Preparation process of flame-retardant color master batch

A preparation process and color masterbatch technology, applied in the field of flame retardant color masterbatch, can solve the problems of uneven mixing, different flame retardant properties of color masterbatch, dust pollution, etc., to improve environmental safety problems, reduce the difficulty of uniform dispersion, Improves uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

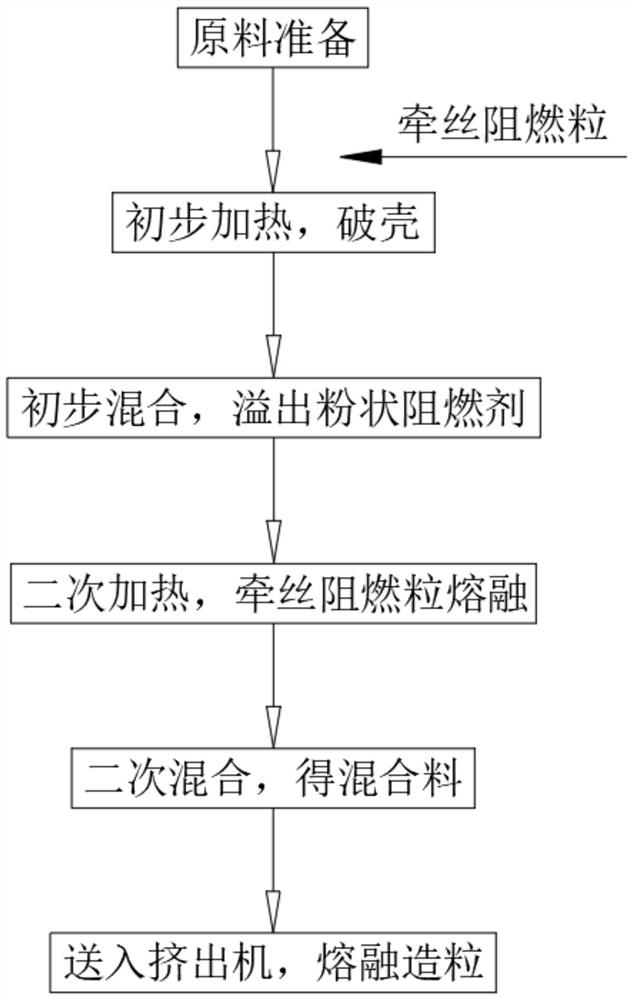

[0046] see figure 1 , a preparation process of flame retardant color masterbatch, comprising the following steps:

[0047] S1. Prepare raw materials: carrier resin, pigments, dispersants, coupling agents, surfactants, plasticizers and flame retardant particles;

