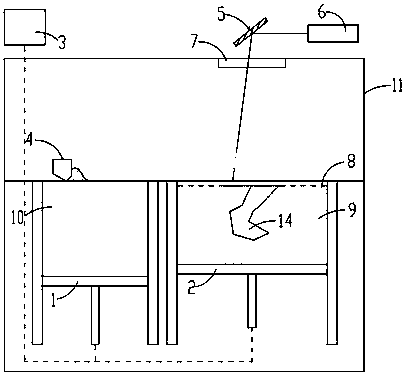

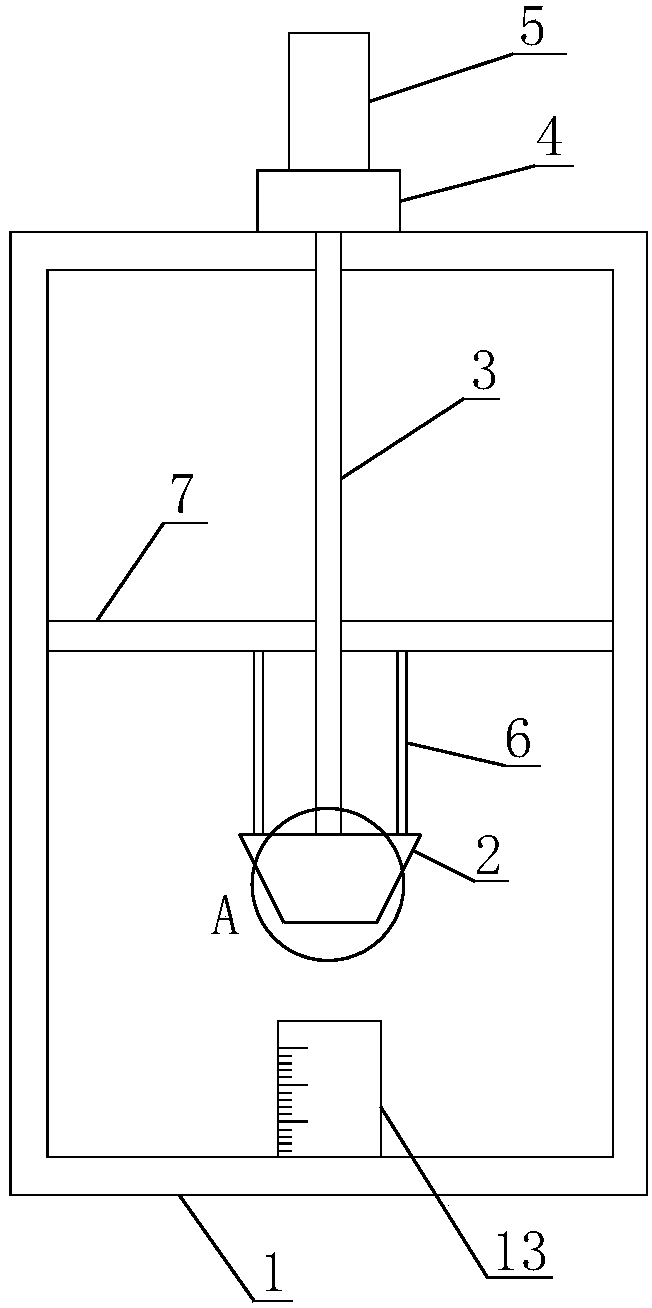

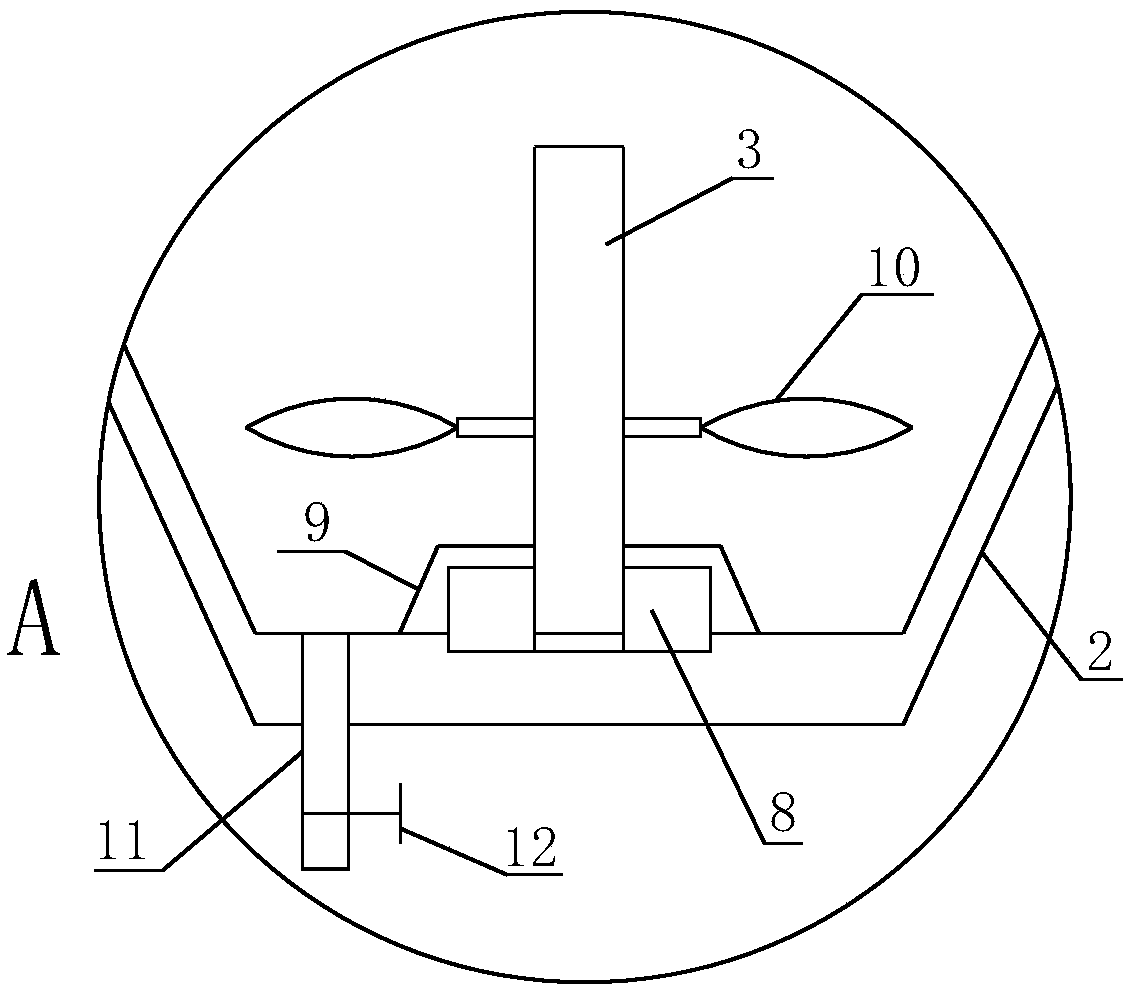

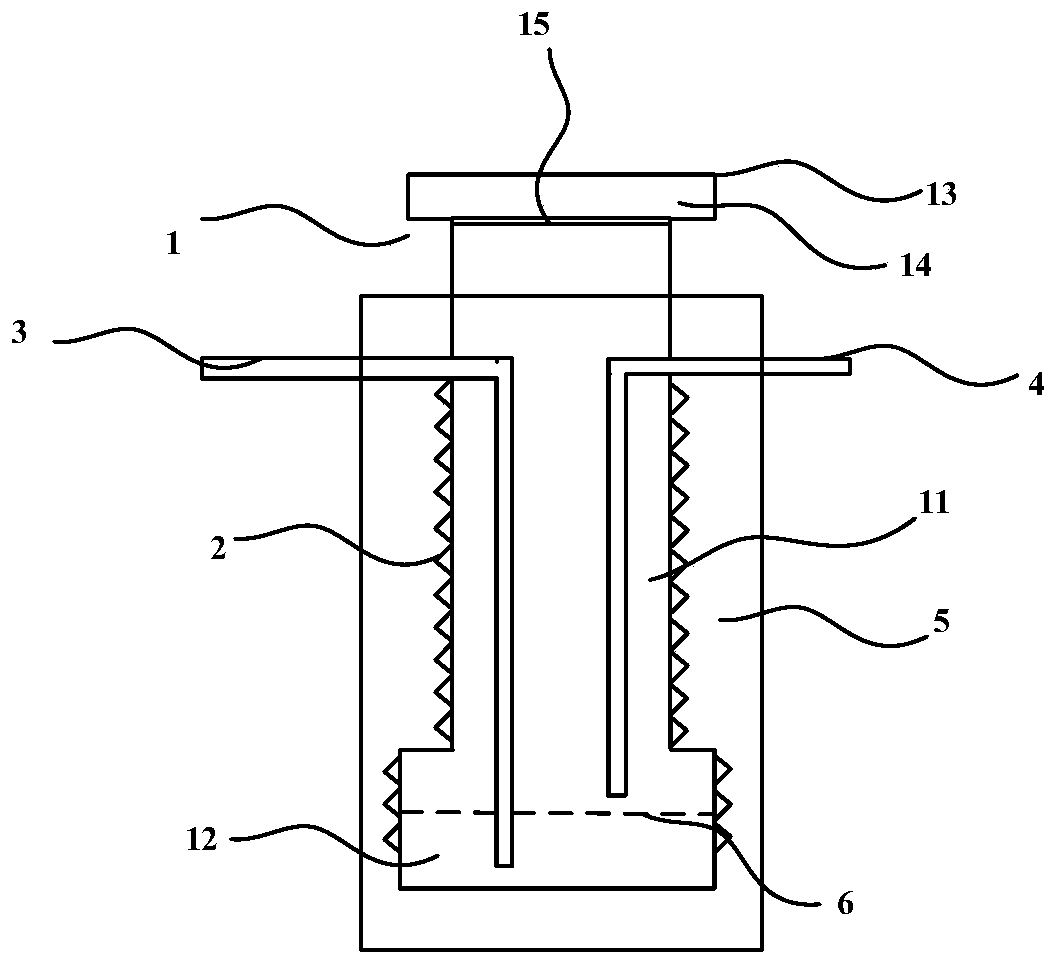

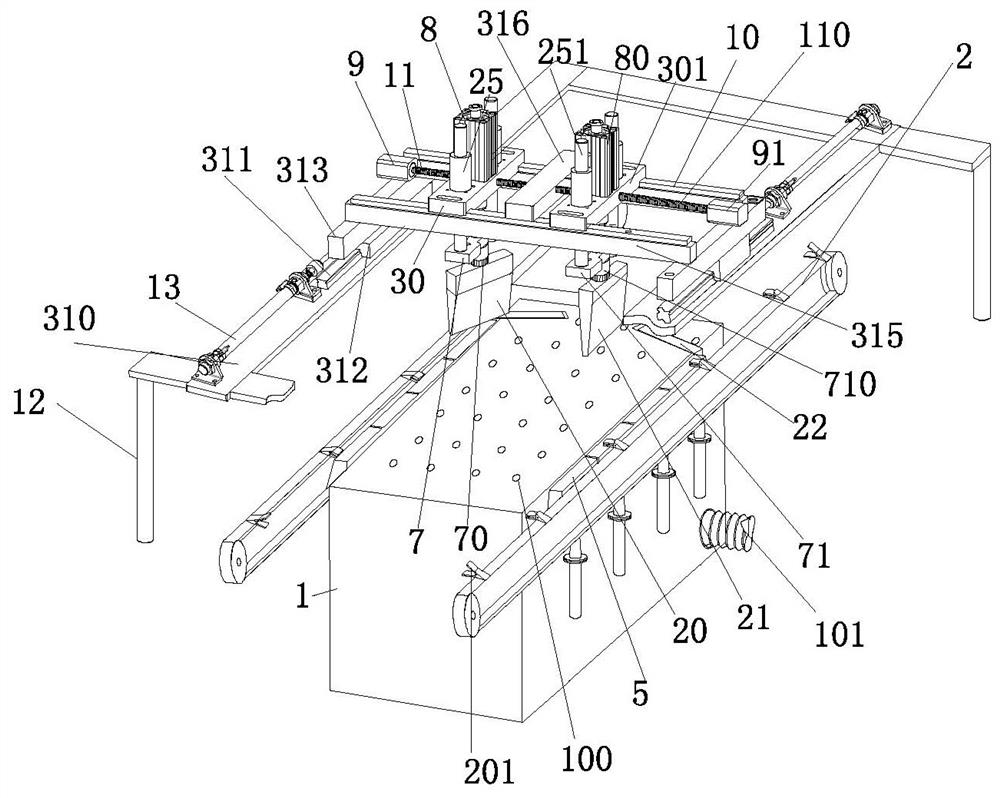

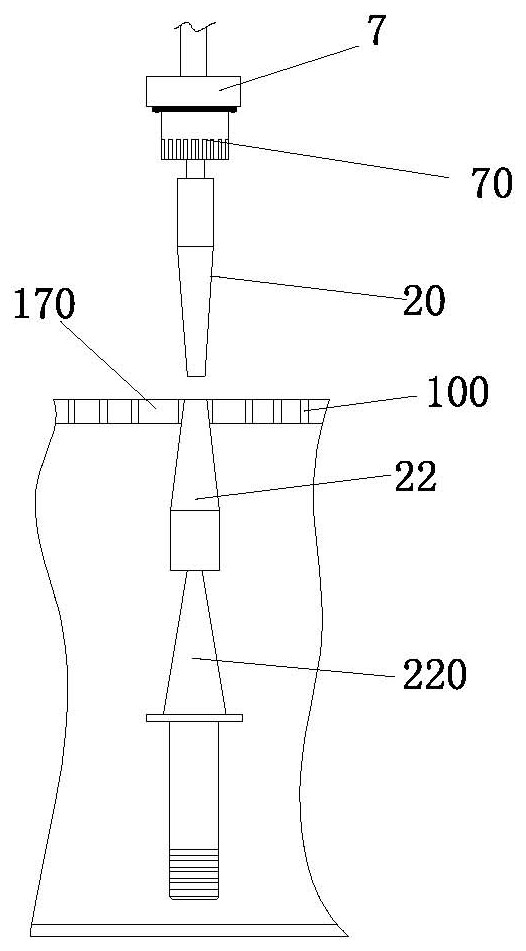

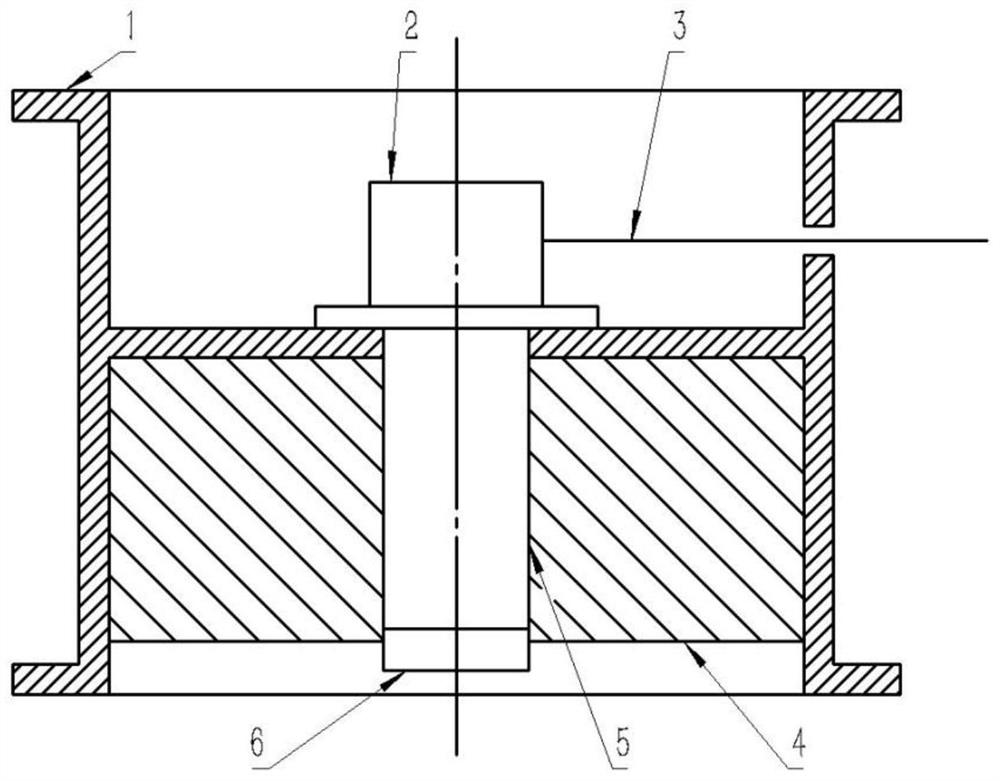

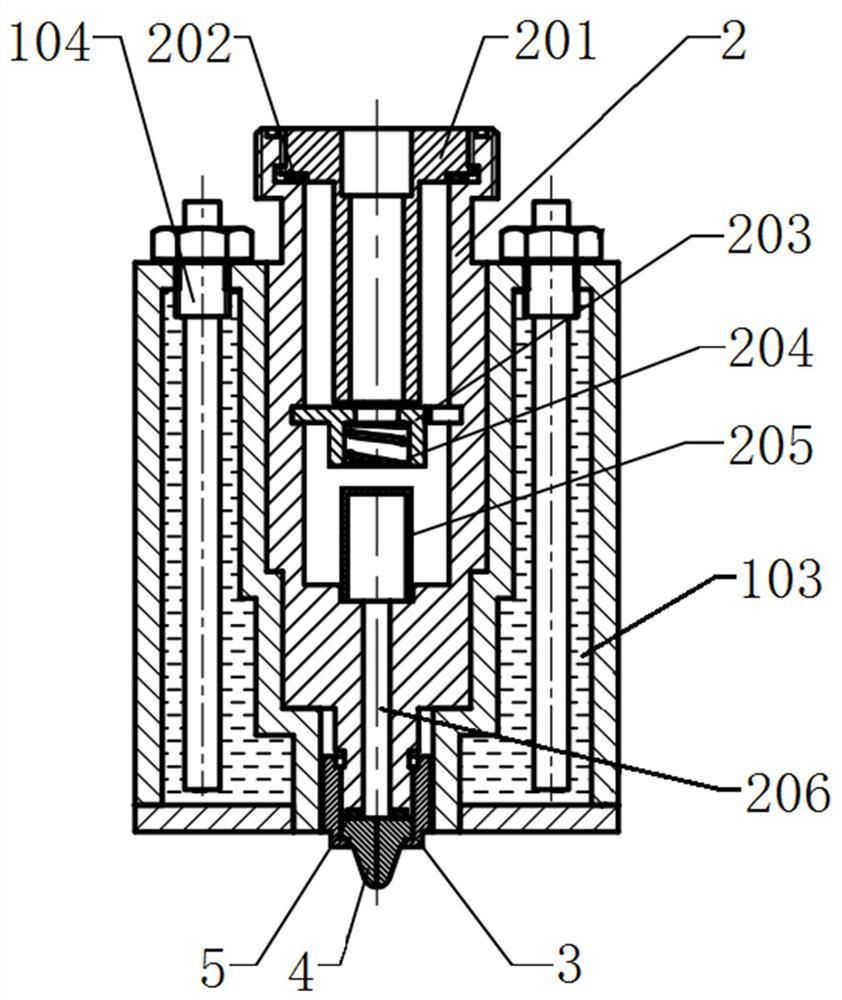

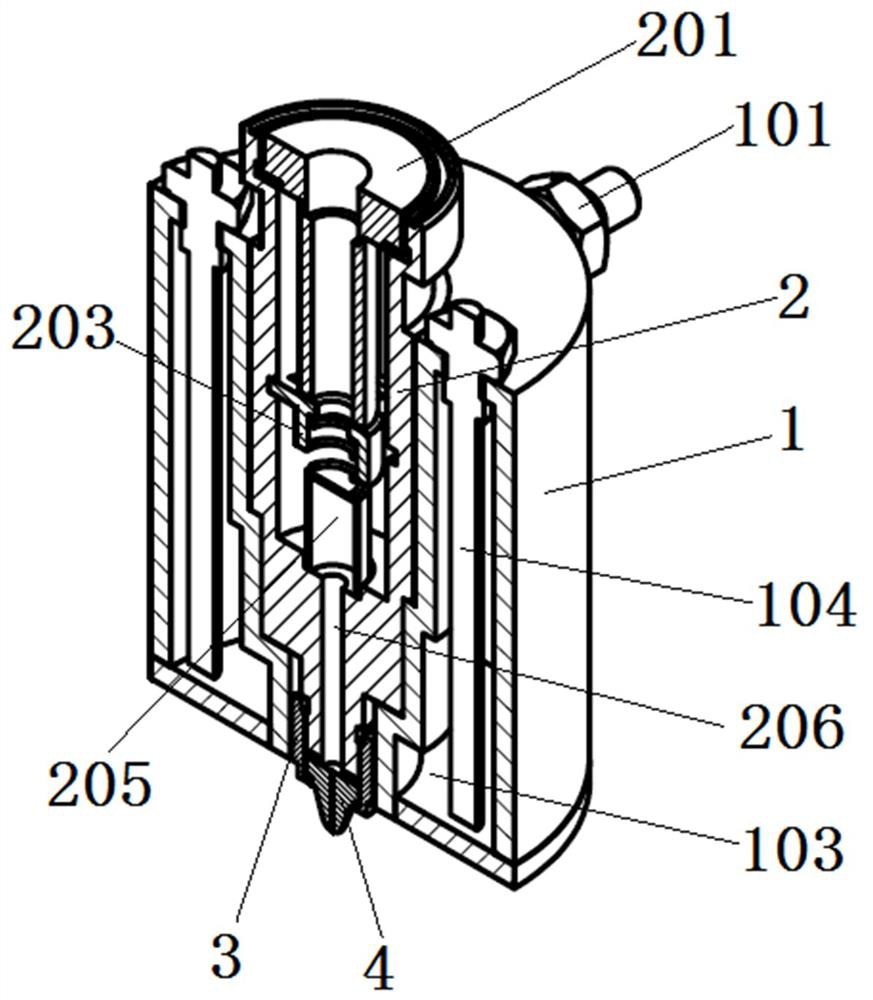

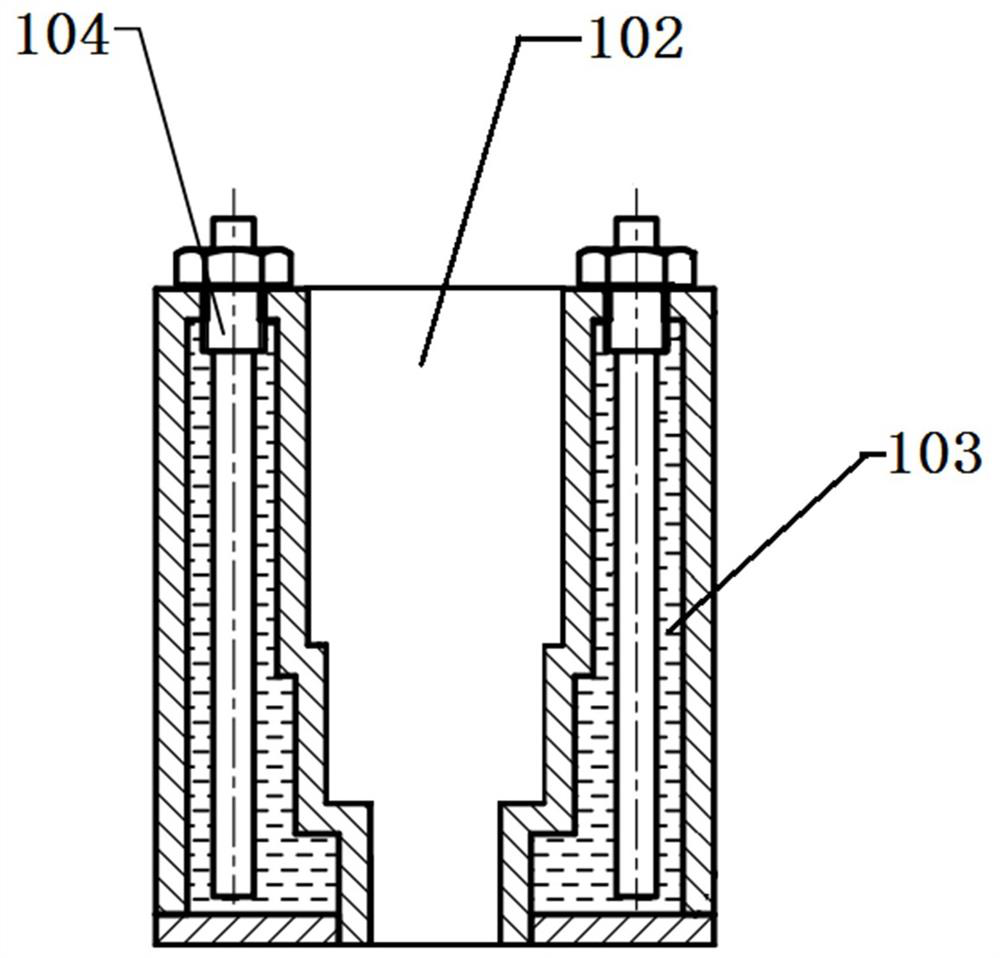

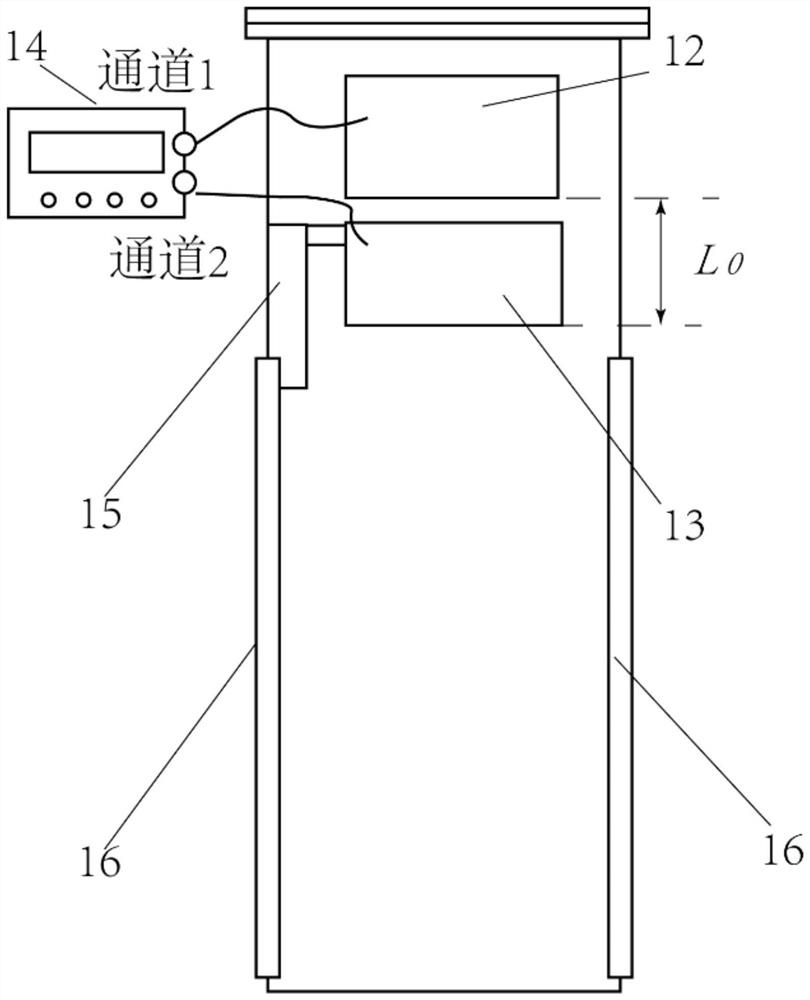

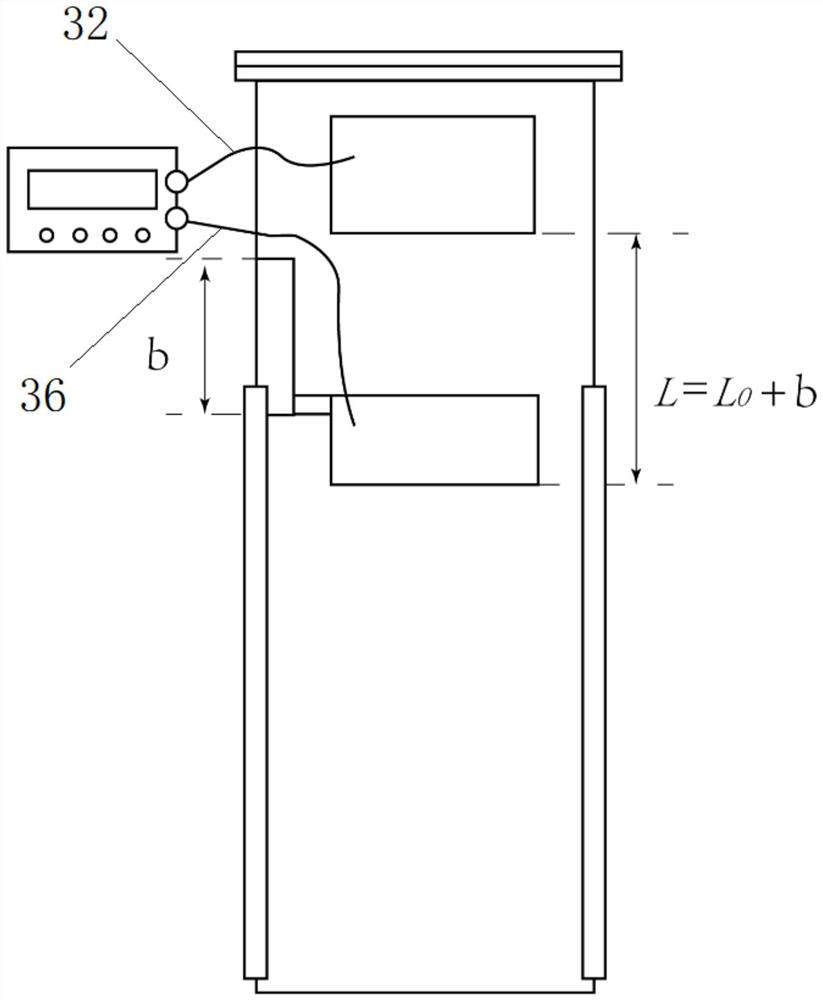

A device for simulating the fusion of molten droplets and solidified droplets in a microgravity environment

ActiveCN113447518BEasy to observeAdjustable vertical positionInvestigating phase/state changeEngineeringMicro gravity

The invention provides a device for simulating the fusion of molten droplets and solidified droplets in a microgravity environment, which solves the disadvantage that the existing drop pipe device cannot complete the uniform droplet fusion test in a ground simulated microgravity environment. The device has a solidified droplet releasing module for containing / releasing solidified metal droplets, and cooperates with a uniform metal droplet ejection module, a position adjustment module and a control module to realize controlled fusion of metal droplets under microgravity conditions, Acquire fusion droplet samples and collect image data (with the help of image acquisition module), laying the foundation for the study of metal droplet microgravity fusion behavior and even space metal 3D printing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Apparatus for melting experiment of biomaterial

