Three-layer composite liquid crystal polymer enhanced pipe

A technology of liquid crystal polymers and reinforced tubes, applied in the direction of tubes, rigid tubes, layered products, etc., can solve the problems of radial pressure and other problems, improve heat resistance and pressure resistance, wide applicability, and increase tensile strength and the effect on the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0026] The abbreviation of liquid crystal polymer is used below to replace the full name of "thermotropic liquid crystal polymer engineering plastic". The model of thermotropic liquid crystal polymer engineering plastic is Vectra A950. For the description of thermotropic liquid crystal polymer engineering plastic, see the attachment.

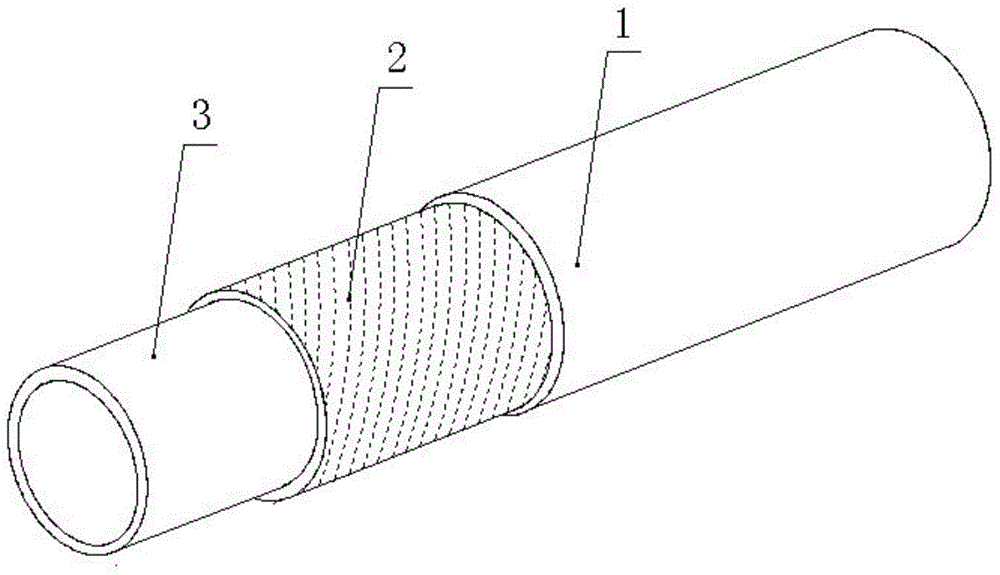

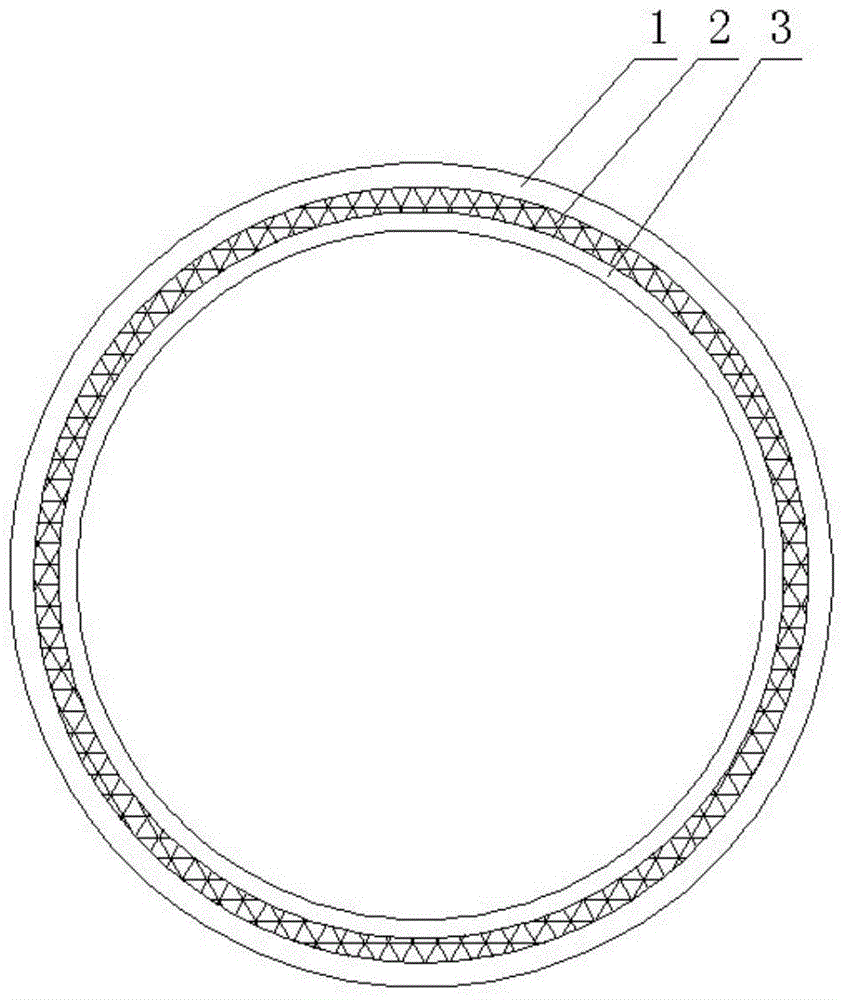

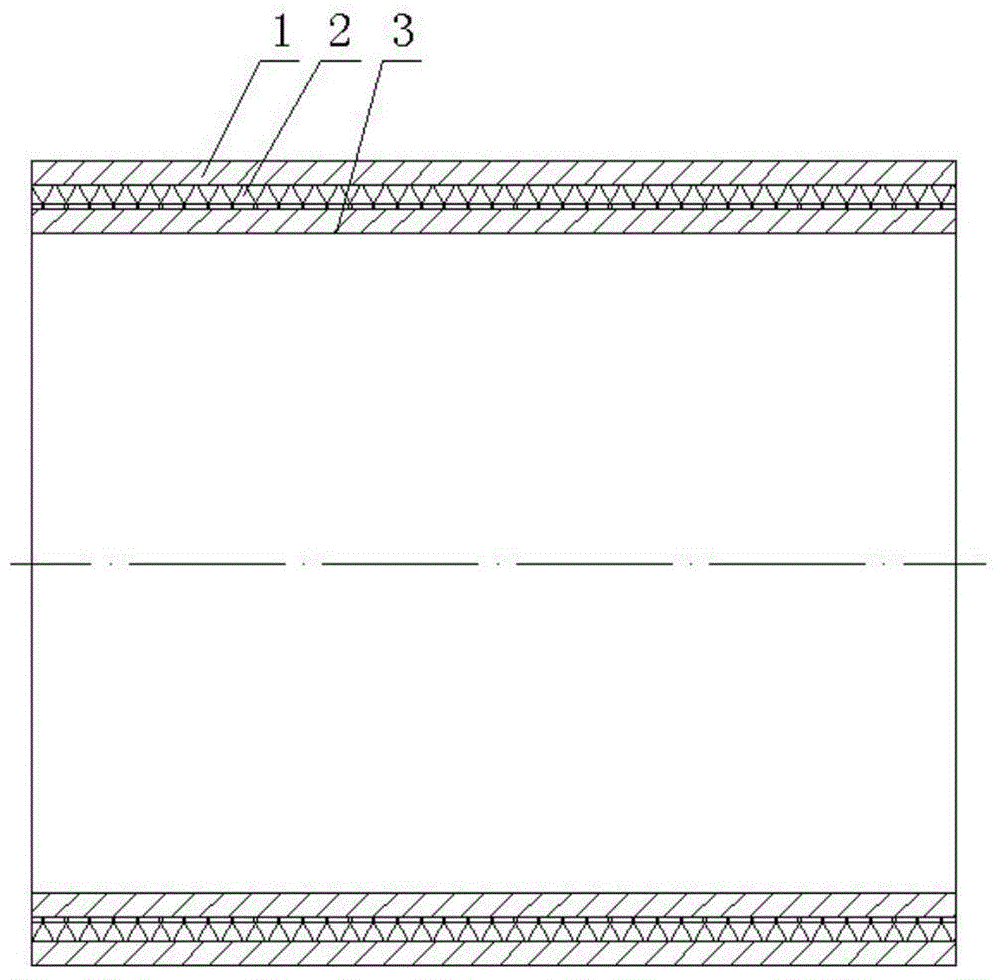

[0027] A three-layer composite liquid crystal polymer reinforced pipe, which is composed of an outer layer of functional material layer 1, an intermediate layer of liquid crystal polymer reinforced layer 2 and an inner layer of functional material layer 3 coaxially wrapped from the inside to the outside, the middle layer and the inner layer The outer edge of the pipe fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com