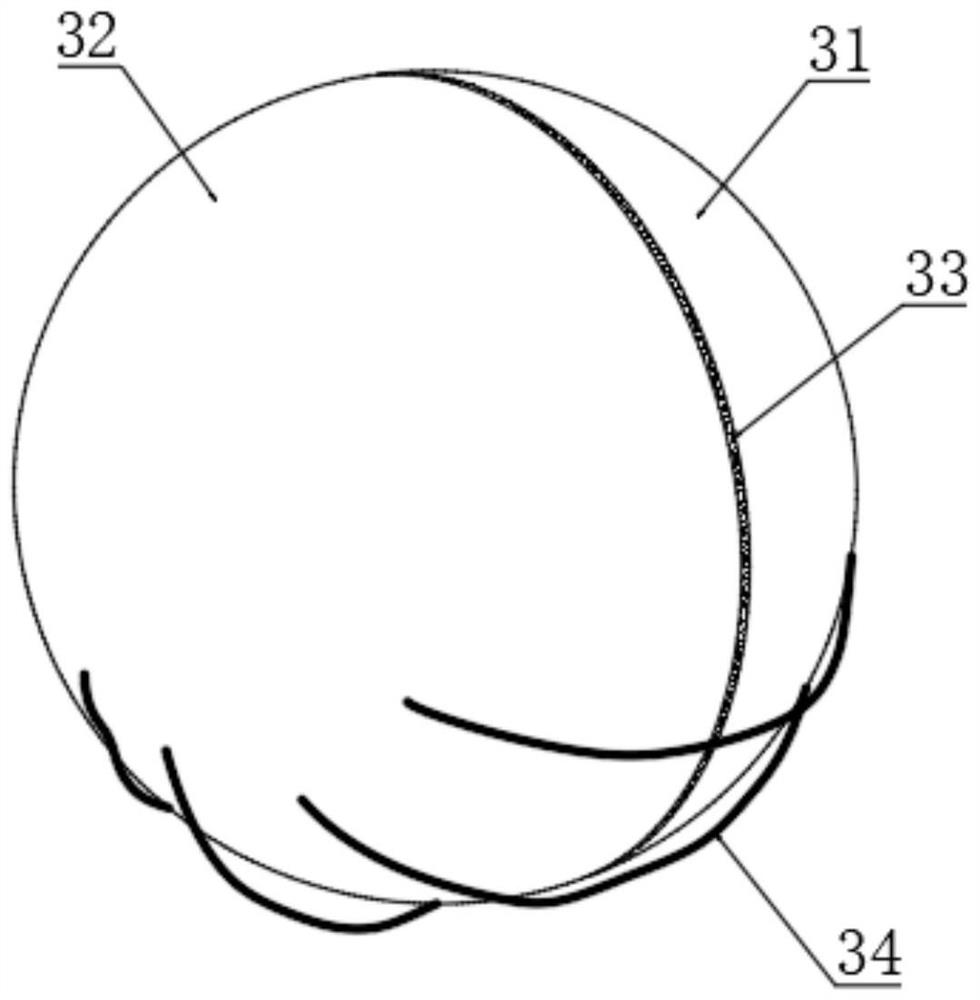

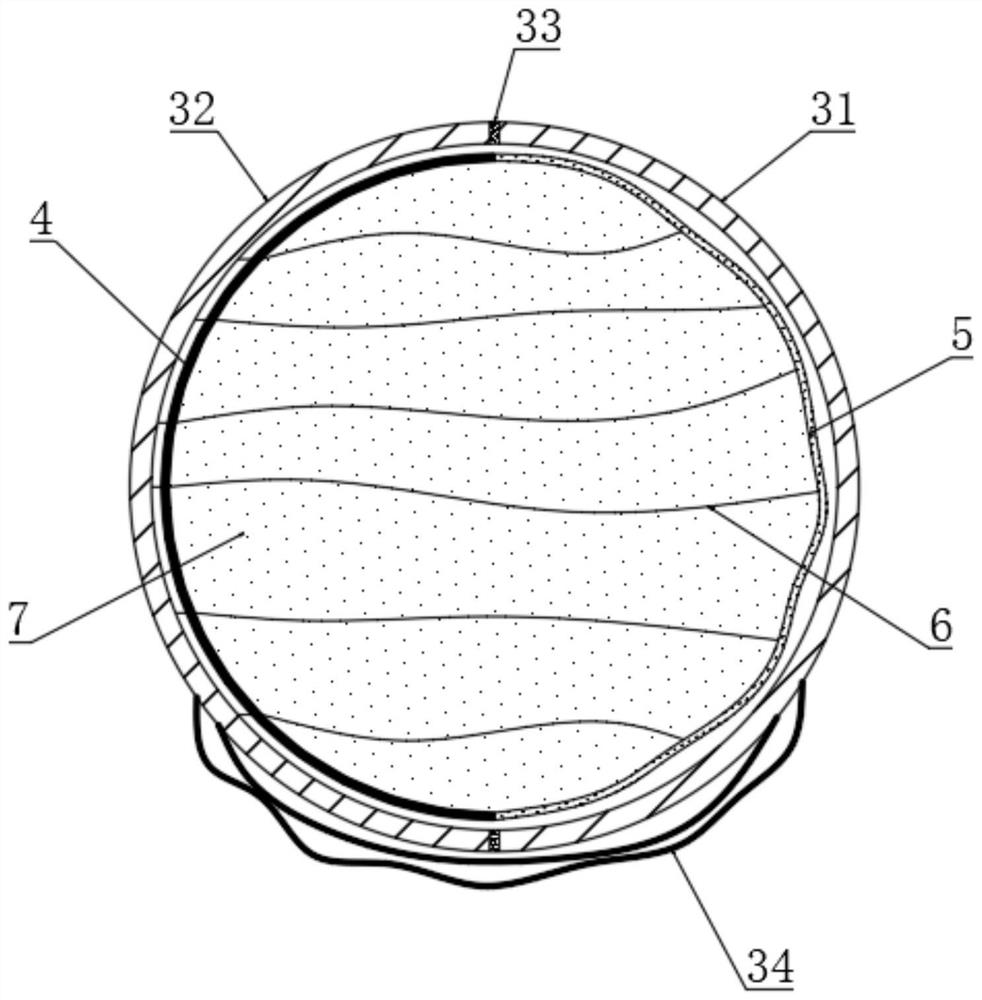

[0048] S2. Add the above-mentioned raw materials into the blender, and initially heat the raw materials to break the shell of the dragging flame-retardant grains (such as Figure 5 shown);

[0049] S3, start the mixer to preliminarily mix the raw materials, semi-separate the shell of the wire-drawing flame-retardant pellets, and extrude the powdery flame retardant 7 under pressure, and mix it into the raw materials (such as Figure 6 and Figure 7 shown);

[0050] S4. Carry out secondary heating to the raw material, so that the wire-drawing flame-retardant particles are completely melted in the raw material;

[0051] S5, start the mixer again and carry out the secondary mixing of the raw materials, so that the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com