The invention specifically relates to an apparatus for a melting experiment of a biomaterial. The apparatus comprises a microwave oven, a crucible, a stirring rod, a speed reducer and a stirring motor, wherein the microwave oven is internally provided with a crossbeam; the crucible is suspended below the crossbeam by a connecting rod; one end of the stirring rod penetrates the top of the microwaveoven and is connected with the stirring motor through the speed reducer, and the other end of the stirring rod is connected with the bottom of the crucible by a rolling bearing; the stirring rod is fixedly connected with the inner ring of the rolling bearing; the outer ring of the rolling bearing is fixedly connected with the crucible; a protective shell is arranged out of the rolling bearing; the stirring rod is provided with stirring paddles; and the stirring paddles are located in the crucible. The apparatus provided by the invention can realize the melting of biomaterials, and has high melting efficiency and short melting time. The apparatus has the advantages of simple structure, low cost, convenient operation, easy promotion, and good practicability. The apparatus has the advantagesof simple structure, low cost, convenient operation, easy promotion, and good practicability.

Owner:成都熠辉科技有限公司

Environment-friendly vehicle-mounted purifier shell and preparation technology thereof

ActiveCN109401247AIncrease the rate of crystallizationShorten molding timeCoatingsMolten stateAntioxidant

The invention belongs to the technical field of preparation or chemical processing of high polymer material compounds, and discloses an environment-friendly vehicle-mounted purifier shell and a preparation technology thereof. The environment-friendly vehicle-mounted purifier shell is prepared from the following raw materials: polylactic acid, a nucleating agent, an antioxidant, a filling agent, toner, a heat stabilizer and a light stabilizer. The preparation technology comprises the following steps that firstly, all the raw materials are dried by using a dryer, and stirring and uniform mixingare carried out so as to form a mixture for later use; then the mixture is heated, stirring is carried out while heating is carried out, so as to enable the raw materials to be in a molten state, andgranulating is carried out to form a modified material; and the modified material is heated and molten to form a molten material, and the molten material is put into a mould for injection molding so as to form the environment-friendly vehicle-mounted purifier shell. The environment-friendly vehicle-mounted purifier shell and the preparation technology thereof solve the problem that an existing vehicle-mounted purifier shell is nondegradable.

