3D (Three Dimensional) printing photosensitive material containing nanocellulose and preparation method of photosensitive material

A nanocellulose, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of poor dispersion, brittle models, low strength, etc., to reduce resource consumption, optimize dispersion, improve tensile strength and The effect of the modulus of elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

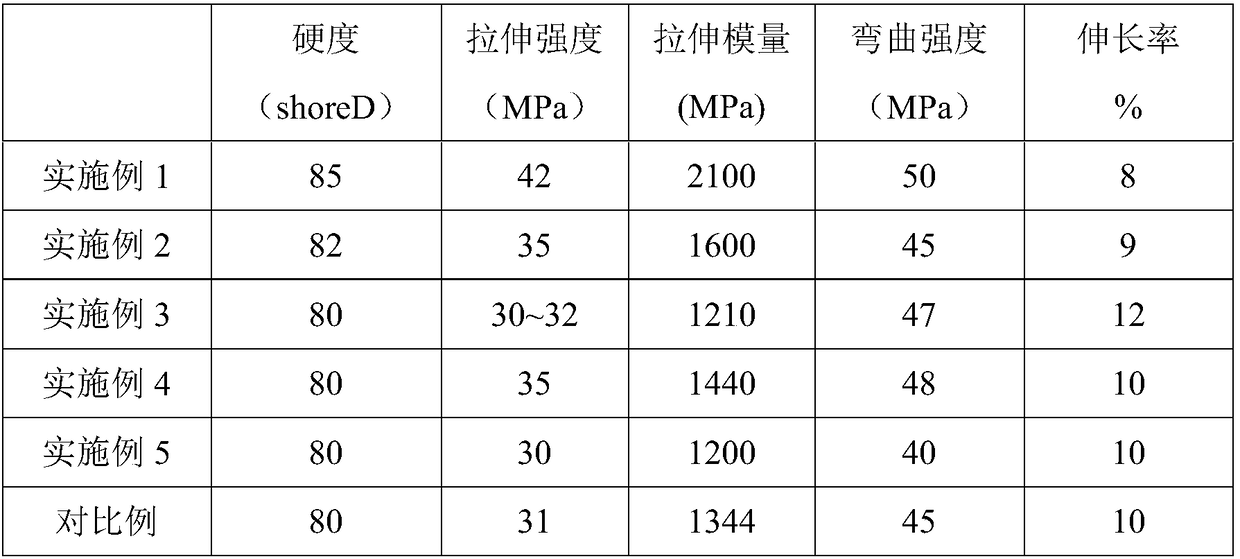

[0029] 30g polyurethane acrylate (brand Sartomer cn9001), 20g tripropylene glycol diacrylate, 15g hexanediol diacrylate, 15g 3,4-epoxycyclohexylmethyl 3,4-epoxycyclohexylmethyl Ester, 11g glycerol triglycidyl ether, 5g chemically modified nanocellulose, 3g 1-hydroxycyclohexyl phenyl ketone, 1g diphenyl-(4-phenylthio)phenylsulfonium hexafluoroantimonate, Add 0.1g of leveling agent and 0.05g of MEHQ into a 300ml stainless steel dispersion tank, raise the temperature to 40-50°C, and stir evenly at a speed of 600rpm for 2 hours, and then carry out light-curing 3D printing. The specific properties of the resin are shown in Table I.

Embodiment 2

[0031] 23g epoxy acrylate (brand Sartomer 2204), 25g tripropylene glycol diacrylate, 17g ethoxylated trimethylol propane triacrylate, 15g 3,4-epoxycyclohexylmethyl 3,4- Epoxycyclohexyl carboxylate, 10g glycerol triglycidyl ether, 6g chemically modified nanocellulose, 3g 1-hydroxycyclohexyl phenyl ketone, 1g diphenyl-(4-phenylthio)phenylsulfonium hexa Add fluoroantimonate, 0.1g leveling agent, and 0.05g MEHQ into a 300ml stainless steel dispersion tank, raise the temperature to 40-50°C, and stir evenly at a speed of 600rpm for 2 hours, and then perform light-curing 3D printing. The specific properties of the resin are shown in Table I.

Embodiment 3

[0033] 30g polyester acrylate (brand Sartomer 790), 25g hexanediol diacrylate, 15g ethoxylated trimethylolpropane triacrylate, 15g 3,4-epoxycyclohexylmethyl 3,4-cyclo Oxycyclohexyl carboxylate, 5g glycerol triglycidyl ether, 6g chemically modified nanocellulose, 3g 1-hydroxycyclohexyl phenyl ketone, 1g diphenyl-(4-phenylthio)phenylsulfonium hexafluoro Add antimonate, 0.1g leveling agent, and 0.05g MEHQ into a 300ml stainless steel dispersion tank, raise the temperature to 40-50°C, stir evenly at 600rpm for 2 hours, and then carry out light-curing 3D printing. The specific properties of the resin are shown in Table I.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com