Device for simulating fusion of molten microdroplet and solidified microdroplet in microgravity environment

A technology for simulating microgravity and microdroplets, applied in the investigation phase/state change, etc., can solve the problems of inability to complete the uniform microdroplet fusion test in a simulated microgravity environment on the ground, and achieve the effects of simple structure, convenient observation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing and specific embodiment content of the present invention is described in further detail:

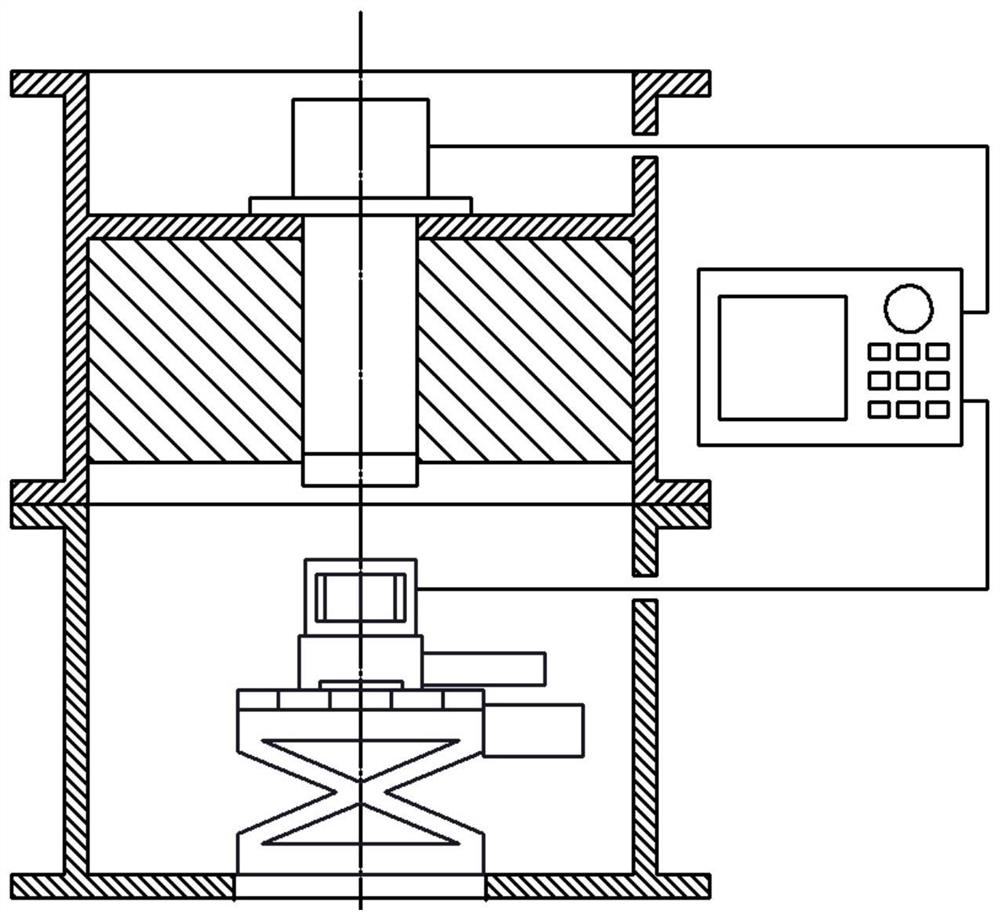

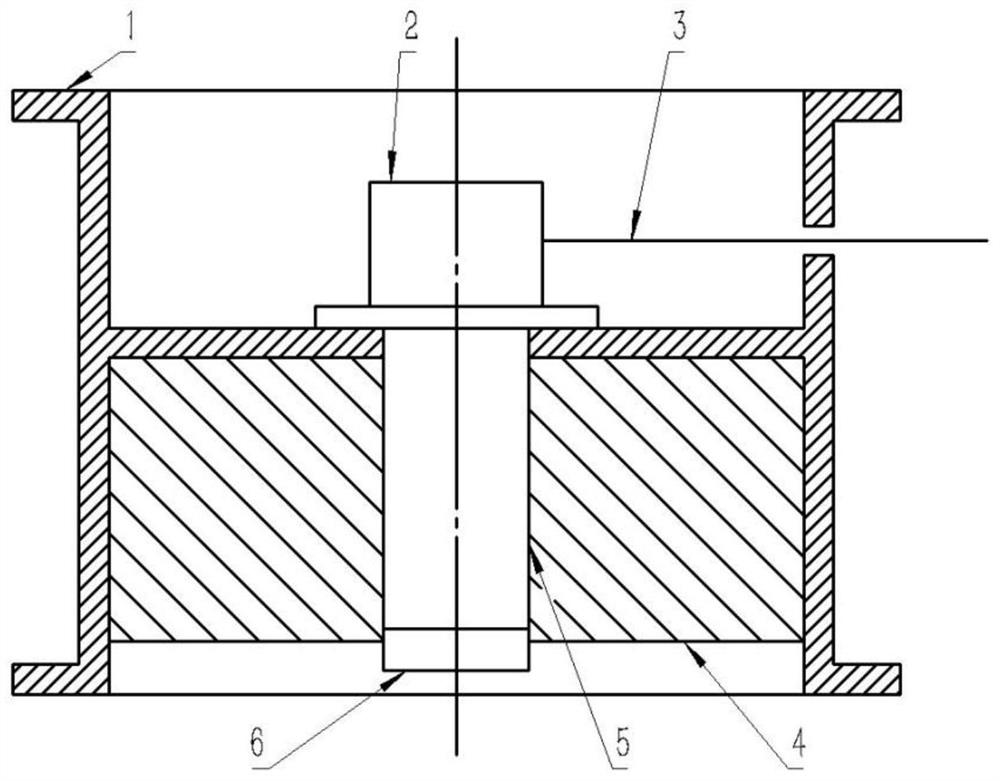

[0057] see Figure 1-Figure 11 , the fusion device in the present invention includes a control module and a uniform metal droplet ejection module, a solidified metal droplet release module and a position adjustment module arranged in a hypoxic environment from top to bottom. The hypoxic environment is provided by the drop pipe device (mainly vacuum environment or inert gas environment), and the height of the drop pipe device is generally not less than 2.5 meters, and the fusion device is set on the top of the drop pipe device. An image acquisition module can be set in the drop tube system to record the chasing and fusion process of molten metal droplets and solidified metal droplets, which is convenient for researchers to understand the falling trajectories of chasing and fusion, and explore the optimal fusion timing.

[0058] The co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com