Owner:CHONGQING UNIV OF ARTS & SCI

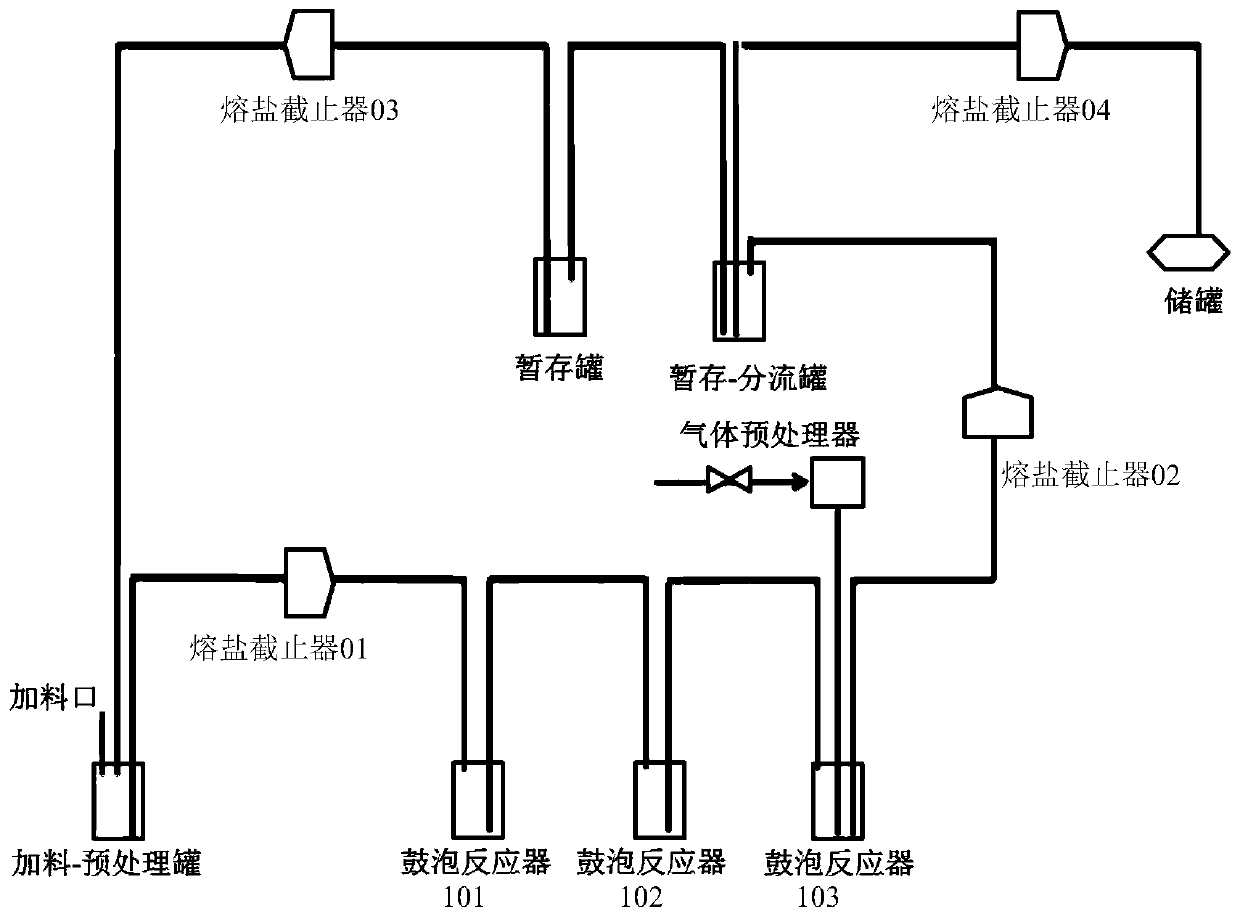

Fused salt stop device, using method and application

ActiveCN110671517ADeadline to achieveAchieve solidificationValve members for heating/coolingLiquid stateMolten salt

The invention discloses a fused salt stop device, a using method and application. The stop device comprises a sealing container used for loading fused salt, a heating system, a first guide pipe and asecond guide pipe. The first guide pipe and the second guide pipe penetrate through the inner wall face of the sealing container from the outer wall face of the upper end of the sealing container respectively; the height of the bottom of the first guide pipe from the bottom face of an inner cavity of the sealing container is shorter than the distance between the bottom of the first guide pipe andthe bottom of the second guide pipe; when the bottom of the second guide pipe is higher than the liquid level of the fused salt or the fused salt is solidified from the liquid state, stop is achieved;when the bottom of the second guide pipe is lower than the liquid level of the fused salt and the fused salt conveyed into the container by means of the first guide pipe is in a liquid state, communication is achieved. According to the fused salt stop device, the feature that the fused salt is well combined with the inner wall of the container after being solidified is utilized, the container with a large space is designed in combination with a large height difference between the guide pipes, complete stop of the fused salt can be achieved, and rapid recovery of communication can be ensured;the airtightness is good, and the service life is long; the phenomenon that fused salt is stuck in a valve and other devices due to solidification after volatilization can be avoided.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Rubber and plastic extruder

The invention discloses a rubber and plastic extruder. The rubber and plastic extruder comprises a feed opening, a discharge opening, a first cylinder, a first extrusion screw, a first reduction gearbox, a first motor, a second cylinder, a second extrusion screw, a second reduction gearbox, a second motor and a connection channel, wherein the first extrusion screw is mounted in the first cylinder and connected with the first reduction gearbox; the first reduction gearbox is connected with the first motor; the second extrusion screw is mounted in the second cylinder and connected with the second reduction box; the second reduction gearbox is connected with the second motor; the feed opening is arranged at the input opening of the first cylinder; the discharge opening is arranged at the output opening of the second cylinder; the connection channel is connected between the output opening of the first cylinder and the input opening of the second cylinder. The rubber and plastic extruder adopts a two-stage serial structure, so that the structure of a traditional single screw extruder is simplified, the overall lengths of the screws are reduced, convenience is brought to the design, manufacture, maintenance and use of the rubber and plastic extruder, and impacts on finished product quality are reduced.

Owner:GUILIN UNITED POWER INT RUBBER & PLASTIC MACHINERY

A method for preparing brittle metal microspheres based on a metal microsphere forming device

Owner:ZHUZHOU KENENG NEW MATERIAL CO LTD

Automatic welding device for medical protective clothing

The invention provides an automatic welding device for medical protective clothing. The automatic welding device comprises a cabinet type workbench and is characterized in that side ultrasonic die heads are arranged on the two sides of the cabinet type workbench correspondingly, wherein a conveying belt is arranged on the outer sides of the side ultrasonic die heads; electromagnetic clamps are arranged on the conveying belt; supports are arranged on the two sides of the cabinet type workbench; a top plate is arranged at the top ends of the supports; a guide rail is fixed to the top plate; a sliding block is arranged on the guide rail; one end of the sliding block is connected with a top telescopic mechanism; and the top of the sliding block is fixedly connected with the bottom of a longitudinal beam. According to the automatic welding device, ultrasonic die pressing automatic welding is adopted, and use is efficient and convenient. The welding positions of an upper protective clothingbody cut piece and a lower protective clothing body cut piece are subjected to automatic pressure welding through a first telescopic mechanism and a second telescopic mechanism, and thorough fusion ofspecial cloth for the protective clothing is achieved.

Owner:湖北新鑫无纺布有限公司

Device for simulating fusion of molten microdroplet and solidified microdroplet in microgravity environment

ActiveCN113447518AEasy to observeAdjustable vertical positionInvestigating phase/state changeEngineeringImaging data

The invention provides a device for simulating fusion of molten microdroplets and solidified microdroplets in a microgravity environment. The device overcomes the defect that an existing drop tube device cannot complete a ground simulation microgravity environment uniform microdroplet fusion test at present. The device is provided with a solidified microdroplet releasing module used for containing / releasing solidified metal microdroplets, the solidified microdroplet releasing module is matched with a uniform metal microdroplet spraying module, a position adjusting module and a control module, controlled fusion of the metal microdroplets under the microgravity condition can be achieved, a fused microdroplet sample is obtained, image data are collected (with the help of an image collecting module), a foundation is laid for metal microdroplet microgravity fusion behavior research and space metal 3D printing.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

