Magnet group for a solenoid valve

A magnet assembly, solenoid valve technology, applied in the direction of electromagnets, electrical components, electromagnetic terminals/connectors, etc., can solve the problems of inability to achieve, difficult to manufacture, and difficult to design the connection position, and achieve a large degree of freedom and simple adaptation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

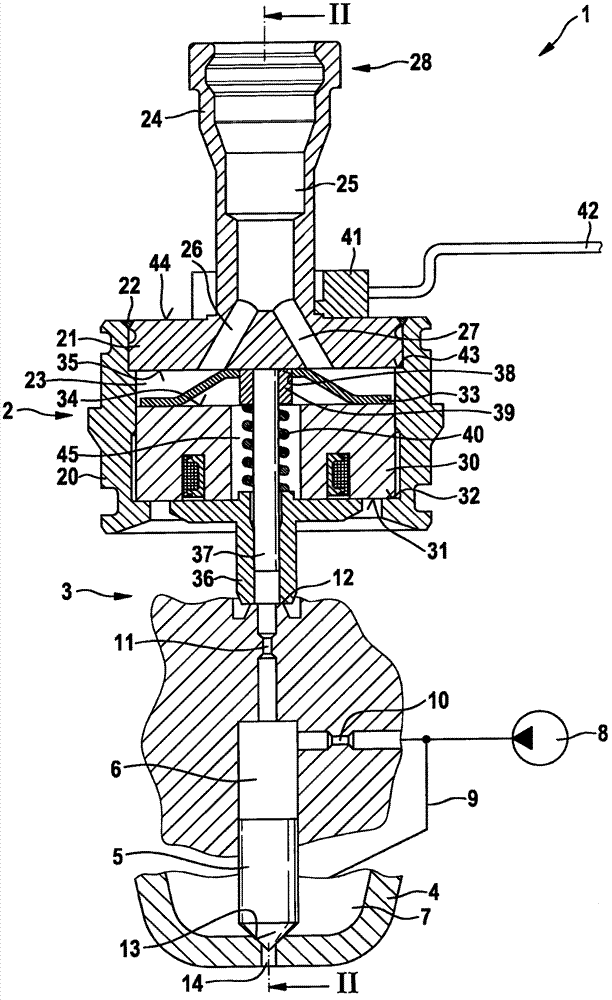

[0025] figure 1 A fuel injector 1 with a magnet arrangement (magnet component set) 2 according to a first exemplary embodiment of the invention is shown in a simplified, schematic sectional illustration. The fuel injection valve 1 can be used in particular as an injector of a fuel injection system for an air-compressed, self-igniting internal combustion engine. The fuel injection valve 1 is preferably used in a fuel injection system having a common rail which guides diesel fuel under high pressure to a plurality of fuel injection valves 1 . The magnet arrangement 2 according to the invention is particularly suitable for such fuel injection valves 1 . In this case, the magnet assembly 2 can be used as part of a solenoid valve 3 , which serves as a solenoid actuator for the fuel injection valve 1 for actuating the fuel injection valve 1 . However, the fuel injector 1 according to the invention and the magnet arrangement 2 according to the invention are also suitable for other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com