Preparation method of photocured crosslinked polyimide film

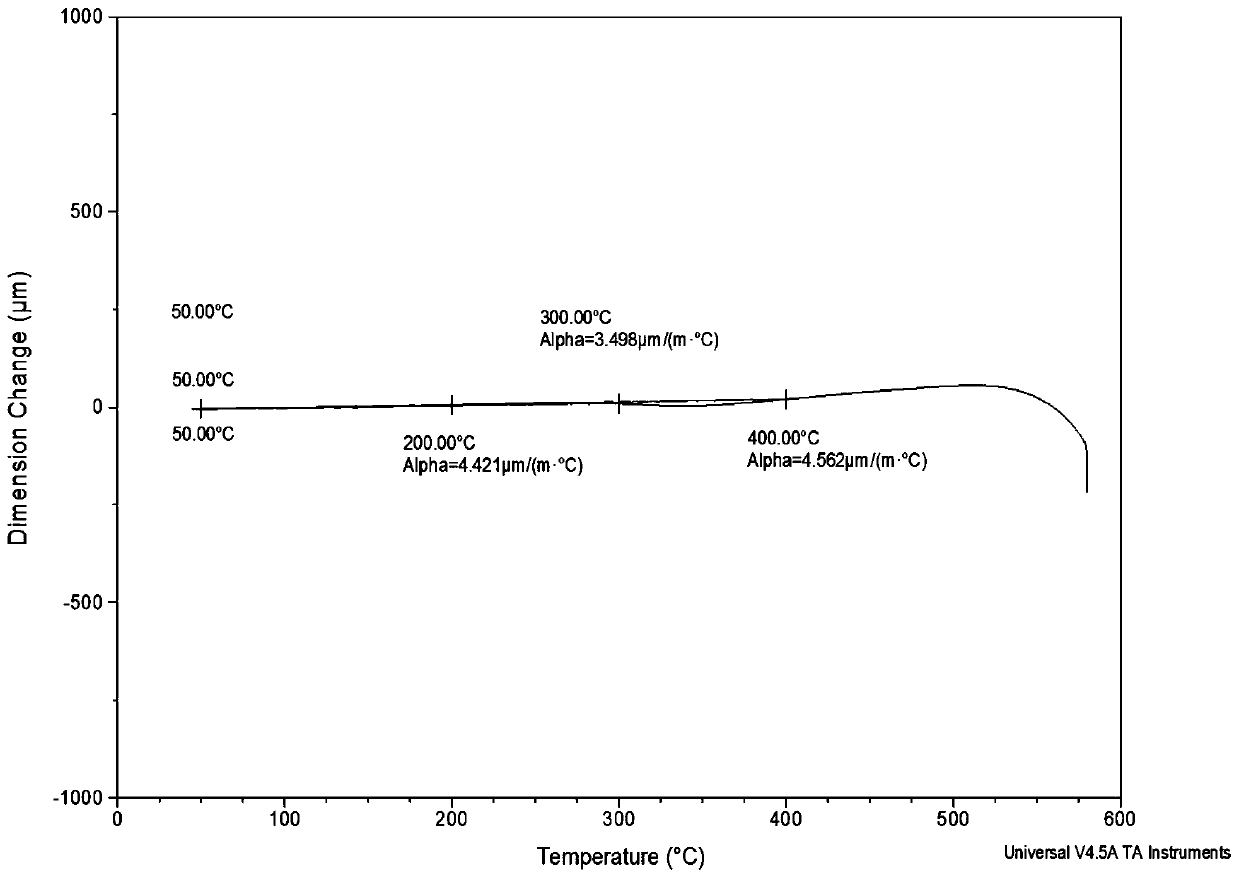

A polyimide film and light-curing technology, which is applied in the field of polymer materials, can solve problems such as not exceeding, and achieve the effects of increased tensile strength and elastic modulus, excellent mechanical properties, and good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0065] The invention provides a kind of preparation method of photocuring cross-linked polyimide film, comprises the following steps:

[0066] (1) polymerizing dianhydride, end-blocking monoanhydride and diamine in an aprotic polar solvent to obtain a polyamic acid slurry with a mass percent concentration of 12% to 30% and a viscosity of 3000 to 9000cp, the (two Anhydride + capped monoanhydride) to diamine molar ratio is (100:95) ~ (100:110), where

[0067] The dianhydride includes the first functional dianhydride and the second functional dianhydride, and the molar ratio of the first functional dianhydride, the second functional dianhydride and the blocked monoanhydride is (2~98.95):(97~1 ):(5~0.05)

[0068] The first functional dianhydride is selected from at least one of the following substances:

[0069]

[0070] The second functional dianhydride is selected from at least one of the following substances;

[0071]

[0072] The end-blocking monoanhydride is selected...