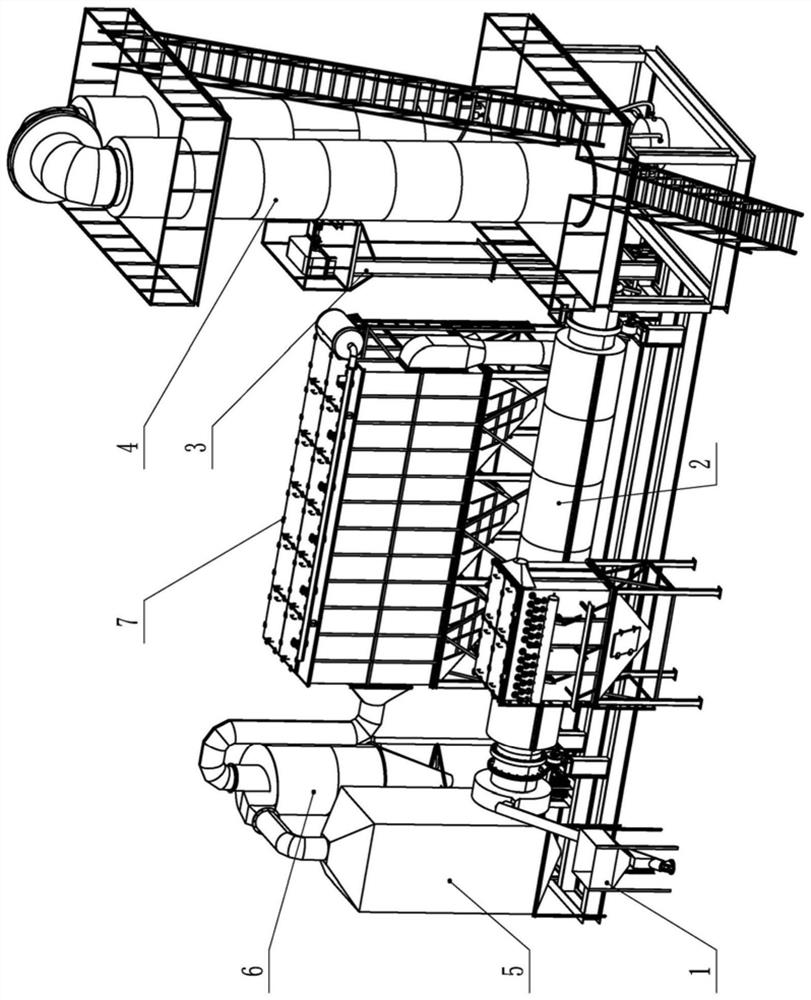

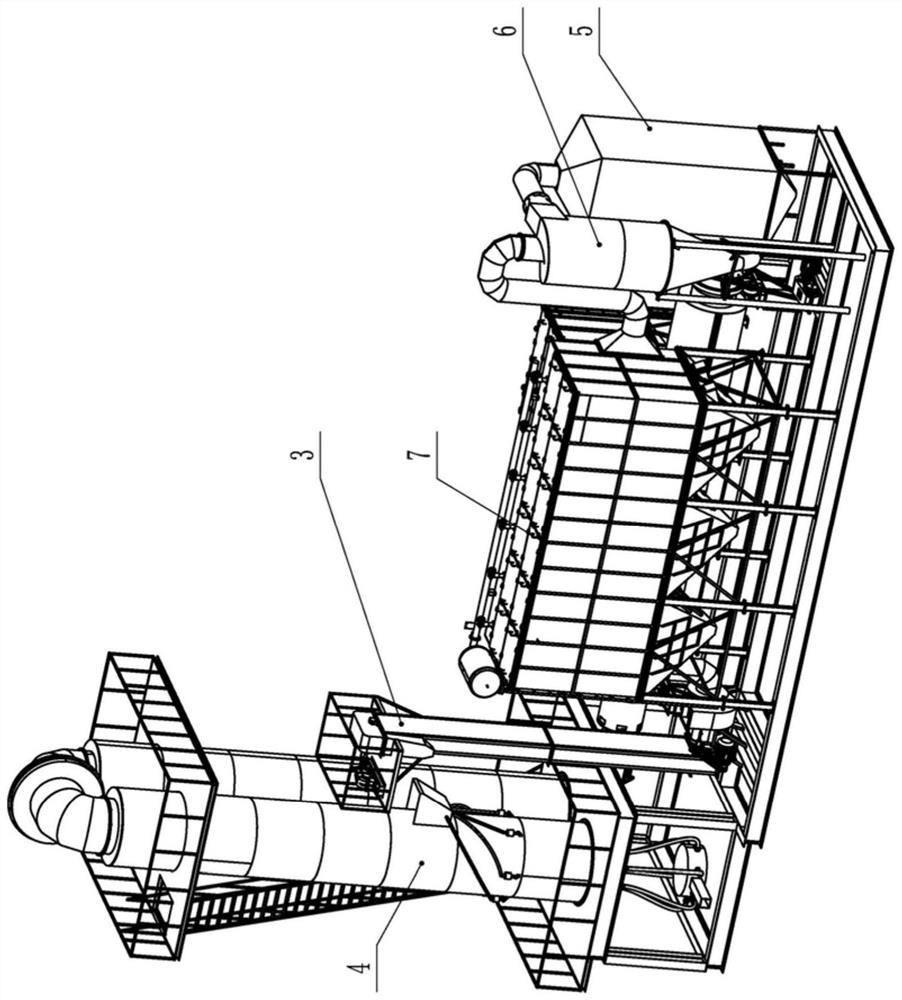

Expanded perlite production process and equipment

The expanded perlite production process comprises material treatment and air duct dust removal, and the material treatment comprises the following steps that feeding is conducted, specifically, materials enter a drying furnace through a feeding bin; materials are preliminarily preheated in the drying furnace and conveyed to one side. The materials subjected to preliminary preheating enter a lifting machine and are conveyed into an expansion furnace through the lifting machine; the materials are expanded twice in the expansion furnace; the materials subjected to secondary expansion are conveyed into the drying furnace; and sixthly, the materials dried through the drying furnace are conveyed into a finished product bin. According to the present invention, the initial material is preheated by using the heat during the drying of the expanded material so as to reduce the energy loss, and the secondary expansion technology is innovatively adopted, such that the technology belongs to the pioneering technology in the whole industry, such that the material melting can be well achieved, the material corner angle can be well eliminated, the energy loss can be well reduced, and the low-nitrogen technology can be well utilized; and the purposes of energy conservation and emission reduction can be well achieved.

