Splayed double-branch channel type heating drying gun and using method thereof

A double split channel technology, applied in the field of eight-character double split channel heating drying gun, can solve the problems that cannot meet the production process requirements, and achieve the effect of simple structure, high heating efficiency and good product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

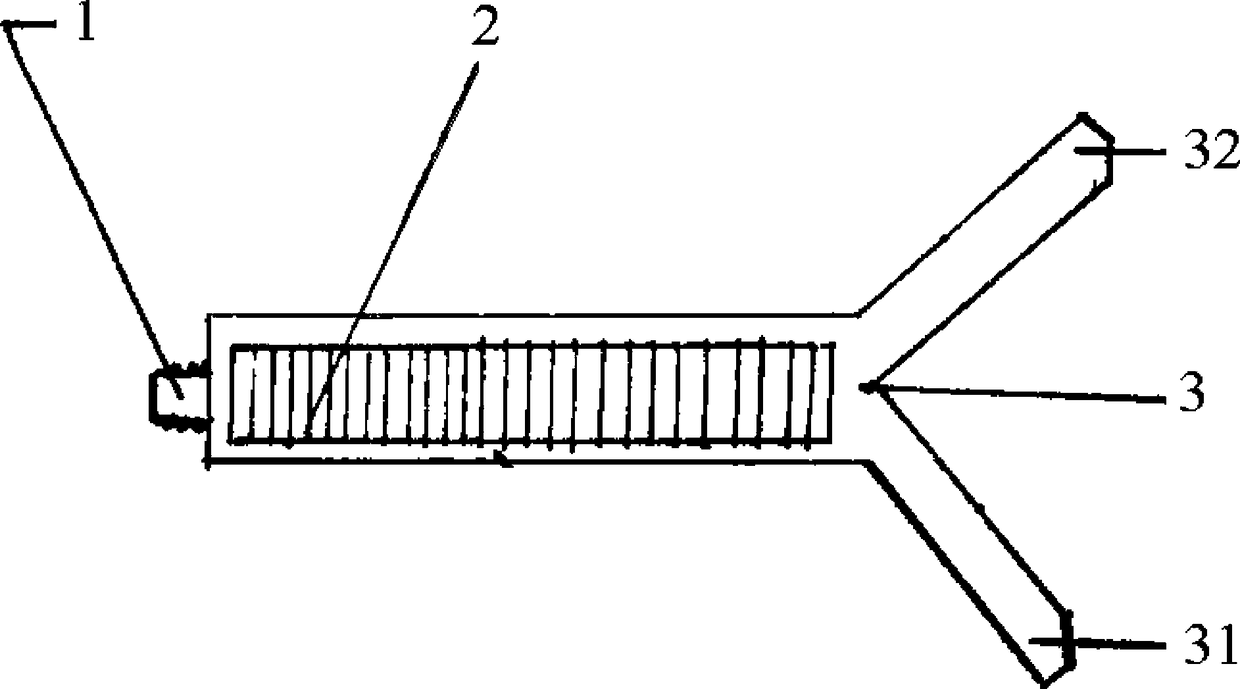

[0021] A character-eight double-channel heating gun, including a blower 1, a ceramic core resistance wire gun body 2 and an air duct 3, such as figure 1 As shown, the specific structure is:

[0022] The air duct 3 is formed by connecting the lower air duct 31 and the upper air duct 32 with an air inlet to form an angular shape with an open end.

[0023] The air inlet end of the ceramic core resistance wire gun body 2 is connected to the air outlet of the blower 1 , and the air outlet end of the ceramic core resistance wire gun body 2 is connected to the air inlet of the air duct 3 .

[0024] The included angle between the lower air passage 31 and the upper air passage 32 is 30°-90°, and 90° is taken in this embodiment.

[0025] When this embodiment is used, it is implemented sequentially as follows:

[0026] ① Blast: Turn on even blower 1 to blow;

[0027] ②Heating: Turn on the ceramic core resistance wire gun body 2 to heat to the set temperature;

[0028] ③Winding: Turn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com