Welding method, preparation method and welding structure of cylindrical battery

A welding method and technology for cylindrical batteries, applied in structural parts, battery pack parts, circuits, etc., can solve the problems of difficult welding, affecting welding performance, brittle fracture of welded joints, etc., to improve welding performance and prevent intermetallic compounds. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

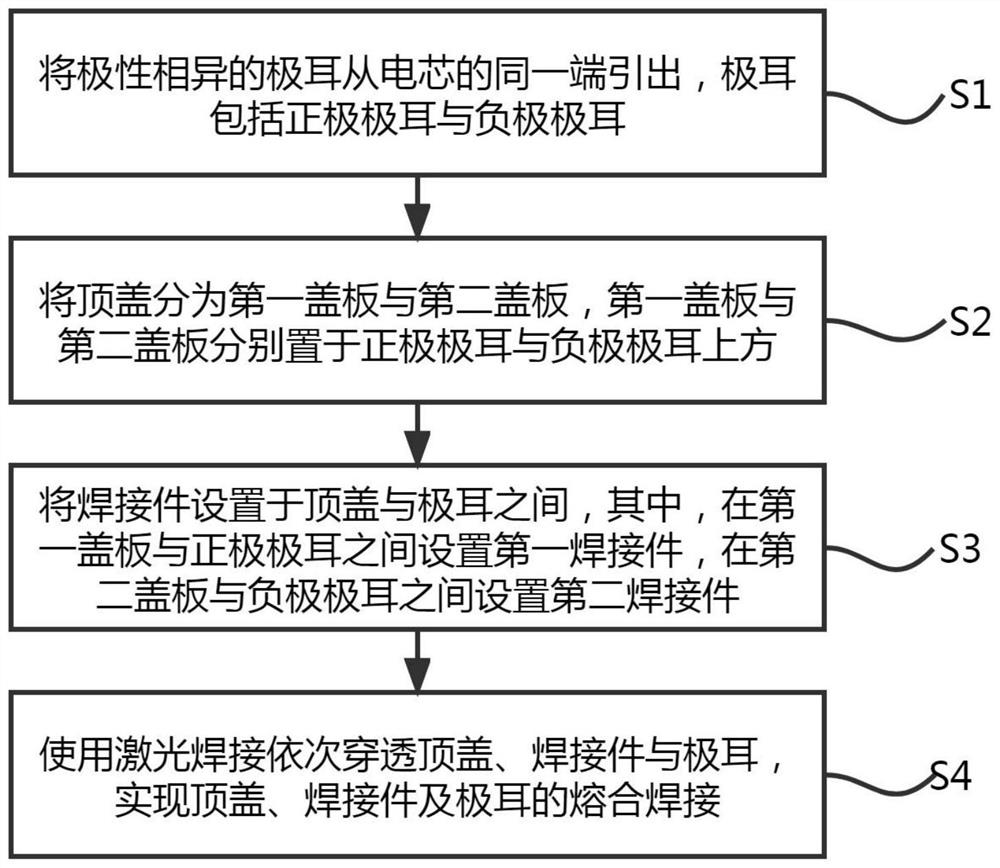

Method used

Image

Examples

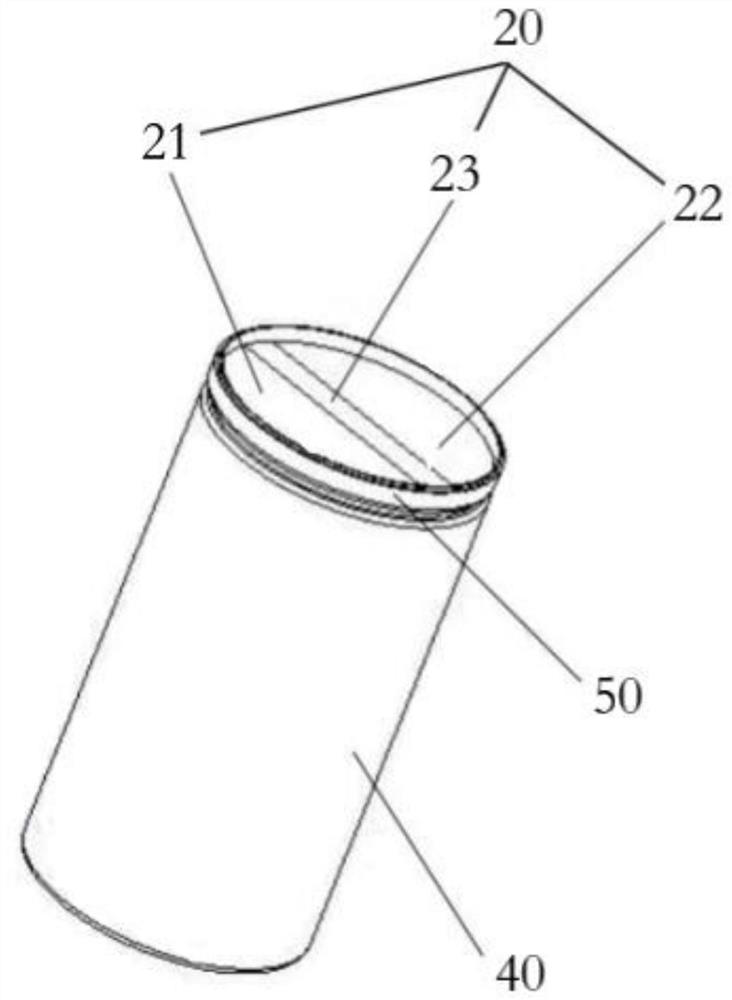

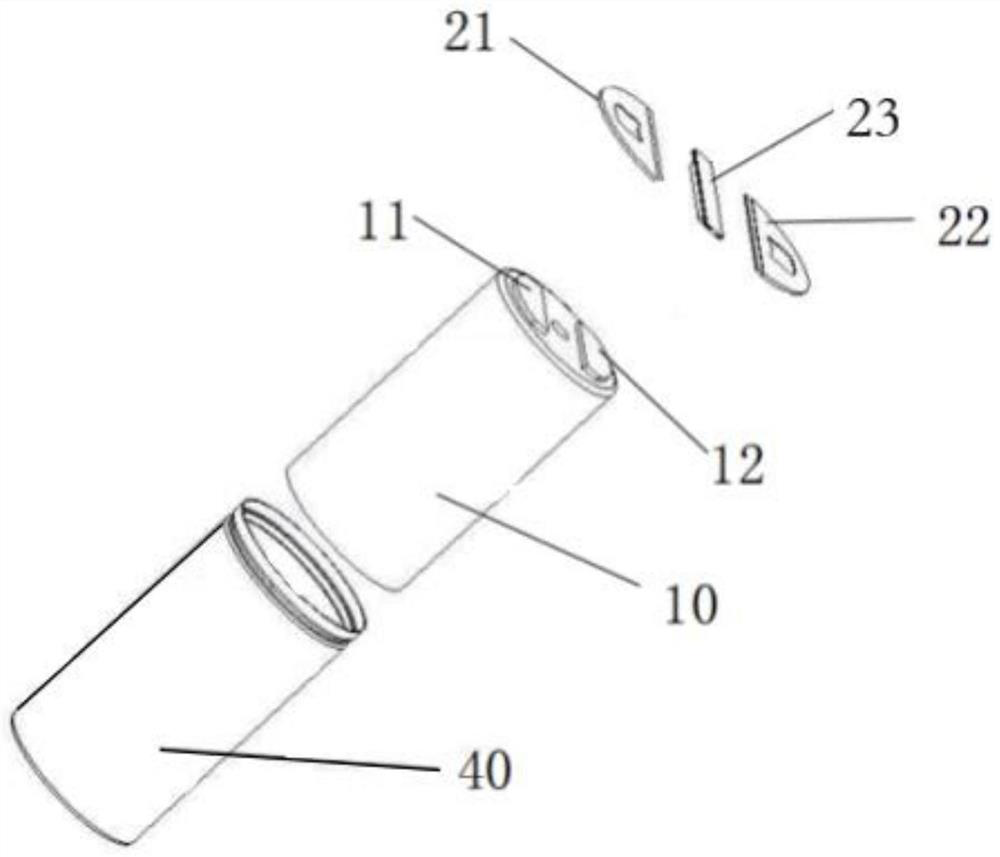

Embodiment Construction

[0054] As used in the specification and claims, certain terms are used to refer to particular components. It should be understood by those skilled in the art that hardware manufacturers may refer to the same component by different nouns. The description and claims do not use the difference in name as a way to distinguish components, but use the difference in function of the components as a criterion for distinguishing. As mentioned in the entire specification and claims, "comprising" is an open-ended term, so it should be interpreted as "including but not limited to". "Approximately" means that within an acceptable error range, those skilled in the art can solve technical problems within a certain error range, and basically achieve technical effects.

[0055] Furthermore, the terms "first," "second," etc. are used for descriptive purposes only and should not be construed to indicate or imply relative importance.

[0056]In the invention, unless otherwise expressly specified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com