Owner:XINYANG BAOZI ENVIRONMENTAL PROTECTION EQUIP

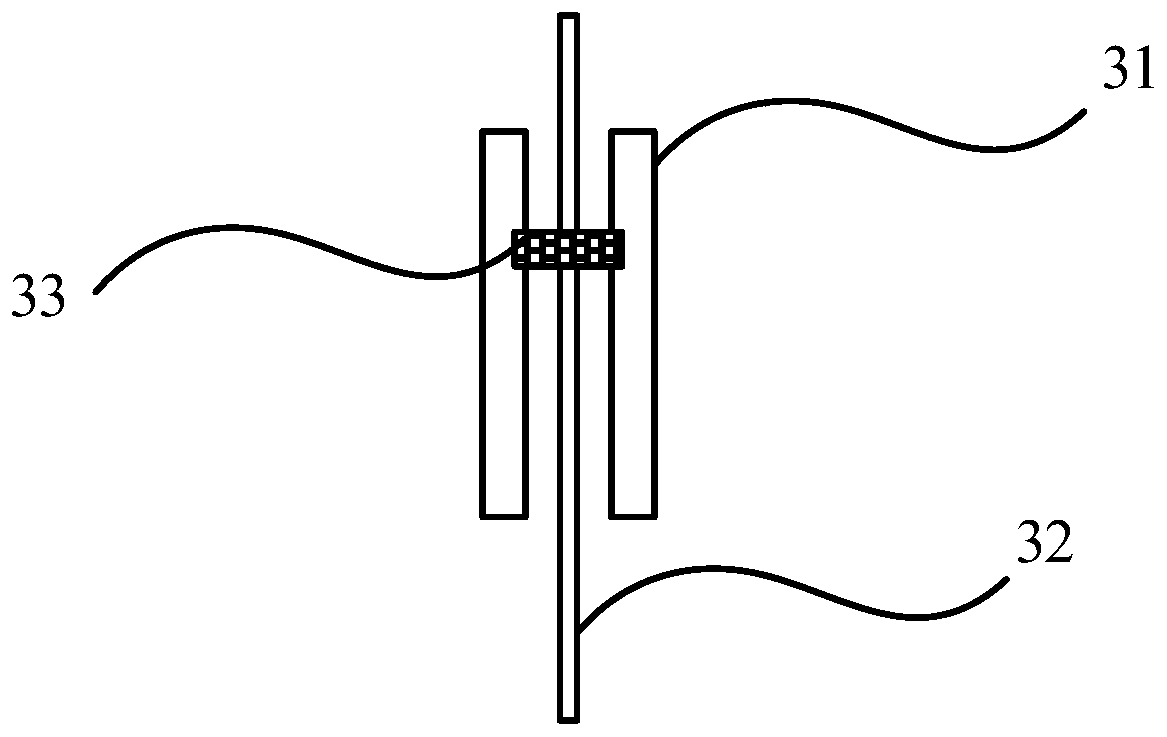

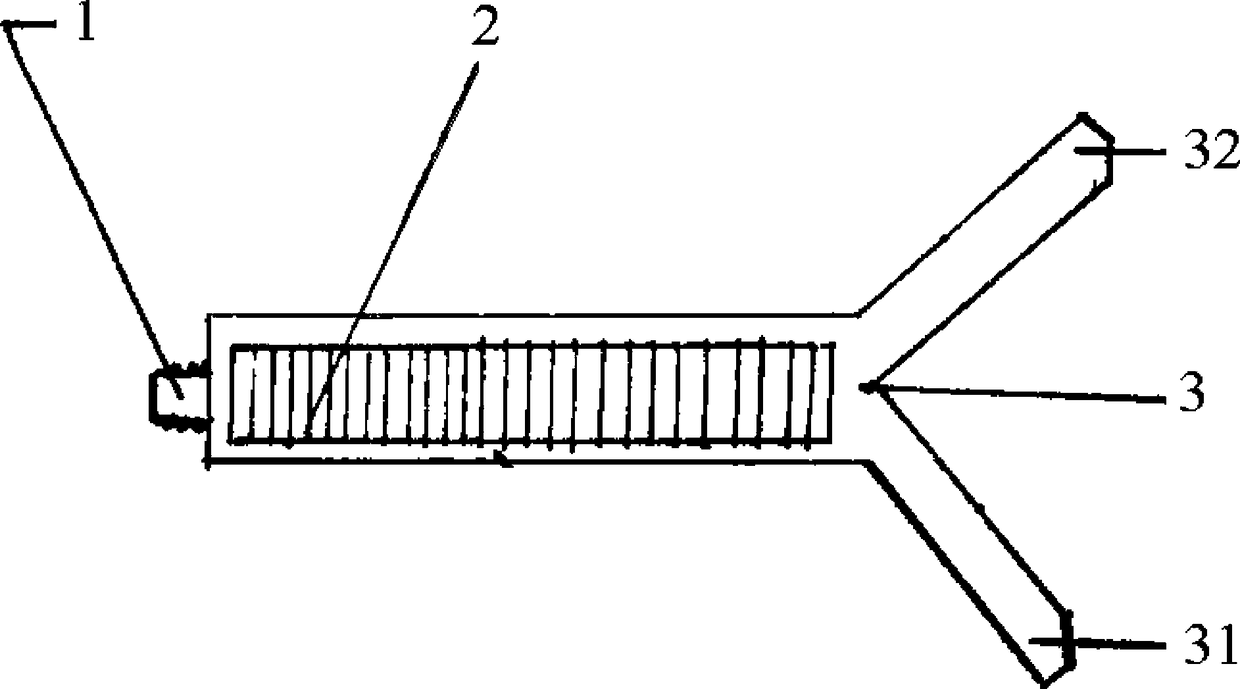

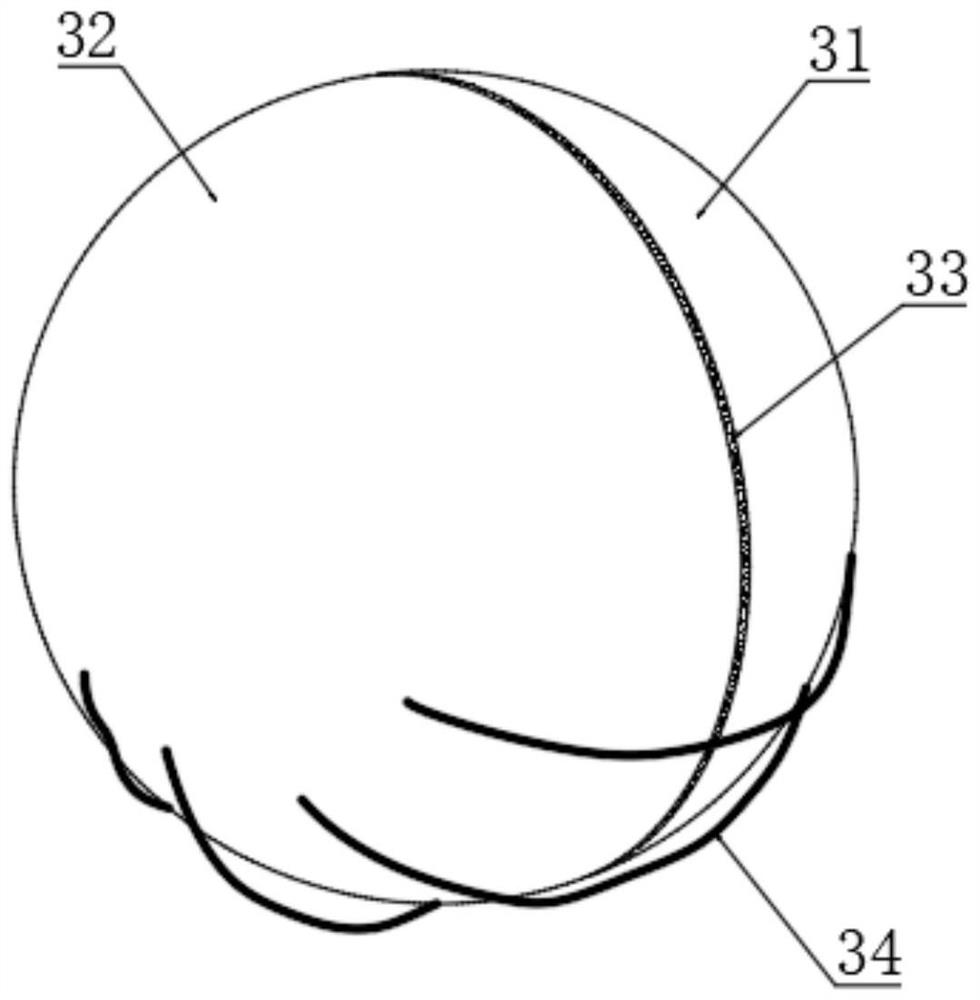

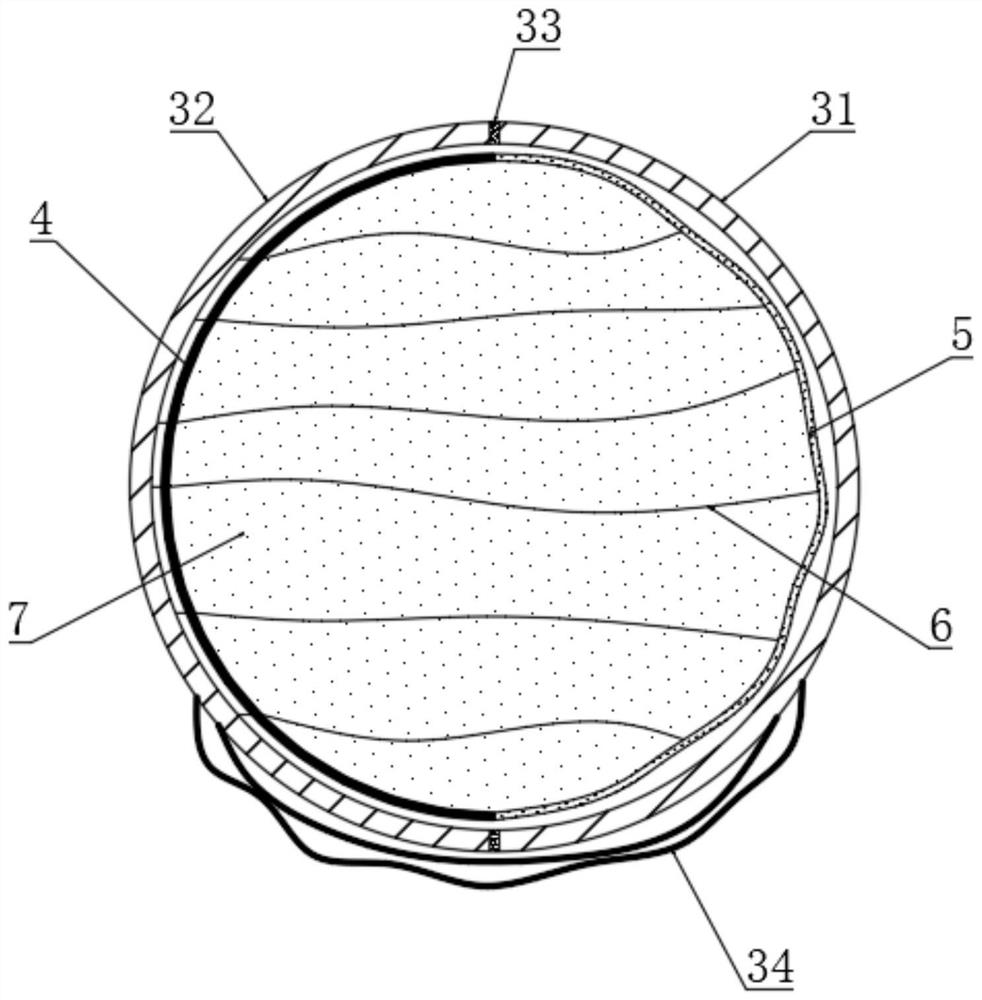

Splayed double-branch channel type heating drying gun and using method thereof

PendingCN109334050AFully and evenly distributedRealize secondary quantitative distributionElectrical resistance and conductanceEngineering

The invention relates to the field of reinforcing polymer compounds by using loose or adhered fibrous materials, in particular to a splayed double-branch channel type heating drying gun and a using method thereof. The splayed double-branch channel type heating drying gun comprises an air blower (1), and is characterized by further comprising a ceramic core resistance wire gun body (2) and an air duct (3), wherein the air duct (3) is characterized in that a lower air duct body (31) and an upper air duct body (32) are connected with an air inlet to form an angle shape with an open end. The usingmethod of the splayed double-branch channel type heating drying gun is characterized by being implemented sequentially according to the following steps of firstly, blasting; secondly, heating; thirdly, winding; and fourthly, hot melting. The heating drying gun and the using method have the advantages that the structure is simple, the use is convenient, the heating efficiency is high, and the product quality is good.