Embodiment 1

[0118] A light-cured PI film adding photoinitiator 1173 0.1% (wt) and co-initiator pentaerythritol tetramercaptoacetate 1.0% (wt), wherein the dianhydride includes the first functional dianhydride and the second functional dianhydride, the second The first functional dianhydride is S-BPDA, the second functional dianhydride is BTDA, the blocked monoanhydride is PEPA, and the molar ratio of the first functional dianhydride, the second functional dianhydride and the blocked monoanhydride is 80 / 18 / 2. The diamine is DMB, the molar ratio of diamine to (dianhydride + blocked monoanhydride) is 1:1, the aprotic solvent is NMP, and the solid content is 15%. The specific implementation plan is as follows:

[0119] (1) Pre-treatment of raw materials and solvents: DMB was dried in a vacuum oven at 60°C for 2 hours, S-BPDA and BTDA were dried in a vacuum oven at 120°C for 3 hours, NMP was added with 4A spherical molecular sieves and allowed to stand for 6 hours;

[0120] (2) Accurately we...

Embodiment 2-14

[0133] By comparing Example 1 and Example 1, it can be seen that the glue viscosity and film-forming performance synthesized in Example 1 are better and meet the requirements, and then the adjustment of other parameters is explored based on the preparation scheme of Example 1. The reaction steps and conditions are the same as in Example 1, and the specific material consumption and test results are as shown in Table 1. Since the viscosity of the system increases sharply after photocuring, the refractive index will also change to a certain extent, so it can be judged from the apparent change of the coating film whether it can be photocured.

