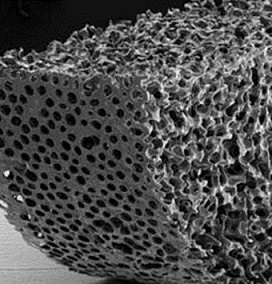

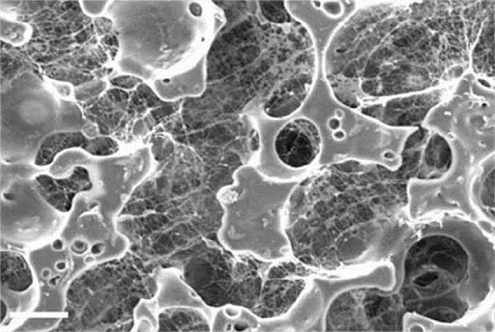

Porous copper-based whisker material

A technology of copper whisker and porous copper, which is applied in polycrystalline material growth, metal material coating process, crystal growth, etc., can solve the problems of specific surface area reduction and reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] A high specific surface area copper whisker material is characterized in that comprising the following processing steps:

[0068] (1) Preparation of Cu-Al alloy block: (a) physically and uniformly mix 30wt.% 2-3μm copper powder and 60wt.% 7-8μm aluminum powder; (b) press molding at 300Mpa; (c) inert atmosphere or reduction High temperature sintering under atmosphere, sintering temperature 800 o C, high temperature duration 1h, natural cooling, wherein the holding time of the press molding is 5min; the inert atmosphere is N 2 , the reducing atmosphere is H 2 ; The programmed temperature rise rate of the high temperature sintering is 10 o C / min.

[0069] (2) Preliminary dealloying by chemical alkali corrosion: the corrosion solution used is 1M NaOH aqueous solution, the corrosion time is 12h, and the temperature is 30 o C, during the corrosion process, the bubbles were removed by ultrasonic wave, and the corrosion was washed with deionized water several times.

[007...

Embodiment 2

[0076] A high specific surface area copper whisker material is characterized in that comprising the following processing steps:

[0077] (1) Preparation of Cu-Al alloy block: (a) physically and uniformly mix 35wt.% 2-3μm copper powder and 65wt.% 7-8μm aluminum powder; (b) press molding at 350Mpa; (c) inert atmosphere or reduction High temperature sintering under atmosphere, sintering temperature 900 o C, high temperature duration 2h, natural cooling, wherein the holding time of the press molding is 8min; the inert atmosphere is N 2 , the reducing atmosphere is H 2 ; The programmed temperature rise rate of the high temperature sintering is 10 o C / min.

[0078] (2) Preliminary dealloying by chemical alkaline corrosion: the corrosion solution used is 1.5M NaOH aqueous solution, the corrosion time is 18h, and the temperature is 33 o C, during the corrosion process, the bubbles were removed by ultrasonic wave, and the corrosion was washed with deionized water several times.

...

Embodiment 3

[0086] A high specific surface area copper whisker material is characterized in that comprising the following processing steps:

[0087] (1) Preparation of Cu-Al alloy block: (a) physically and uniformly mix 30-40wt.% 2-3μm copper powder and 60-70wt.% 7-8μm aluminum powder; (b) 400Mpa compression molding; (c) High temperature sintering under inert atmosphere or reducing atmosphere, sintering temperature 950 o C, high temperature duration 3h, natural cooling, wherein the holding time of the press molding is 10min; the inert atmosphere is N 2 , the reducing atmosphere is H 2 ; The programmed temperature rise rate of the high temperature sintering is 10 o C / min.

[0088] (2) Preliminary dealloying by chemical alkali corrosion: the corrosion solution used is 2M NaOH aqueous solution, the corrosion time is 24h, and the temperature is 35 o C, during the corrosion process, the bubbles were removed by ultrasonic wave, and the corrosion was washed with deionized water several times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com