Owner:上海英泰塑胶股份有限公司

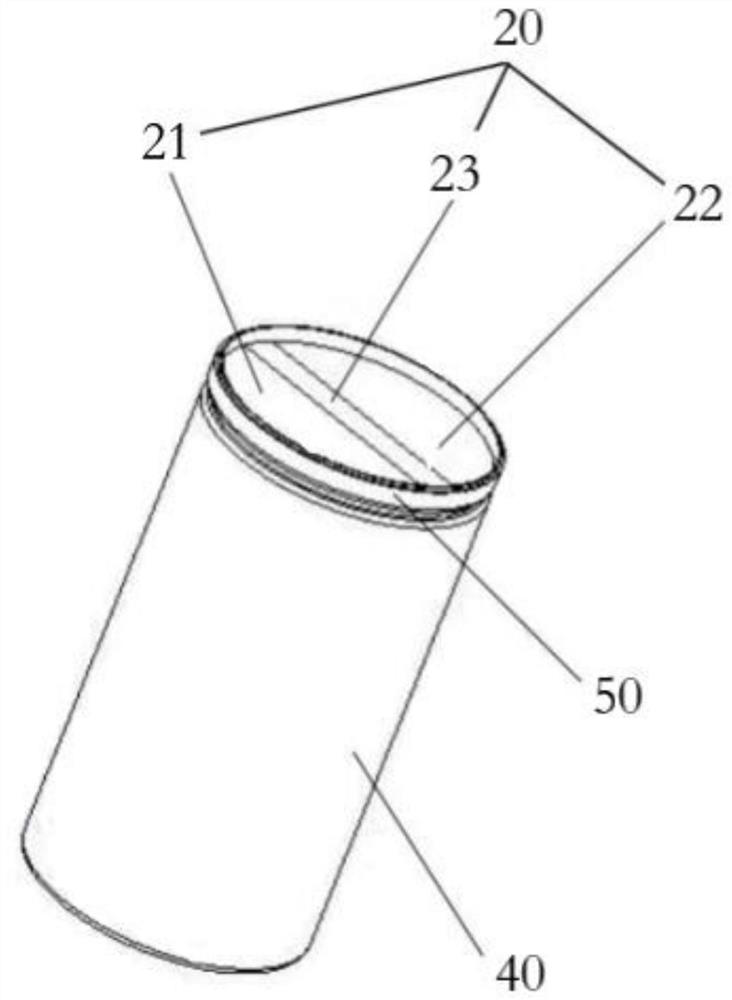

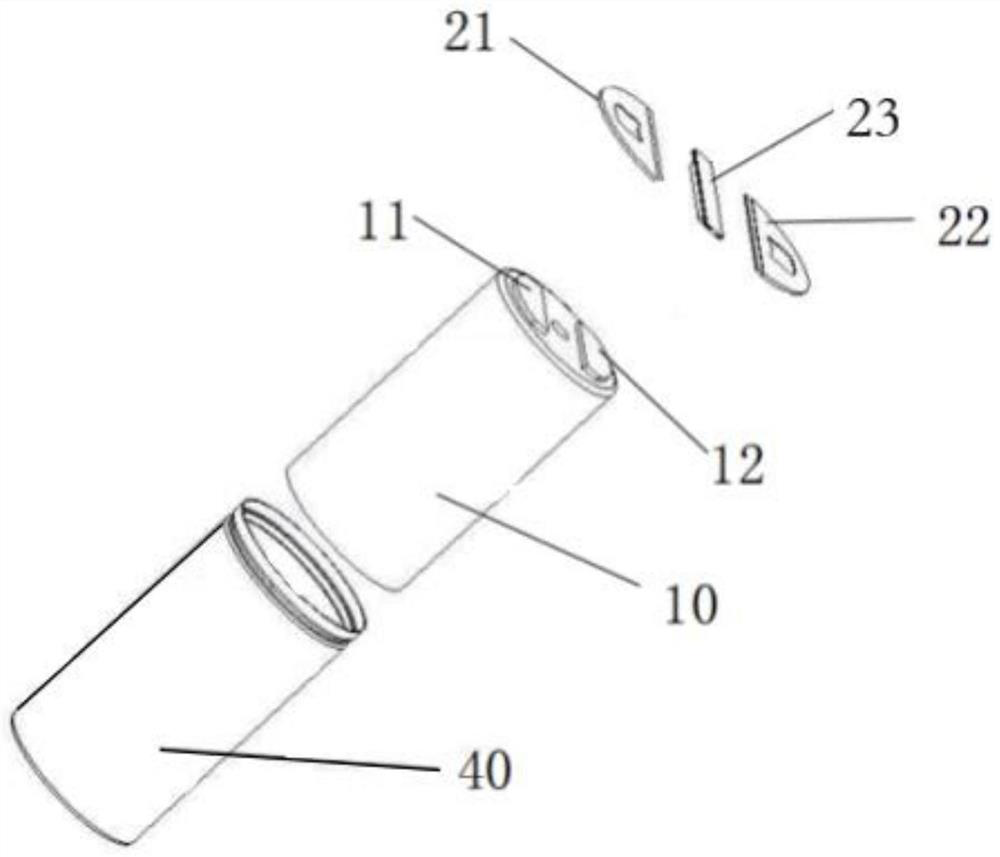

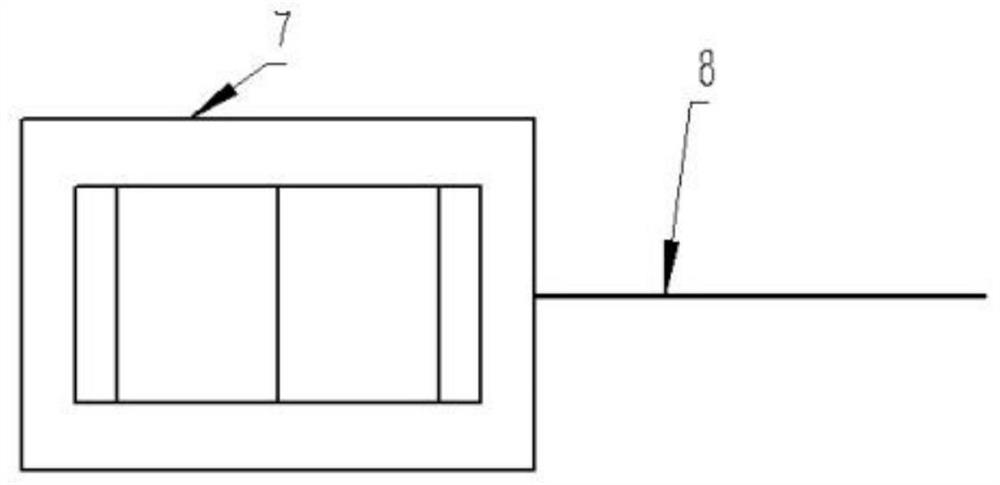

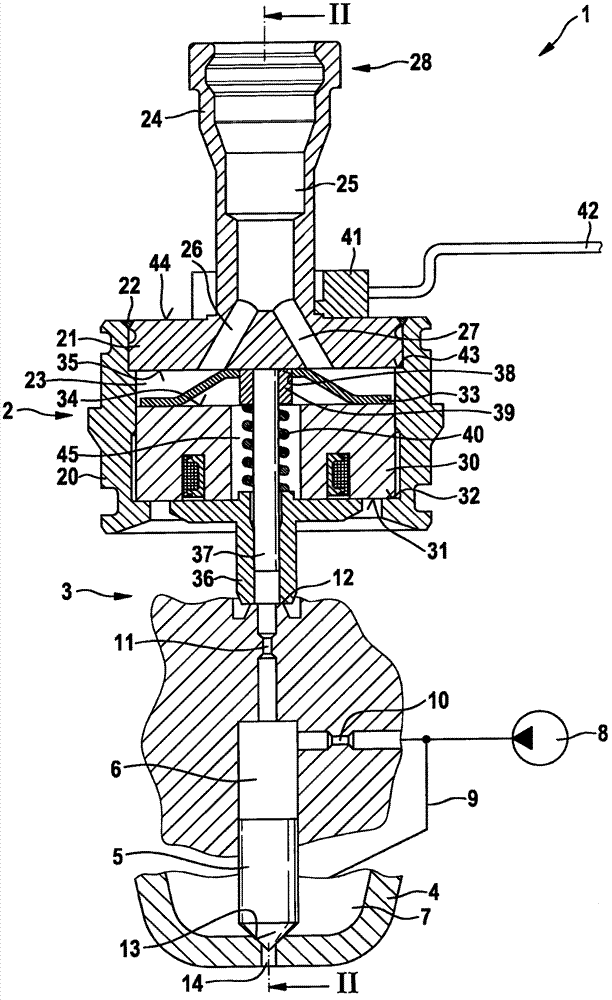

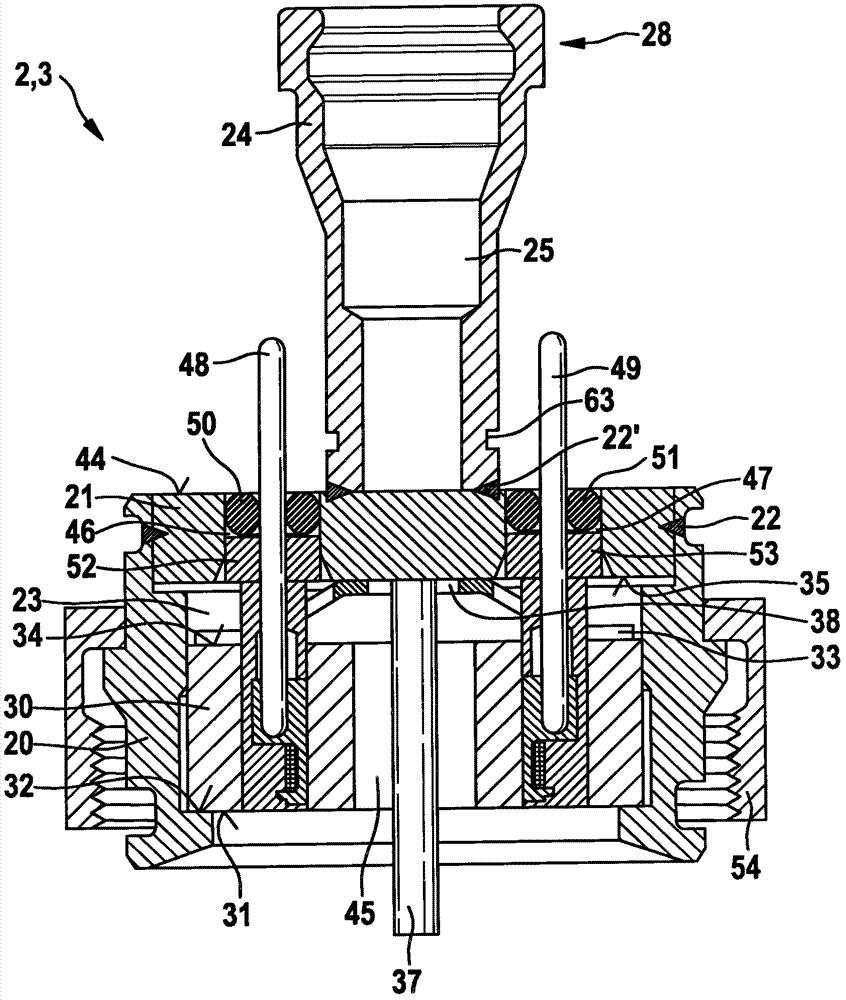

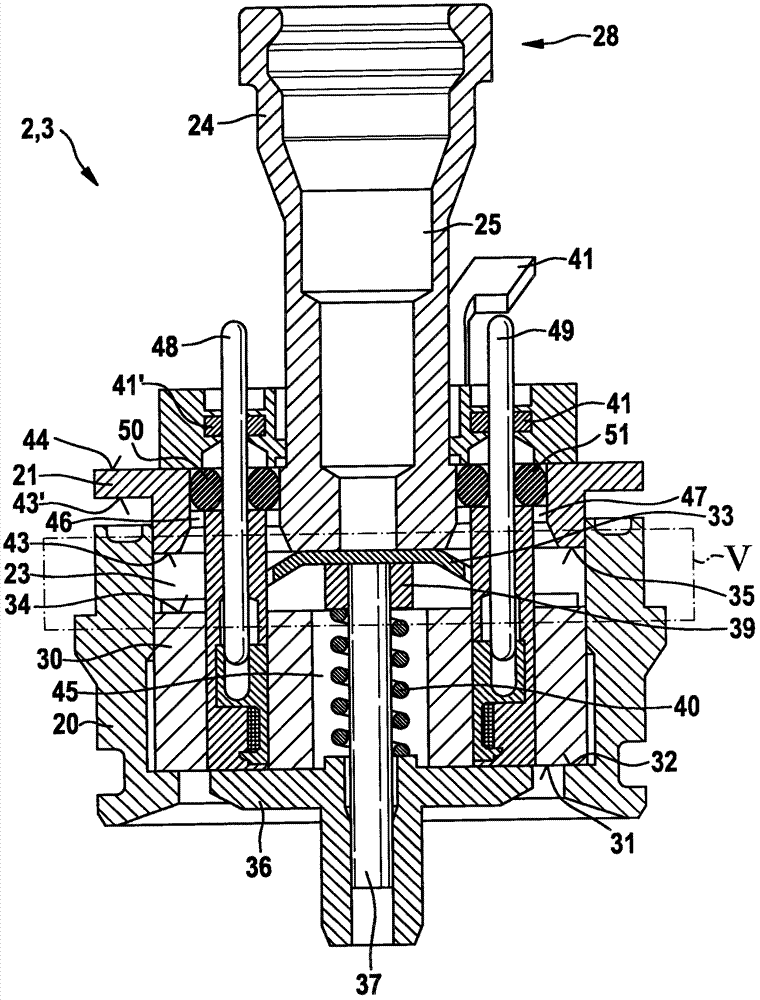

Magnet group for a solenoid valve

ActiveCN102047355BSimple adaptationEasy to manufactureMachines/enginesSpecial fuel injection apparatusSolenoid valveEngineering

A magnet group (2) serves in particular for a magnet actuator (3) of a fuel injection valve (1). The magnet group (2) has a housing part (20) into which a coil (30) is placed. In addition, an armature (36) is arranged on a first side (31) of the coil (30). Furthermore, a cover (21), which closes off the housing part (20), is arranged on a second side (34), facing away from the first side (31), of the coil (30), wherein the cover (21) is connected to the housing part (20) by a weld seam (22). The multi-part design permits, in particular, adaptation of an interface (28) to a connector (24) which is connected to the housing part (20) or embodied in one piece therewith.

Owner:ROBERT BOSCH GMBH

A three-layer composite liquid crystal polymer reinforced pipe

ActiveCN104527143BIncrease pressureImprove impact resistanceSynthetic resin layered productsRigid pipesEngineering plasticConductor Coil

The invention discloses a three-layer composite liquid crystal polymer enhanced pipe. The composite liquid crystal polymer enhanced pipe is characterized by sequentially and coaxially covering an outer functional material layer, an intermediate thermotropic liquid crystal polymer engineering plastic enhanced layer and an inner functional material layer; the intermediate thermotropic liquid crystal polymer engineering plastic enhanced layer forms a spiral directional array in an equal distance on the outer edge of the inner layer of a pipe along a flowing direction. According to the composite liquid crystal polymer pipe, liquid crystal winding molding is carried out by using a special device and utilizing the strength and the pressure resistance property of the liquid crystal, as well as the high intensity and high flexibility and self-fusion property of polyethylene, so that the use of inner layer materials and outer layer materials under special work conditions such as abrasion resistance, corrosion resistance, flame retardant, anti-static electricity and super-lubrication can be realized, the heatproof property and pressure resistance levels of the pipeline can be improved based on the property of the liquid crystal polymer, and the water delivery requirement of the pressure of 20 MPa can be realized at maximum.

Owner:HEBEI WANGYUAN PIPES

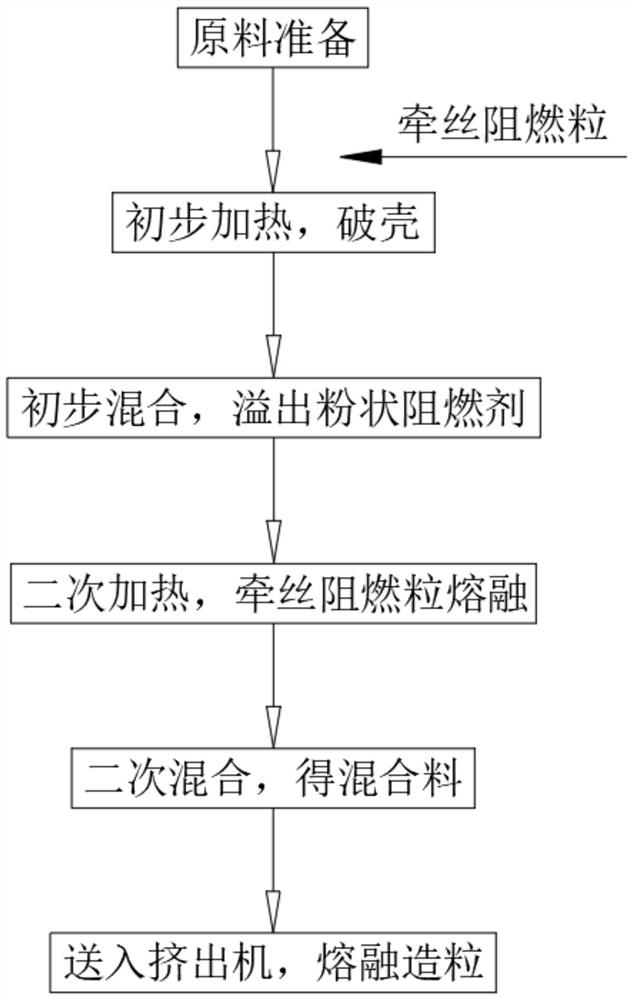

Preparation process of flame-retardant color master batch

The invention discloses a preparation process of flame-retardant color master batches, and belongs to the field of flame-retardant color master batches, granular wire-drawing flame-retardant particles are prepared by coating a powdery flame retardant, and when the granular wire-drawing flame-retardant particles are mixed with raw materials, not only can the dust problem caused by the flame retardant be effectively avoided and the environmental safety problem be improved, but also the flame-retardant flame-retardant particles can be used for preparing flame-retardant flame-retardant particles. In the mixing process of the wire-drawing flame-retardant particles and the raw materials, the shell-broken wire-drawing flame-retardant particles can be driven by the stirring force of the stirrer to move in the raw materials, and the flame retardant in the wire-drawing flame-retardant particles is extruded under pressure in the moving process and is dispersed in all areas in the raw materials in a multi-point manner; the flame retardant is uniformly diffused in a small range in a nearby area, and the uniform dispersion difficulty of the flame retardant can be greatly reduced and the uniformity of the flame retardant property of the color master batch can be improved in a manner of mixing the whole body and the local part.