PUM

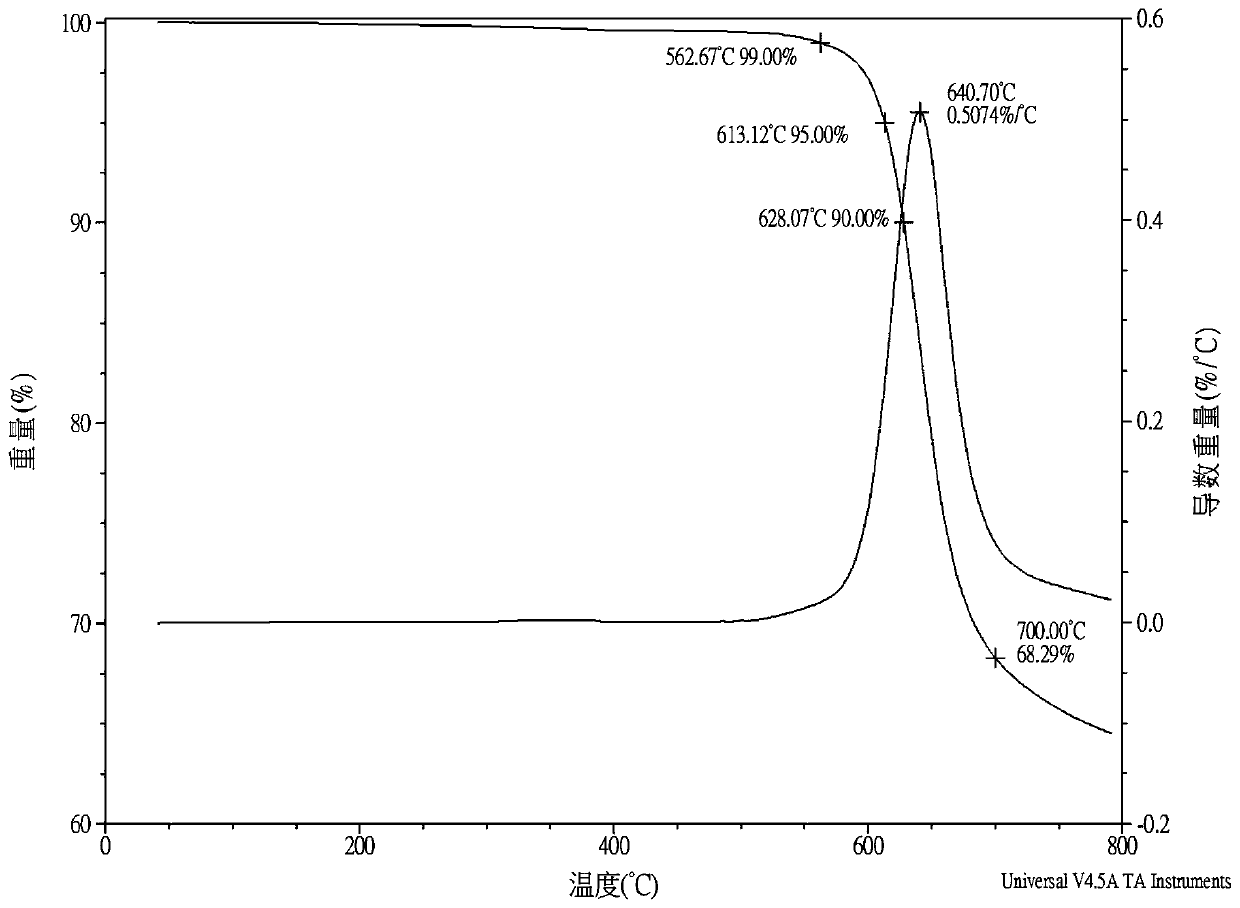

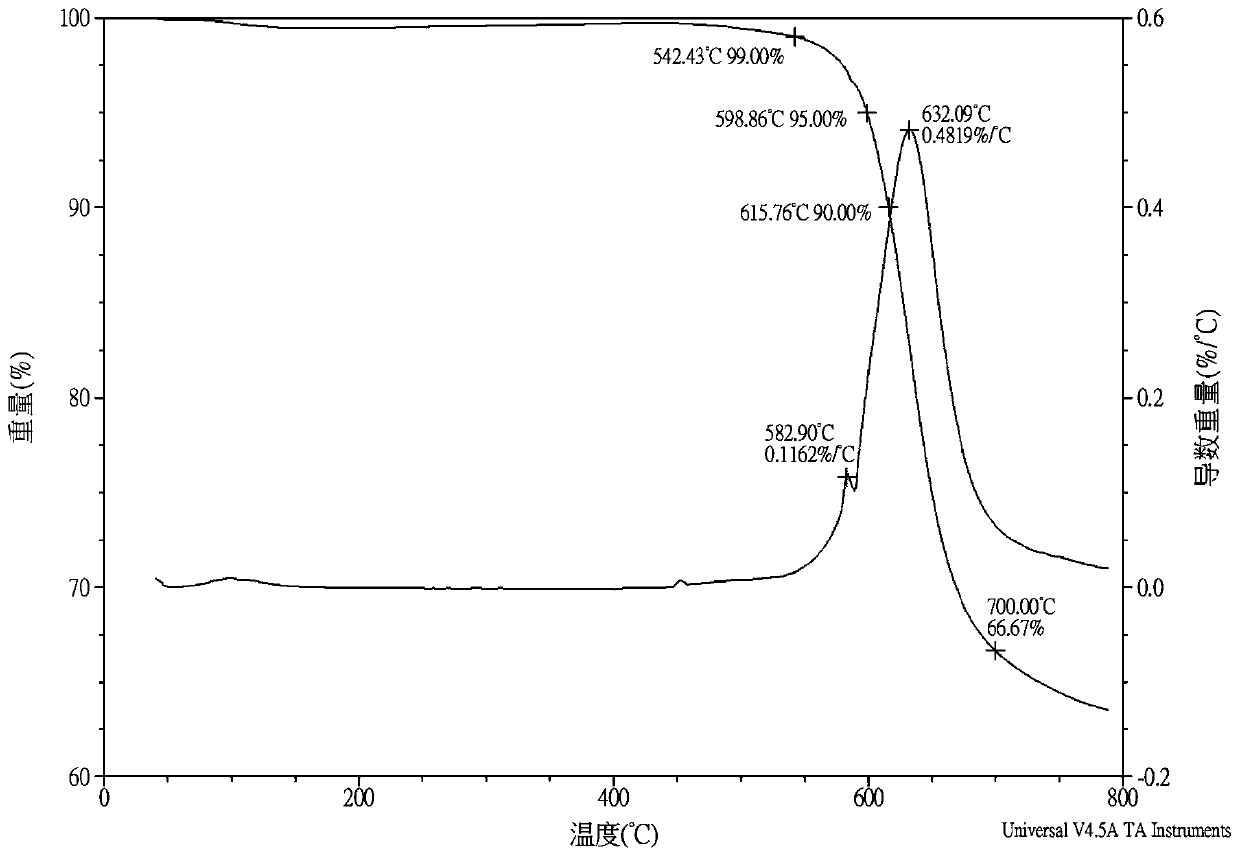

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com