Owner:湖南省升阳新材料有限公司

Molten droplet generating device for EUV light source

PendingCN112540513AAchieve heatingAchieve fusionHeating element shapesPhotomechanical exposure apparatusThermodynamicsSpray nozzle

The invention provides a molten liquid drop generating device for an EUV light source, which is characterized in that a heat conduction oil input port and a heat conduction oil output port are formedin the outer wall of a body; a heating cavity is filled with heat conduction oil, and an electric heating rod extends into the heat conduction oil; an inner cavity is installed in the inner cavity, the top of the inner cavity of the top cover is connected, a fixing cap is installed in the inner cavity, a compression spring is fixed to the bottom of the fixing cap, the bottom of the compression spring is a filter cap, the bottom of the filter cap is communicated with an output channel, the output channel is connected with a high-speed spray nozzle, and the high-speed spray nozzle is connected with a compression nut fixed to the bottom of the body. The device has the advantages that the filtering cap is used for removing metal impurities; the sealing ring and the compression spring are usedfor maintaining the melting device to be used in a high-temperature and high-pressure environment, and the inner cavity realizes heating, melting and conveying of metal; the heating cavity is used fortransmitting a heat-conducting medium; the electric heating rod maintains the whole experiment temperature environment of the melting device; and the high-speed spray nozzle sprays experimental metalliquid drops according to requirements.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI +1

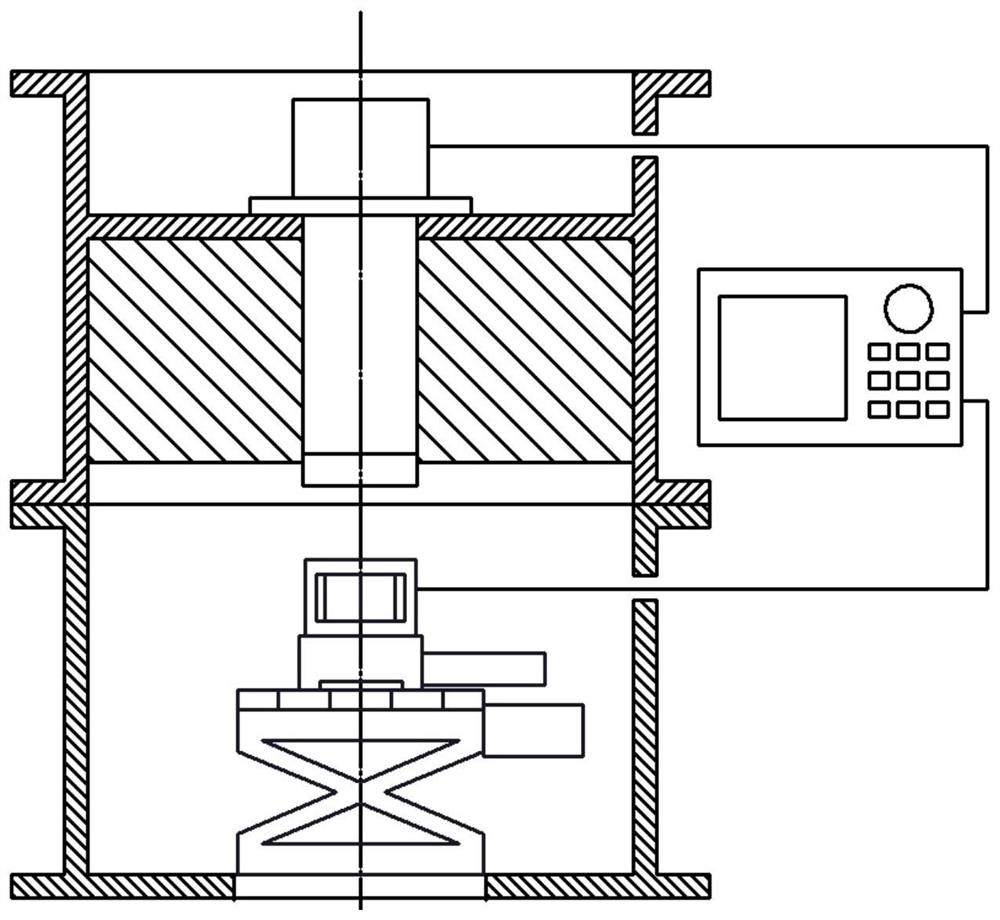

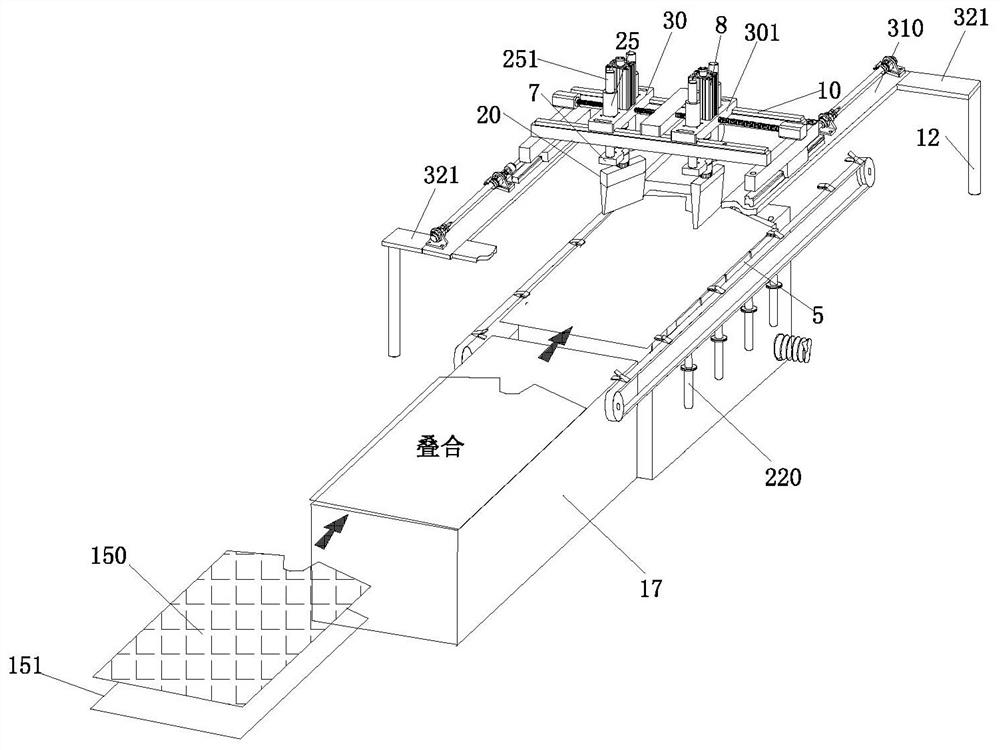

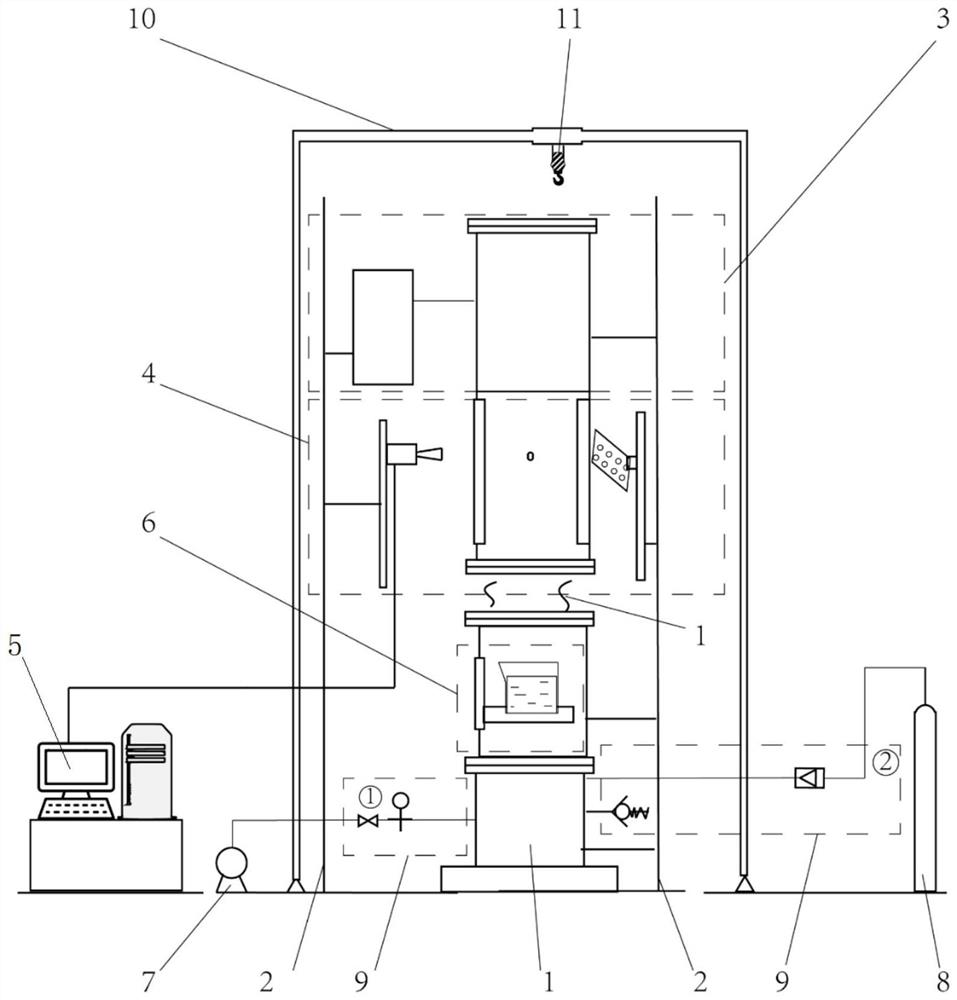

A real-time capture system for simulating the fusion process of metal droplets under microgravity

ActiveCN113500214BIncrease vacuumHigh microgravity levelsAdditive manufacturing apparatusIncreasing energy efficiencyVacuum pumpingImaging processing

The invention provides a real-time capture system for simulating the metal droplet chasing and fusion process under microgravity, and solves the insufficiency of the existing drop tube technology that cannot complete the metal droplet fusion test in the microgravity environment. A real-time capture system for simulating the pursuit and fusion process of metal droplets under microgravity comprises a tube body, a main body support frame, a microgravity droplet pursuit and fusion module, a microgravity droplet pursuit and fusion real-time capture module, an image processing module, a collection module and a vacuum pumping module. With the inert gas supplement module; the tube body is vertically fixed by the main support frame, which is connected with the vacuum and the inert gas supplement module to create an inert gas environment in the tube body, the microgravity droplet pursuit fusion module, the microgravity droplet pursuit fusion module The real-time capture module and the collection module are arranged in sequence from top to bottom along the height direction of the pipe body.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com